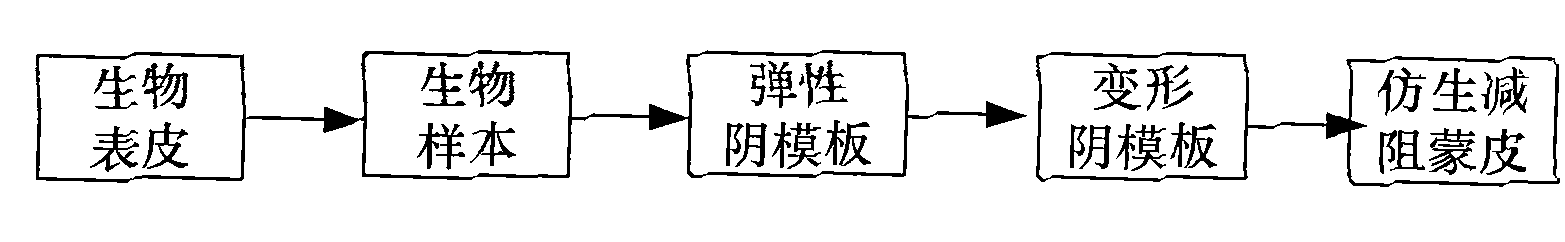

Manufacture method of transformative shark-simulation anti-drag skin based on adjustable surface appearance and size

A technology of surface topography and manufacturing method, applied in ships, hydrodynamic characteristics/hydrostatic characteristics, hulls, etc., can solve the problem of affecting the drag reduction effect, the best applicable speed range, difficult to meet various application objects, grooves Issues such as fixed size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

