Automobile engine disassembling and assembling detection practical training assessment device

An automobile engine and training technology, which is applied to educational appliances, instruments, teaching models, etc., can solve the problems of difficult operation and detection, inconvenient rotation of the engine, etc., to achieve the effect of convenient use and reduction of free time and effort.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] In order to have a clearer understanding of the technical features, purposes and effects of the present invention, the specific implementation of the present invention will now be described with reference to the accompanying drawings, but the protection scope of the present invention is not limited to the following description.

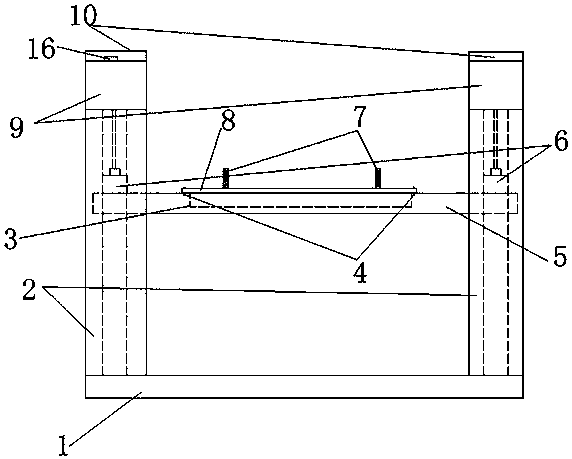

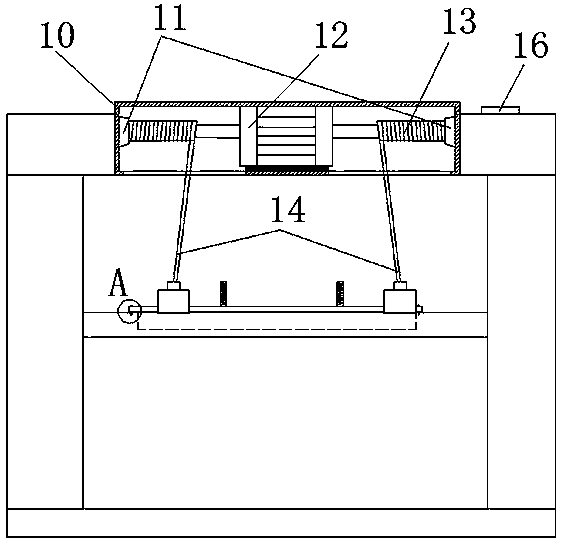

[0016] Such as Figure 1-4 As shown, the present invention provides a kind of automobile engine disassembly detection training assessment device, including base 1, support column 2, thrust bearing 3, load bearing plate 5, installation fixed plate 8, support beam 9, motor case 10 and biaxial Alternating current motor 12, support columns 2 are all welded on the four end feet of the square base 1, two support beams 9 are arranged above the support columns 2, a motor steering switch 16 is arranged above the left support beam 9, and the two support beams 9 A motor case 10 is welded in the middle of the motor case 10, and a double-axis AC motor 12 is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com