A kind of metal sulfide/mxene composite catalyst for electrolysis of water and preparation method thereof

A metal sulfide and catalyst technology, applied in the field of electrolysis of water, can solve the problem of low activity, and achieve the effects of good catalytic performance, simple preparation method, and enhanced electronic/ionic conductivity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

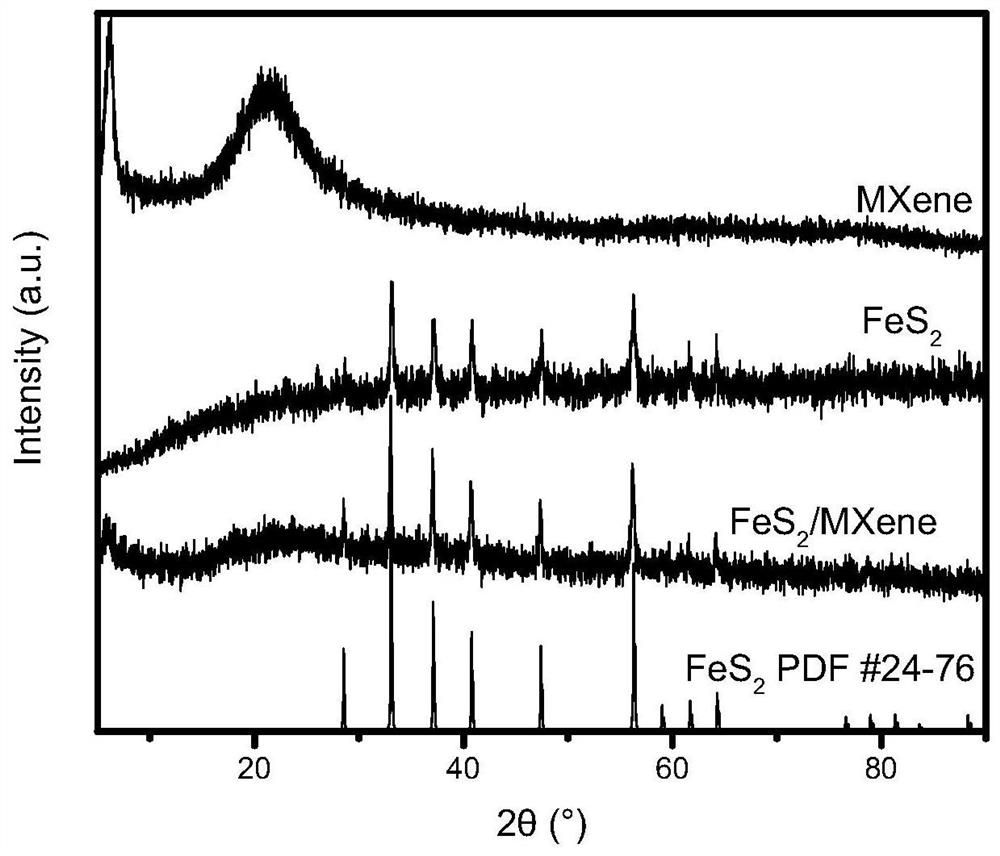

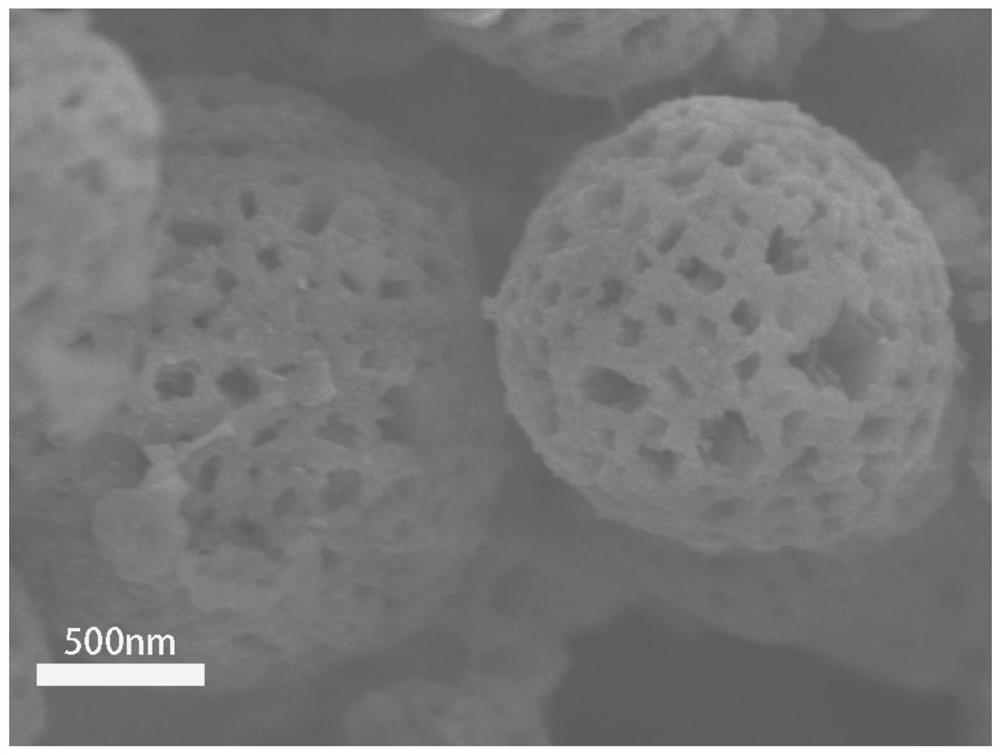

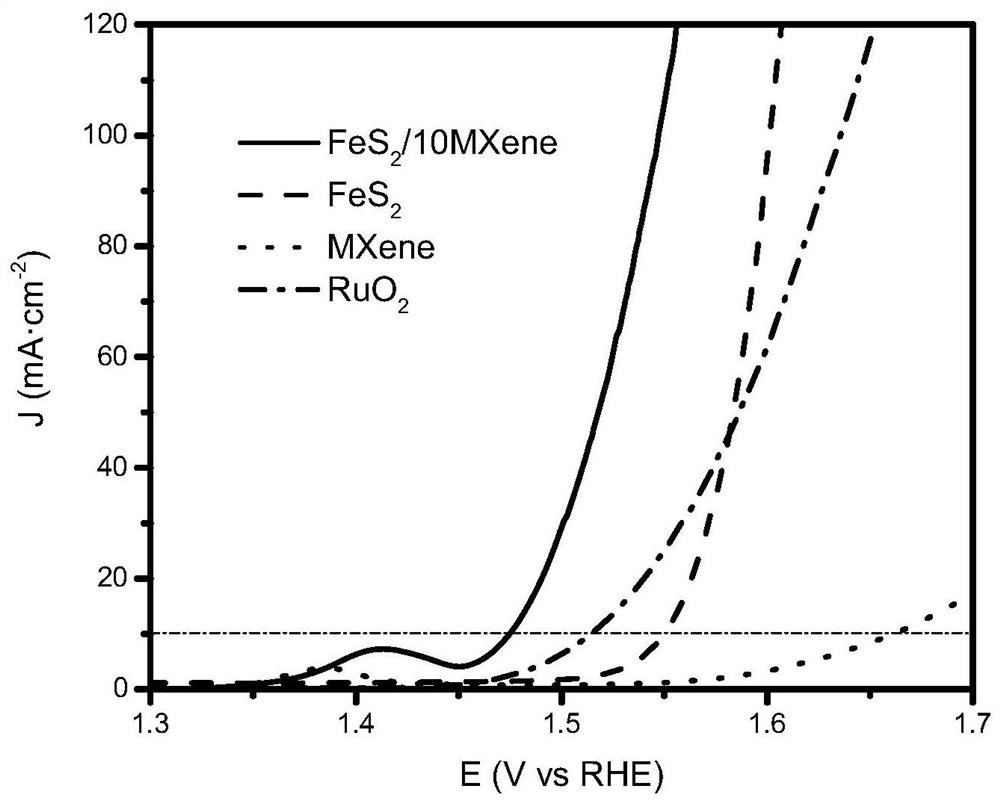

[0052] In the metal sulfide / MXene composite catalyst for electrolysis of water in this embodiment, FeS 2 Particles are distributed on the MXene sheet to form FeS 2 / MXene complex catalyst.

[0053] FeS in this example 2 The preparation method of / MXene composite catalyst comprises the steps:

[0054] 1) Add 80mg of sulfur powder and 10mg of MXene tablets into 100mL of carbon disulfide solution, disperse and evaporate to dryness to obtain a mixture of MXene and S;

[0055] 0.275g FeSO 4 ·7H 2 O was added in 70mL of triethylene glycol, stirred to make it dissolve completely to obtain a solution;

[0056] 2) The mixture of MXene and S prepared in step 1) was added to the solution, stirred for 3 hours, then transferred to a 100mL reactor for solvothermal reaction, the reaction temperature was 200°C, and the time was 24 hours; centrifuged, and the solid was washed with water After lyophilization, the freeze-drying temperature is -40 ℃, the time is 24h, and the FeS 2 / 10MXene....

Embodiment 2

[0059] The preparation method of metal sulfide / MXene composite catalyst for electrolysis of water in this embodiment comprises the following steps:

