Three-phase inversion power module based on two-way spiral flow channel water cooling heat radiation substrate

A technology of water cooling and heat dissipation and three-phase inverter, which is applied in the direction of conversion of AC power input to DC power output, output power conversion device, cooling/ventilation/heating transformation, etc. And problems such as heavy weight, difficult quick plug-in and unplug installation, etc., to improve the anti-interference performance of the drive signal, low processing accuracy requirements, and save the effect of external quick connection devices

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

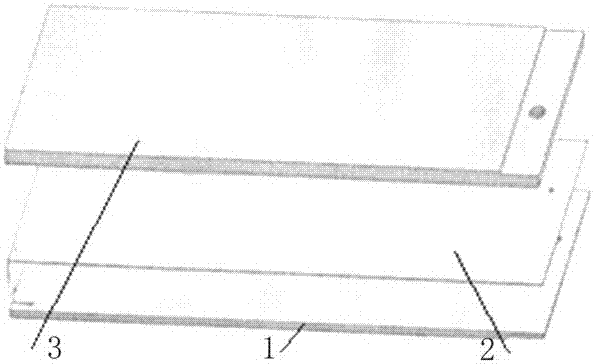

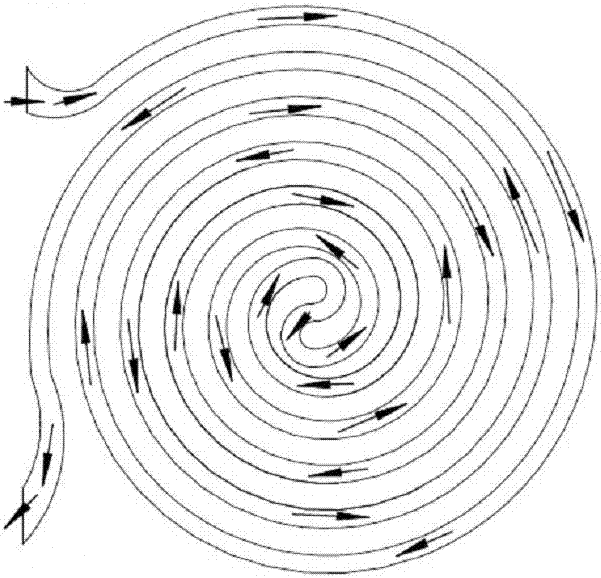

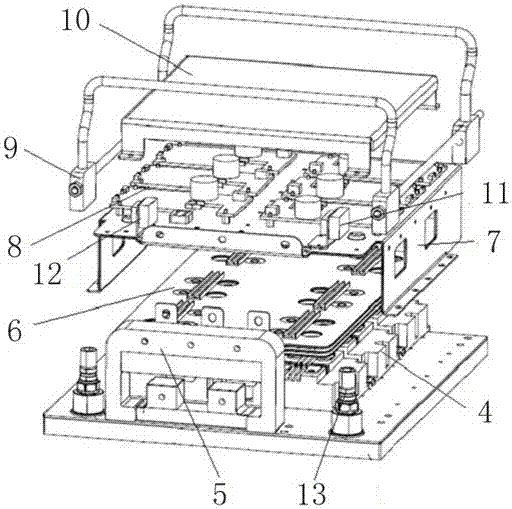

[0010] A three-phase inverter power module based on a two-way spiral flow channel water-cooled heat-dissipating substrate, including a water-cooled heat-dissipating substrate, the water-cooled heat-dissipating substrate includes a cooling main board 1, a brazing board 2, and a cover board 3 stacked in three layers; the cooling The main board 1 is provided with a bidirectional spiral flow channel with a center symmetry and a smoothly penetrating center of symmetry. The cover plate 3 is provided with two water connectors 13 perpendicular to the surface of the cover plate. The water connectors 13 are connected to the two ends of the flow channel respectively. The cover plate 3 and the cooling main board 1 have a plurality of installation threaded holes; the front edge of the upper surface of the water-cooled heat dissipation substrate is vertically fixed with an insulating support seat 5, and the water connector 13 is arranged on the insulating On both sides of the support base 5, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com