High-temperature resistant CO2 foam cleaning and associated fracturing fluid and preparation method and application thereof

A fracturing fluid and CO2 technology, applied in chemical instruments and methods, earthwork drilling, wellbore/well components, etc., can solve the problem of difficult control of cross-linking performance stability, unsuitability for medium and high temperature reservoirs, cost and temperature resistance problems and other problems, to achieve a good effect of stable production, increase single well production, and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

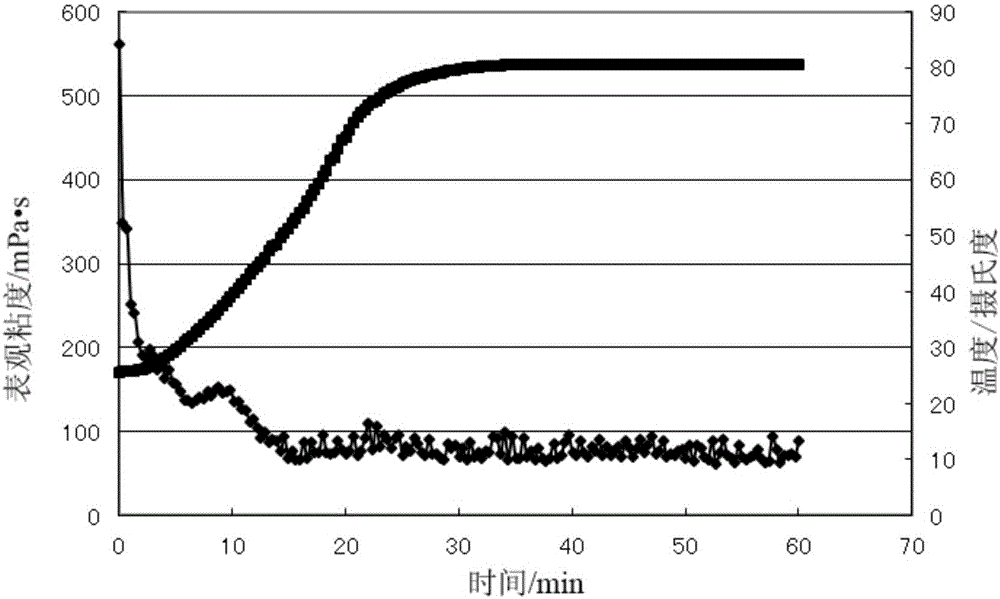

Embodiment 1

[0059] This embodiment provides a fracturing fluid base fluid A, which includes:

[0060] 0.25% thickener;

[0061] 0.5% foaming agent;

[0062] 0.2% cross-linking modifier;

[0063] and the remainder of the water;

[0064] Wherein, the mass percent of each monomer component of the thickener: 15% of acrylamide monomer, 4% of N-vinylpyrrolidone, 3% of polydiene dimethyl ammonium chloride, 7% of acrylic acid, persulfuric acid Ammonium is 0.05%, sodium acetate is 0.04%, and the rest is water.

[0065] The preparation method of this thickening agent comprises the following steps:

[0066] It was synthesized under the reaction conditions of ternary copolymerization, nitrogen was passed through to remove oxygen, the reaction temperature was 55° C., and the reaction time was 4 hours. After the reaction, the polymerization product is dried, granulated, and crushed into the required mesh to make a fracturing fluid thickener.

[0067] Based on the calculation that the total mass o...

