Single-pump hydraulic control loop of key drilling action of cutting drill rig

A control circuit and key technology, applied in the automatic control system of drilling, the driving device for drilling in the wellbore, mechanical equipment, etc., can solve the problems of large single-turn feed of the drill bit, low rotary resistance, and stuck pipe. , achieve the effect of shortening the operation cycle time, improving the automatic adaptability and preventing the drill bit from slipping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

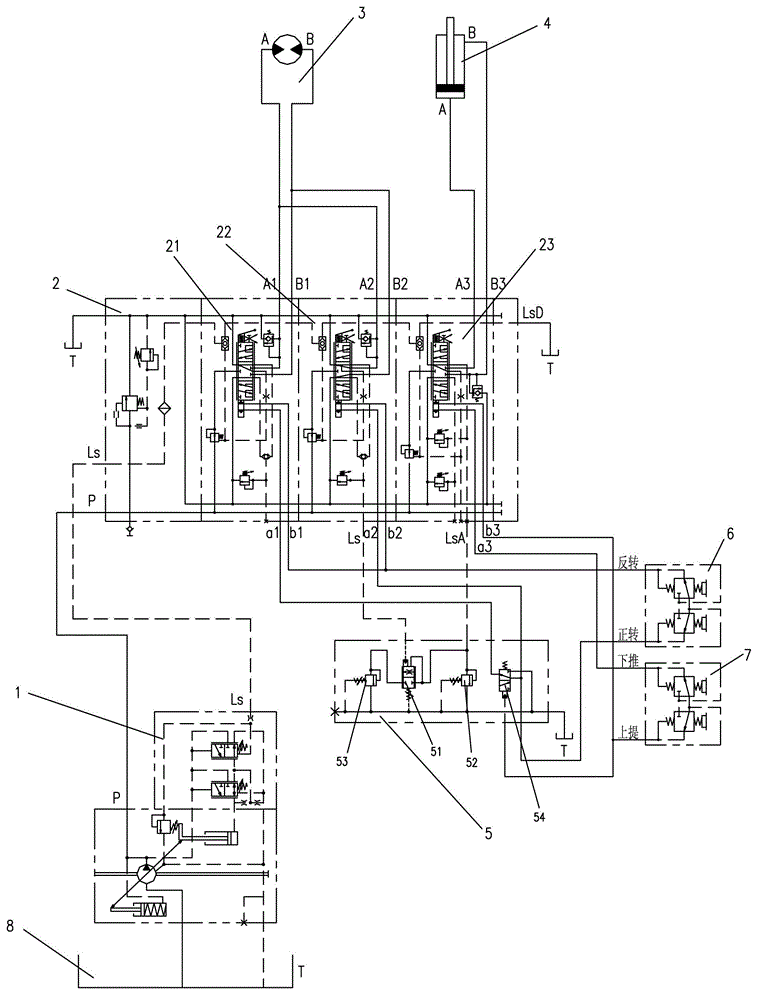

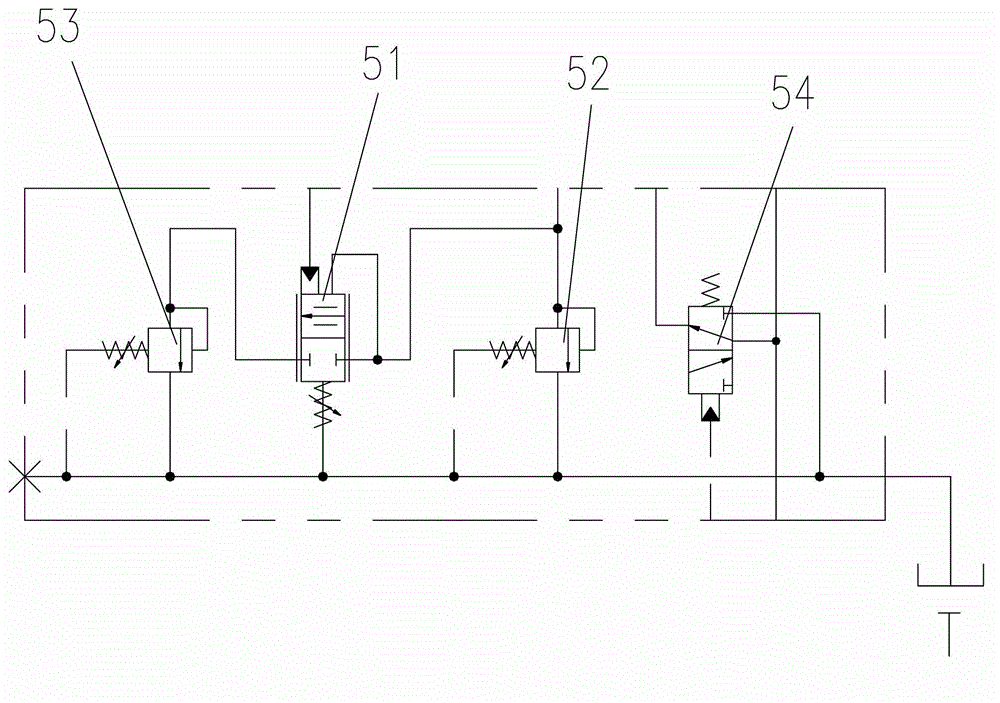

[0014] A single-pump hydraulic control circuit for the key rock drilling action of a cutting rig, which consists of a load-sensitive variable pump 1, a load-sensitive proportional multi-way valve 2, a rotary motor 3, a propulsion cylinder 4, and a hydraulic oil tank 8, etc. The main oil circuit: the logical control and pilot control oil circuit of the key rock drilling action of the cutting drilling rig is composed of the rock drilling logic control block 5, the rotary pilot handle 6, and the push pilot handle 7.

[0015] The function and configuration features of the load-sensitive proportional multi-way valve 2 are as follows: each valve has a pressure difference compensator and its load-sensitive external control port, and the pressure difference compensator of the propulsion-connected multi-way valve 23 especially has independent l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com