Fuel gas electronic injection valve used for gas fuel engine

A gas fuel and engine technology, which is applied to combustion engines, internal combustion piston engines, engine components, etc., can solve the problems of easy cold welding effect on the sealing surface, accelerate the wear of the sealing surface, limit the service life of the EFI valve, etc., and achieve good self-efficacy. Sealing effect, weight reduction, effect of suppressing generation of eddy current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

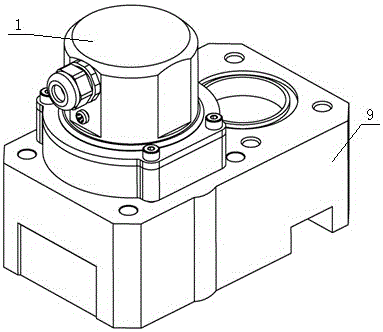

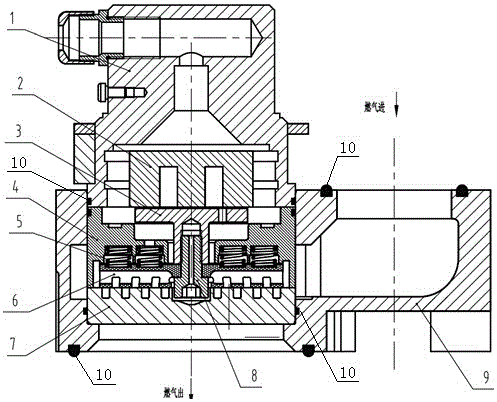

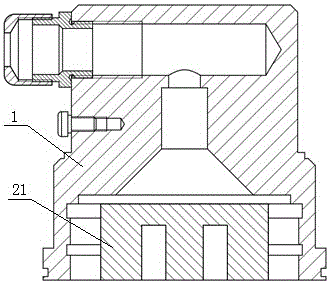

[0022] In order to further explain the technical solution of the present invention, the present invention will be described in detail below in conjunction with the accompanying drawings.

[0023] see Figure 1 to Figure 7 As shown, the gas electric injection valve for a gas fuel engine includes a housing 9, a solenoid valve part and a valve core part, the solenoid valve part and the valve core part are coaxially installed on the housing, and the solenoid valve part is located above the valve core part. The casing 9 is made of hard aluminum alloy, and high-performance fluororubber is installed between the magnetic valve part and the casing 9, between the valve core part and the casing 9, and around the gas inlet and gas outlet of the casing 9. Material O-ring seal 10. The solenoid valve components include a solenoid valve casing 1 and an iron core coil 2. The iron core 21 of the iron core coil 2 is E-shaped, and is formed by stacking FeSiCr sheet materials.

[0024] The valve...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com