Thermal control film with controllable emissivity

A technology of thermal control thin film and emissivity, which is applied in the field of aerospace materials, can solve the problems that the thermal control performance cannot be changed, and achieve the effects of good space environment stability, improved resistance to space radiation, and convenient manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

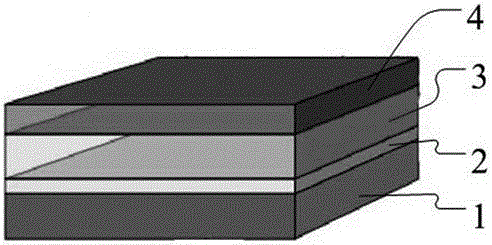

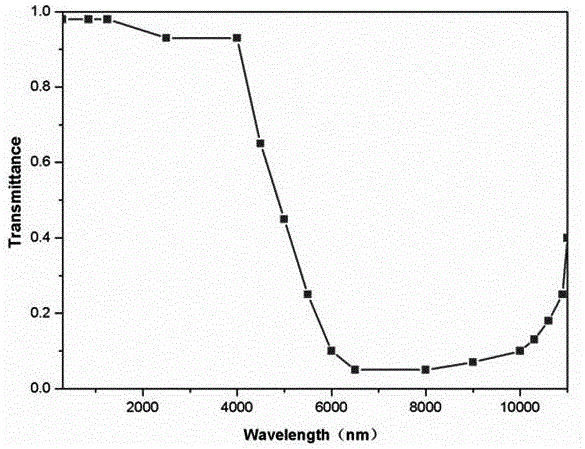

[0047] A thermal control thin film with controllable emissivity, the substrate is polyimide, on the surface of the substrate from inside to outside is a 150nm thick silver film, 1.9μm thick Al 2 o 3 layer and a 400nm thick SiO 2 layer, structured as figure 1 shown. The solar absorptivity of the film was 0.13.

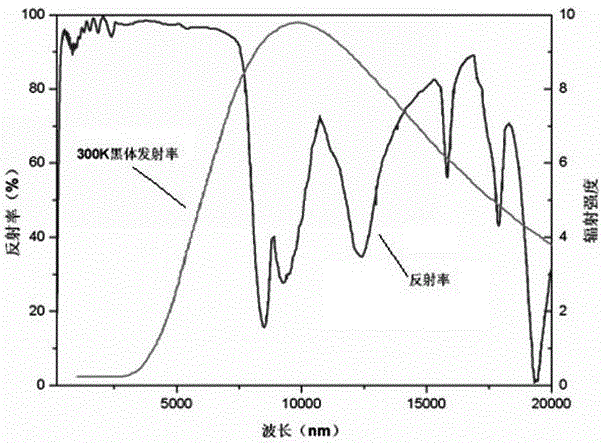

[0048] The reflectance spectrum of the thermal control film at a wavelength of 200-20000nm and the 300K black body radiation intensity curve are shown in image 3 . It can be seen from the figure that the film has a high solar absorption rate in the thermal infrared region of 8-13 μm), and the peak radiation intensity of the 300K black body is in this band, which indicates that the prepared thermal control film has a high thermal emissivity. The calculated hemispherical emissivity of the film is 0.59, and the hemispherical emissivity of the film measured by the AE radiometer is 0.58, and the results are basically consistent.

Embodiment 2

[0050] The solar absorptivity of the film prepared in Example 1 increases significantly after being exposed to the atmosphere for a long time, and the Ag reflective layer of the film turns black. The analysis shows that the silver reflective layer has been oxidized because the polyimide substrate is not dense enough to allow the oxygen molecules in the atmosphere to penetrate into the Ag film to oxidize it. For this reason, the film of Example 1 is improved, and the improvement is in the Add a layer of 50nm thick Al between the polyimide substrate and the silver film 2 o 3 Barrier layer, improved film structure see Figure 4 . After the improved film was exposed to the atmosphere for 8 months, no decline in absorption rate was found.

Embodiment 3

[0052] A thermal control film with controllable emissivity, the substrate is polyimide, and the surface of the substrate is sequentially covered with 50nm thick Al 2 o 3 Barrier layer, 150nm thick silver film, 1.9μm thick Al 2 o 3 layer and a 550nm thick SiO 2 Floor. The spectral reflectance curve and 300K blackbody radiation intensity curve of the thermal control film are shown in Figure 5 (A is the 300K blackbody radiation intensity curve of the film of this embodiment, B is the spectral reflection curve of the film of this embodiment, and C is the spectral reflection curve of the film of Embodiment 1), it can be seen that SiO 2 The thickness of the layer can increase the absorption of 5 μm to 8 μm and improve the infrared emissivity. The solar absorptivity of the film is 0.12, the hemispheric emissivity is 0.68, and the absorbed radiation ratio is 0.18.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| reflectance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com