Patents

Literature

65 results about "Crank Arm Assembly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

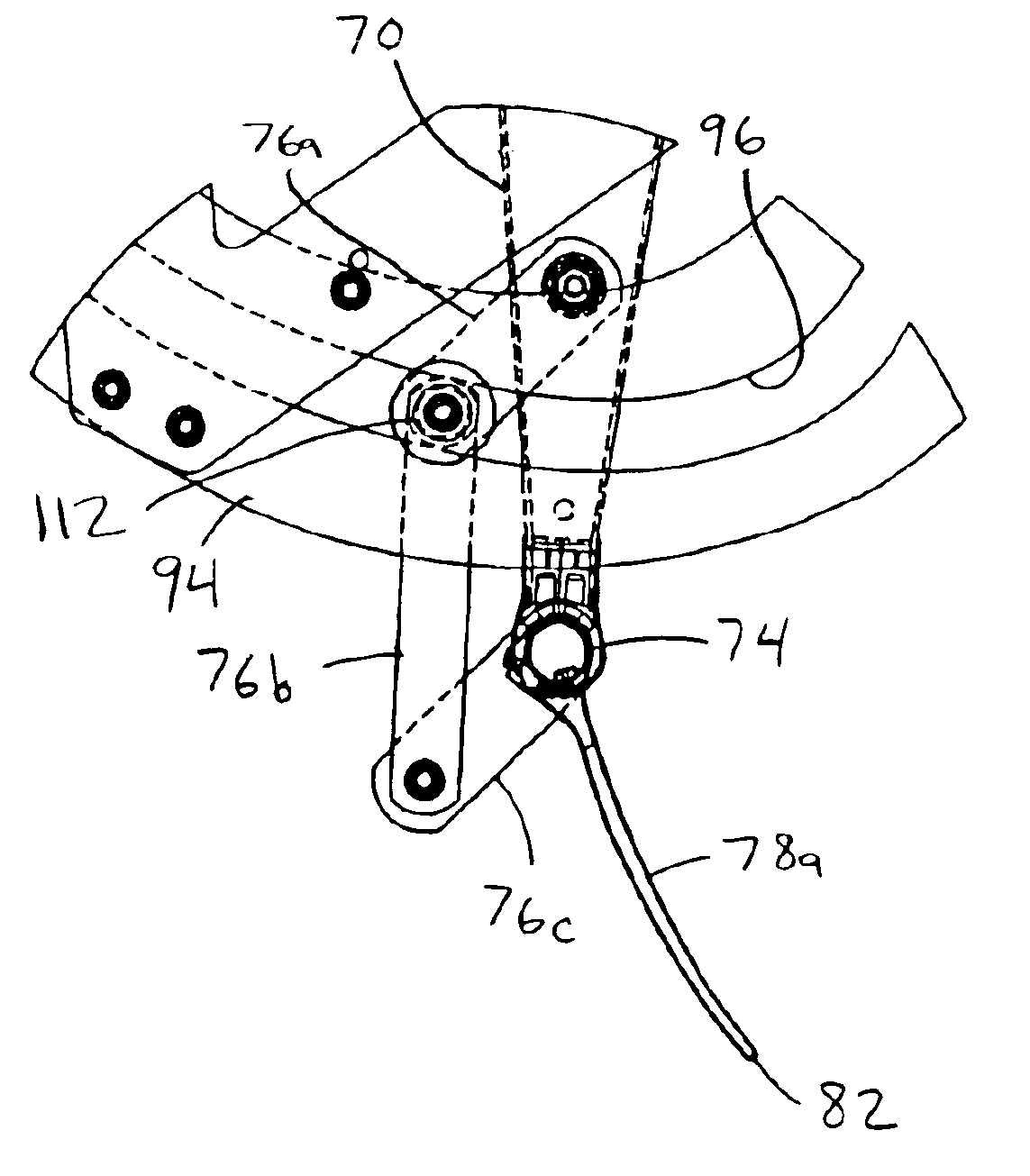

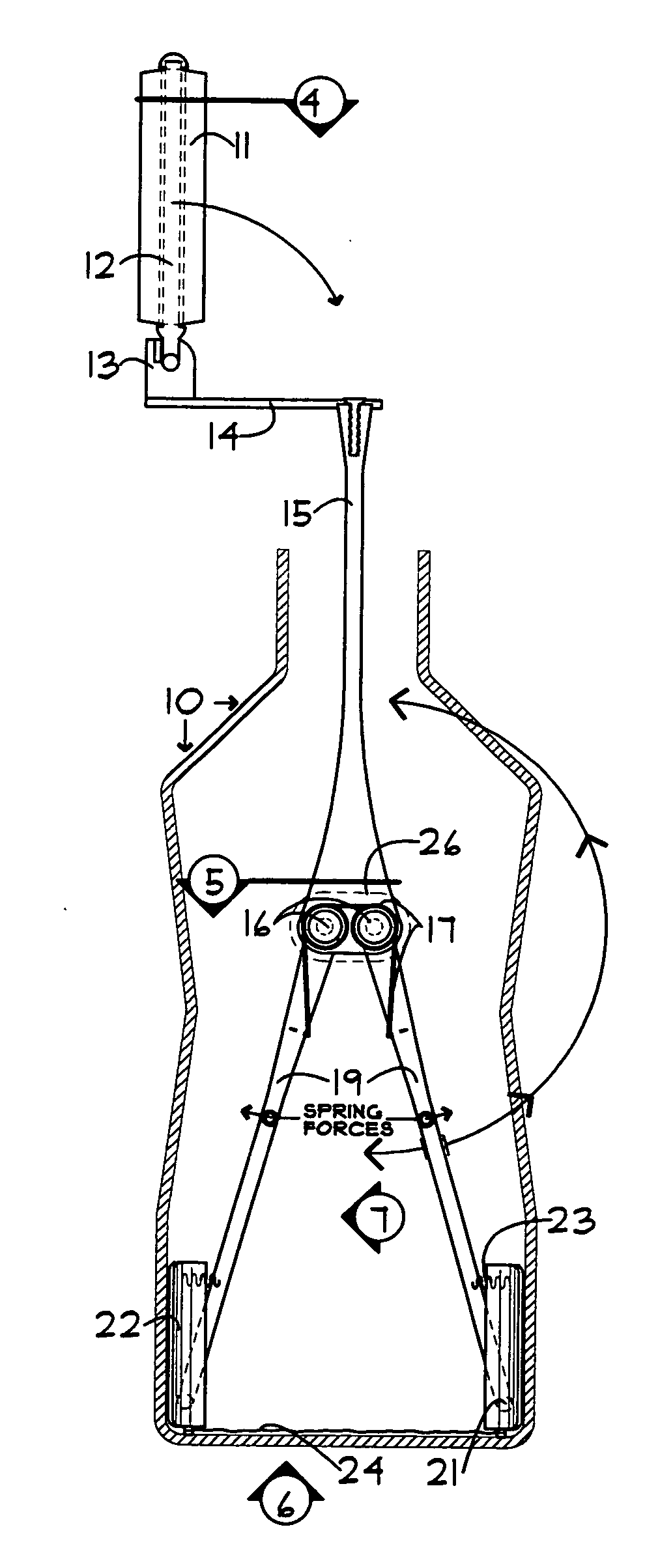

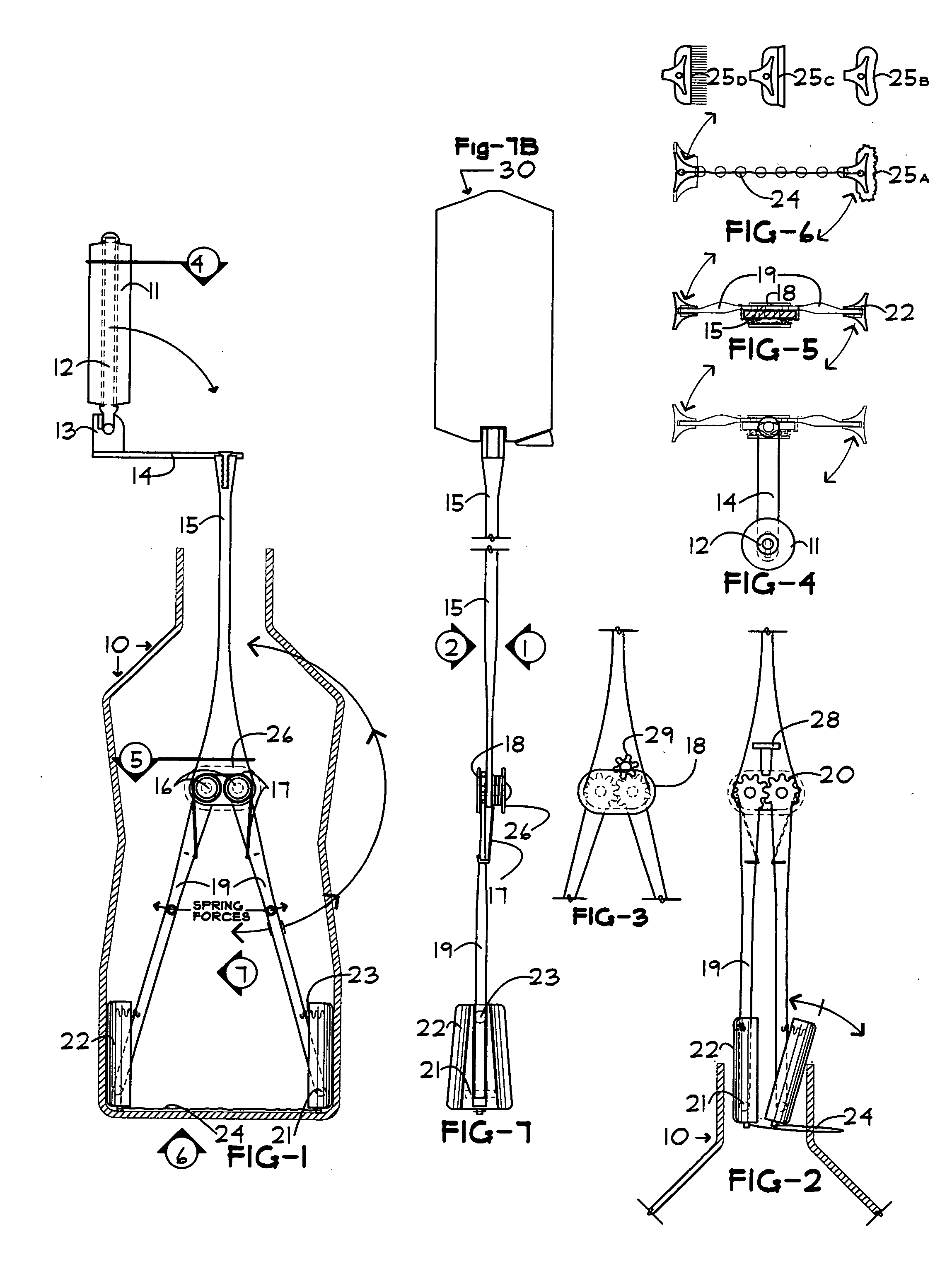

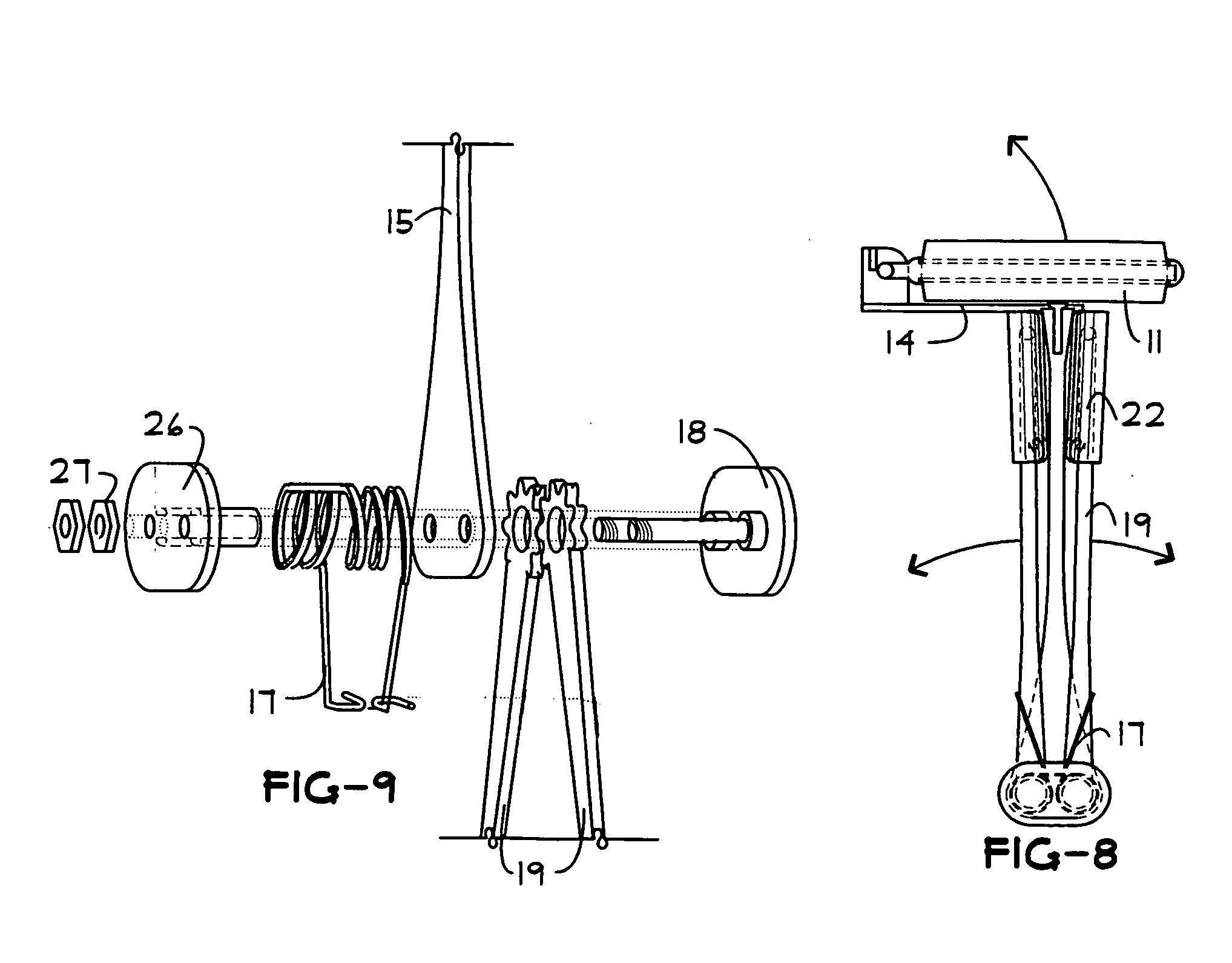

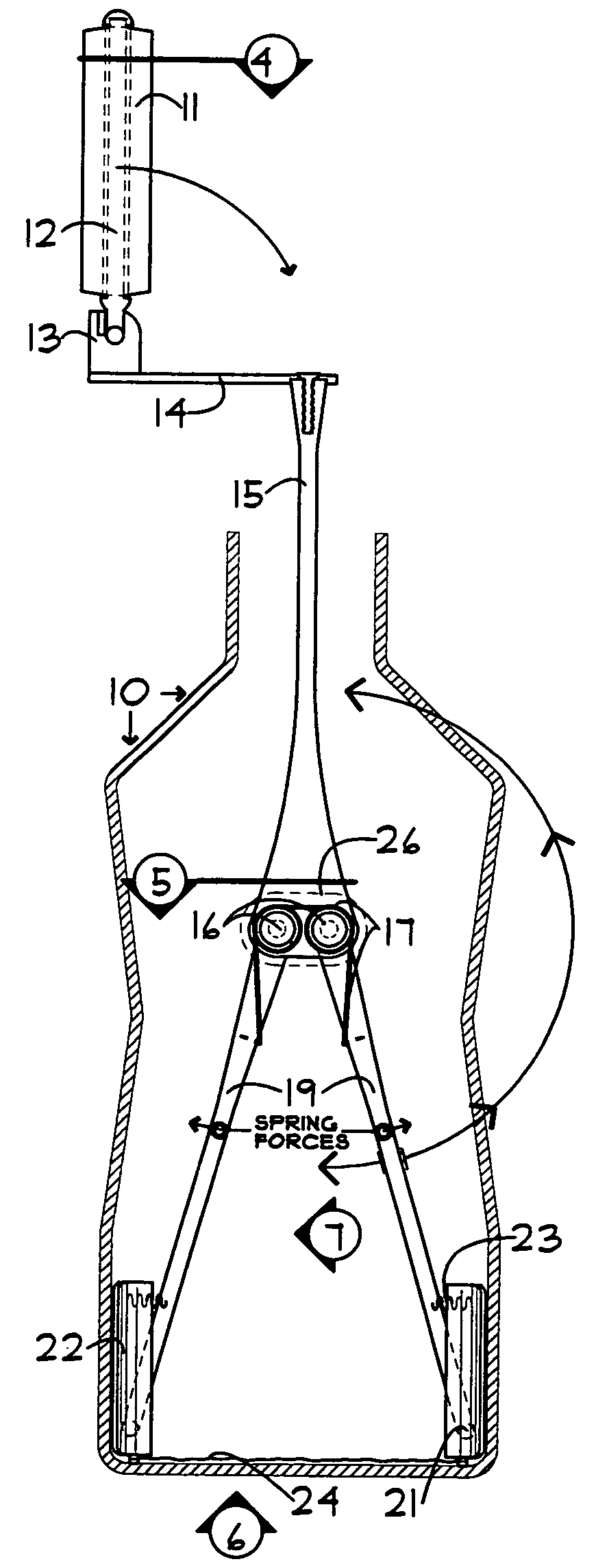

Harvester pickup reel controlling the tine tip path

A pickup reel for a harvesting machine comprising a reel support and a first shaft rotatably supported by the reel support and extending along an axis transverse to the frame. A cam is supported by the reel support and defines a generally endless cam path extending about the first shaft. An arm extends radially from the first shaft and is rotatable with the first shaft. A second shaft is connected to the arm and supports a first tine and a second tine located on opposite axial sides of the cam. A cam follower is engageable with the cam and movable along the cam path. A crank arm assembly is connected between the cam follower and the second shaft. The rotation of the first shaft and movement of the cam follower along the cam path cooperate to cause the tips to move along the tip path.

