Electro-hydraulic logic control loop of rock drilling actions of hydraulic rock drilling machine

A logic control, rock drilling rig technology, applied in the drilling automatic control system, fluid pressure actuating device, fluid pressure actuating system components, etc. control, non-adjustment and other problems to achieve the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

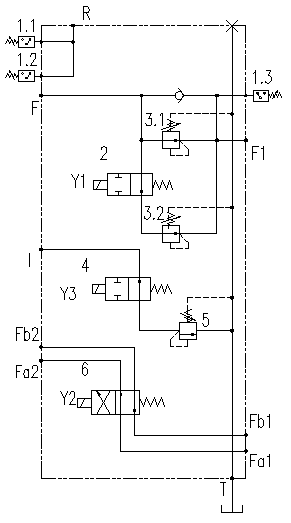

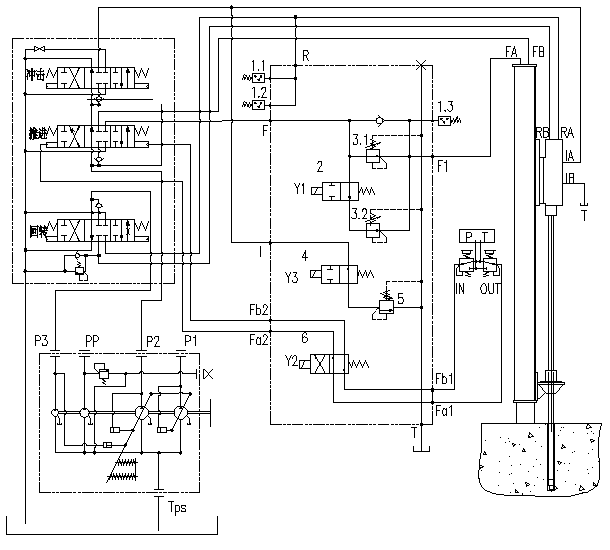

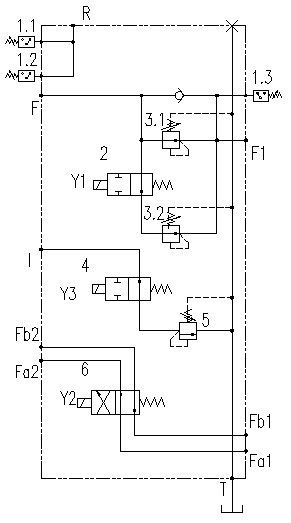

[0016] attached figure 1 and figure 2 The electro-hydraulic logic control circuit for the rock drilling action of a hydraulic rock drilling rig is shown, which consists of an adjustable pressure relay 1.1, a pressure relay 1.2, a pressure relay 1.3, a pressure reducing valve 3.1, a pressure reducing valve 3.2, and an electromagnetic reversing valve 2 , electromagnetic reversing valve 4, and overflow valve 5 constitute a two-stage pressure propulsion logic control loop for rotary pressure control, and simultaneously low-pressure propulsion control and low-pressure impact logic control loop; pressure relay 1.3, electromagnetic reversing valve 4, and overflow valve 5 form a propulsion pressure control level Two-stage impact pressure logic control loop; pressure relay 1.2 and electromagnetic reversing valve 6 form a rotary pressure control push-up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com