Laminar flow element

A component, solid technology, applied in the detection of fluid flow by measuring differential pressure, volume/mass flow generated by mechanical effects, etc., can solve the problems of difficult processing, high price, narrow flow range, etc., to achieve stable laminar flow, processing The effect of high precision and wide flow range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

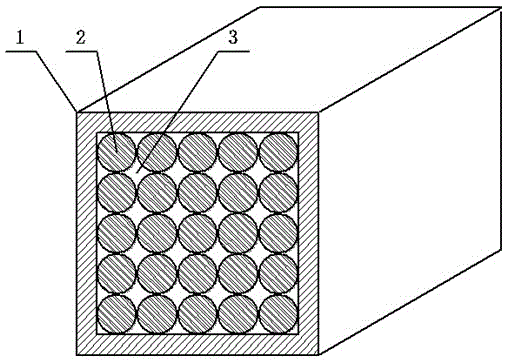

[0017] The wall thickness of the hollow cylinder 1 is 5mm, the length is 30mm, and the size of the square through hole is 10*10mm. The material of the hollow cylinder 1 can be selected from materials such as stainless steel, aluminum alloy or ceramics.

[0018] 100 solid round rods 2 with a smooth surface, a diameter of 1 mm, and a length of 30 mm are closely arranged along the axial direction of the through hole in the hollow cylinder 1 . The arrangement of the solid round rods 2 in the hollow cylinder is arranged in parallel. The hollow cylinder 1 and the solid round rod 2 are fixed with each other through interference fit. The hollow cylinder 1 and the solid round rod 2 , and the gap between the solid round rods 2 form a laminar flow channel 3 . The solid round rod 2 can be made of materials such as stainless steel, aluminum alloy or pottery.

[0019] When the laminar flow element is actually used, the fluid passes through the laminar flow channel 3 to form a laminar flo...

Embodiment 2

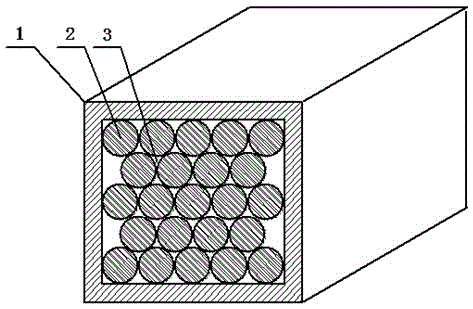

[0022] The discharge method of the solid round rod 2 in the laminar flow element can also adopt another method, such as figure 2 As shown, the solid round rods 2 are closely arranged in the fork row in the hollow cylinder 1, and the specific scheme refers to the first embodiment. Compared with the first embodiment, the laminar flow formed by the laminar flow element in this embodiment is more stable.

Embodiment 3

[0024] The laminar flow element can also be made by using a solid round rod 2 with a diameter of 3 mm. For a specific implementation, please refer to the method of using a solid round rod 2 with a diameter of 1 mm to make a laminar flow element. Compared with the first embodiment, in this embodiment, the laminar flow stability formed by the laminar flow element is lowered, and the applicable flow range is slightly lowered, but the manufacturing cost is lowered.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com