Highly flowing halogen-free flame-retardant enhanced PA66 composition

A technology of PA66 and composition, which is applied in the field of high-flow halogen-free flame-retardant PA66 composition and its preparation, can solve problems such as the limitation of application prospects, and achieve the effects of cost reduction, simple and efficient preparation method, and excellent mechanical and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

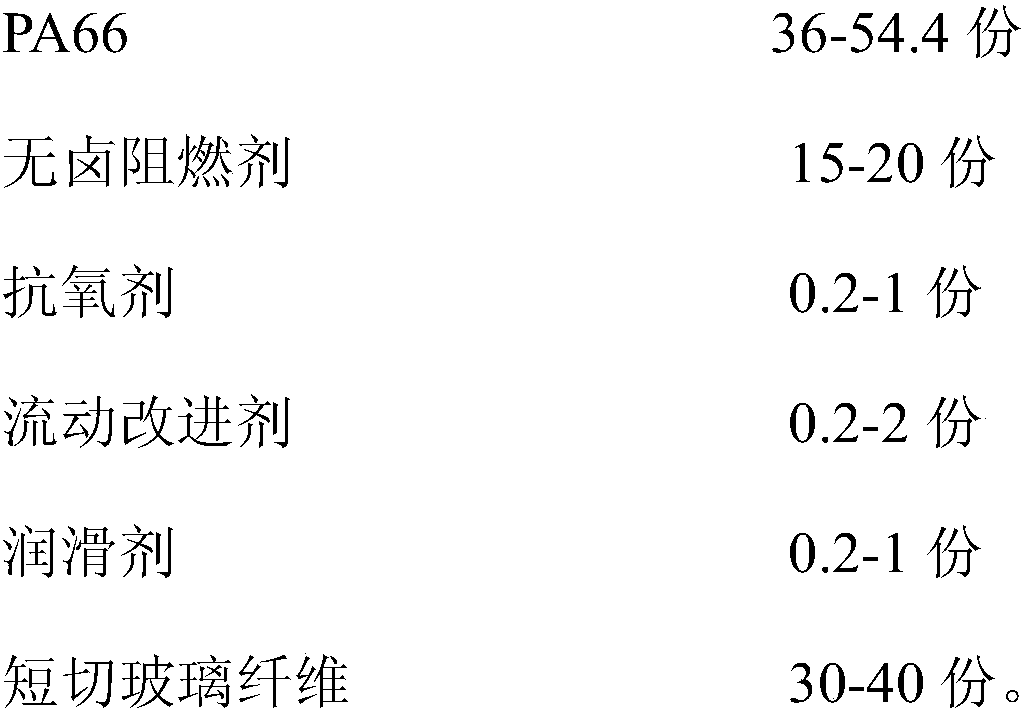

Method used

Image

Examples

Embodiment Construction

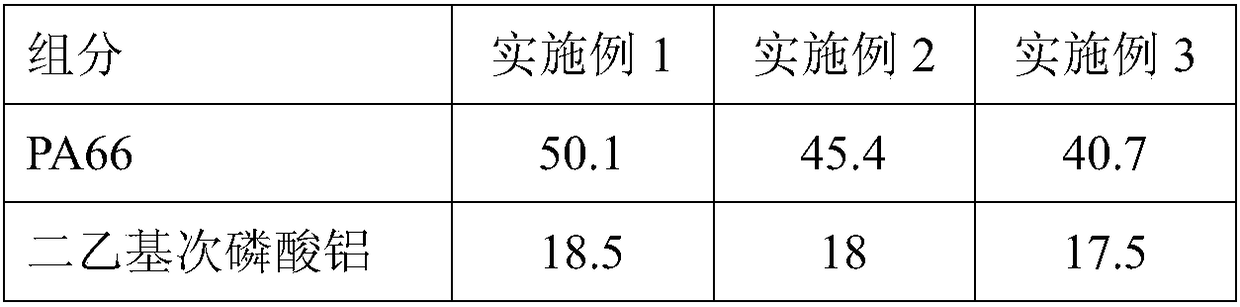

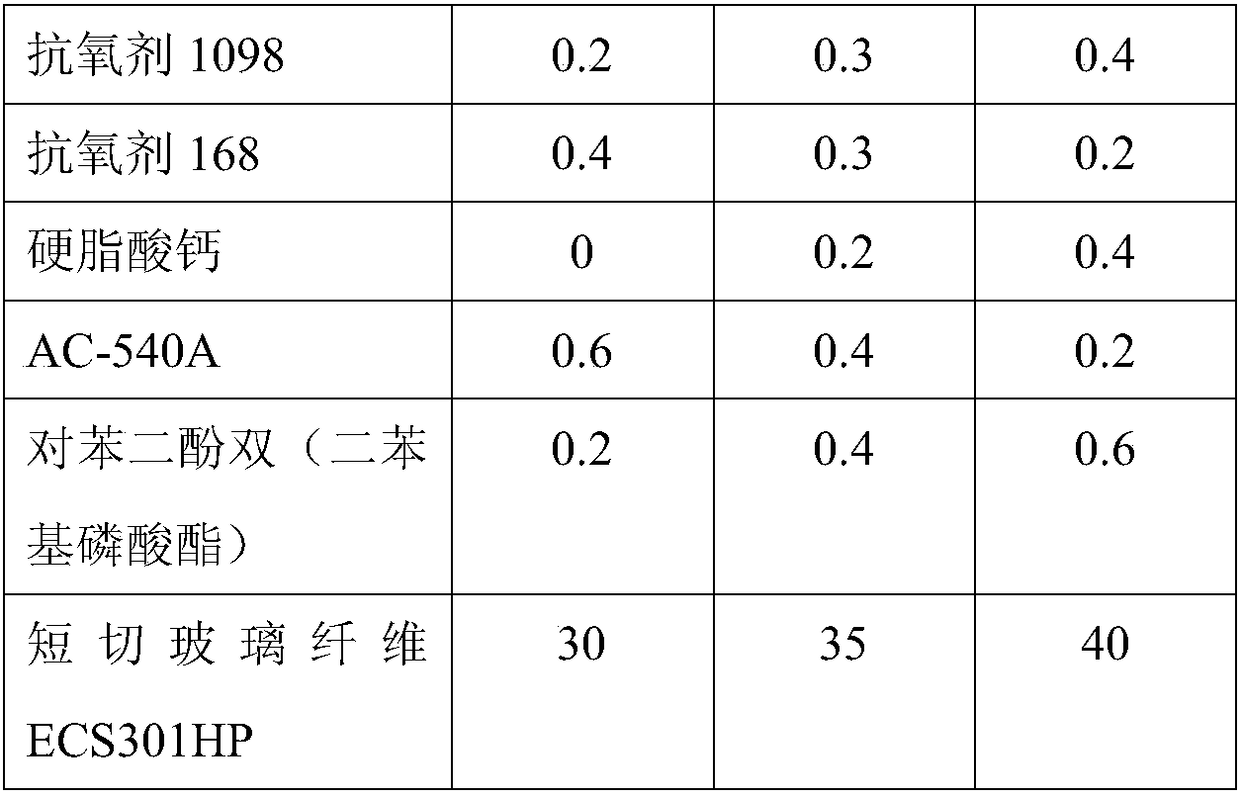

[0018] The raw materials are weighed according to the percentages by weight of the raw materials in the embodiment composition shown in Table 1, and the raw materials other than the chopped glass fibers are fully mixed by the mixing equipment and then put into the feeding port of the twin-screw extruder, chopped The glass fiber is added to the extruder by measuring the feed, and all the materials are melted and mixed and extruded to pelletize; the melt temperature of Example 1 is 254°C, the melt temperature of Example 2 is 262°C, and the melt temperature of Example 3 is The melting temperature of the compound is 258° C.; the performance test is performed after the pellets are dried or prepared into a standard sample. The performance test results of the composition of the example are shown in Table 2. The application evaluation results of the compositions of the examples are shown in Table 3. See Table 4 for the application evaluation results of the comparative composition (wit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melt flow index | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com