Owner:HCC

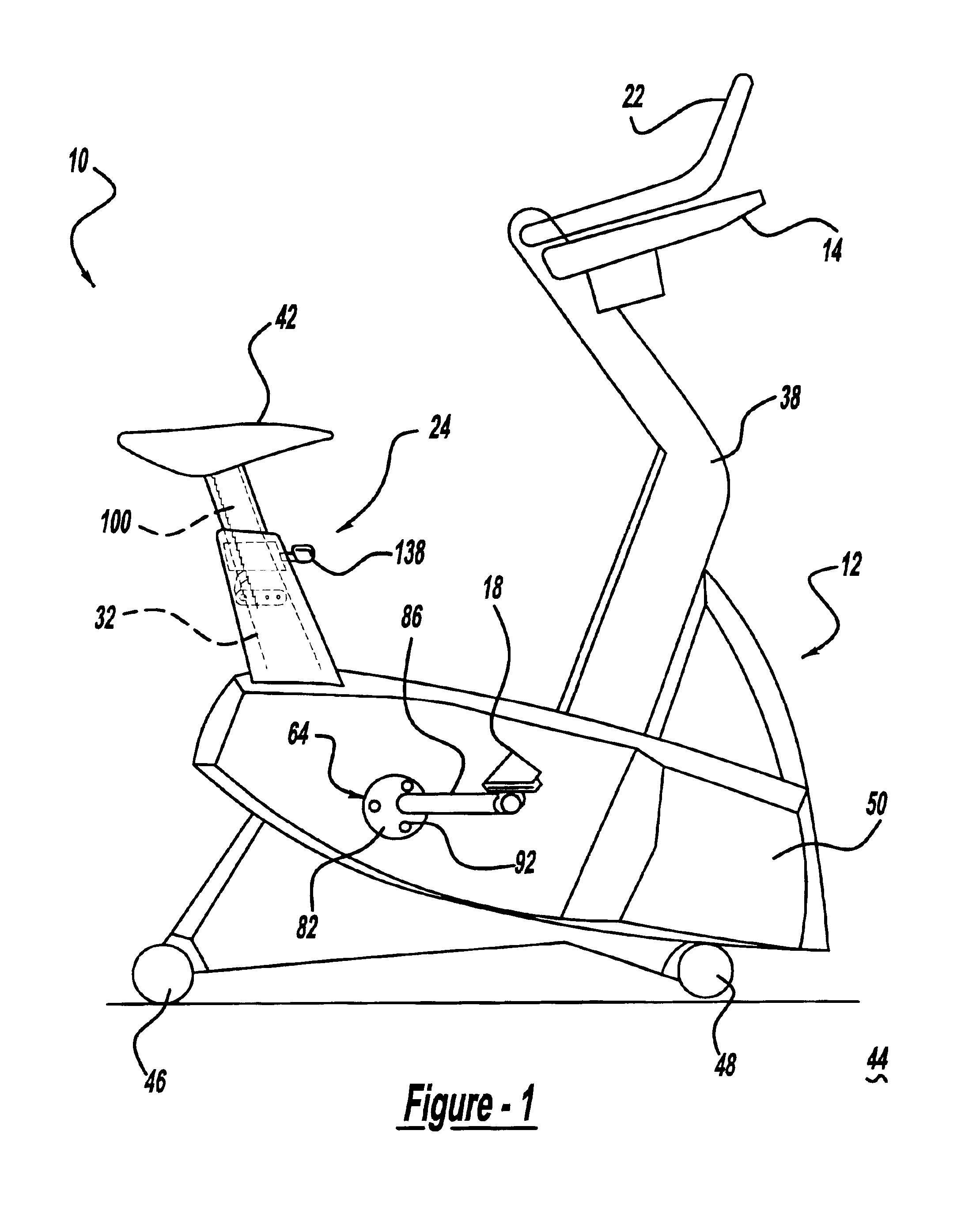

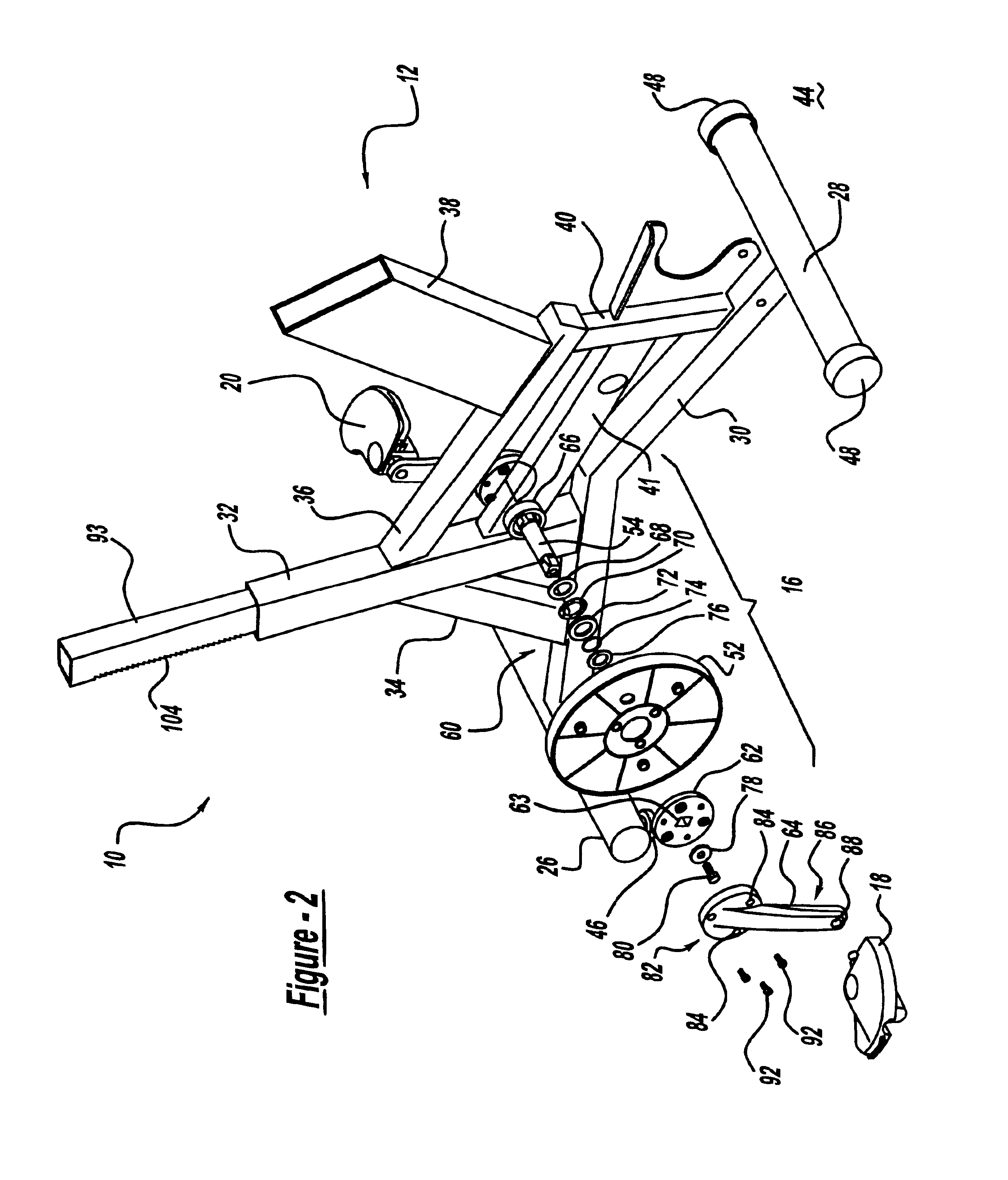

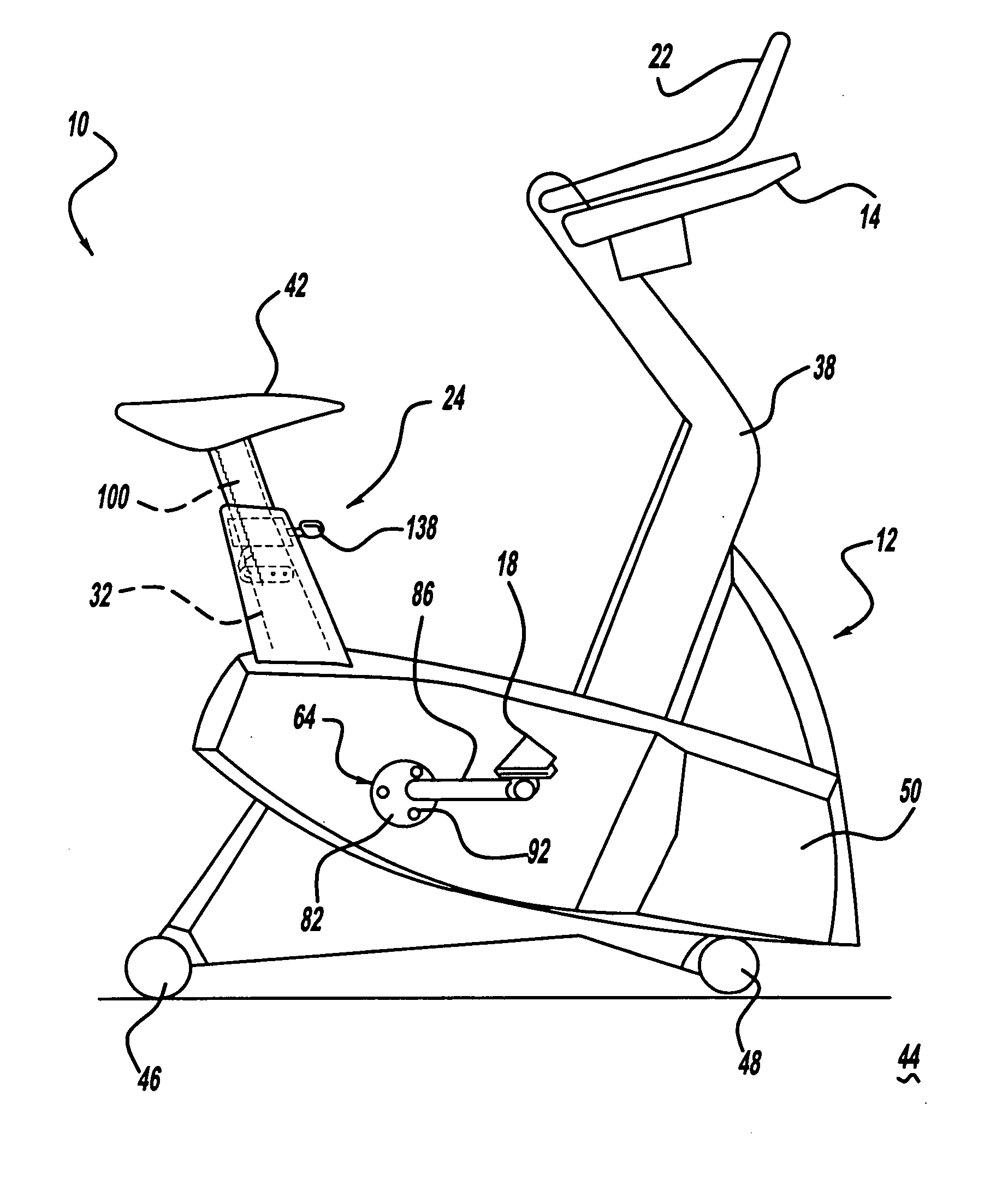

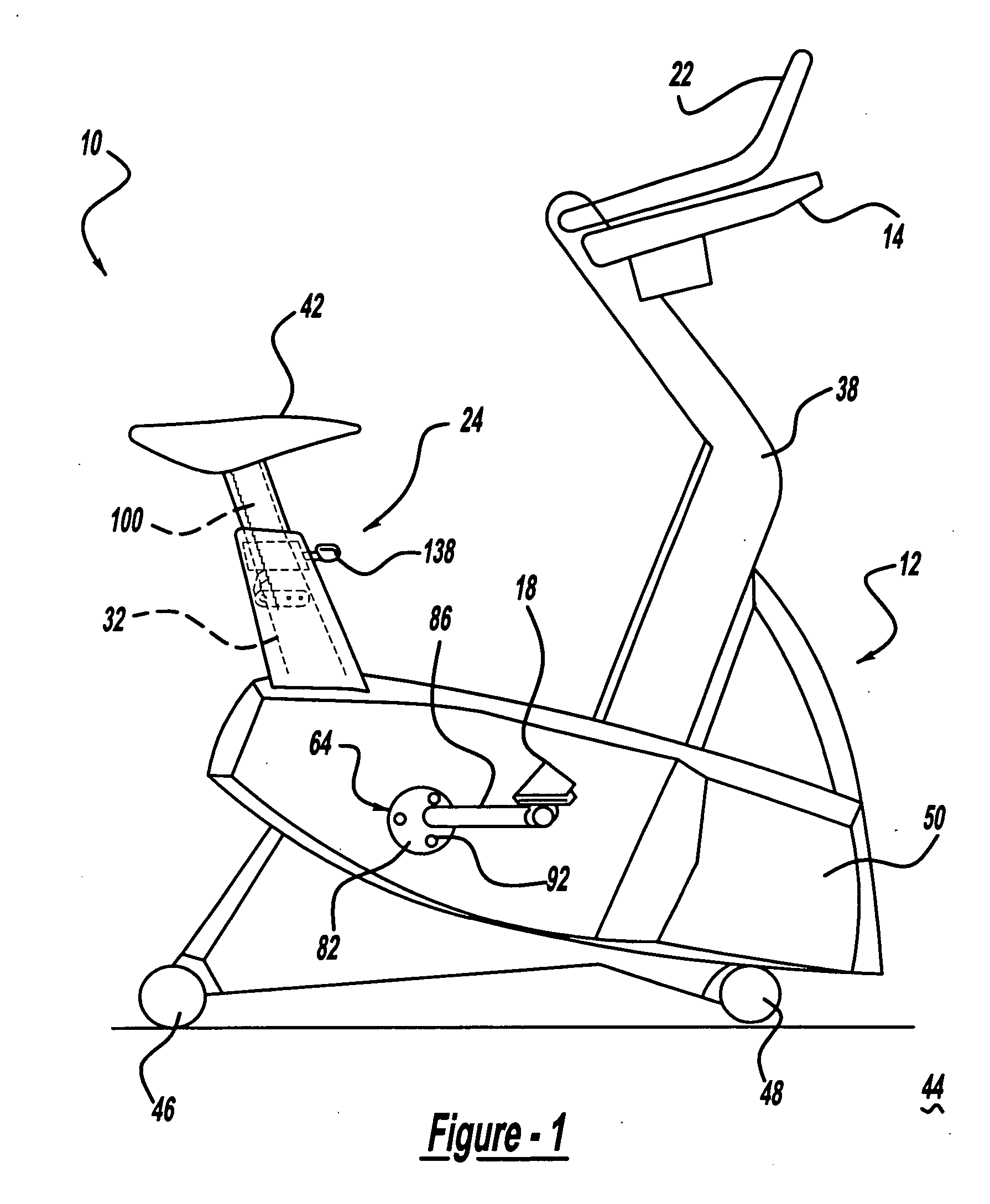

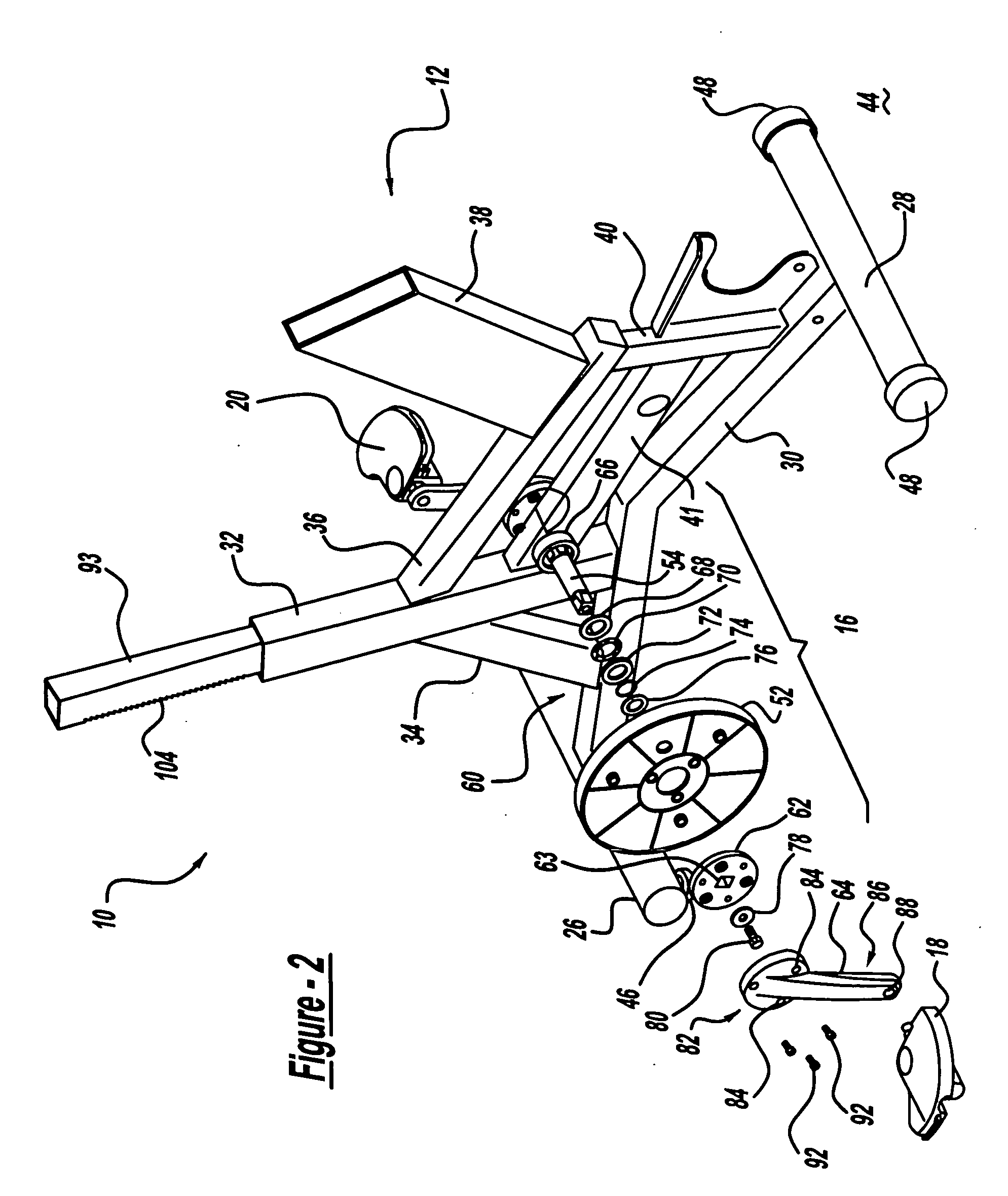

Stationary bike

InactiveUS6913560B2Accurately and dynamically simulatesSimple designStands/trestlesKitchen equipmentEngineeringCrank Arm Assembly

A stationary exercise bicycle is provided having a frame, a resistance member, a drive assembly, a right pedal, a left pedal, a seat and an adjustable seat mechanism utilizing a rack. Assembly and disassembly of a three piece crank arm assembly is accomplished without requiring the assembling and disassembling of the entire drive assembly. The stationary exercise bicycle also provides a variety of users with an optimum seat position and with a convenient latch mechanism to adjust the position of the seat.

