Novel nitrogen-modified composite metal oxide plug-in catalyst and application thereof

A composite metal and catalyst technology, which is applied in the synthesis field of new nitrogen-modified composite metal oxide intercalated catalysts, can solve the problems of poor selectivity and high catalyst preparation cost, and achieve strong solubilizing ability, excellent comprehensive performance, and easy rinsing Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

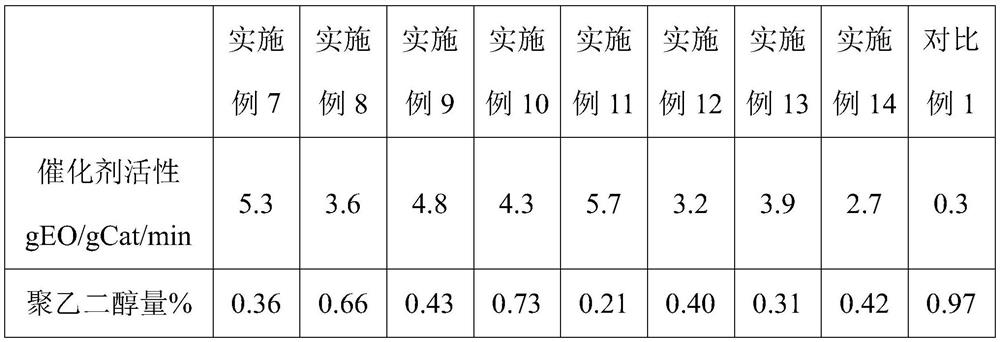

Examples

Embodiment 1

[0028] Add MgO 80g in 2L autoclave, add the Al(NO of 10wt%) 3 ) 3 500g of aqueous solution and 10g of ammonium nitrate were immersed for 30 hours at 40°C; 500g of 20% sodium hydroxide was added to the reactor at one time, and the temperature was raised to 70°C for 1 hour; React for 30 hours; after the reaction, wash, dry, and grind to obtain a catalyst, which is designated as CAT-1.

Embodiment 2

[0030] Add MgO 100g in 2L autoclave, add 10wt% Co(NO 3 ) 2 Liquid 500g and ammonium nitrate 5g, impregnated at 50°C for 25 hours; 600g mass fraction of 20% sodium hydroxide was added to the reactor at one time, and the temperature was raised to 80°C for 1 hour; React for 30 hours; after the reaction, wash, dry, and grind to obtain a catalyst, which is designated as CAT-2.

Embodiment 3

[0032] Add MgO 90g in 2L autoclave, add the Al(NO 3 ) 3 500g of aqueous solution and 15g of ammonium nitrate were immersed at 50°C for 30h; 500g of 20% sodium hydroxide was added to the reactor at one time, and the temperature was raised to 70°C for 1h; React for 30 hours; after the reaction, wash, dry, and grind to obtain a catalyst, which is designated as CAT-3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com