A kind of biodegradable water-based metal cleaning agent and its preparation method and application

A metal cleaning agent, biodegradable technology, applied in the field of mechanical industry cleaning agents, can solve the problems of metal surface damage, poor anti-rust effect, long cleaning time, etc., to achieve improved oil removal performance, outstanding solubilization effect, and water-soluble speed fast effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

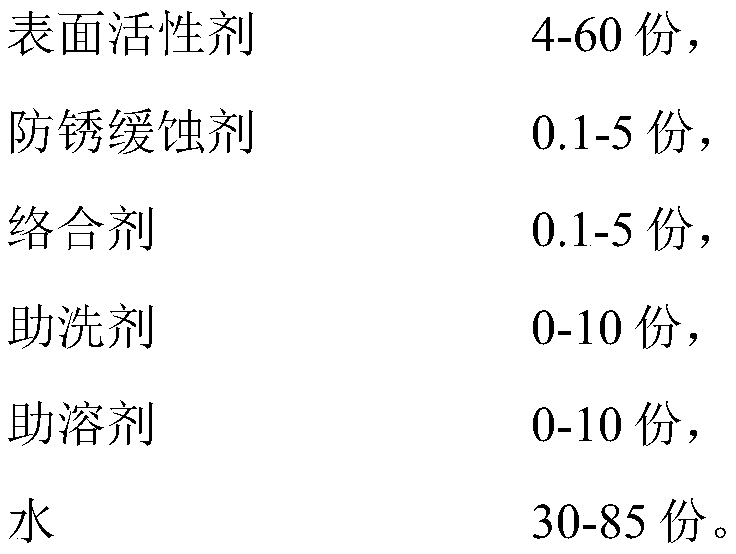

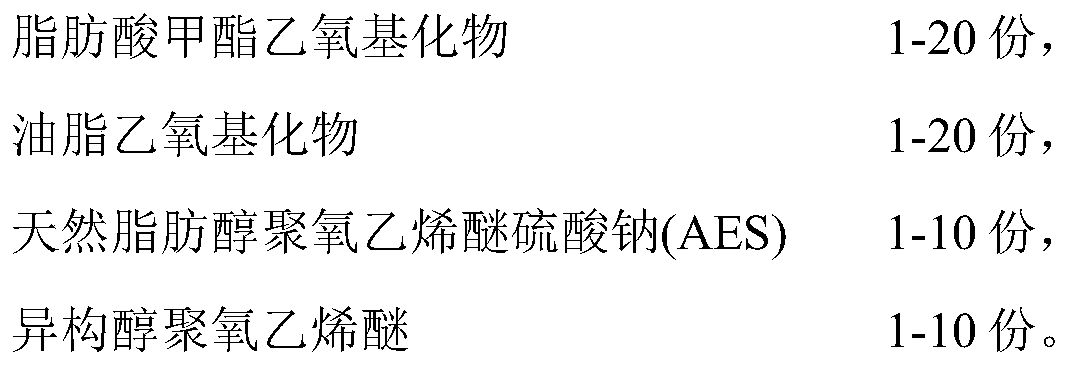

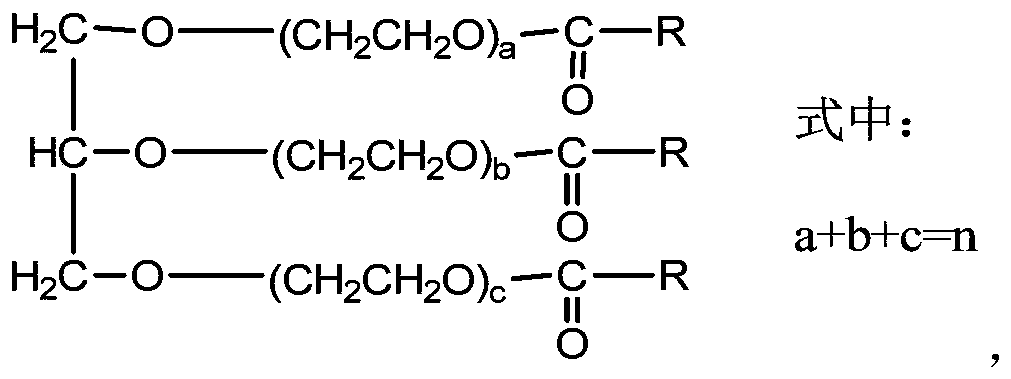

[0038] A kind of biodegradable water-based metal cleaning agent is made of the components in parts by weight in table 1:

[0039] Table 1

[0040] name parts by weight Methyl palmitate ethoxylate FMEE-P-6805 5 Soybean Oil Ethoxylate NOE-S-42 20 Sodium fatty alcohol polyoxyethylene ether sulfate AES 10 Isomerized Alcohol Polyoxyethylene Ether C1009 3 Phosphite 1 Sodium carbonate 3 EDTA disodium salt 5 Isopropanol 10 distilled water 43

[0041] A preparation method of a biodegradable water-based metal cleaning agent comprises the following steps:

[0042] First weigh 43 parts of distilled water and put them into the production device, start stirring, add 3 parts of builder sodium carbonate under slow stirring, and raise the temperature to 40°C, and stir until the sodium carbonate is completely dissolved. Continue to add 5 parts of methyl palmitate ethoxylate FMEE-P-6805, 20 parts of soybean oil ethoxylate NOE-...

Embodiment 2

[0044] A kind of biodegradable water-based metal cleaning agent is made of the components in parts by weight in table 2:

[0045] Table 2

[0046] name parts by weight Soybean oil methyl ester ethoxylate FMEE-S-2408 20 Coconut Oil Ethoxylate NOE-C-75 3 Sodium fatty alcohol polyoxyethylene ether sulfate AES 3 Isomerized Alcohol Polyoxyethylene Ether C1305 5 Triethanolamine 1.5 sodium hydroxide 5 sodium oxalate 1 Propylene glycol butyl ether 4 distilled water 57.5

[0047] A preparation method of a biodegradable water-based metal cleaning agent comprises the following steps:

[0048] First weigh 57.5 parts of distilled water and put it into the production device, start the stirring, add 5 parts of builder sodium hydroxide under the condition of slow stirring, and raise the temperature to 40°C, and stir until the sodium hydroxide is completely dissolved. Continue to add 20 parts of soybean oil methyl ester etho...

Embodiment 3

[0050] A kind of biodegradable water-based metal cleaning agent is made of the components in parts by weight in table 3:

[0051] table 3

[0052]

[0053]

[0054] A preparation method of a biodegradable water-based metal cleaning agent comprises the following steps:

[0055]First weigh 56 parts of distilled water into the production device, start stirring, add 10 parts of coconut oil methyl ester ethoxylate FMEE-C-2410, 10 parts of palm oil ethoxylate NOE-P-15, 6 parts of natural fat Alcohol polyoxyethylene ether sodium sulfate AES, 8 parts of isomeric alcohol polyoxyethylene ether C1307, stirring at constant temperature until all surfactants are completely dissolved. Continue to add 2 parts of complexing agent sodium citrate, stir well, make it dissolve, stir and mix evenly. Continue to add 3 parts of anti-rust and corrosion inhibitor benzotriazole, stir well, wait until all components are completely mixed and cool down to room temperature, add 5 parts of co-solvent...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com