Manufacture method for diatomite composite drag reduction surface absorbed with drag reducer

A production method and diatomite technology, which are applied in the field of bionics, can solve the problems such as the inability of the drag reducer to effectively act in the turbulent effective area, the high cost of use and maintenance, and the rapid consumption of the drag reducer, so as to reduce the cost of use and maintenance and improve the The effect of utilizing efficiency and reducing dosage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

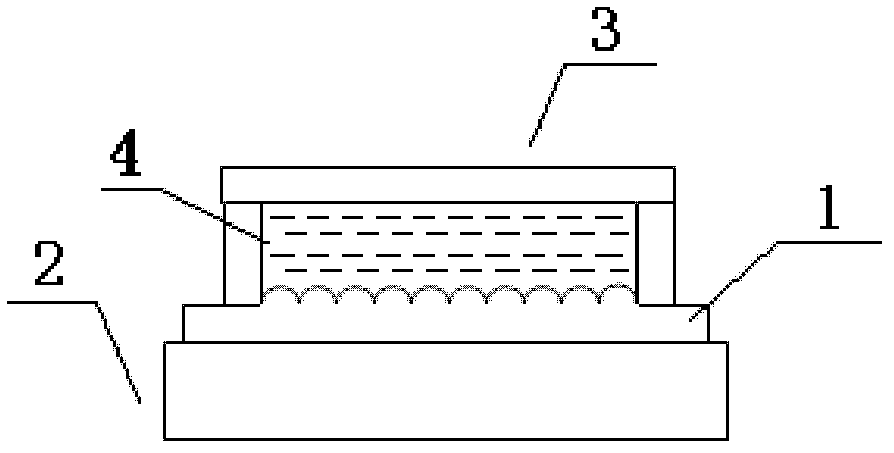

[0041] In order to make the technical means, creative features, goals and effects achieved by the present invention easy to understand, the present invention will be further described below in conjunction with specific diagrams.

