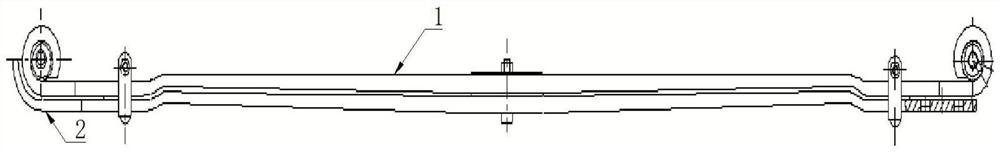

Single-leaf spring for heavy truck

A leaf spring and monolithic technology, applied in the direction of springs, leaf springs, springs/shock absorbers, etc., can solve problems such as poor stability and non-compliance with lightweight requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

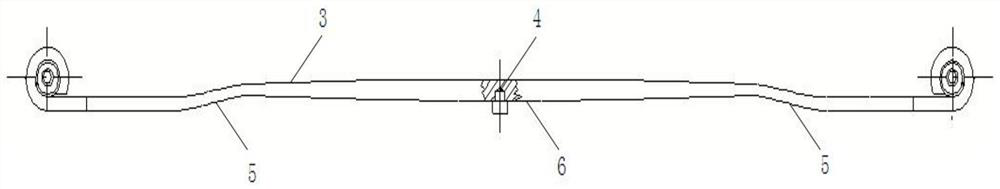

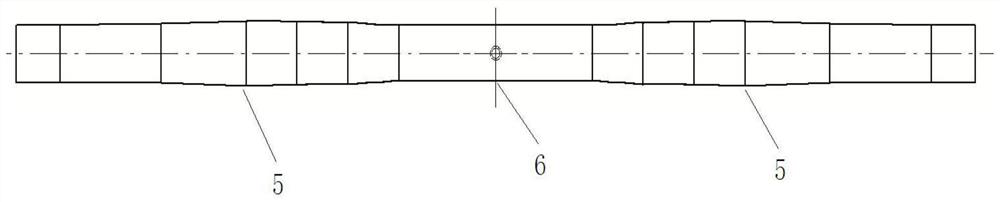

[0026] This embodiment provides a single leaf spring for a heavy truck, its structure is as follows Figure 2-3 As shown, it includes a single leaf spring roll lug 3, and the single leaf spring roll lug 3 is a spring leaf with unequal width and a trapezoidal or parabolic cross-section whose thickness varies along the length direction. A positioning pin 4 is arranged in the center hole of the sheet leaf spring roll lug 3, and the positioning pin 4 is in interference fit with the center hole, and the single leaf spring roll lug 3 is rigidly connected to the positioning pin 4 through the center hole on the chassis axle.

[0027] Specifically, the surface of the single leaf spring roll lug 3 is divided into a variable section area 5 and an intermediate clamping area 6, the variable section area 5 is located at both ends of the intermediate clamping area 6, and the intermediate clamping area The width of 6 is smaller than the width of the variable cross-section area 5 at its two e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com