Actuation assembly for variable geometry turbochargers

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

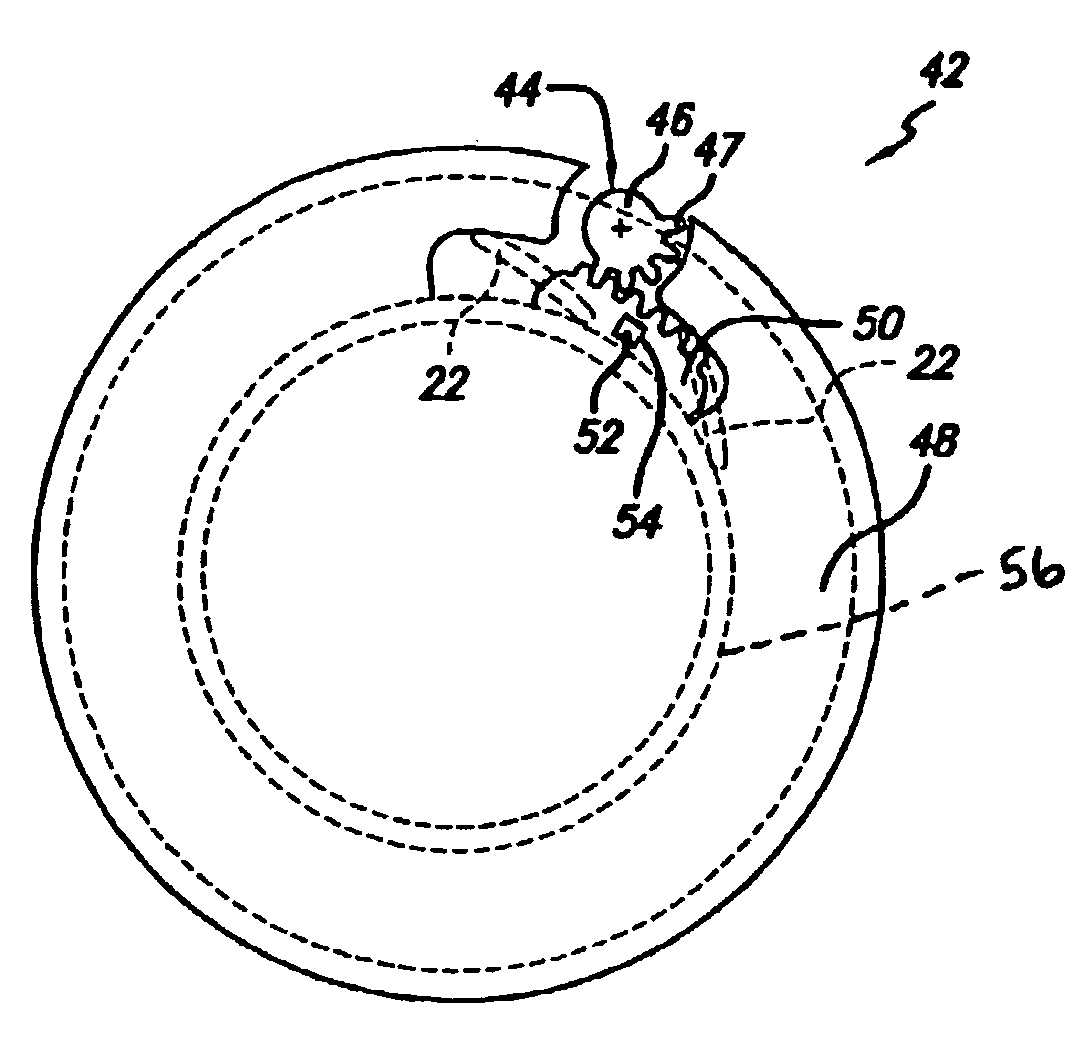

Image

Examples

Embodiment Construction

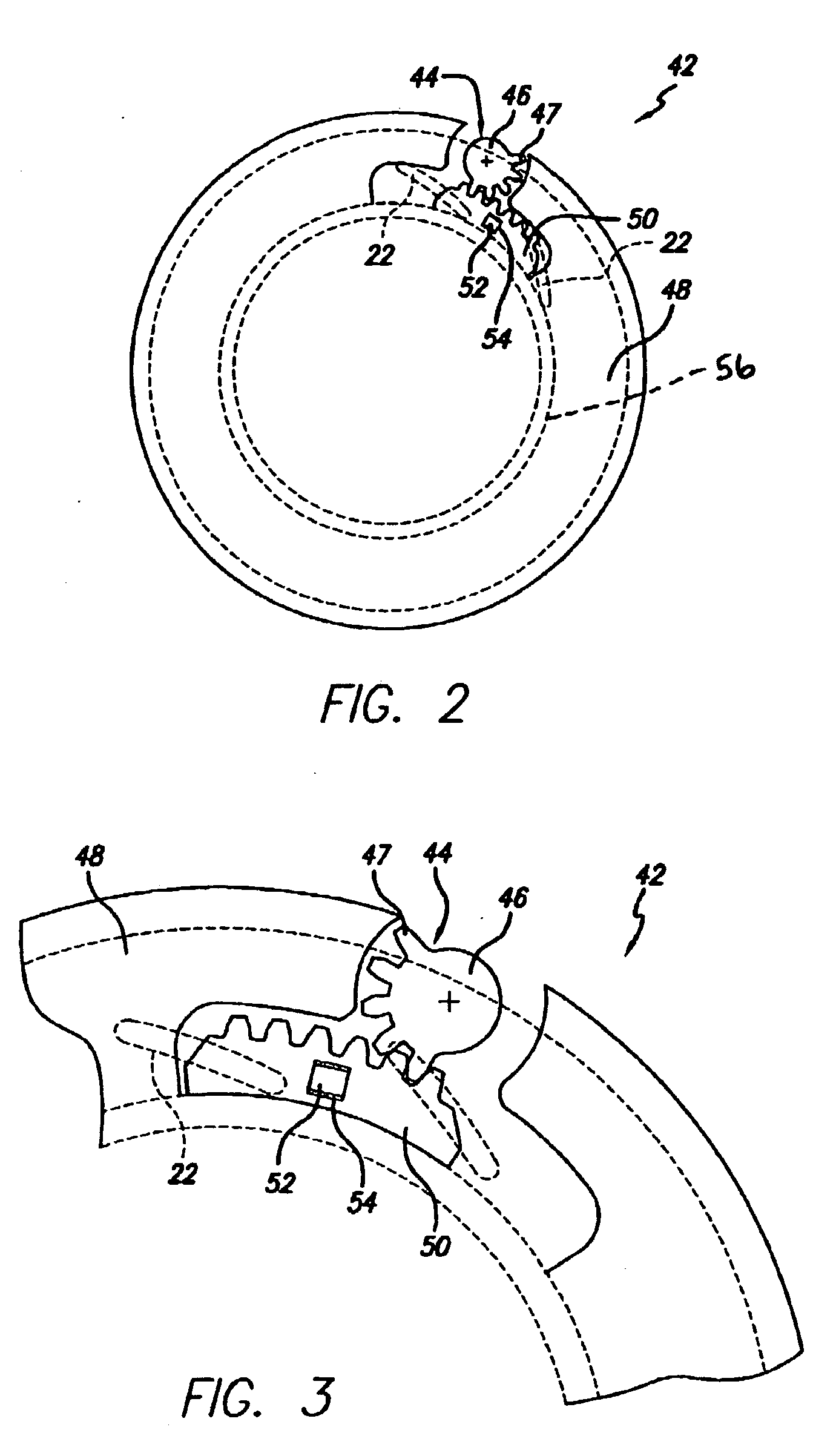

[0018] The invention, constructed in accordance with the principles of this invention, comprises an improved actuation assembly for causing rotational movement of a unison ring used in a turbocharger, including but not limited to a variable geometry turbocharger (VGT). For convenience, an exemplary embodiment using a VGT will be described throughout this specification. However, it will be readily understood by those skilled in the relevant technical field that the improved crank arm assembly of the present invention could be used in a variety of turbocharger configurations.