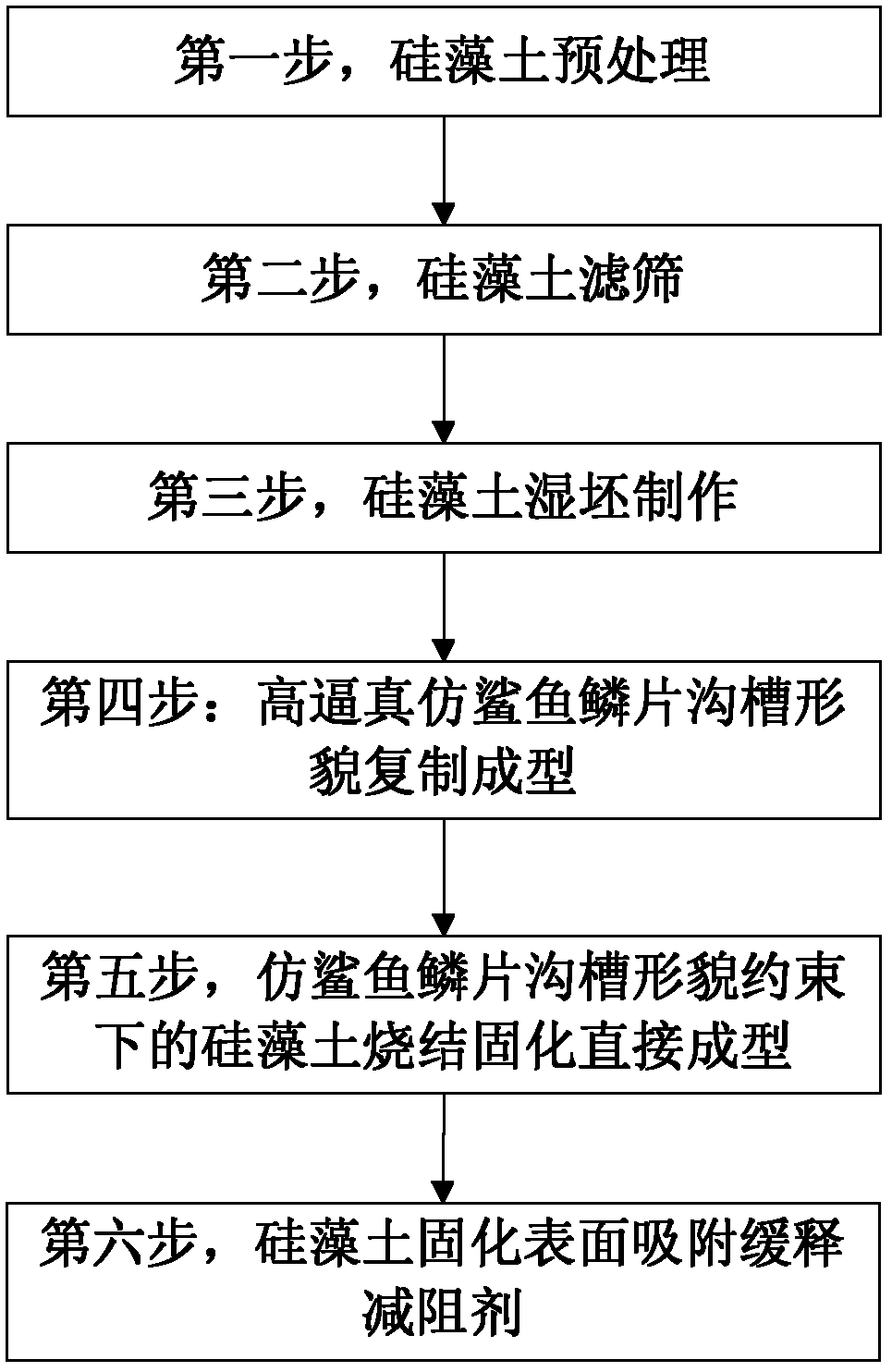

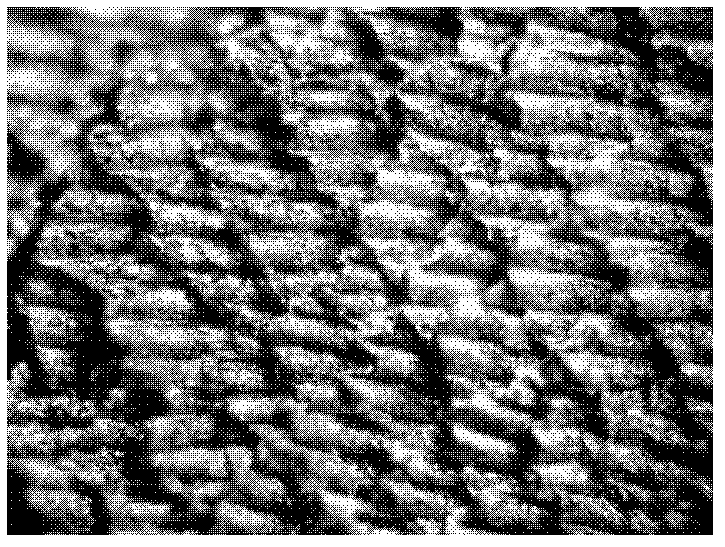

[0042] refer to figure 1The method for making a diatomite composite drag-reducing surface adsorbed with a drag reducing agent comprises the following steps: the first step is a diatomite pretreatment process to prepare a diatomite mixture. Diatomite pretreatment process can adopt common pretreatment method, also can adopt following diatomite pretreatment steps: Soaking for 3 minutes to 5 minutes, and then filtering with a filter cloth of 5 μm to 20 μm to obtain the first diatomite mixture. (B) Soak the first diatomaceous earth mixture in NH4, H2O2, H2O mixture (1:2:7) at a temperature of 80°C to 90°C for 10min to 20min, and then use a 5μm to 20μm filter Cloth was filtered to obtain the second diatomaceous earth mixture. (C) Add deionized water to ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com