Crude oil viscosity-breaking pour-point depressant composition, and preparation method and application thereof

A technology of pour point depressant and composition, which is applied in the field of petroleum transportation, and can solve the problems of unfavorable on-site dispensing of oil transportation, increasing transportation cost of pour point depressant, and affecting oil products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

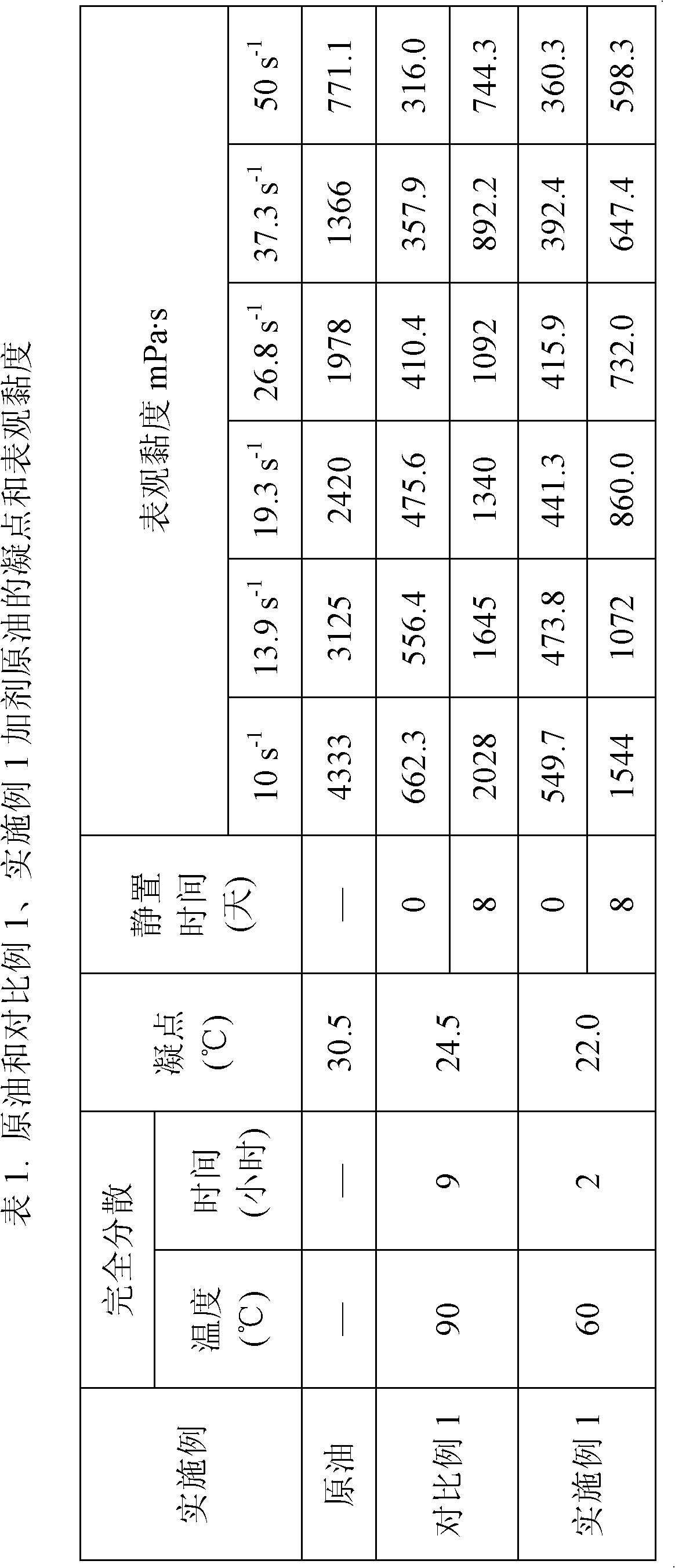

Embodiment 1

[0059] Inorganic pour point depressant and organic pour point depressant are the same as in comparative example 1.

[0060] Premix 1000g of inorganic pour point depressant and 1000g of organic pour point depressant in a high-speed mixer at room temperature, and then melt, blend, extrude and granulate through a twin-screw extruder at 160-190°C to obtain organic-inorganic hybrid Crude oil viscosity reducer composition 1.

[0061] Add 1 g of Composition 1 to 99 g of diesel oil, and stir mechanically at 60°C for 2 hours to uniformly disperse Composition 1 in the diesel oil to form an inorganic-organic hybrid viscosity depressant composition 1 with a concentration of 1% by mass of the dispersion.

[0062] Add 1g of the dispersion of the above composition 1 to 100g of crude oil, control the temperature at about 64°C, and mechanically stir at a speed of 500rpm for 5 minutes, so that the composition 1 is uniformly dispersed in the crude oil to form the added crude oil, and its freezi...

