Cold plate performance test device

A testing device and cold plate technology, applied in the direction of measuring devices, instruments, etc., can solve the problems of difficulty in ensuring the heat flux density of electrical components, uneven thickness of thermally conductive silica gel, and insufficient thermal insulation measures to eliminate adverse effects, high pressure head, The effect of low heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

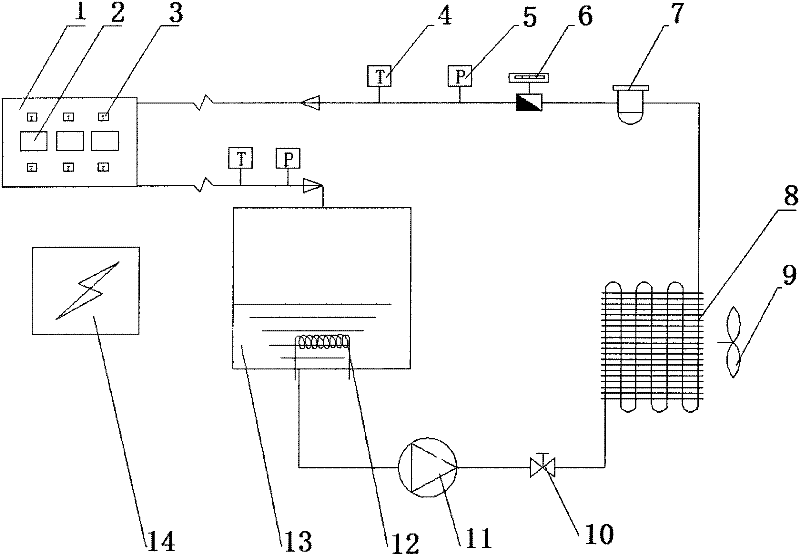

[0035] The cold plate performance testing device of the present embodiment includes a thermometer 4, a pressure gauge 5, a flow meter 6, a filter 7, a radiator 8, a flow valve 10, a water pump 11, a water tank 13 and a cold plate connected in series through pipelines. 1; the fan 9 is fixed together with the radiator 8 through the bracket; the electric heater 12 is installed on the side wall of the water tank 13 through screw connection; the heating resistance module 2 and the wall temperature sensor 3 are fixed on the surface of the cold plate 1 through bolts; the control unit 14 It is connected with the heating resistance module 2, the wall temperature sensor 3, the thermometer 4, the pressure gauge 5, the flow meter 6, the fan 9, the water pump 11, and the electric heater 12 through wires to form the control part of the device.

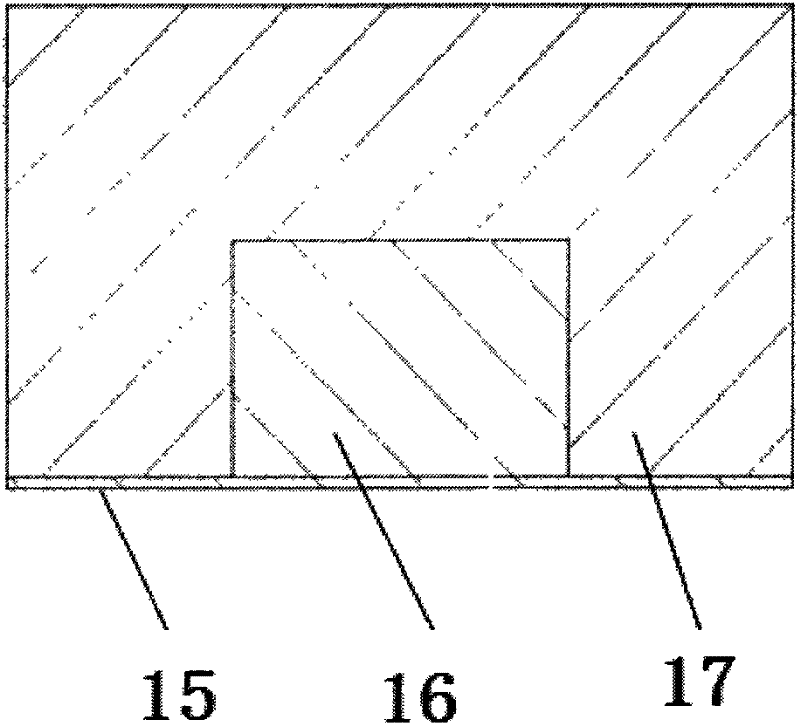

[0036] The heating resistance module 2 includes heat-conducting silicone grease, resistance and tetrapolyethylene fluoride insulation material.

[...

Embodiment 2

[0064] The performance testing device of the cold plate in this embodiment is basically the same as that in Example 1, except that the tetrafluoroethylene insulation material is covered around the resistor except the contact surface between the resistor and the cold plate, and its thickness is 20mm.

[0065] The thickness of thermal grease is 0.5mm.

Embodiment 3

[0067] The performance testing device of the cold plate in this embodiment is basically the same as that in Example 1, except that the tetrapolyethylene fluoride insulation material is covered around the resistor except the contact surface between the resistor and the cold plate, and its thickness is 15mm.

[0068] The thickness of thermal grease is 0.4mm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com