Controlled manufacturing method for shark imitated drag reduction surface structure under variable environment

A manufacturing method and surface structure technology, applied in the direction of the fuselage bulkhead, etc., can solve the problems of increased resistance and difficulty in meeting the complex and changeable environmental conditions of the vehicle, and achieve high manufacturing efficiency, excellent drag reduction effect, and deformation The effect of easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

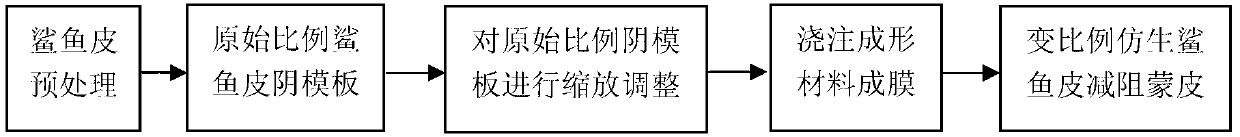

[0037] see figure 1 As shown, the present invention is a manufacturing method for imitating a shark-like drag-reducing surface structure in a variable environment. The specific steps of the method are as follows:

[0038] Step 1: Prepare rolling negative template device

[0039] (A) Cut the shark skin 200×100mm, wash it with clean water and deionized water for 3-5 times respectively, and complete the cleaning of the shark skin;

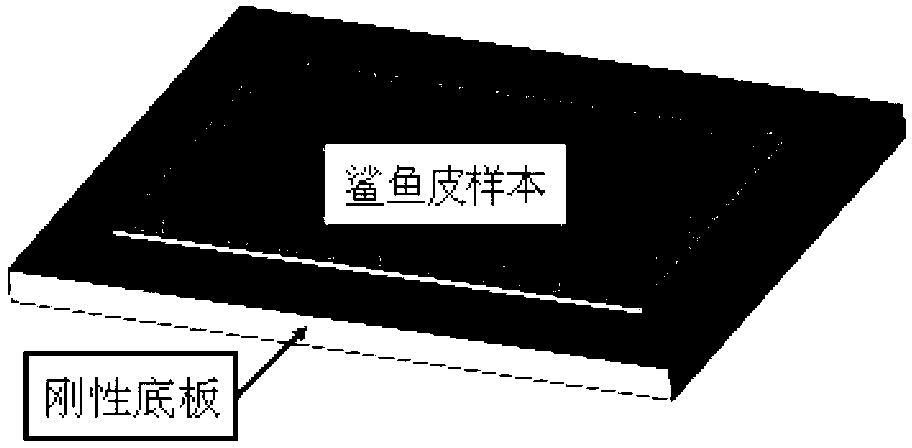

[0040] (B) In order to ensure that the shark skin remains flat after fixing and to avoid damage to its scale structure by the traditional method of flattening with heavy objects, nails are fixed along the shark skin to tighten it on the wooden frame, as shown in figure 2 shown;

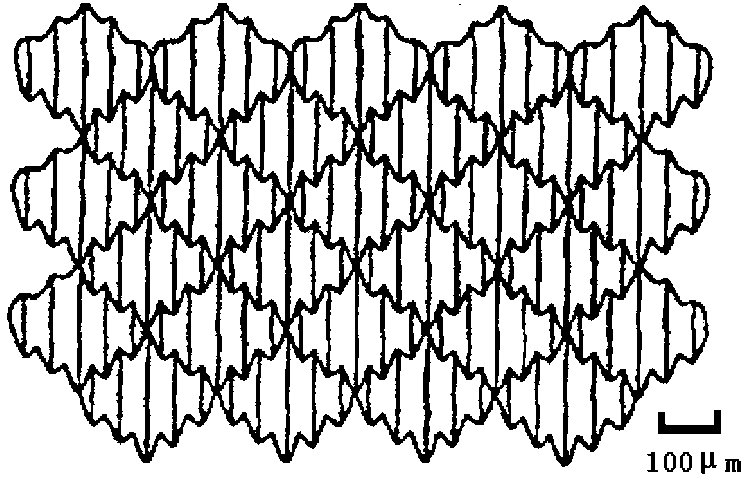

[0041] (C) Soak the washed shark skin completely in 2.5% glutaraldehyde solution, place it in a constant temperature environment at 4°C ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com