[0060] 1) Add 80mg of sulfur powder and 5mg of TiC MXene tablets (same as Example 1) into 100mL of carbon disulfide solution, evaporate to dryness after dispersing, and obtain a mixture of MXene and S;

[0061] 0.275g FeSO 4 ·7H 2 O was added in 70mL of triethylene glycol, stirred to make it dissolve completely to obtain a solution;

[0062] 2) The mixture of MXene and S prepared in step 1) was added to the solution, stirred for 3 hours, then transferred to a 100mL reactor for solvothermal reaction, the reaction temperature was 200°C, and the time was 24 hours; centrifuged, and the solid was washed with water After lyophilization, the freeze-drying temperature was -40°C and the time was 24h to obtain FeS 2 / 5MXene.

Embodiment 3

[0064] The preparation method of metal sulfide / MXene composite catalyst for electrolysis of water in this embodiment comprises the following steps:

[0065] 1) Add 80mg of sulfur powder and 20mg of TiC MXene flakes (same as Example 1) into 100mL of carbon disulfide solution, evaporate to dryness after dispersing, and obtain a mixture of MXene and S;

[0066] 0.275g FeSO 4 ·7H 2 O was added in 70mL of triethylene glycol, stirred to make it dissolve completely to obtain a solution;

[0067] 2) The mixture of MXene and S prepared in step 1) was added to the solution, stirred for 3 hours, then transferred to a 100mL reactor for solvothermal reaction, the reaction temperature was 200°C, and the time was 24 hours; centrifuged, and the solid was washed with water After lyophilization, the freeze-drying temperature was -40°C and the time was 24h to obtain FeS 2 / 20MXene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com