Coated sand and preparation method thereof

A technology of coated sand and silica sand, applied in the field of foundry, can solve the problems such as deformation of the coated sand cylinder body casting, excessive wall thickness, etc., and achieve the effect of eliminating the deformation of the oil channel core, reducing the deformation of the oil channel core, and improving the quality of the casting.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

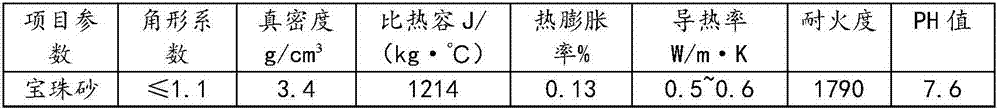

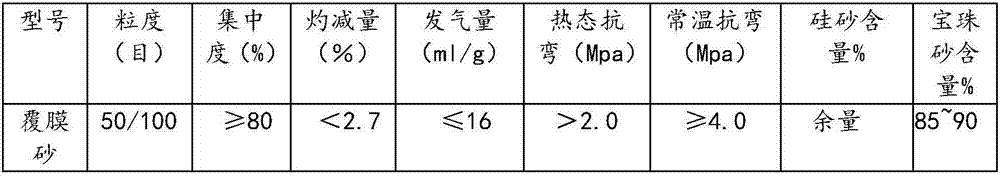

[0029] This embodiment provides a kind of coated sand, and this coated sand comprises pearl sand, resin, curing agent, coupling agent, lubricant, auxiliary material and silica sand; Wherein, pearl sand accounts for 80%~90% of the total weight of coated sand %, the resin accounts for 1% to 3% of the total weight of the coated sand, the curing agent accounts for 0.5% to 1% of the total weight of the coated sand, the coupling agent accounts for 0.04% to 0.08% of the total weight of the coated sand, and the lubricant accounts for 0.1% to 0.5% of the total weight of the coated sand, auxiliary materials account for 0.3% to 0.7% of the total weight of the coated sand, and the balance is silica sand.

[0030] Specifically, the pearl sand accounts for 85% of the total weight of the coated sand, the resin accounts for 2% of the total weight of the coated sand, the curing agent accounts for 0.7% of the total weight of the coated sand, and the coupling agent accounts for 0.06% of the total...

no. 2 example

[0053] The present embodiment provides a kind of preparation method of coated sand, and the preparation method of coated sand comprises the following steps:

[0054] Step A: Preheat the pearl sand and silica sand.

[0055] Among them, the preheating temperature is preferably 130°C to 150°C. Pearl sand accounts for 80% to 90% of the total weight of the coated sand; preferably, pearl sand accounts for 85% of the total weight of the coated sand, and the balance is silica sand.

[0056] Pearl sand includes alumina, titanium dioxide, iron oxide and silicon dioxide; among them, aluminum oxide accounts for 78% to 85% of the total weight of pearl sand, titanium dioxide accounts for 1.5% to 3.5% of the total weight of pearl sand, iron oxide Accounting for 2%-4% of the total weight of the pearl sand and silica accounting for 8%-15% of the total weight of the pearl sand. Preferably, aluminum oxide accounts for 82% of the total weight of the pearl sand, titanium dioxide accounts for 3% ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com