Forced plasticity deforming method for preparing super fine crystal material

A technology of plastic deformation and ultra-fine grain, which is applied in the field of materials to achieve the effect of uniform and controllable deformation and simple device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical scheme of the present invention is further described below in conjunction with accompanying drawing and embodiment: embodiment is carried out under the premise of technical scheme of the present invention, has provided detailed implementation mode and concrete operation process, but protection scope of the present invention does not Limited to the following examples.

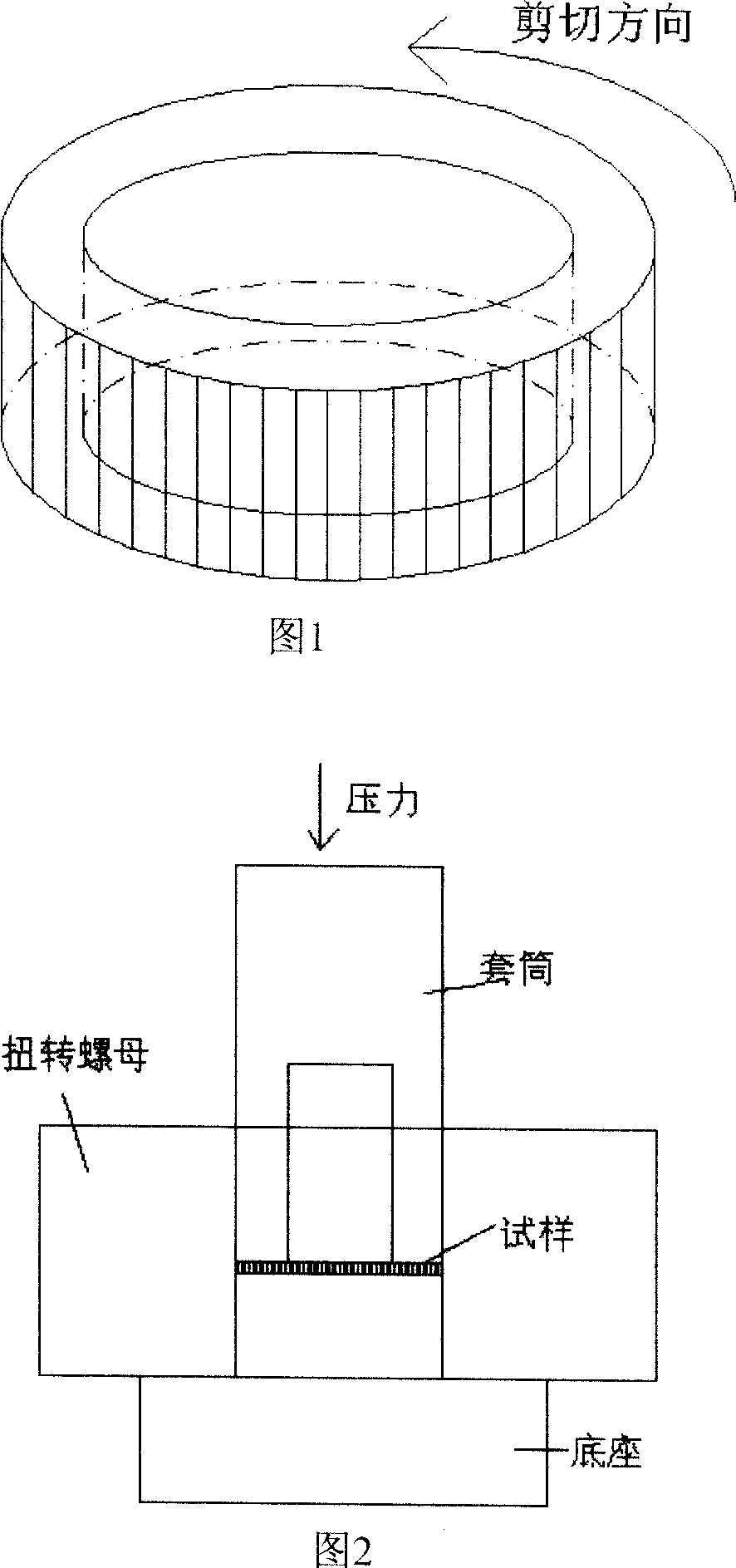

[0017] Find out according to Fig. 1, the mode of the shear processing material of the present invention: material plastic deformation takes place under certain pressure, then make it torsion under the effect of inner and outer ring surface friction force by the drive of mould, thereby produce Shear deformation is a strong plastic deformation method for processing materials.

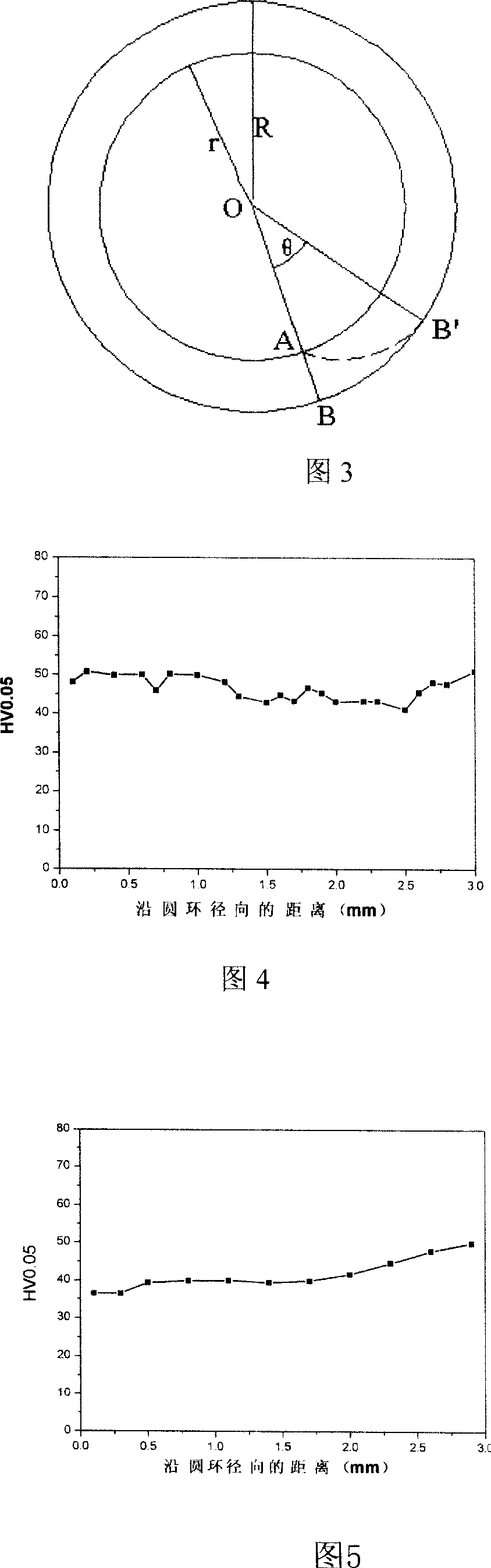

[0018] Find out according to Fig. 2, the mold that the present invention uses comprises base, sleeve and torsion nut 3 parts, the position of the used aluminum ring in the mould: place the ring sample at the correspondi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Radius | aaaaa | aaaaa |

| Circle radius | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com