Owner:LIFE FITNESS LLC

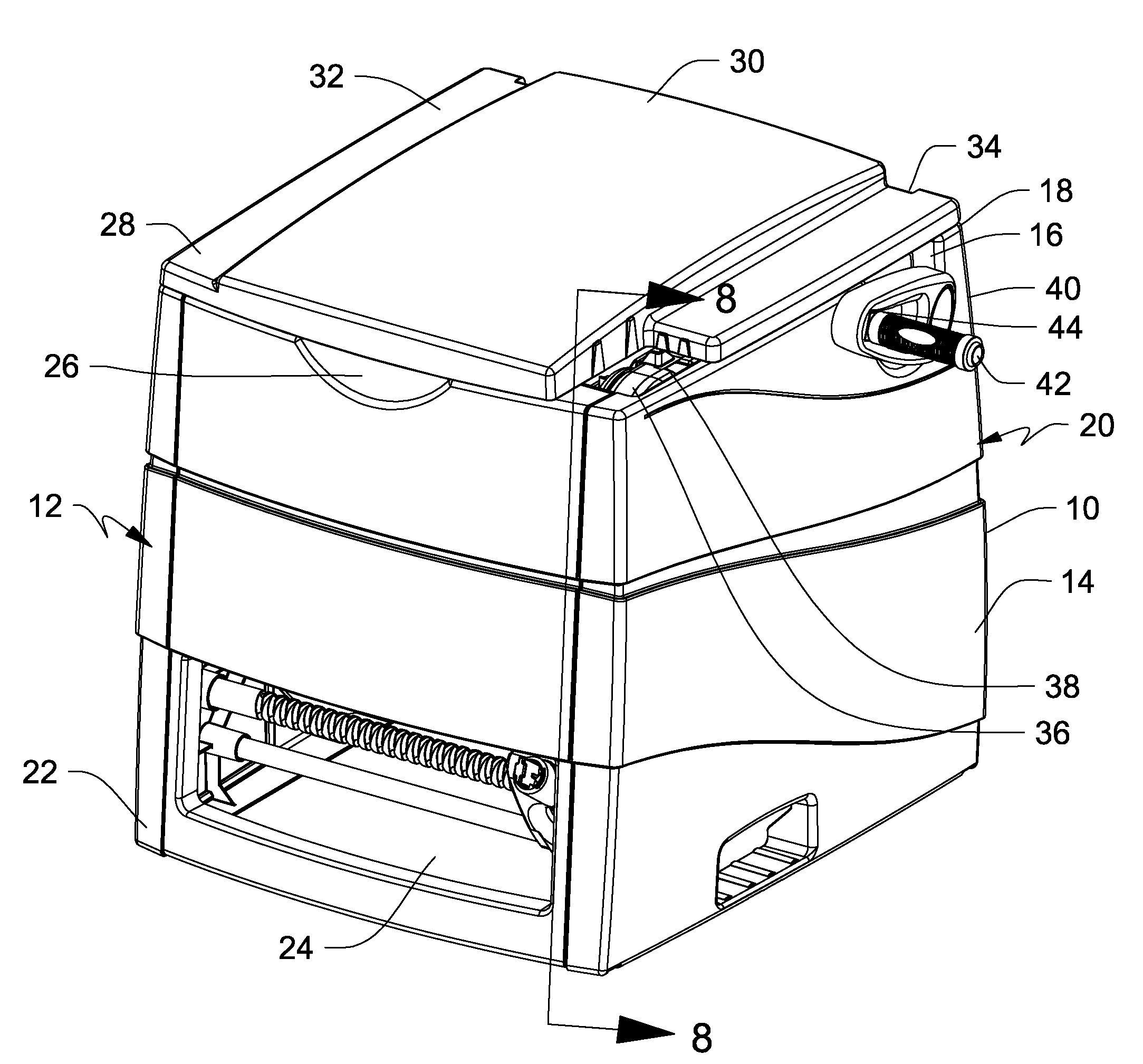

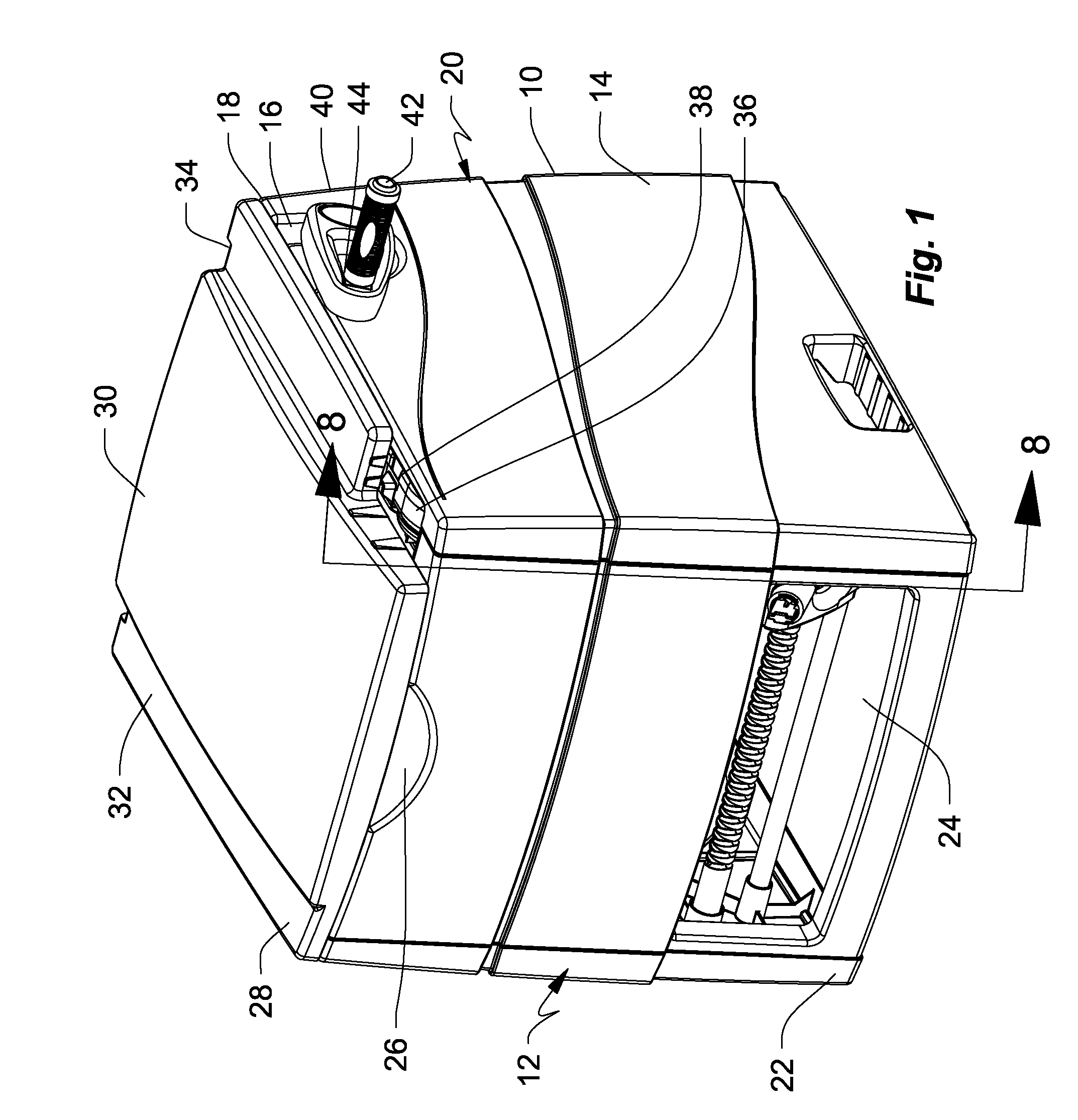

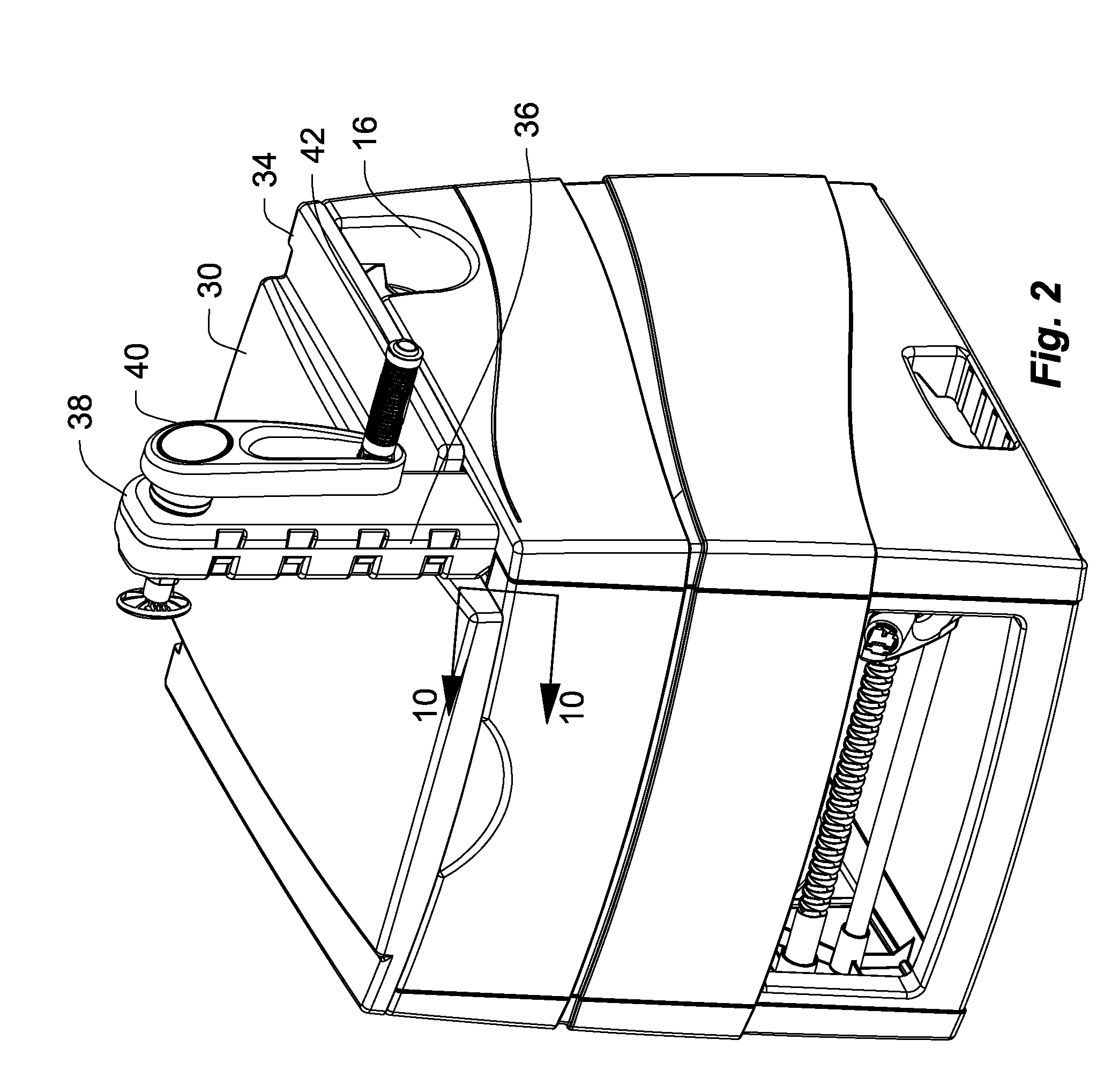

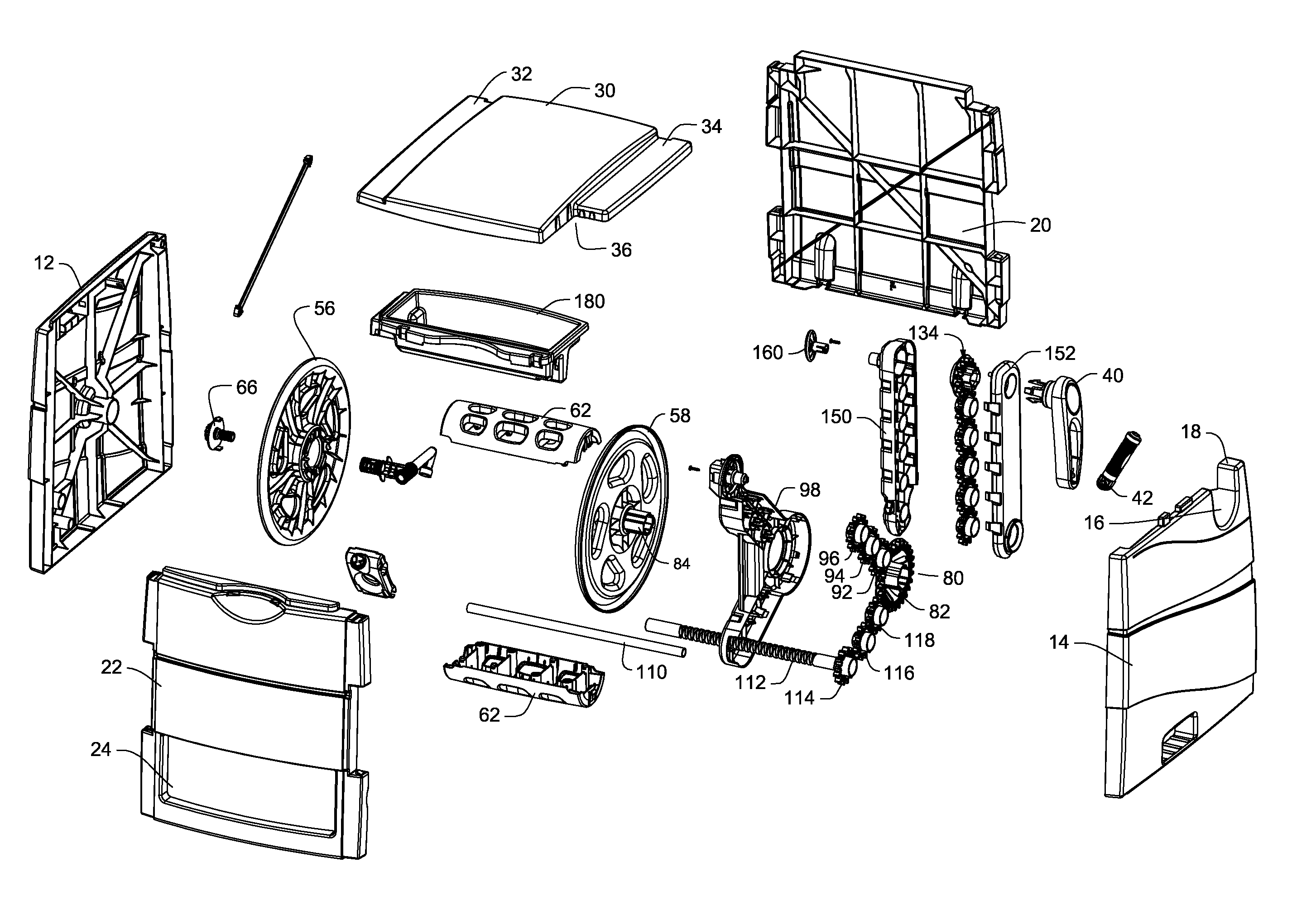

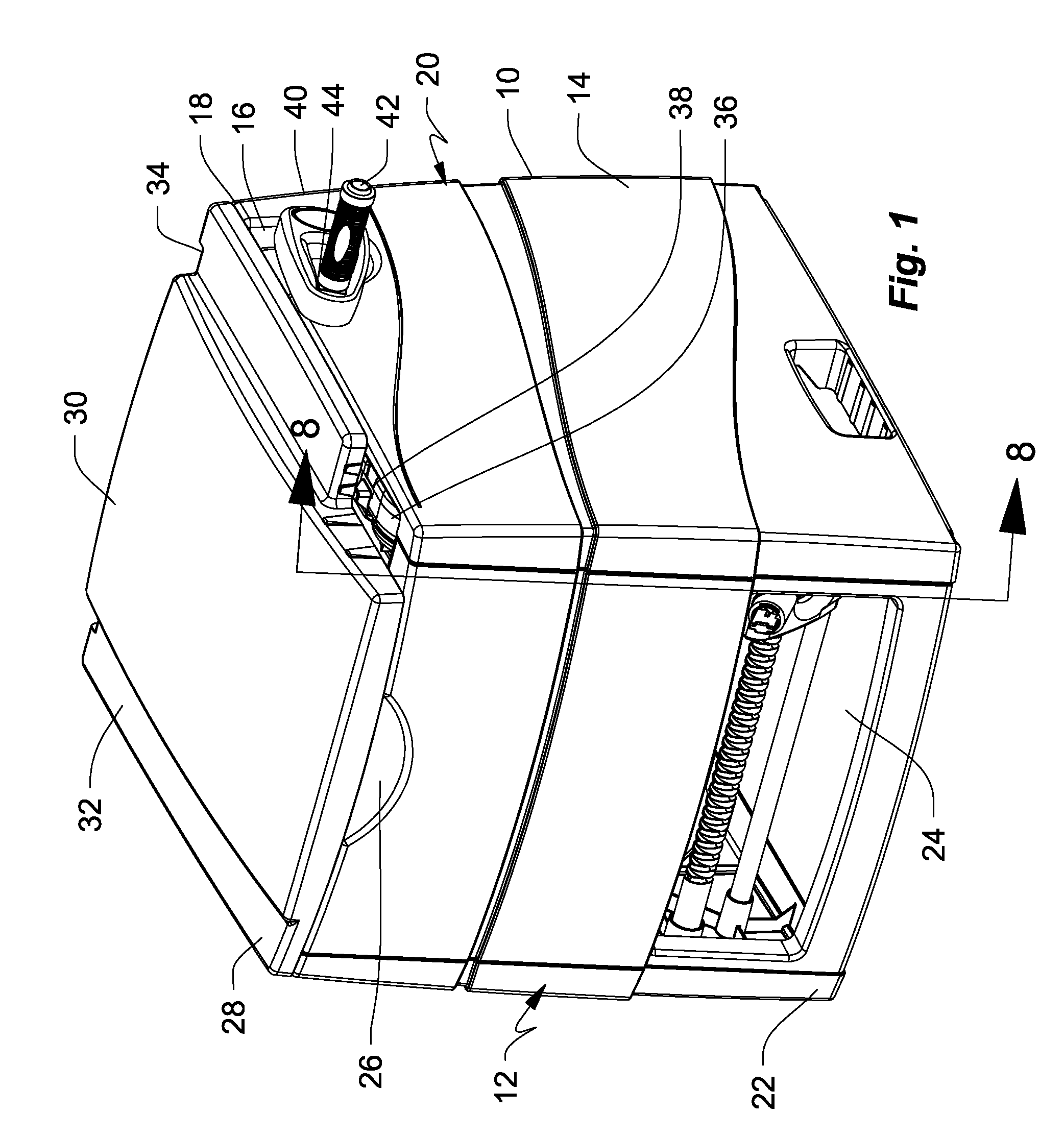

