Method for controlling on-line self-centering perforation of seamless tube blank puncher

An automatic centering and punching machine technology, applied in the direction of use feedback control, manufacturing tools, arc welding equipment, etc., can solve the problems of difficulty in meeting continuous production, difficulty in meeting process requirements, high processing costs, etc., to ensure centering and The effect of punching quality, good punching quality and fast punching speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

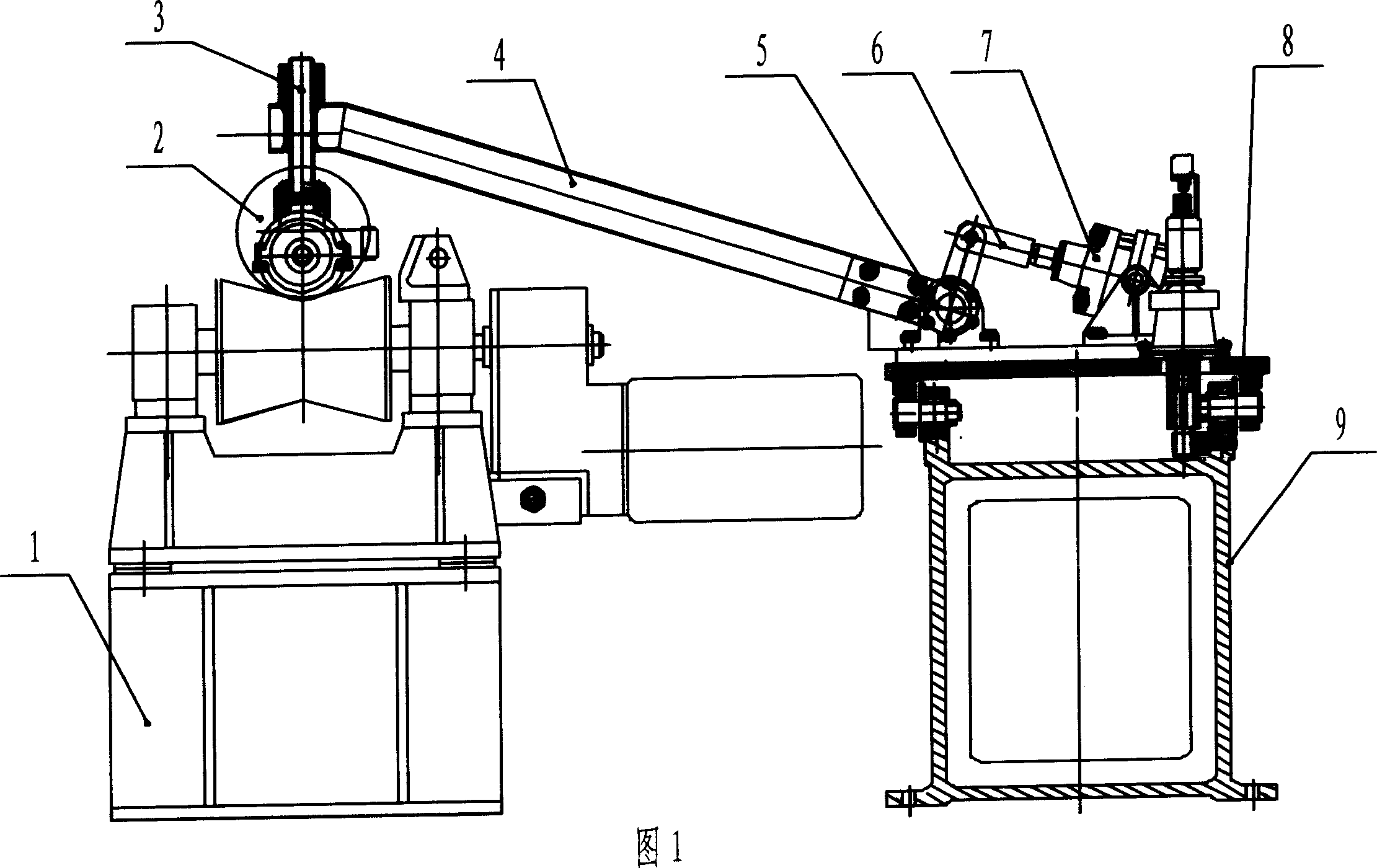

