Safety complex function valve and two-way valve composed by same

A compound function and safety technology, applied in the directions of safety valve, functional valve type, balance valve, etc., can solve the problems of inability to communicate the positive and negative directions of the chamber, narrow applicable flow range, no emergency structure, etc., to achieve simple structure, Good sealing effect and high safety effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments

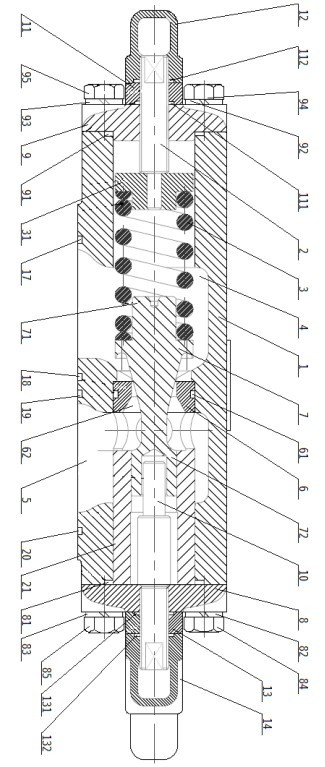

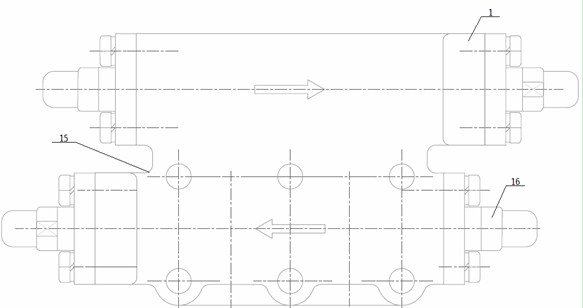

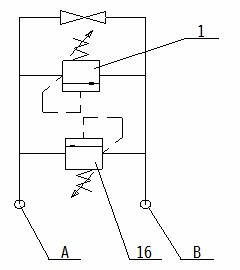

[0027] see figure 1 — image 3 , a safety composite function valve, including a valve body 1, an adjusting screw 2 and a spring 3, the inside of the valve body 1 includes a left valve cavity 4 and a right valve cavity 5, and the left valve cavity 4 is provided with an adjusting screw 2 and a spring 3. A spring seat 31 is provided between the adjusting screw 2 and the spring 3;

[0028] The inside of the valve body 1 is located between the left valve chamber 4 and the right valve chamber 5. A valve sleeve 6 is provided, and a valve sleeve sealing ring 61 is provided between the outer surface of the valve sleeve 6 and the valve body 1. The valve sleeve 1 A cone-shaped valve core 7 is provided through the cone-shaped inner hole 62 of the cone, and the cooperation mode between the valve core 7 and the valve sleeve 1 is a cone seal fit; ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com