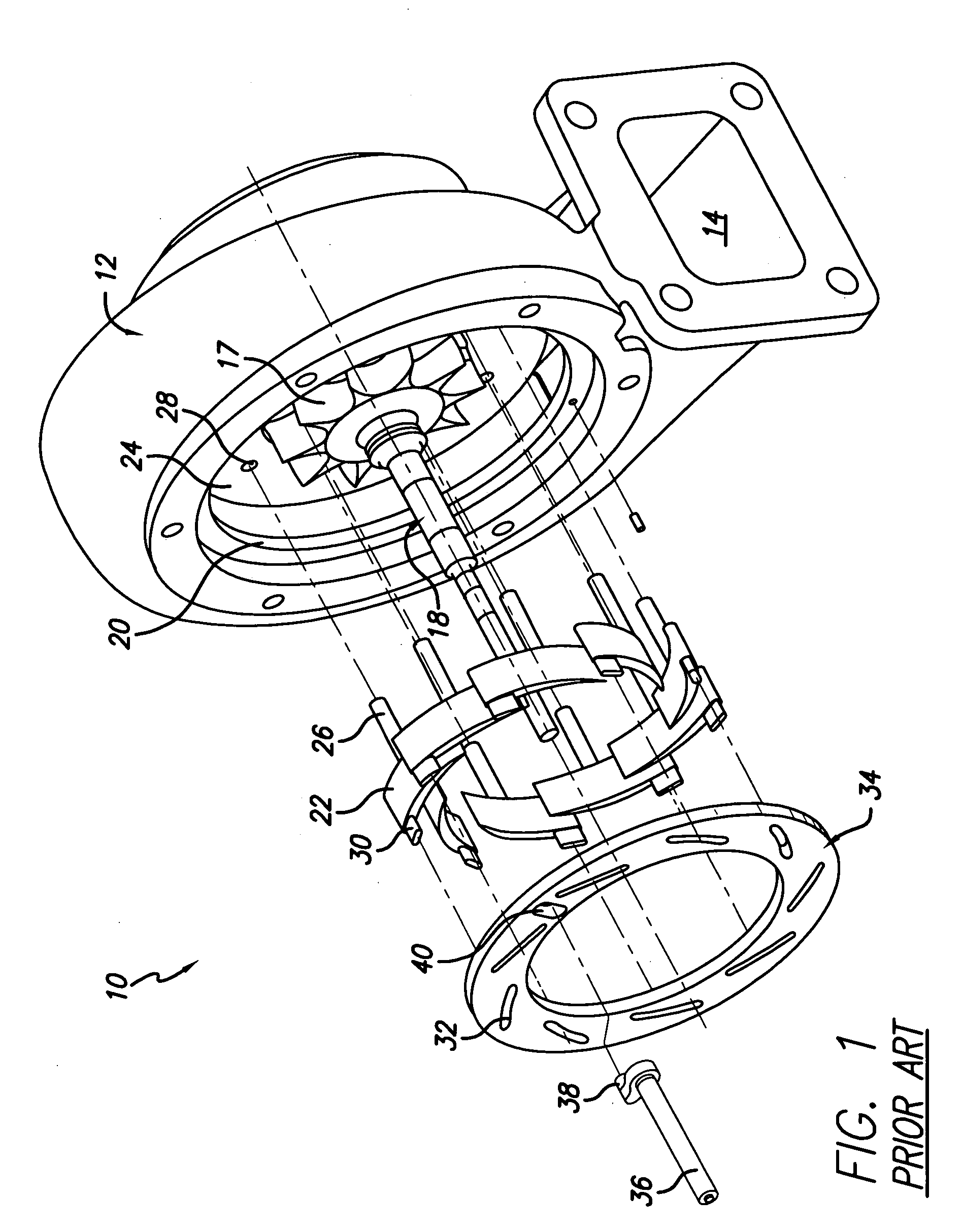

[0019]FIG. 1 illustrates a known VGT 10 that includes a turbine housing 12. An exhaust gas-driven turbine 17 is rotatably disposed within the housing and is mounted onto one end of a shaft 18 that is common to a radial air compressor (not shown) mounted onto an opposite end of the shaft 18 and housed in a compressor housing. The turbine housing 12 is configured having an exhaust gas inlet 14 that is configured to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com