Marine diesel engine SCR common rail type urea solution spraying system

An injection system, Tianlan technology, applied in the direction of mechanical equipment, engine components, combustion engines, etc., can solve the problems of increasing manufacturing, installation and operating costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

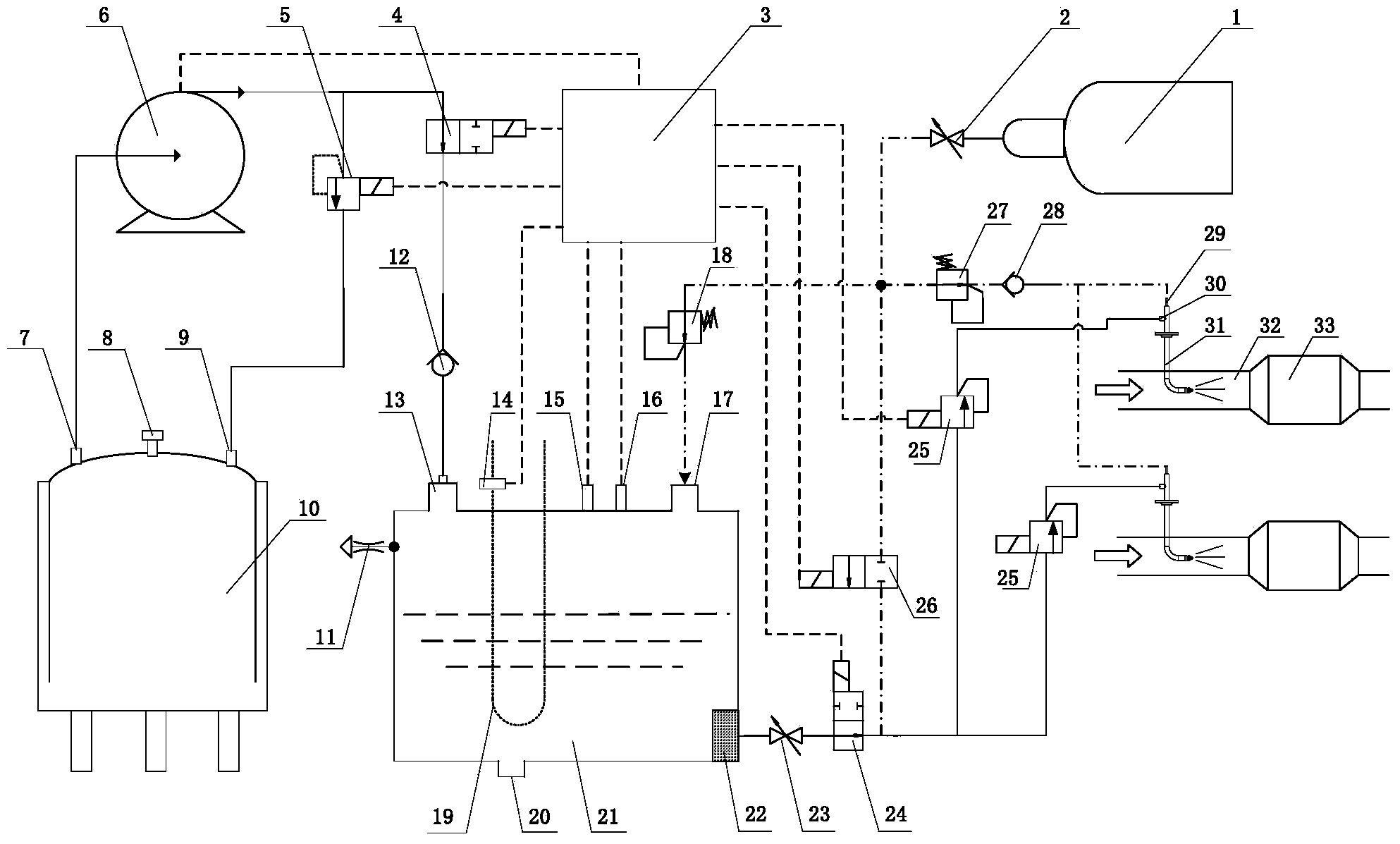

Embodiment 1

[0040] In embodiment 1, the number of engines that are supplied to Tianlan at the same time is not limited to two, and can be adjusted arbitrarily within the capacity of Tianlan's daily cabinet 21.