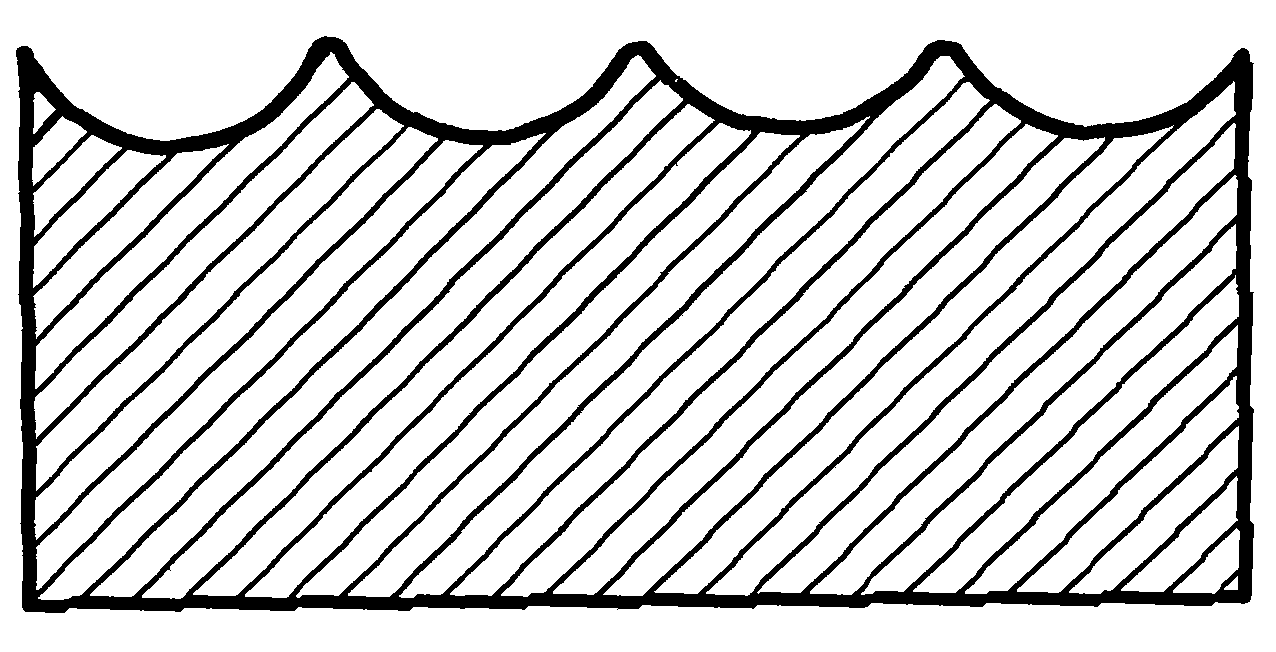

Method used

Image

Examples

Embodiment 1

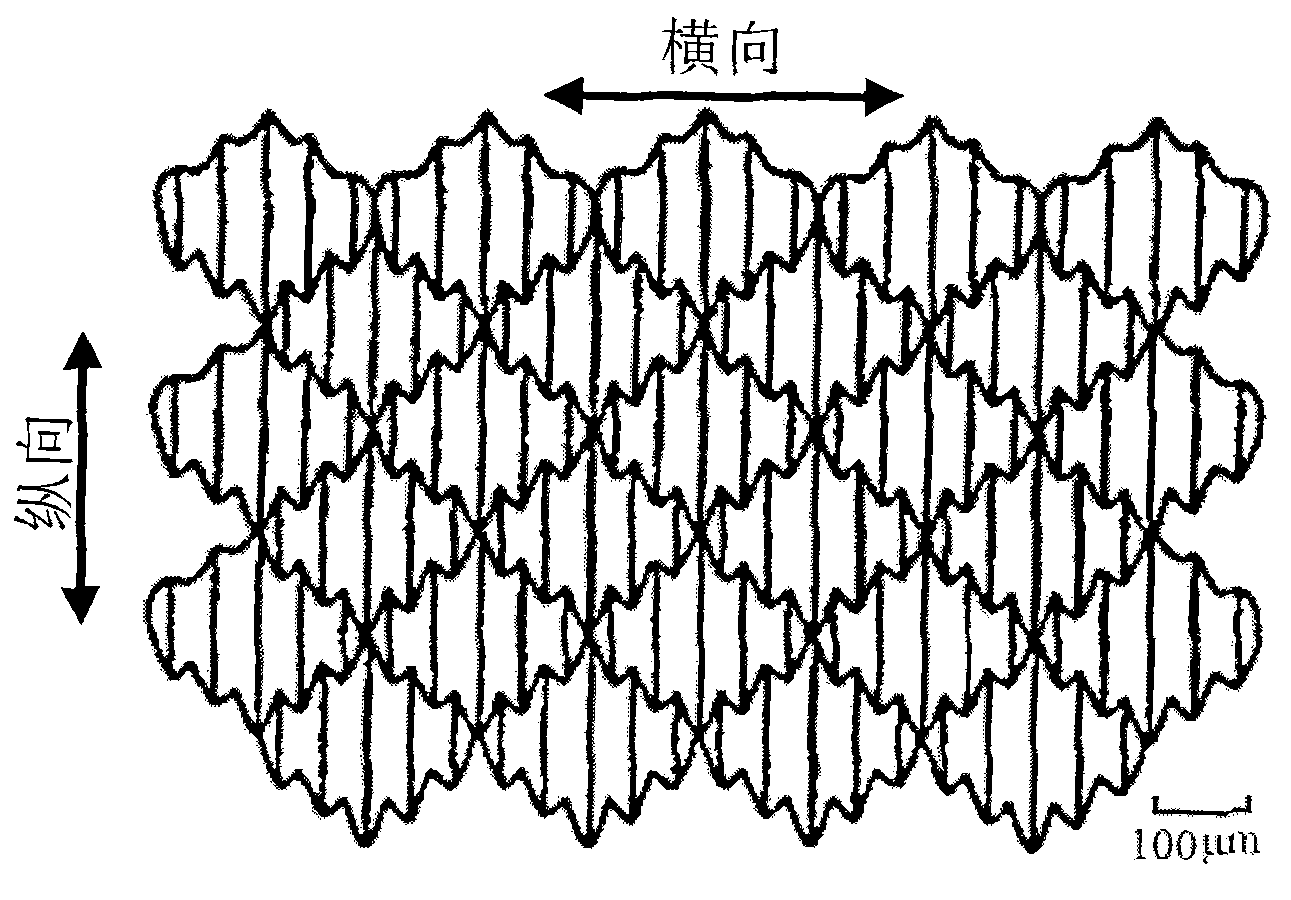

[0079] Create deformable shark-like drag-reducing skin using mako sharks.

[0080] Step 1: Make a Sharkskin Creature Template

[0081] (A) Wash the skin of the purchased mako shark with deionized water for 5 times, then chemically fix the washed skin of the shark in 2.5% glutaraldehyde solution for 6-87 hours, and the chemical fixation temperature is 3°C to prepare the fixation test. like epidermis;

[0082] (B) Wash the fixed sample epidermis prepared by step (A) with deionized water for 5 times, then put the cleaned fixed sample epidermis into 50% ethanol solution for dehydration for 25min, and then dehydrate in 75% ethanol solution. Dehydrate in medium for 20 to 30 minutes, dehydrate in 95% ethanol solution for 25 minutes, and dehydrate in 100% ethanol solution for 25 minutes to obtain the epidermis of the dehydrated sample;

[0083] (C) Dry the skin of the dehydrated sample prepared in step (B) at 60° C. for 10 h to prepare a shark skin biological template, the surface m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com