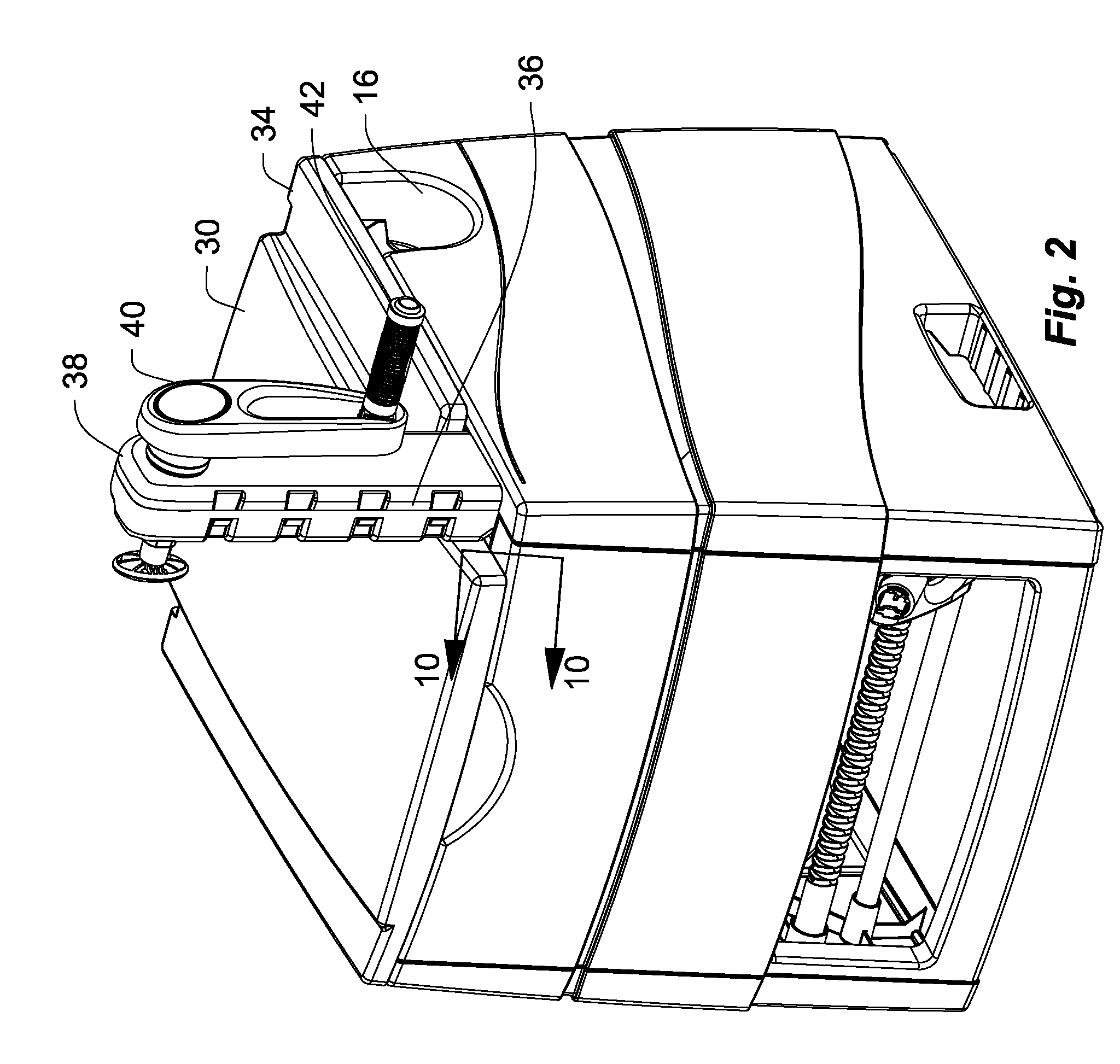

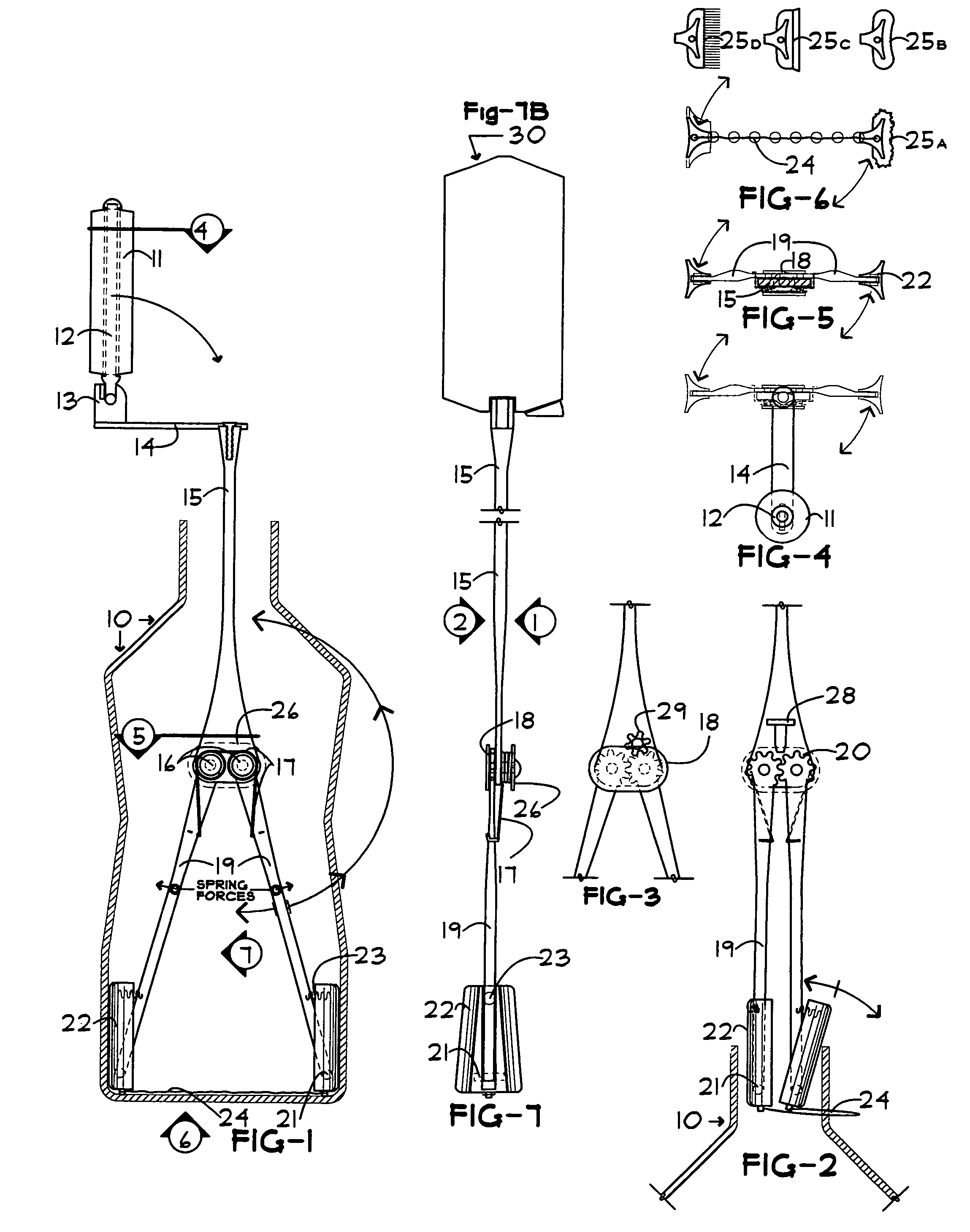

Hose Reel Cart With Multi-Position Crank Handle

ActiveUS20100155520A1Reduce the amount of bendingEliminate needFilament handlingFire rescueGear wheelEngineering