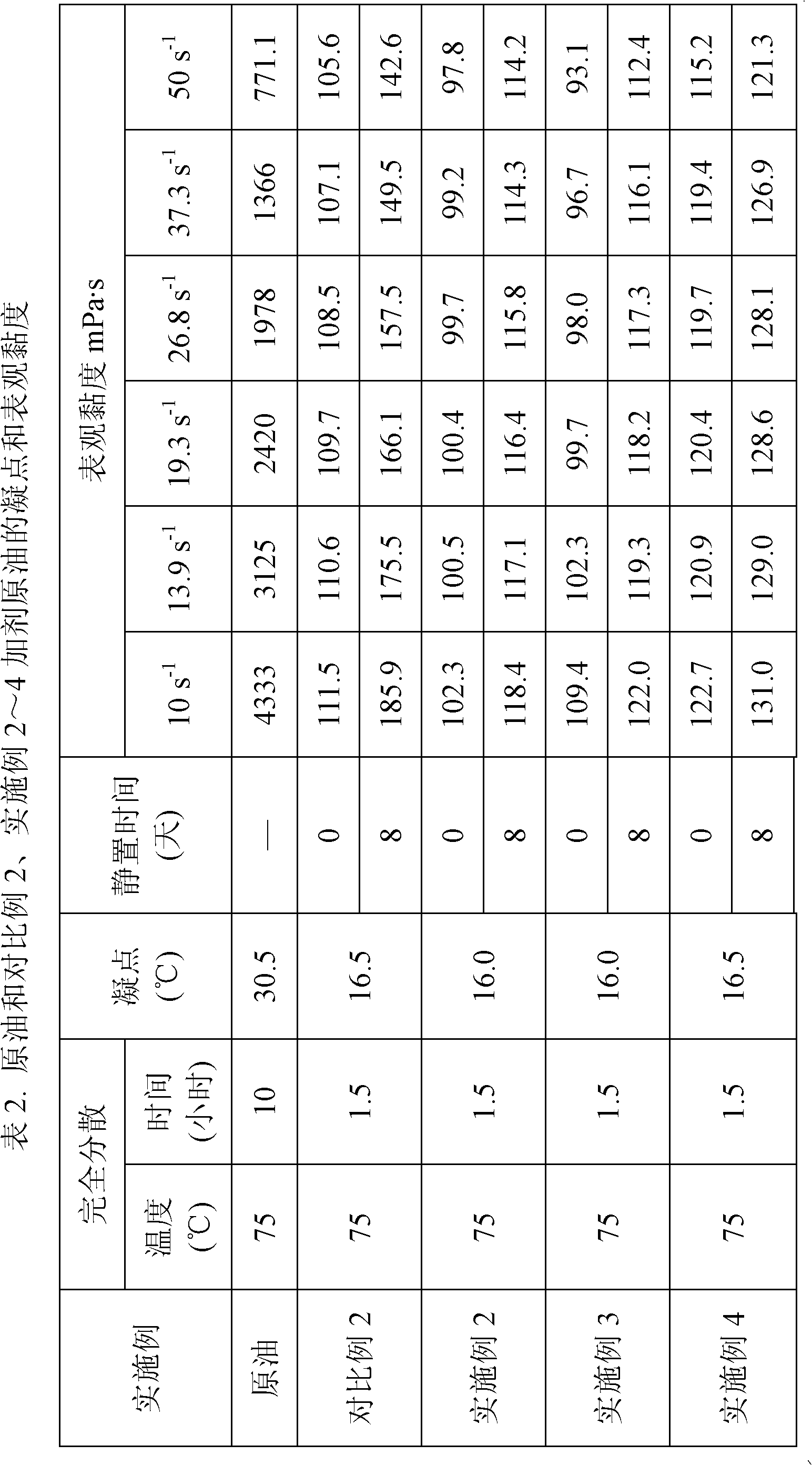

Embodiment 2

[0069] Inorganic pour point depressant and organic pour point depressant are the same as in comparative example 2.

[0070] At room temperature, 1000g of organic montmorillonite, 1000g of EVA, and 20g of silane coupling agent γ-aminopropyltriethoxysilane (KH-550) are pre-mixed in a high-speed mixer, and then passed through the A single-screw extruder is melted, blended, extruded and granulated to obtain an inorganic-organic hybrid crude oil viscosity and pour point depressant composition 2.

[0071] Add 5 g of Composition 2 to 95 g of kerosene, and stir mechanically at 75°C for 1.5 hours to uniformly disperse Composition 2 in the kerosene to form an inorganic-organic hybrid viscosity depressant composition 2 with a concentration of 5% by mass of the dispersion.

[0072] Add 0.2g of the dispersion of the above composition 2 to 100g of crude oil, control the temperature at about 60°C, and mechanically stir at a speed of 1000rpm for 5 minutes to make the composition 2 uniformly ...

Embodiment 3

[0074] Inorganic pour point depressant and organic pour point depressant are the same as in comparative example 2.

[0075] Premix 1000g organic montmorillonite, 1000g EVA, and 50g lubricant ethylene bisstearamide (EBS) in a high-speed mixer at room temperature, and then melt blend them through a twin-screw extruder at 160-190°C Extrude and granulate to obtain an inorganic-organic hybrid crude oil viscosity and pour point depressant composition 3.

[0076] Add 5 g of Composition 3 to 95 g of kerosene, and mechanically stir at 75°C for 1.5 hours to uniformly disperse Composition 3 in the kerosene to form an inorganic-organic hybrid viscosity depressant composition 3 with a concentration of 5% by mass of the dispersion.

[0077] Add 0.2 g of the dispersion of the above composition 3 to 100 g of crude oil, control the temperature at about 60 ° C, and mechanically stir at a speed of 1000 rpm for 5 minutes, so that the composition 3 is uniformly dispersed in the crude oil to form ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com