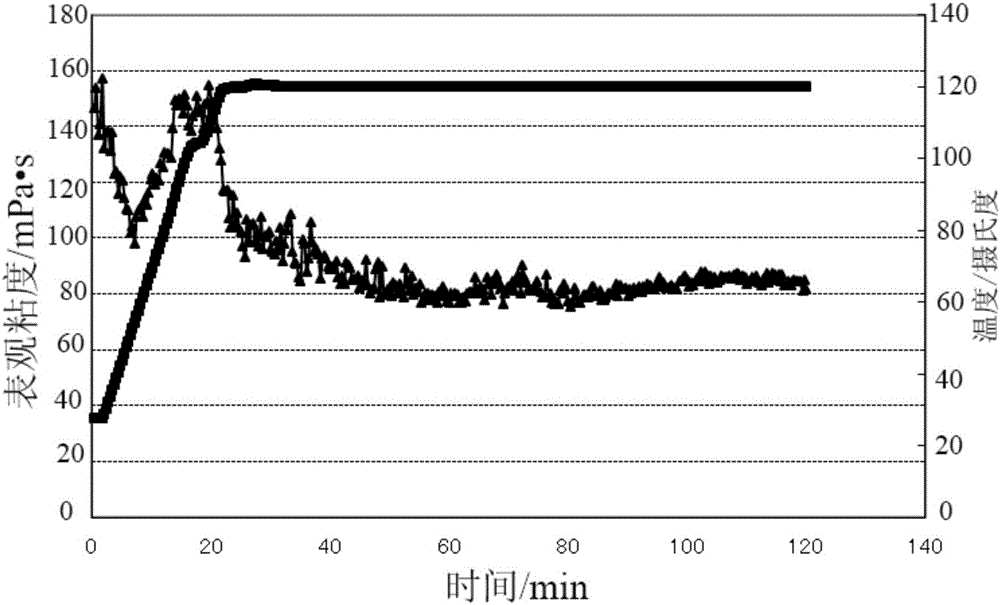

Embodiment 2

[0071] This embodiment provides a fracturing fluid base fluid B, which includes:

[0072] 0.4% thickener;

[0073] 0.5% foaming agent;

[0074] 0.3% cross-linking modifier;

[0075] and the remainder of the water;

[0076] Wherein, the mass percent of each monomer component of the thickener: 17% of acrylamide monomer, 3% of N-vinylpyrrolidone, 5% of alkyl methacrylate, 6% of sodium p-styrenesulfonate, Ammonium persulfate is 0.08%, sodium acetate is 0.04%, and the rest is water.

[0077] The preparation method of this thickening agent comprises the following steps:

[0078] It was synthesized under the reaction conditions of ternary copolymerization, nitrogen was passed through to remove oxygen, the reaction temperature was 55° C., and the reaction time was 4 hours. After the reaction, the polymerization product is dried, granulated, and crushed into the required mesh to make a fracturing fluid thickener. When the concentration of the thickener is 0.4%, the viscosity is 2...

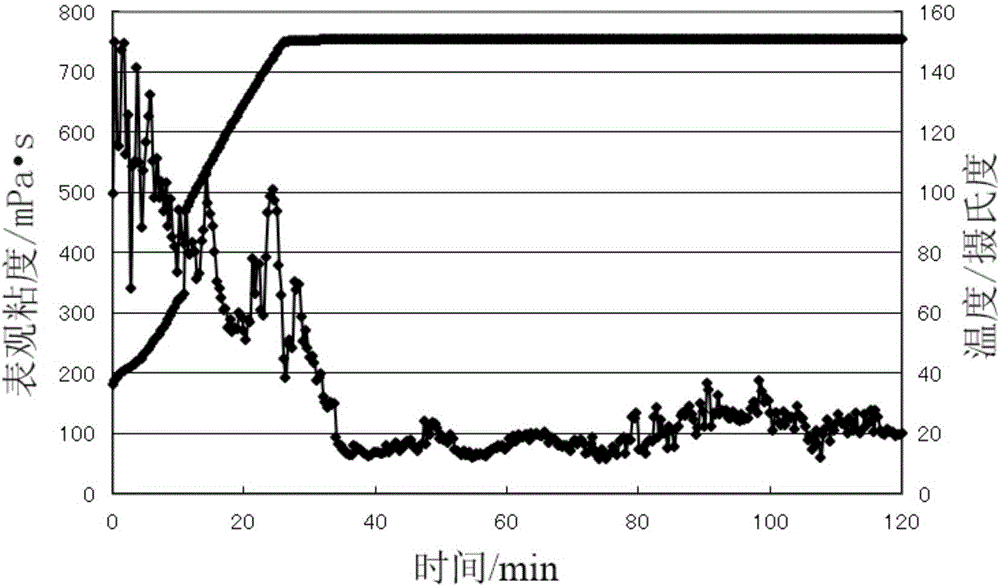

Embodiment 3

[0082] This embodiment provides a fracturing fluid base fluid C, which comprises:

[0083] 0.6% thickener;

[0084] 0.5% foaming agent;

[0085] 0.5% cross-linking modifier;

[0086] and the remainder of the water;

[0087] Among them, the mass percent of each monomer component of the thickener: 21% of acrylamide monomer, 5% of N-tris(hydroxymethyl)methyl-acrylamide, 5% of polydiene dimethyl ammonium chloride, 7% of 2-acrylamido-2-methyl-1-propanesulfonic acid, 0.06% of potassium thiosulfate, 0.03% of sodium acetate, and the rest is water.

[0088] The preparation method of this thickening agent comprises the following steps:

[0089] It was synthesized under the reaction conditions of ternary copolymerization, nitrogen was passed to remove oxygen, the reaction temperature was 60° C., and the reaction time was 4 hours. After the reaction, the polymerization product is dried, granulated, and crushed into the required mesh to make a fracturing fluid thickener.

[0090] Ass...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com