Coupling impactor used for petroleum drilling

A technology of oil drilling and coupling impact, which is applied to the driving device for drilling in the wellbore, drilling equipment, earthwork drilling and production, etc. It can solve the problems of easy to produce mud balls, expensive use costs, clogged nozzles and other problems of the drill bit, so as to improve rock crushing. The effect of reducing drilling cost and improving drilling speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

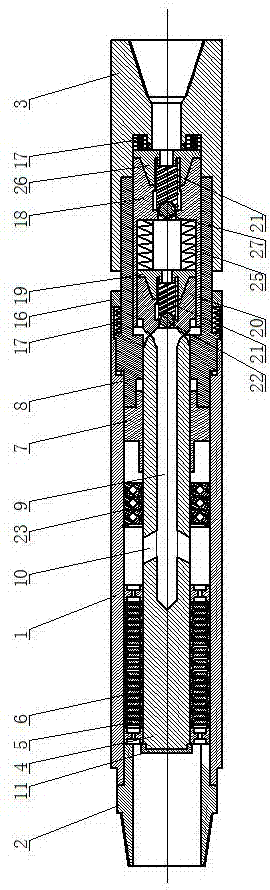

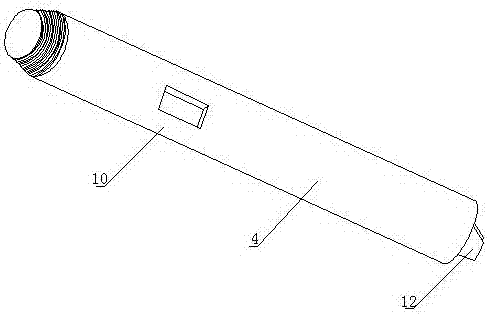

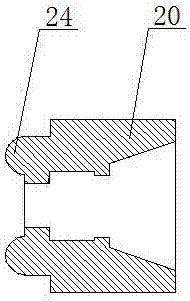

[0029] The coupling impactor for oil drilling includes a housing 1 , an upper joint 2 , a lower joint 3 , a central shaft 4 , a fixed turbine valve 5 , a dynamic turbine valve 6 , an upper hammer body 7 , and a lower hammer body 8 . One end of the casing 1 is threaded with an upper joint 2, and the upper end of the upper joint 2 has pipe threads for connecting with the upper drill string. The housing 1 on the inner side of the upper joint 2 is equipped with a central shaft 4 through the fixed turbine valve 6 and the dynamic turbine valve 6; the central part of the central shaft 4 is axially provided with a flow channel 9, and the upper diameter of the central shaft 1 at the end of the flow channel 9 A flow hole 10 is arranged in the direction, and the flow hole 10 communicates with the flow channel 9; a gland 11 is threadedly mounted on one end of the central shaft, and a central shaft hammer head 12 is symmetrically arranged on the other end surface of the central shaft 4 .

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com