The present invention relates to hose reel carts for handling and storage of flexible hoses, such as garden or air hoses. The hose reel cart is primarily constructed of plastic components having a centrally rotatable spool for winding of the flexible hose, a frame for supporting the spool and a multi-position crank arm assembly allowing the consumer to place the crank handle in a lowered position or a raised position. The crank remotely drives the spool, for winding the hose, through a series of gears located within the crank arm assembly. The device may further include a reciprocating guide assembly that operates during rotation of the spool to rewind the hose into a compact configuration.

Owner:SUNCAST TECH

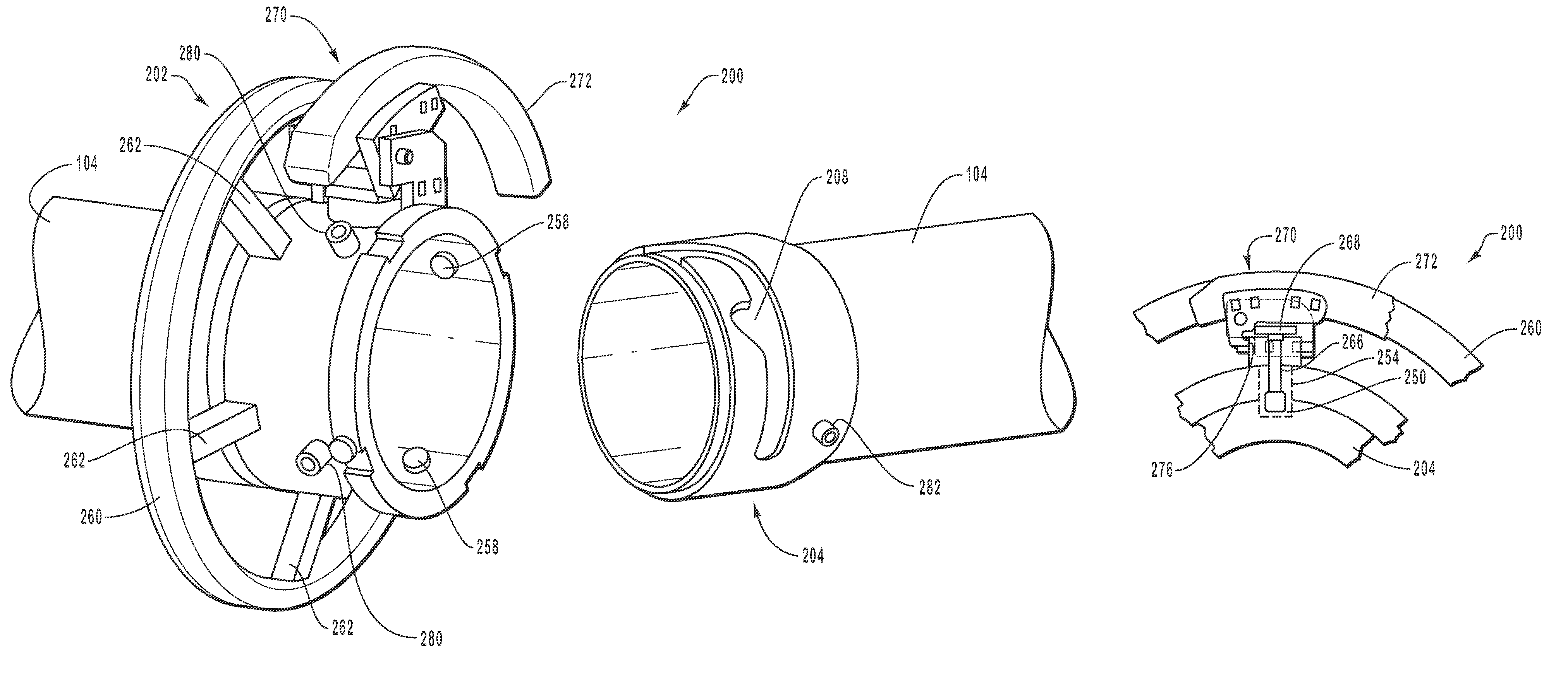

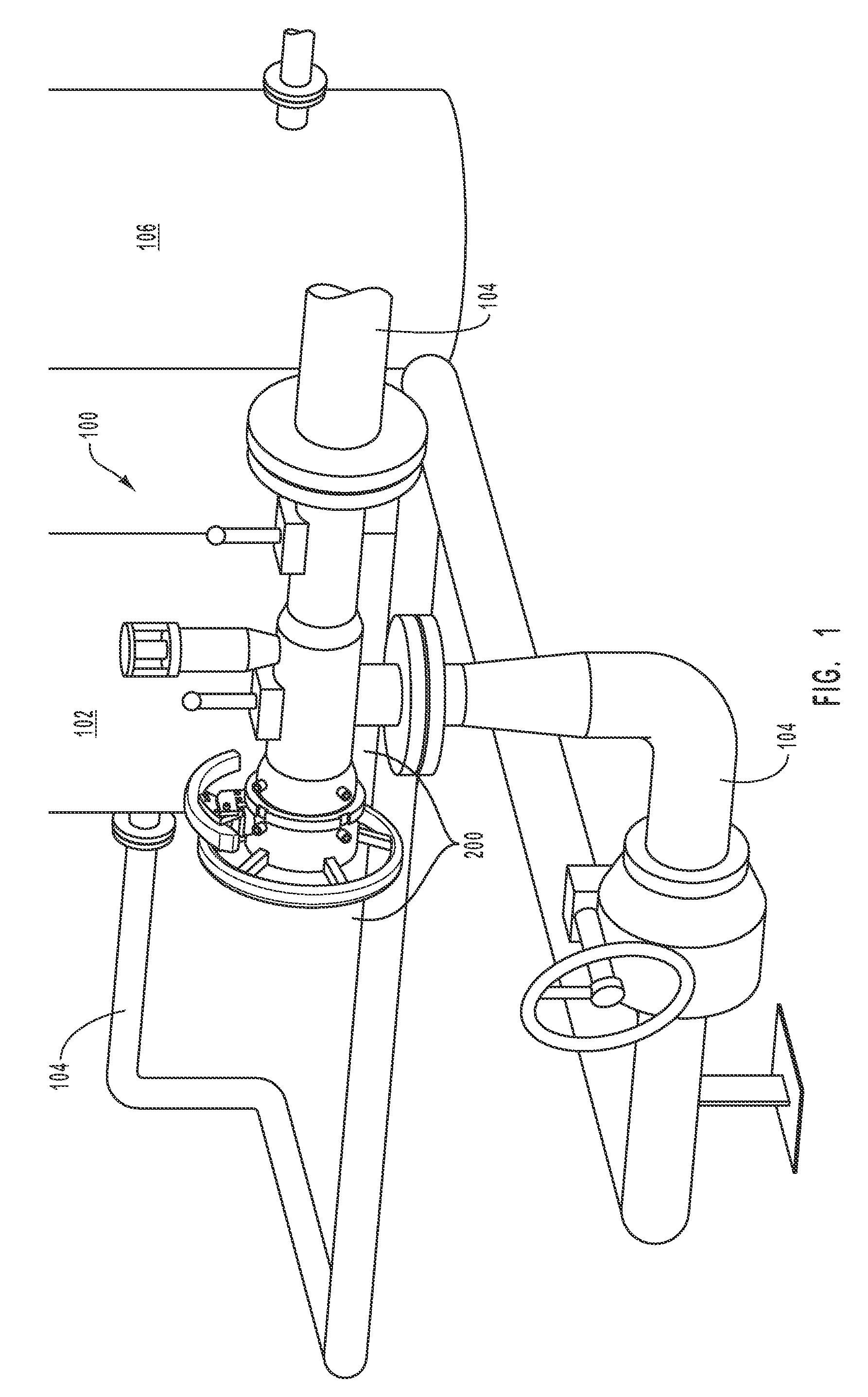

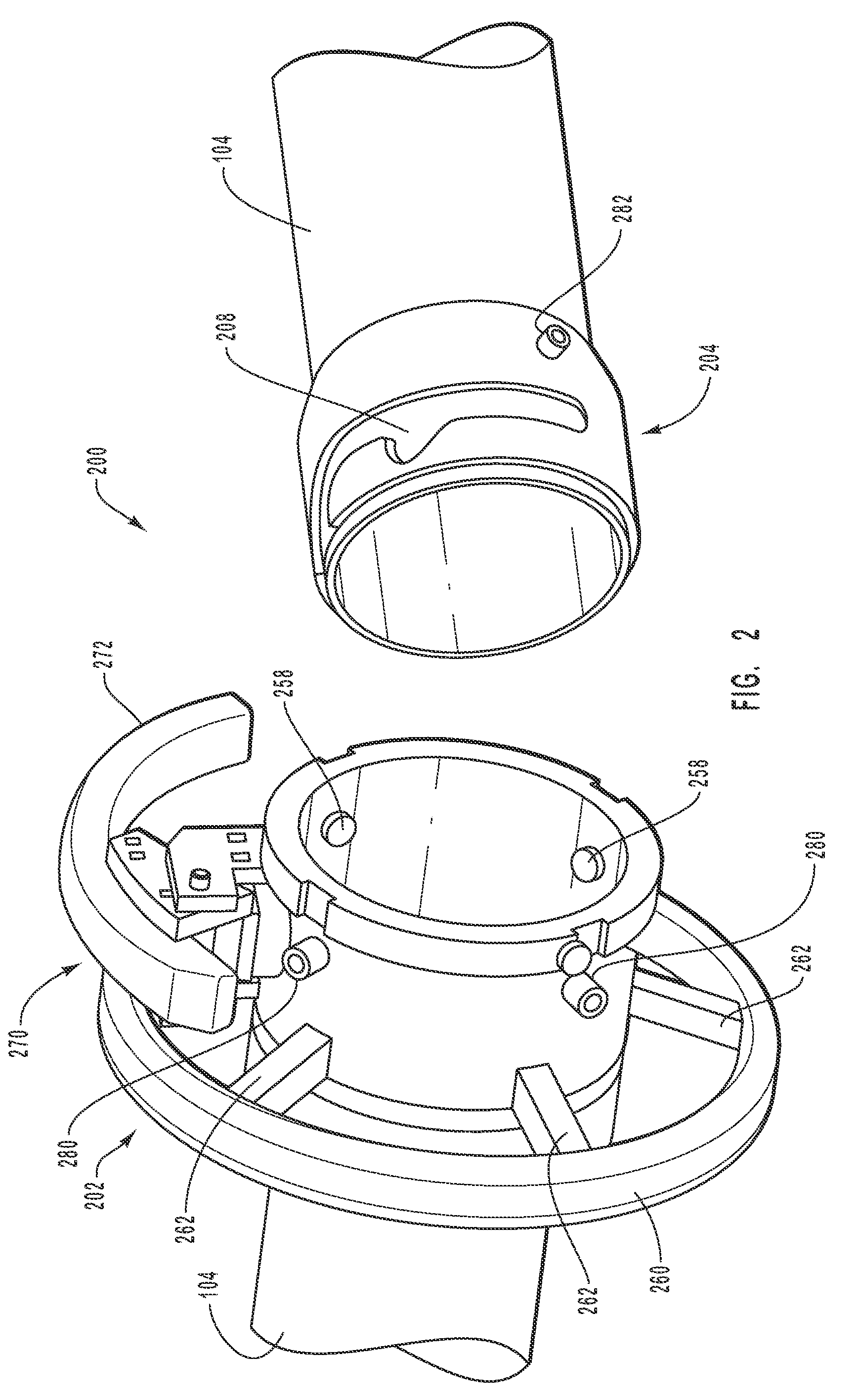

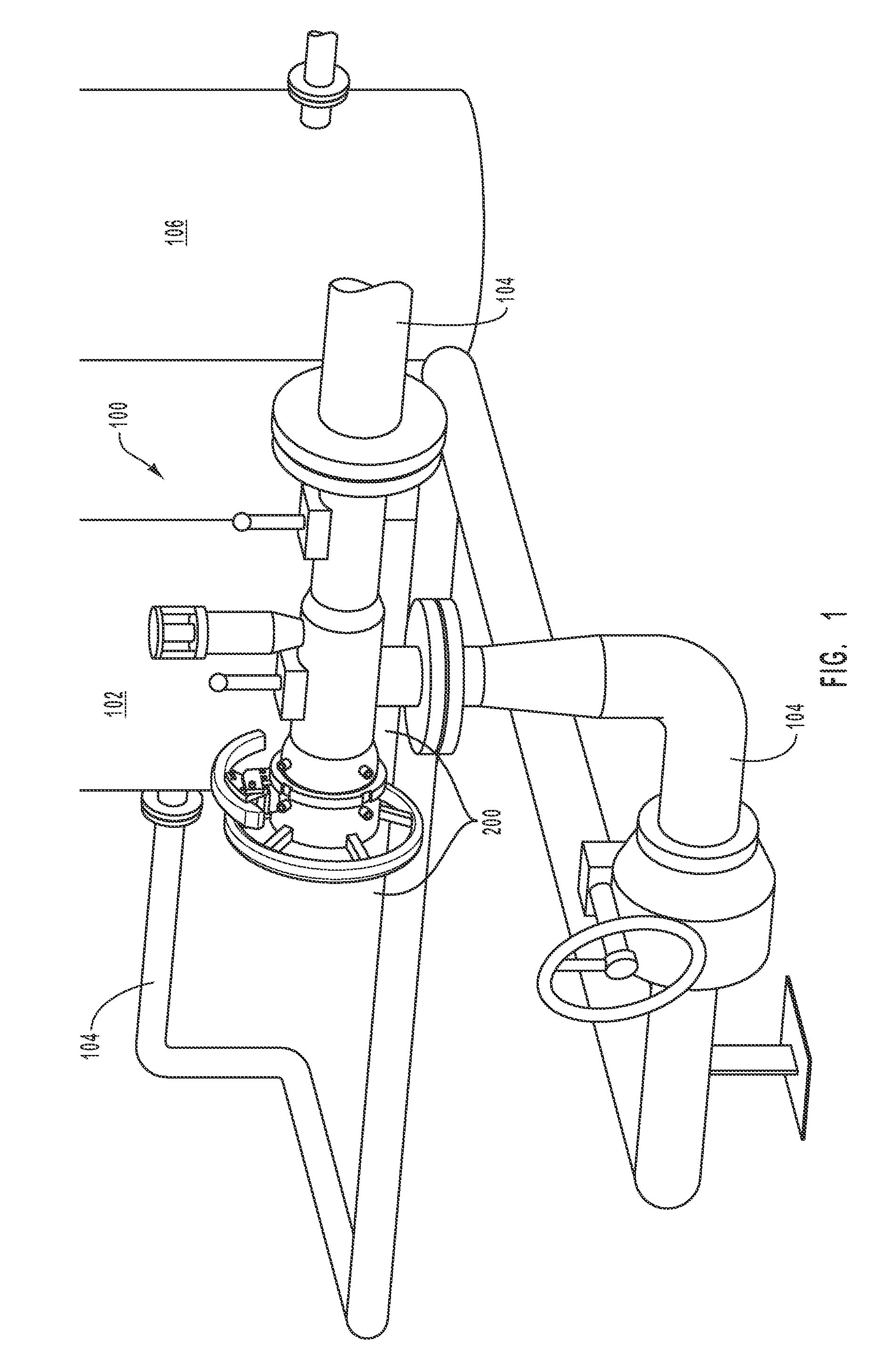

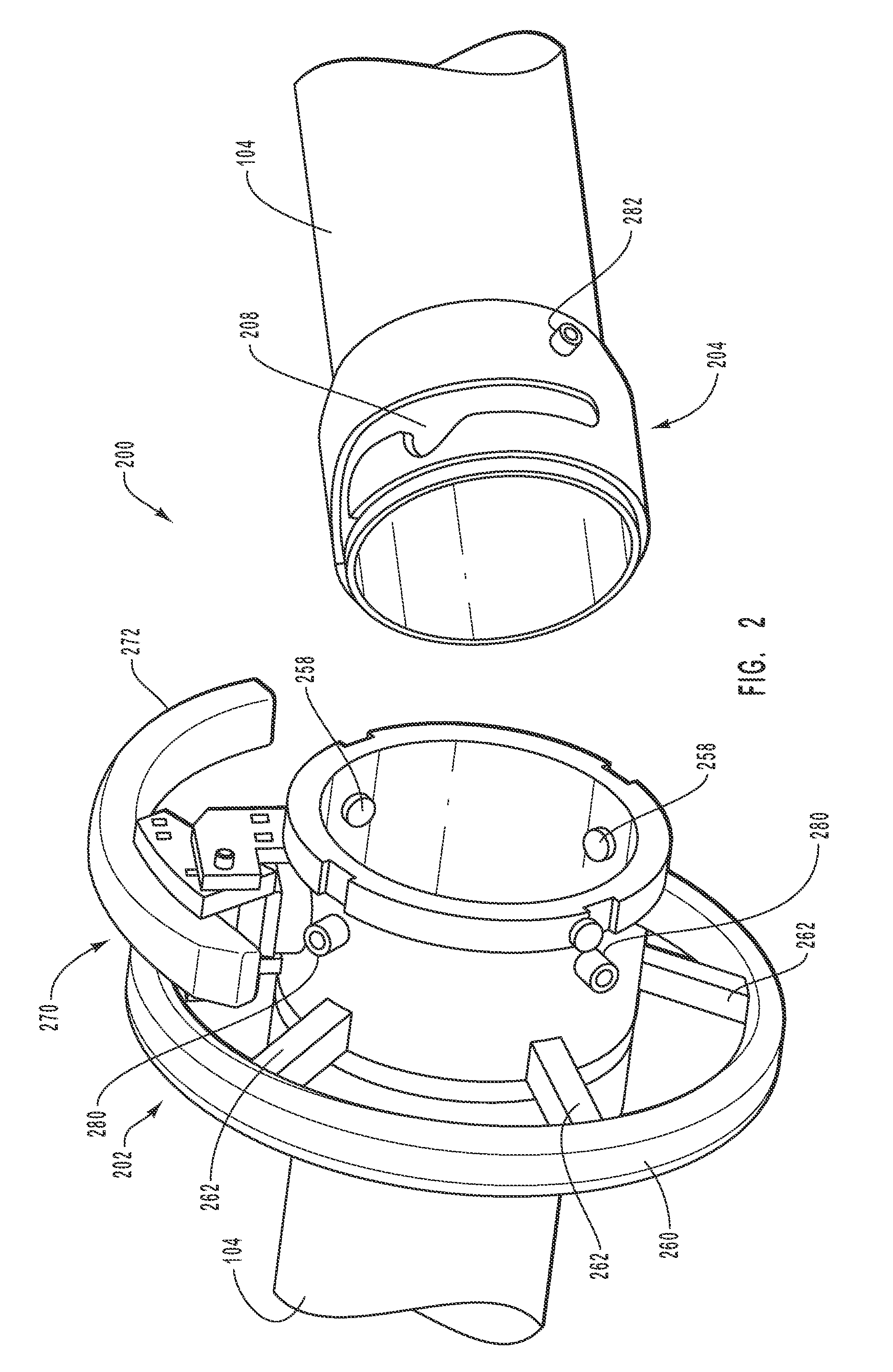

Fluid system coupling with pivoting handle actuating member

ActiveUS7988200B2Easy to engagePreventing intentional and accidental disengagementSleeve/socket jointsEngine sealsLine tubingCrank Arm Assembly

A fluid system component includes first and second elements configured to be removably engaged with each other to define a fluid passageway. The first element defines at least one groove. Correspondingly, the second element includes at least one engagement member configured to be received in a corresponding groove. The presence of a line pressure in the passageway substantially forecloses disengagement of the first and second elements until the fluid pressure in the fluid passageway has decreased to a predetermined magnitude. A handling and locking mechanism for selectively securing the second element relative to the first element is included. The locking mechanism includes a pin controlled by a crank arm assembly adjacent a collar handle. The crank arm assembly includes a crank arm handle that rotates to withdrawn the pin from the second element and which facilitates rotation of the first element relative to the second element.

