High-stress and long-service-life variable section single steel plate spring and manufacturing method thereof

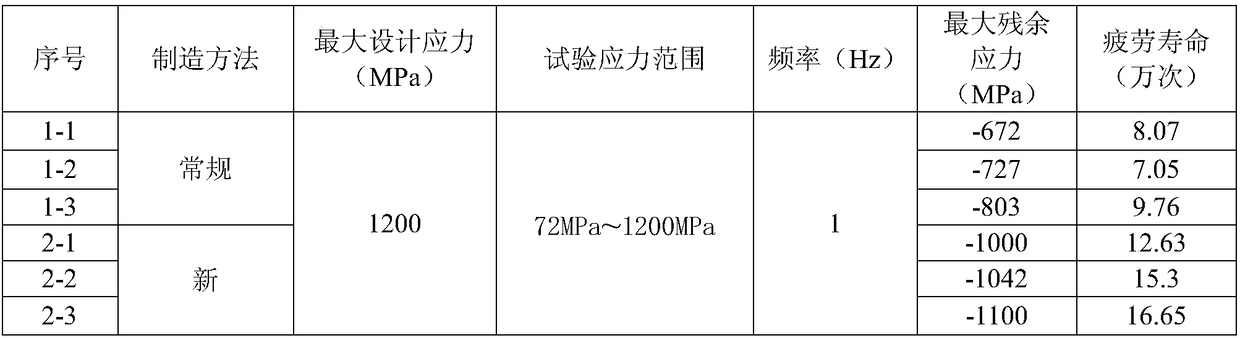

A technology of a leaf spring and a manufacturing method, applied in the field of leaf spring manufacturing, can solve the problems of neglecting the full utilization of material properties, failing to improve the tensile strength of the leaf spring and the residual compressive stress level on the surface of the leaf spring, and failing to effectively improve the fatigue life of the leaf spring.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

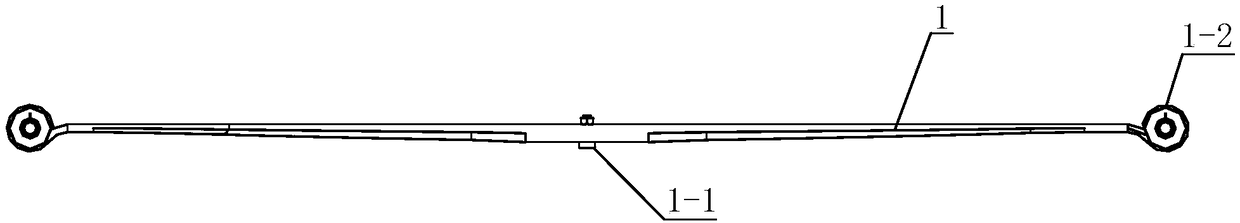

[0028] A high-stress, high-life variable cross-section single leaf spring, the structure of which can be referred to figure 1 , including the single leaf spring 1 body, the steel plate of the single leaf spring 1 body is a high-strength spring flat steel with a tensile strength ≥ 1870MPa and a yield strength ≥ 1680Mpa. After forming, the section of the single leaf spring 1 with variable cross-section is along its length The shape of the parabola changes in direction, and the central bolt hole 1-1 is the center, and the front, rear, left and right are symmetrical.

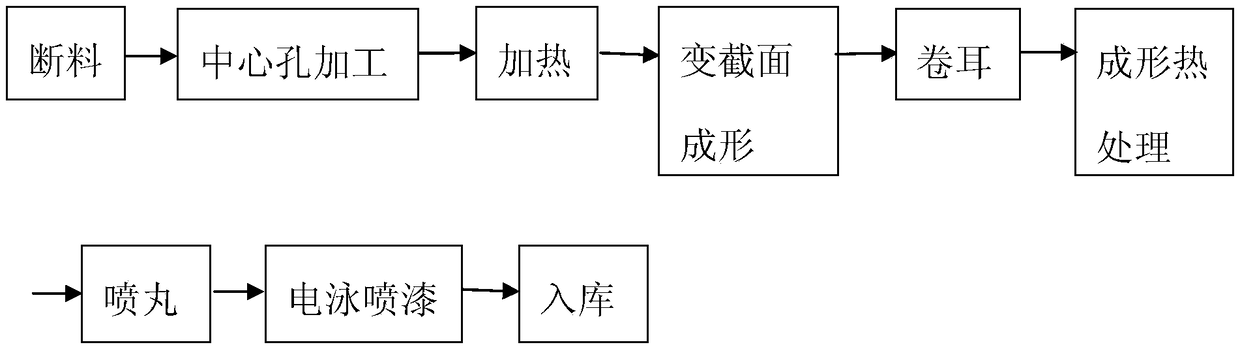

[0029] A high-stress, high-life variable cross-section single leaf spring manufacturing method, see figure 2 , which includes the following steps: S1. In the material cutting process: select high-strength spring flat steel with tensile strength ≥ 1870MPa and yield strength ≥ 1680Mpa, and perform material breaking according to the required length; S2. In the center hole processing process: Drill a center hole in th...

Embodiment 2

[0035] A high-stress, high-life variable cross-section single leaf spring, the structure of which can be referred to figure 1 , including the single leaf spring body 1, the steel plate of the single leaf spring 1 body is a high-strength spring flat steel with a tensile strength ≥ 1870MPa and a yield strength ≥ 1680Mpa. After forming, the section of the single leaf spring 1 with variable cross-section is along its length The shape of the parabola changes in direction, and the central bolt hole 1-1 is the center, and the front, rear, left and right are symmetrical.

[0036] A high-stress, high-life variable cross-section single leaf spring manufacturing method, see figure 2, which includes the following steps: S1. In the material cutting process: select high-strength spring flat steel with tensile strength ≥ 1870MPa and yield strength ≥ 1680Mpa, and perform material breaking according to the required length; S2. In the center hole processing process: Drill a center hole in the...

Embodiment 3

[0042] A high-stress, high-life variable cross-section single leaf spring, the structure of which can be referred to figure 1 , including the body of the single leaf spring 1, the body of the single leaf spring 1 is a high-strength spring flat steel with a tensile strength ≥ 1870MPa and a yield strength ≥ 1680Mpa. After forming, the section of the single leaf spring 1 with variable cross-section changes along its length direction The parabolic shape is centered on the central bolt hole 1-1, and the front, rear, left and right are symmetrical.

[0043] A high-stress, high-life variable cross-section single leaf spring manufacturing method, see figure 2 , which includes the following procedures: S1, in the material cutting process: select high-strength spring flat steel with a tensile strength of 1870MPa and a yield strength of 1680Mpa, and perform material cutting according to the required length; S2, in the center hole processing process: in the single Drill a center hole in...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com