Automatic regulating lance device for steel making oxygen lance

A technology for automatic adjustment of oxygen lances, applied in the direction of manufacturing converters, etc., can solve the problems of low labor productivity, contrary to rapid steelmaking, and deviation of furnace mouth center, so as to shorten the adjustment time and improve production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0010] Below in conjunction with accompanying drawing and specific embodiment the present invention will be further described:

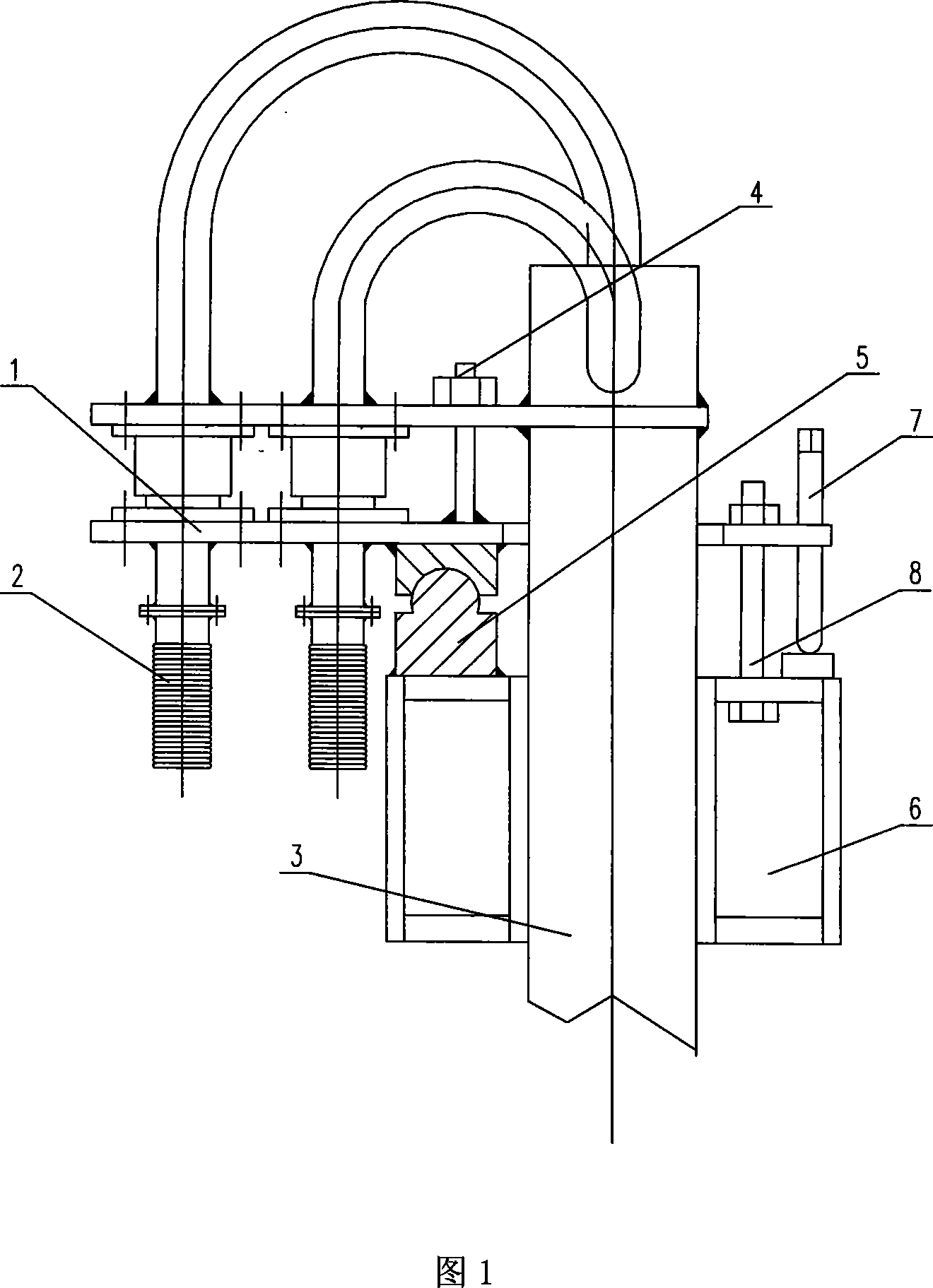

[0011] An automatic oxygen lance adjustment device for steelmaking, including a lifting trolley and a metal hose 2, characterized in that an adjustment plate 1 is provided on the lifting trolley, the metal hose 2 is connected to the adjustment plate 1, and the oxygen lance body 3 It is also fixed on the adjustment plate 1, and the adjustment plate 1, the oxygen lance body 3, and the metal hose 2 form a whole through the fixing device 4, and a hemispherical support point 5 is designed on the center of gravity of the whole to act on the trolley body 6 , through this supporting point 5, the whole can be adjusted in any angle in the horizontal direction, and after adjustment, the whole is fixed with the trolley body 6 through the manual adjustment device 7 and the connecting device 8.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com