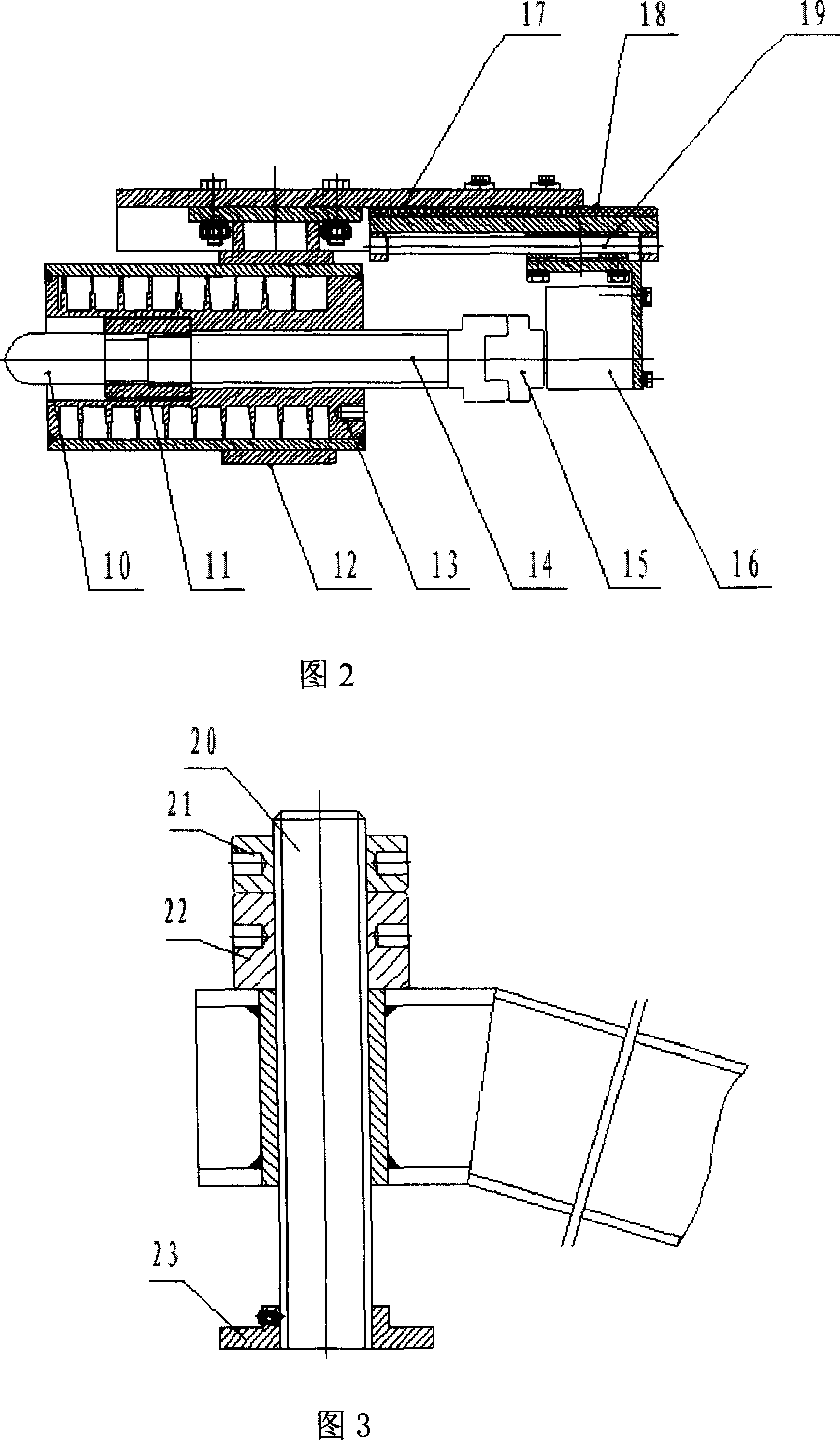

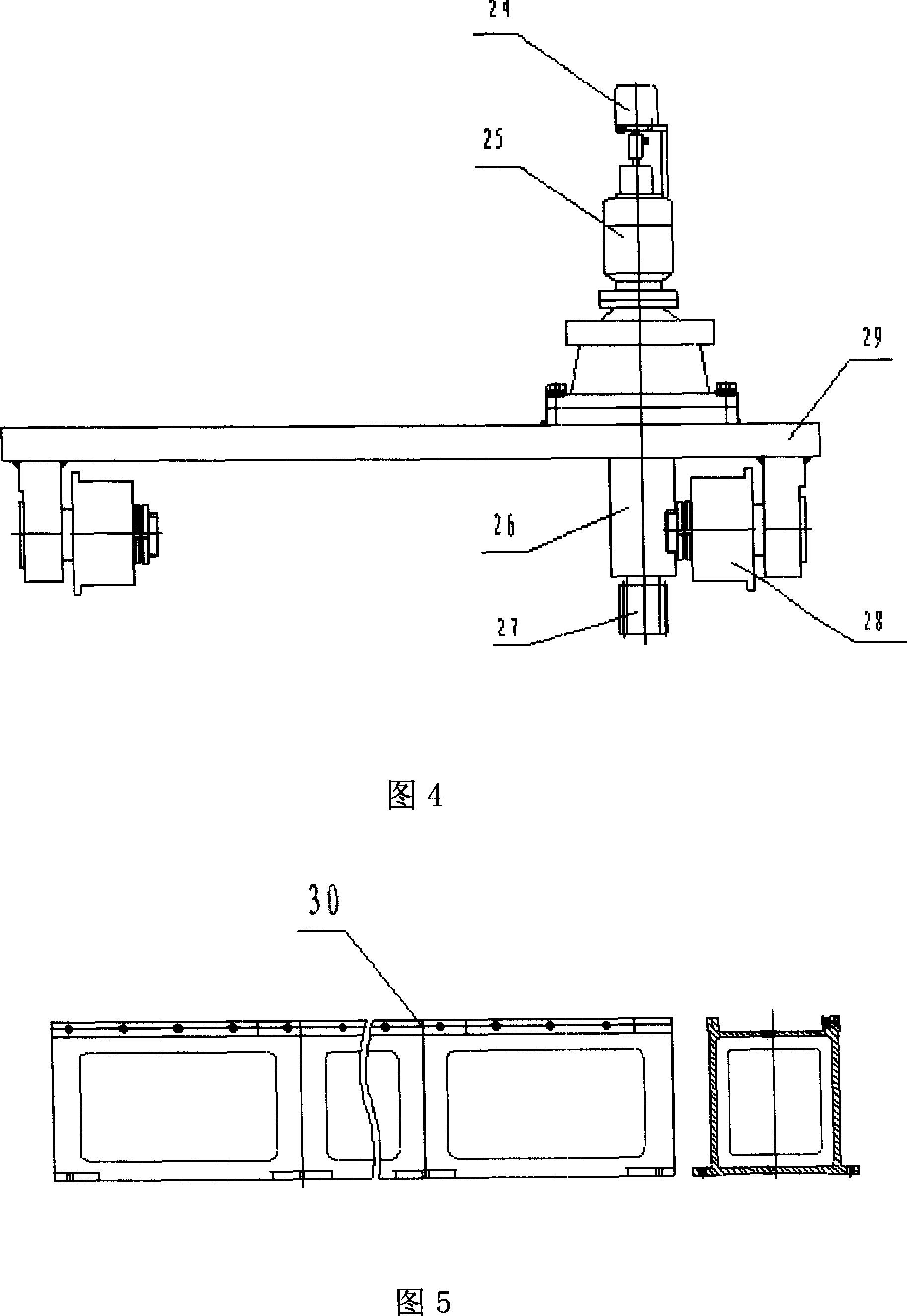

[0031] Referring to the accompanying drawings, the seamless pipe blank punching machine is composed of a track traveling trolley 8 and a manipulator. The manipulator is composed of a contact clamping device 2, a cantilever 4, a bearing seat 5, a crank 6 and a cylinder 7. The piston rod of the cylinder 7 is connected to the The crank 6 is connected with a pin shaft, the crank 6 is connected with the bearing in the bearing seat 5, one end of the cantilever 4 is connected with the crank 6, the other end of the cantilever 4 is connected with the contact clamping device 2 through a contact centering device 3, and the cylinder 7 and bearing block 5 are installed on the car body 29 of track walking dolly. The contact clamping device 2 adopts a rotary feed clamping device, which is composed of a base plate 17, a connecting nut 11, a screw 14, an electric screw nut 13, a fixed support 12, a shaft coupling 15, a motor 16, and a sliding seat 19. , the fixed support 12 and the sliding sea...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com