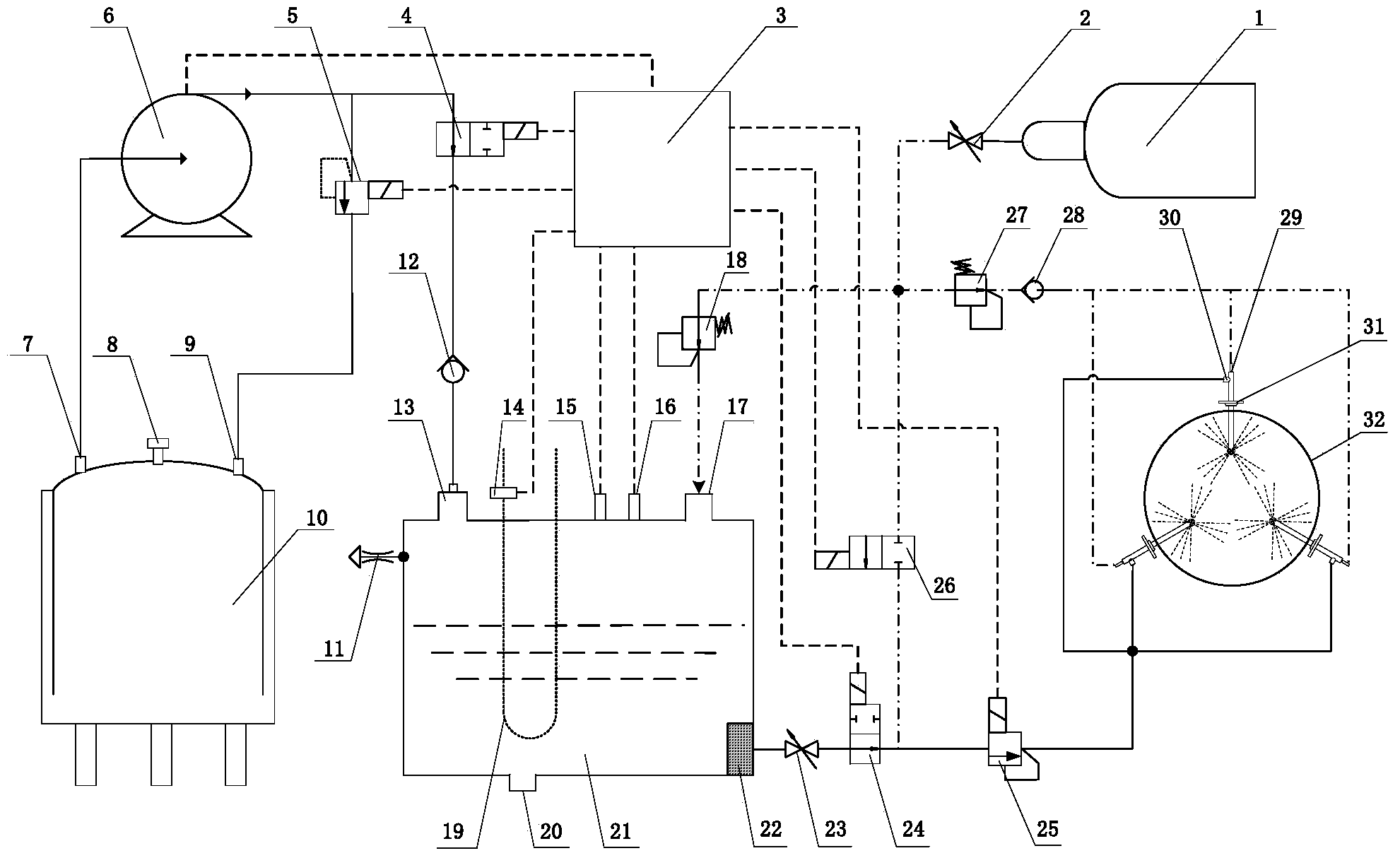

[0041] The second embodiment of the present invention is as figure 2 As shown, there are three spray guns 31 , which are located in the same engine exhaust pipe 32 and evenly arranged along the circumferential direction of the inner wall of the engine exhaust pipe 32 . After passing through filter 22, Tianlan cut-off valve 23, output solenoid valve 24 and metering solenoid valve 25, Tianlan is divided into three circuits, which are respectively connected with liquid inlets 30 of three spray guns 31; The compressed air is also divided into three paths through the compressed air stop valve 2, the second pressure reducing valve 27 and the compressed air check valve 28, which are respectively connected to the gas inlets 29 of the three spray guns 31; since the gas and liquid flow rat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com