Bubbling rinsing mechanism with rotating function

A technology with bubbling rinsing and rotating functions, applied in the field of mask cleaning, can solve problems such as dead corners, inability to effectively remove foreign objects in workpieces, etc., to save costs, avoid insufficient cleaning, and improve cleaning effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

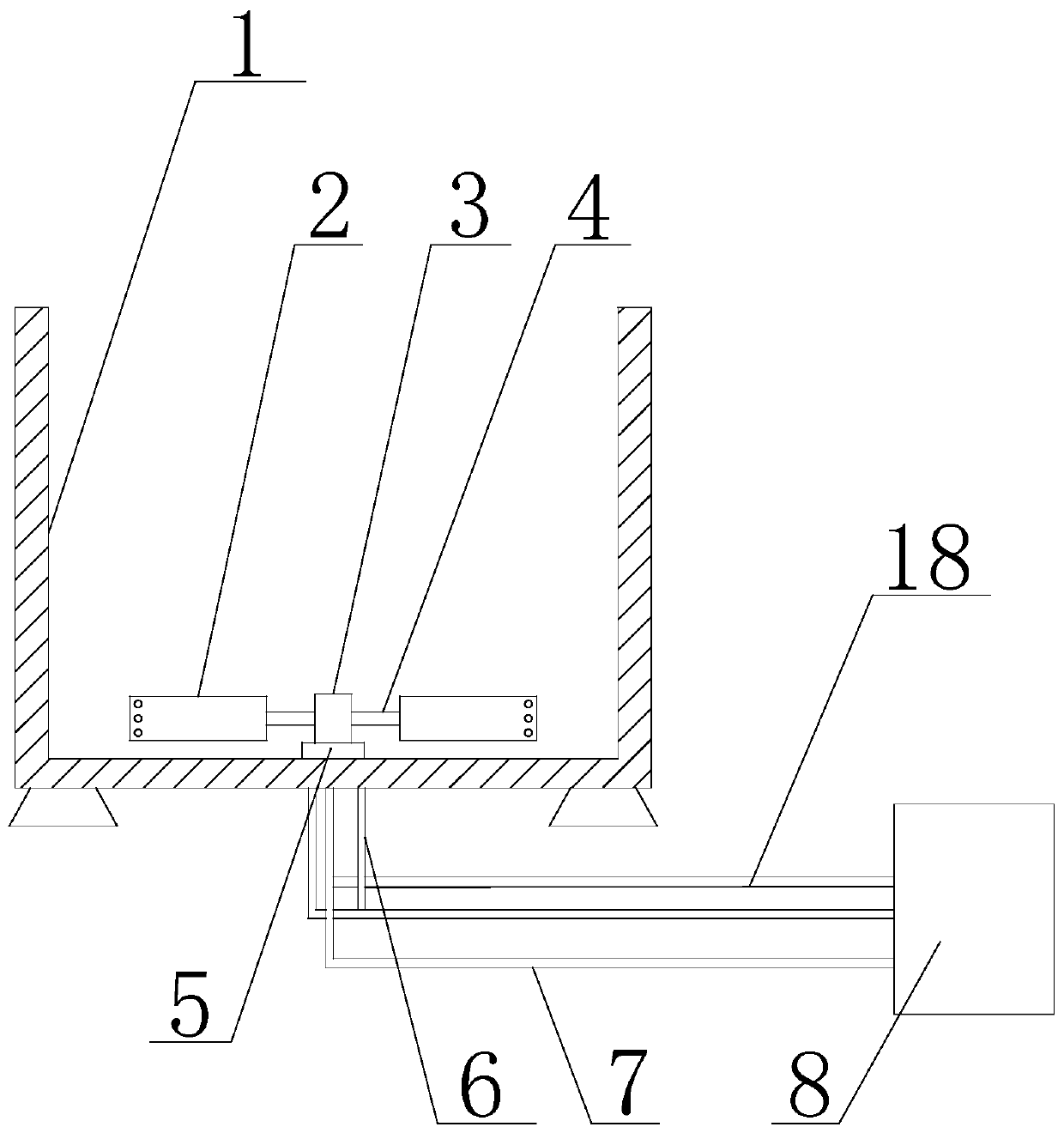

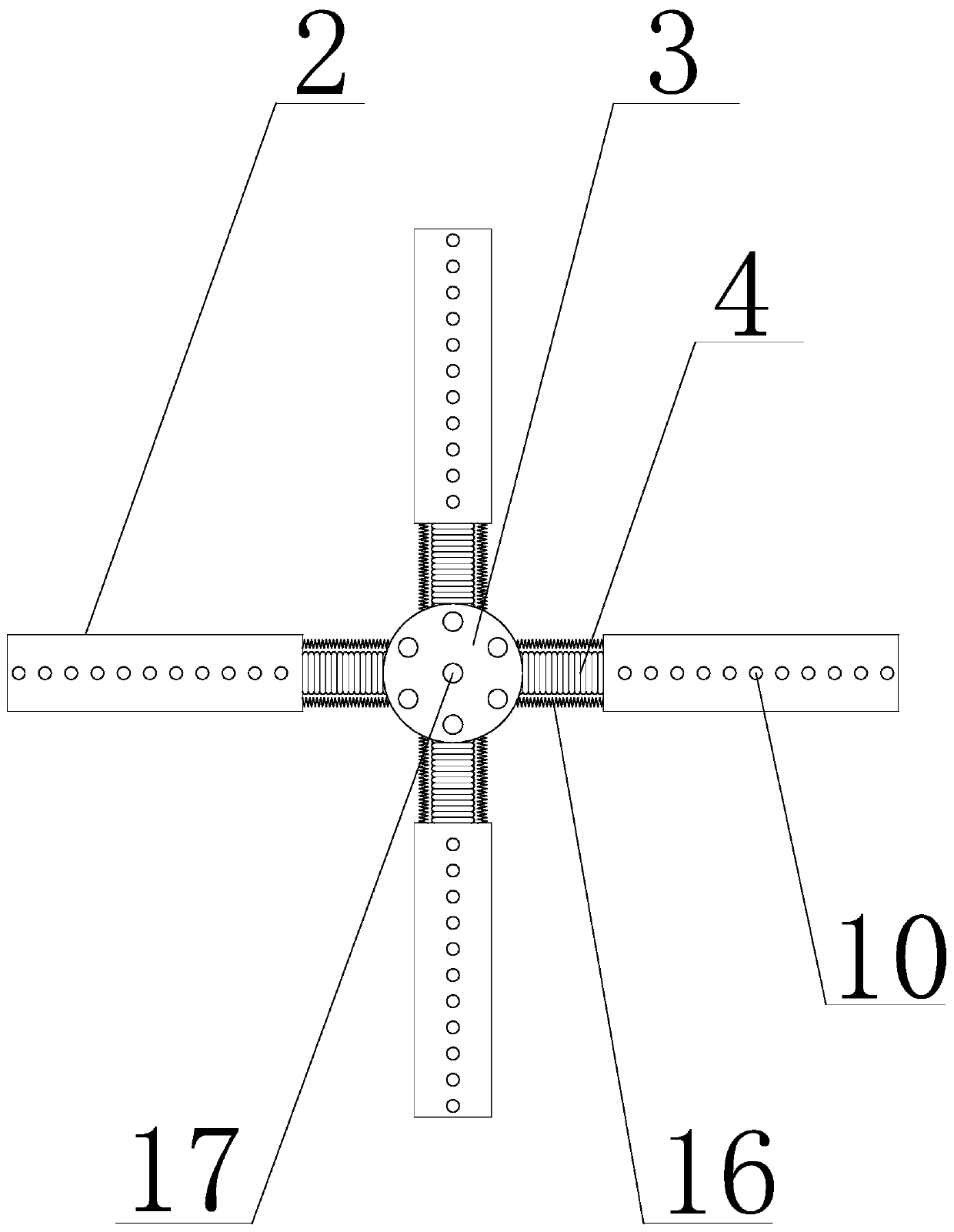

[0033] Such as figure 1 As shown in 4, a bubbling rinsing mechanism with a rotating function in the present invention includes a pool body 1 and an electric air pump 8. The inner bottom of the pool body 1 is provided with a movable rod 3, which can rotate around its axis Rotate in the opposite direction, the outer peripheral wall of the movable rod 3 is provided with several bellows 4, the length of the bellows 4 can be stretched after the interior of the bellows 4 is inflated, one end of the bellows 4 is connected with the inner wall cavity 11 of the movable rod 3, and the other end is connected to the inner wall cavity 11 of the movable rod 3. Stirring plates 2 are all provided, and the upper surface of the stirring plate 2 is provided with some vertical nozzles 10, and the vertical nozzles 10 are evenly distributed along the long axis direction of the stirring plate 2, and some horizontal nozzles are arranged on both sides of the stirring plate 2. Nozzle 12, the first air v...

