Onboard three-optical-axis consistency test component, system and method

A technology for testing components and consistency, applied in the direction of determining the optical axis, testing optical performance, determining the position of the lens, etc., can solve problems affecting measurement accuracy, optical axis deviation, and large environmental impact, so as to improve detection accuracy and facilitate installation and adjustment , small size effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] An embodiment of the present invention will be described in detail below in conjunction with the accompanying drawings.

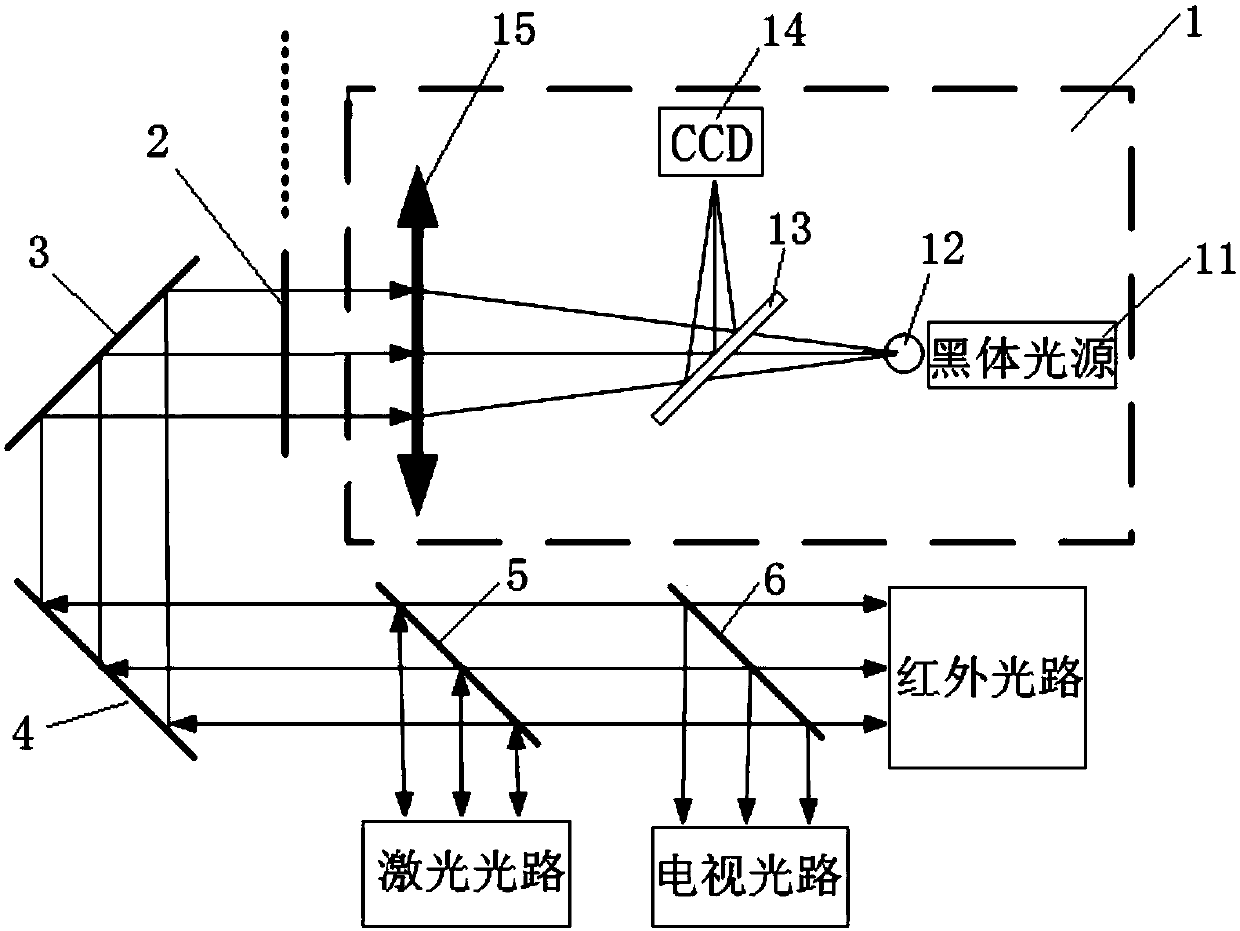

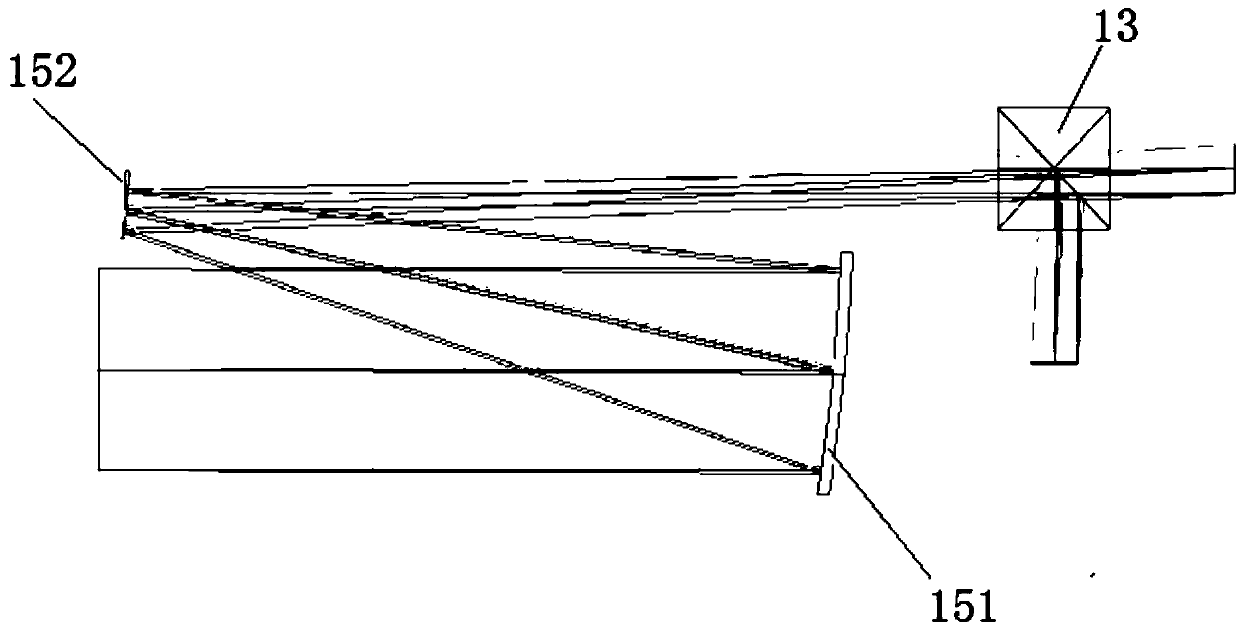

[0040] Such as figure 1 As shown, the airborne three optical axis consistency test system 1 of the present invention includes an airborne three optical axis consistency test assembly and a peripheral optical path, wherein the airborne three optical axis consistency test assembly includes a collimator 15, a beam splitter 13, Star point plate, CCD detector 14 and blackbody light source 11; one end of collimator 15 is the entrance of converging light, and the other end is the entrance of parallel light; beam splitter 13, target plate 12, CCD detector 14 and blackbody light source 11 are located The collimator 15 converges one end of the light entrance and exit; the target target plate 12 is located on the focal plane of the collimator 15; the black body light source 11 is used to illuminate the target target plate 12; the outgoing light of the target ta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com