Emission-rate-controllable heat control material and preparing method thereof

A technology of emissivity and thermal control, which is applied in the field of aerospace materials, can solve the problems of insufficient independent temperature control capability, small ratio variation range, and limited application range, etc., and achieve good resistance to atomic oxygen and space radiation, and low cost , The effect of convenient production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

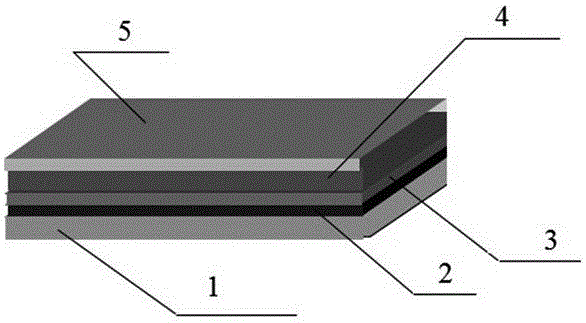

[0026] Such as figure 1 As shown, an emissivity-controllable thermal control material, on the surface of a flexible polyimide substrate, there are two aluminum oxide transition layers, a silver film, two aluminum oxide films and a silicon dioxide layer in sequence from the inside to the outside.

[0027] First, a 50nm aluminum oxide transition layer was prepared on a flexible polyimide substrate by pulse-reaction DC magnetron sputtering, then a 150nm silver film was prepared by DC magnetron sputtering, and finally pulse-reaction DC magnetron sputtering was used. A 2 μm aluminum oxide film and a 0.5 μm silicon dioxide layer were sequentially prepared by the irradiation method. Finally, the performance of the sample reaches: the solar absorption ratio is 0.15, and the emissivity is 0.56.

[0028] The specific operation process is as follows:

[0029] (1) Al2O3 transition layer was plated by pulse reaction DC magnetron sputtering method: the polyimide substrate was placed on th...

Embodiment 2

[0034] First, a 20nm AlO transition layer was prepared on a flexible polyimide substrate by pulse-reaction DC magnetron sputtering, then a 100nm silver film was prepared by DC magnetron sputtering, and finally pulse-reaction DC magnetron sputtering was used. A 1.5 μm Al2O3 film and a 0.2 μm SiO2 layer were sequentially prepared by the irradiation method. Refer to Example 1 for the specific operation process, and adjust the thickness of each coating layer by controlling the sputtering power and time. Finally, the performance of the sample reaches: the solar absorption ratio is 0.13, and the emissivity is 0.45.

Embodiment 3

[0036] A 80nm Al2O3 transition layer was prepared on a flexible polyimide substrate by pulse-reaction DC magnetron sputtering, then a 200nm silver film was prepared by DC magnetron sputtering, and finally pulse-reaction DC magnetron sputtering was used. A 1.0 μm Al2O3 film and a 0.1 μm SiO2 layer were sequentially prepared by the irradiation method. Refer to Example 1 for the specific operation process, and adjust the thickness of each coating layer by controlling the sputtering power and time. Finally, the performance of the sample reaches: the solar absorption ratio is 0.12, and the emissivity is 0.34.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com