Embodiment 2

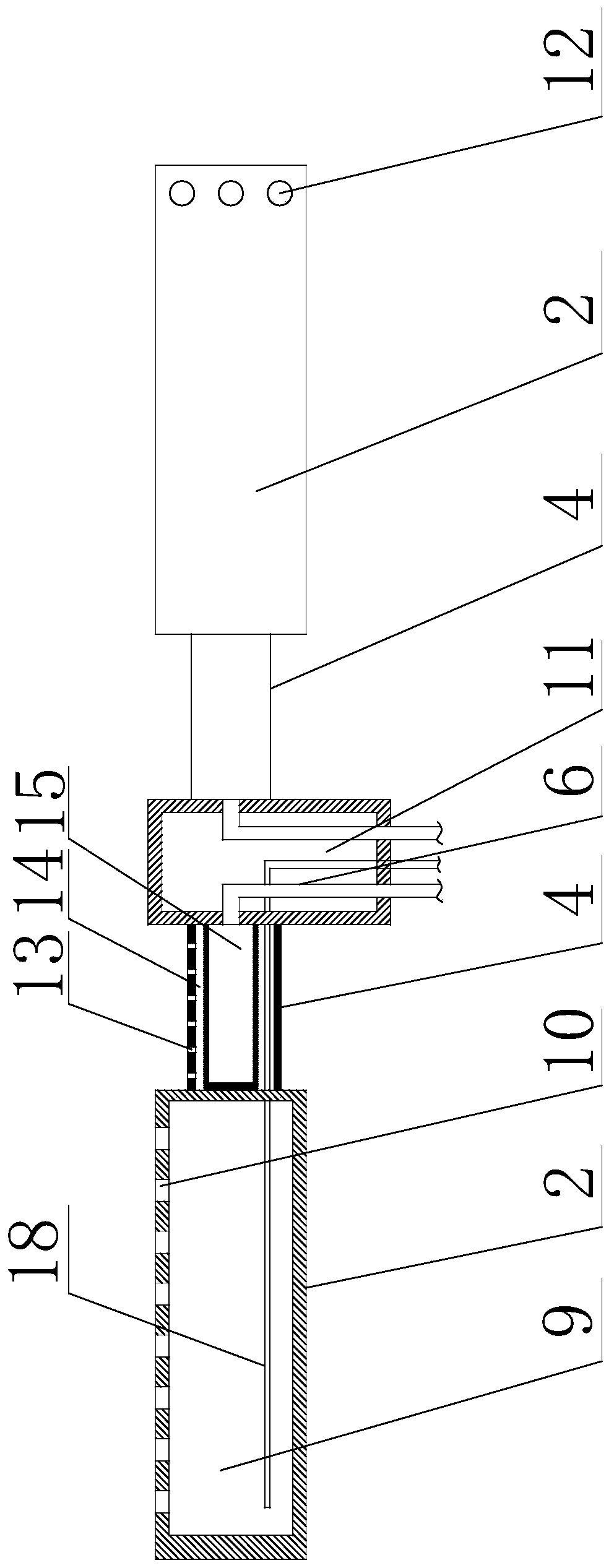

[0035]On the basis of Embodiment 1, the bellows 4 is provided with a cavity 15, and the cavity 11 of the movable rod 3 is also provided with the same number of first air pipes 6 as the bellows 4, the first air pipes One end of 6 is connected to the output end of the electric air pump 8, and the other end is communicated with the cavity 15. The bellows 4 is also provided with an annular cavity 14, the annular cavity 14 communicates with the cavity 11 of the movable rod 3, and the top of the bellows 4 is also provided with a plurality of first air holes 13, and the first air holes are along the corrugated surface. The axial direction of the pipe 4 is distributed, and the first air hole 13 communicates with the annular cavity 14 .

Embodiment 3

[0037] On the basis of Embodiment 2, the stirring plate 2 is provided with an air collecting chamber 9, the air collecting chamber 9 communicates with the annular cavity 14, the vertical nozzle 10 communicates with the air collecting chamber 9, and the air collecting chamber 9 is provided with There is a third air delivery pipe 18, one end of the third air delivery pipe 18 communicates with the horizontal nozzle 12, and the other end passes through the annular cavity 14, and the cavity 11 is connected with the output end of the electric air pump 8 in turn.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com