Logic control loop for rock drilling operations of hydraulic rock drilling machine

A technology of rock drilling rig and action logic, which is applied in the field of compound logic control circuit of hydraulic rock drilling rig, can solve problems such as poor adaptability, broken drill rod, inability to realize automatic matching of key rock drilling actions, compound logic control, etc. To achieve the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

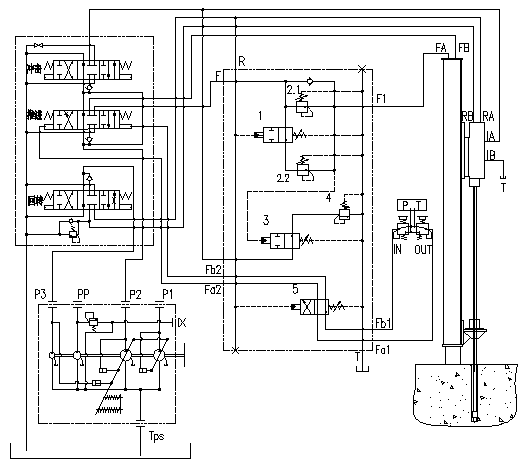

[0013] Below in conjunction with accompanying drawing, specific embodiment of the present invention is described in further detail:

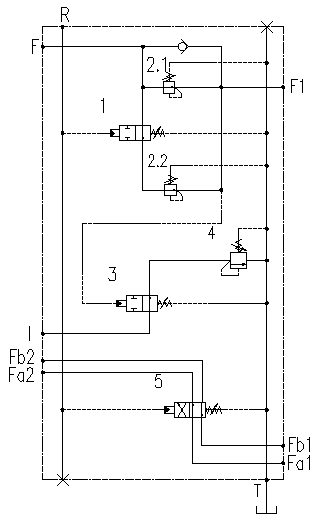

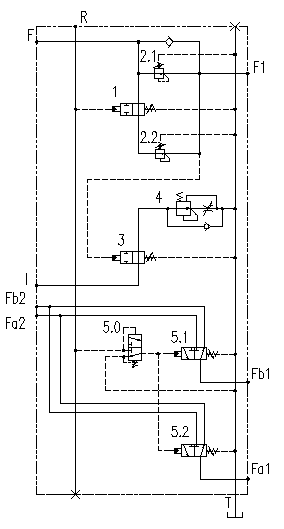

[0014] Such as figure 1 and image 3 In the first embodiment shown, hydraulically controlled directional valve 1, pressure reducing valve 2.1, pressure reducing valve 2.2, hydraulically controlled directional valve 3, and overflow valve 4 form a rotary pressure to control two-stage pressure propulsion, while low pressure propulsion controls low pressure impact Logical control loop; hydraulically controlled reversing valve 3 and overflow valve 4 form a logic control loop for propulsion pressure control, high and low, two-stage impact pressure; two-position, four-way hydraulically controlled reversing valve 5 constitutes a logical control loop for rotary pressure control, propulsion and lifting .

[0015] The rotary pressure is introduced into the rock drilling action logic control block from the rotary main oil circuit through the oil port R, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com