Owner:HILTAP FITTINGS

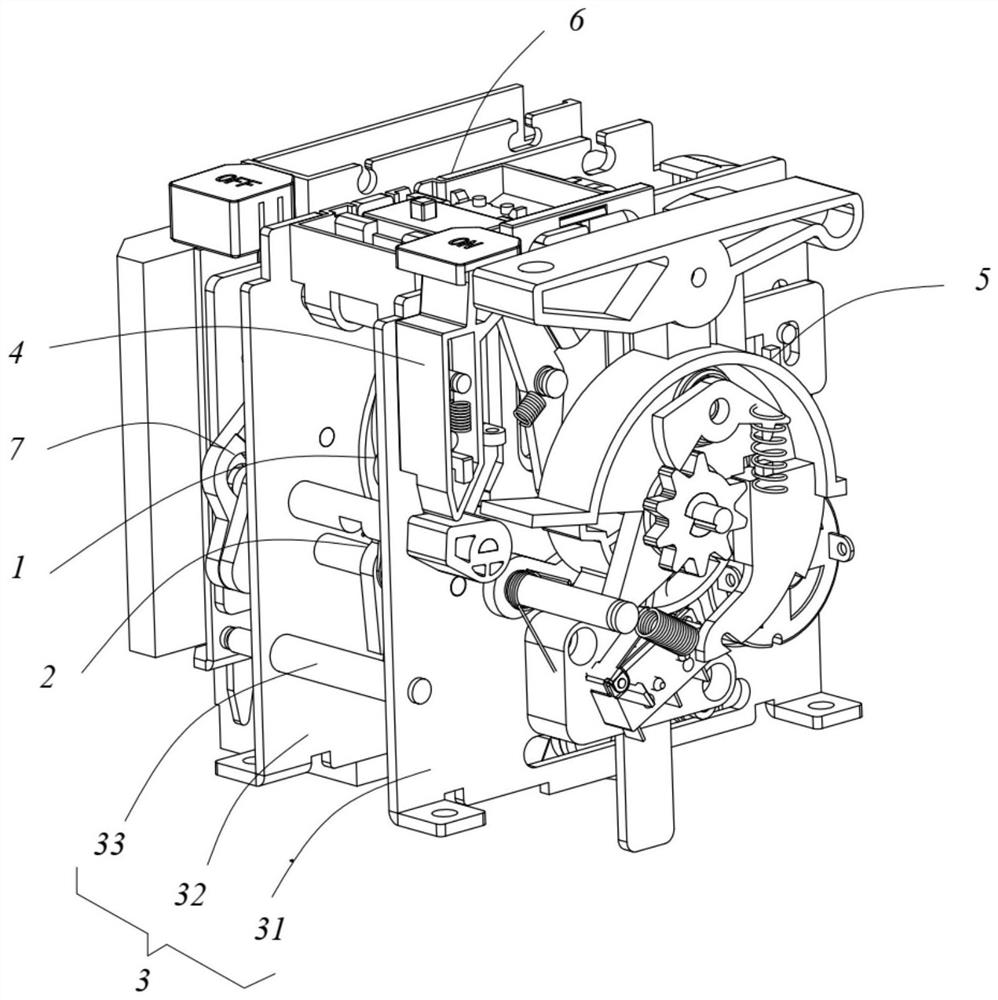

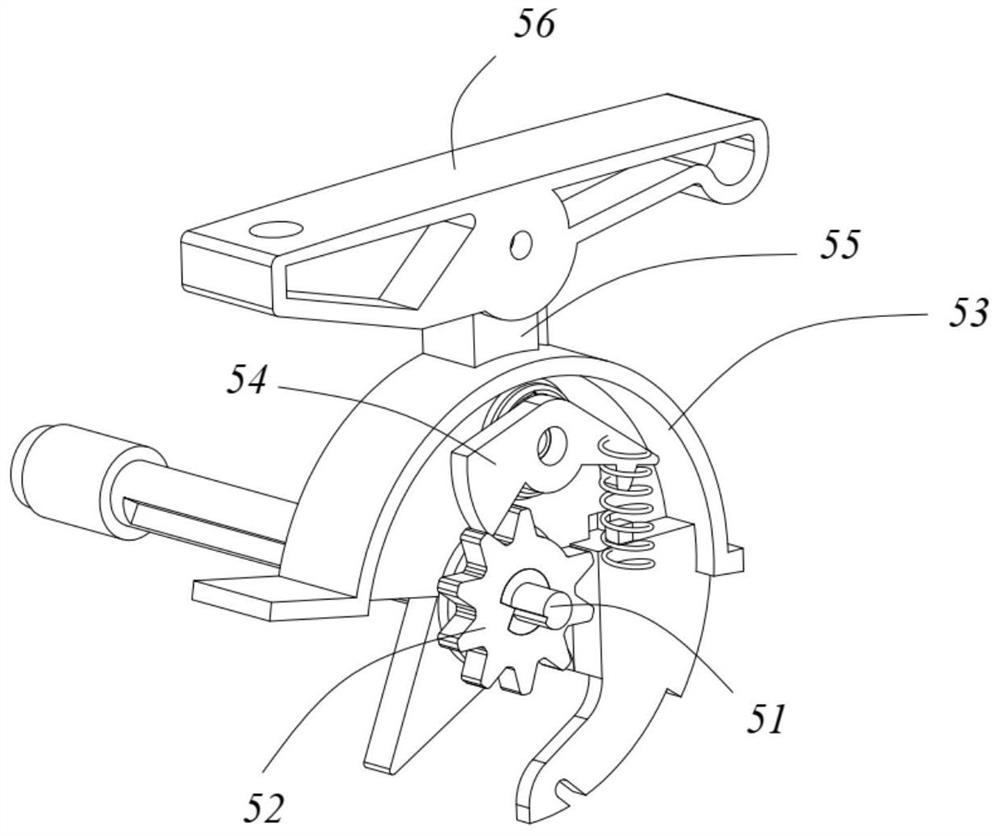

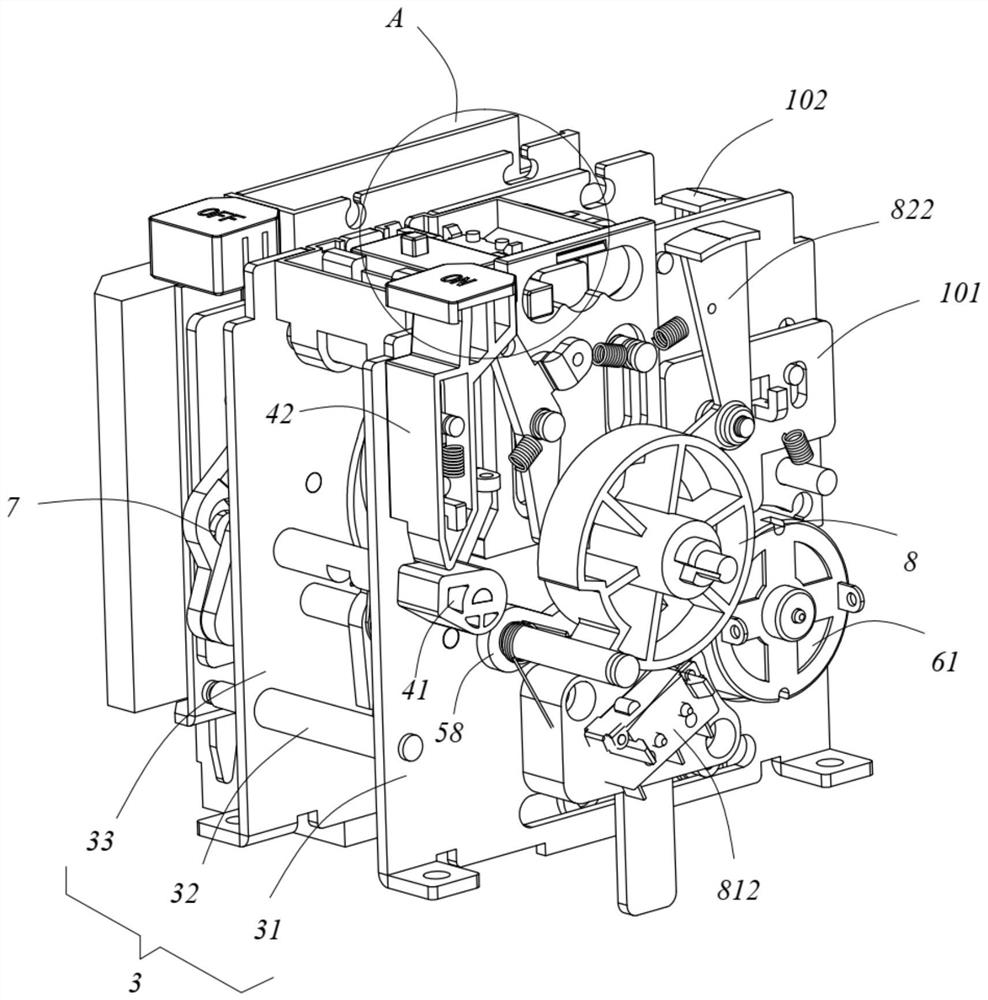

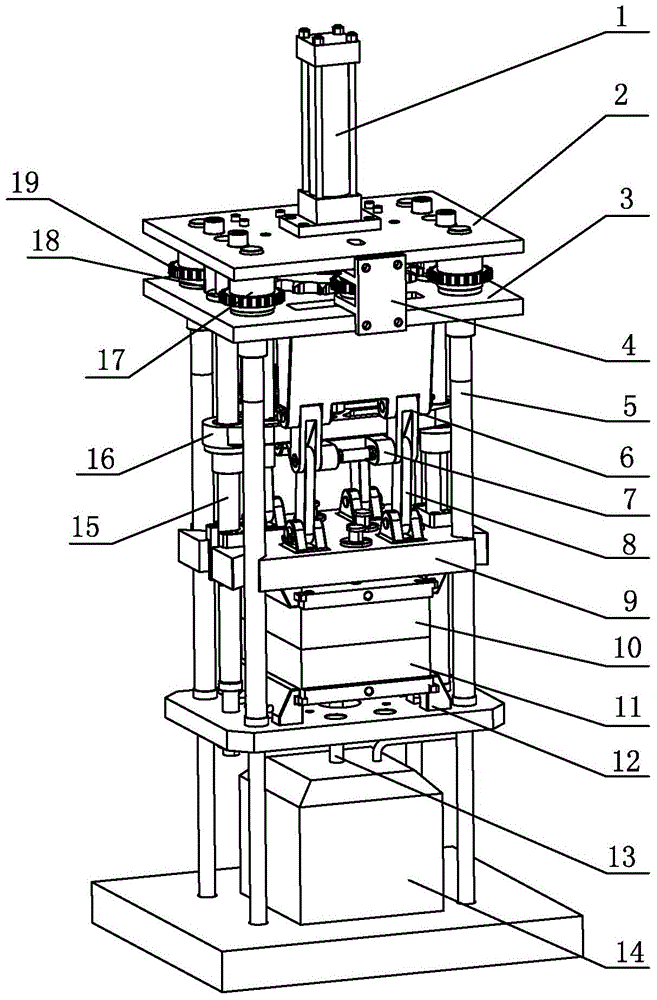

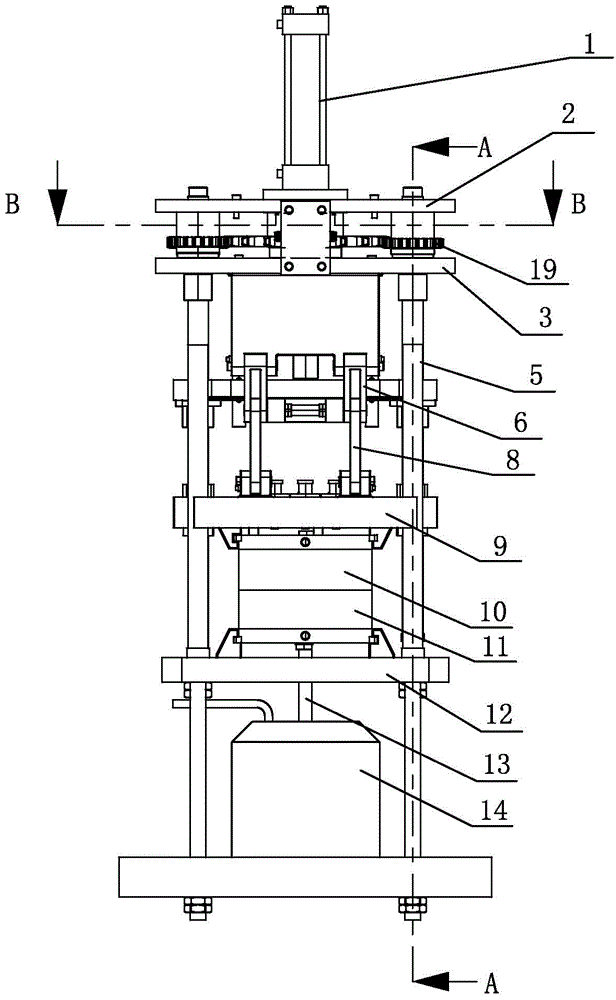

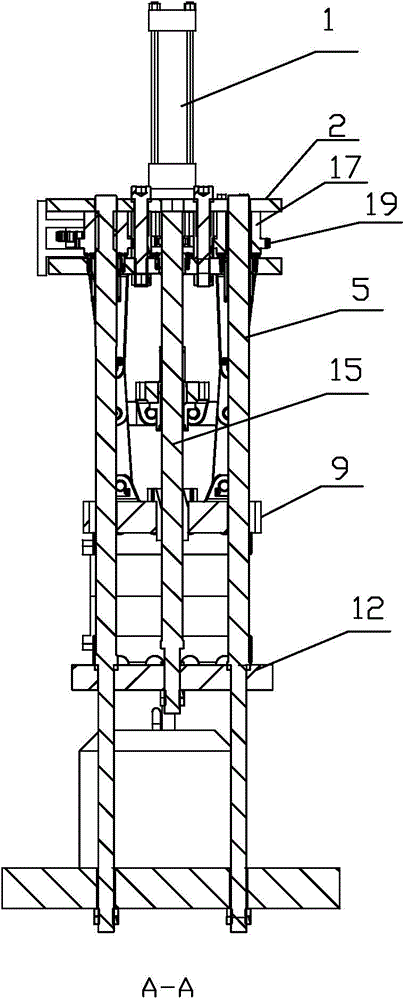

Energy storage type operating mechanism for circuit breaker

PendingCN113421804AIncrease freedomEasy to operateProtective switch operating/release mechanismsRatchetDrive shaft

The invention relates to an energy storage type operating mechanism for a circuit breaker, which comprises a crank arm assembly, a tripping assembly, a tripping driving assembly, a bracket and a manual energy storage driving assembly, wherein the manual energy storage driving assembly comprises a driving shaft connected to the crank arm assembly, a first ratchet wheel arranged on the driving shaft, a rotating handle arranged on the driving shaft, a first ratchet arranged on the rotating handle and a first reset spring, and the first ratchet is matched with the first ratchet wheel; a second ratchet wheel is arranged on the driving shaft, a second ratchet is arranged on the support, and the second ratchet wheel is matched with the second ratchet. Manual energy storage operation is achieved through cooperation of the first ratchet wheel and the first ratchet, meanwhile, what is guaranteed is that the rotating shaft can only rotate in the same direction and cannot rotate in the reverse direction through cooperation of the second ratchet wheel and the second ratchet, the energy storage position is kept, the energy storage mechanism can be suitable for application occasions needing rapid closing, and meanwhile in the maintenance process, maintenance personnel can manually store and release energy on site, the freedom degree of on-site maintenance is improved, and operation is convenient.

Owner:SUZHOU FUTURE ELECTRICAL APP

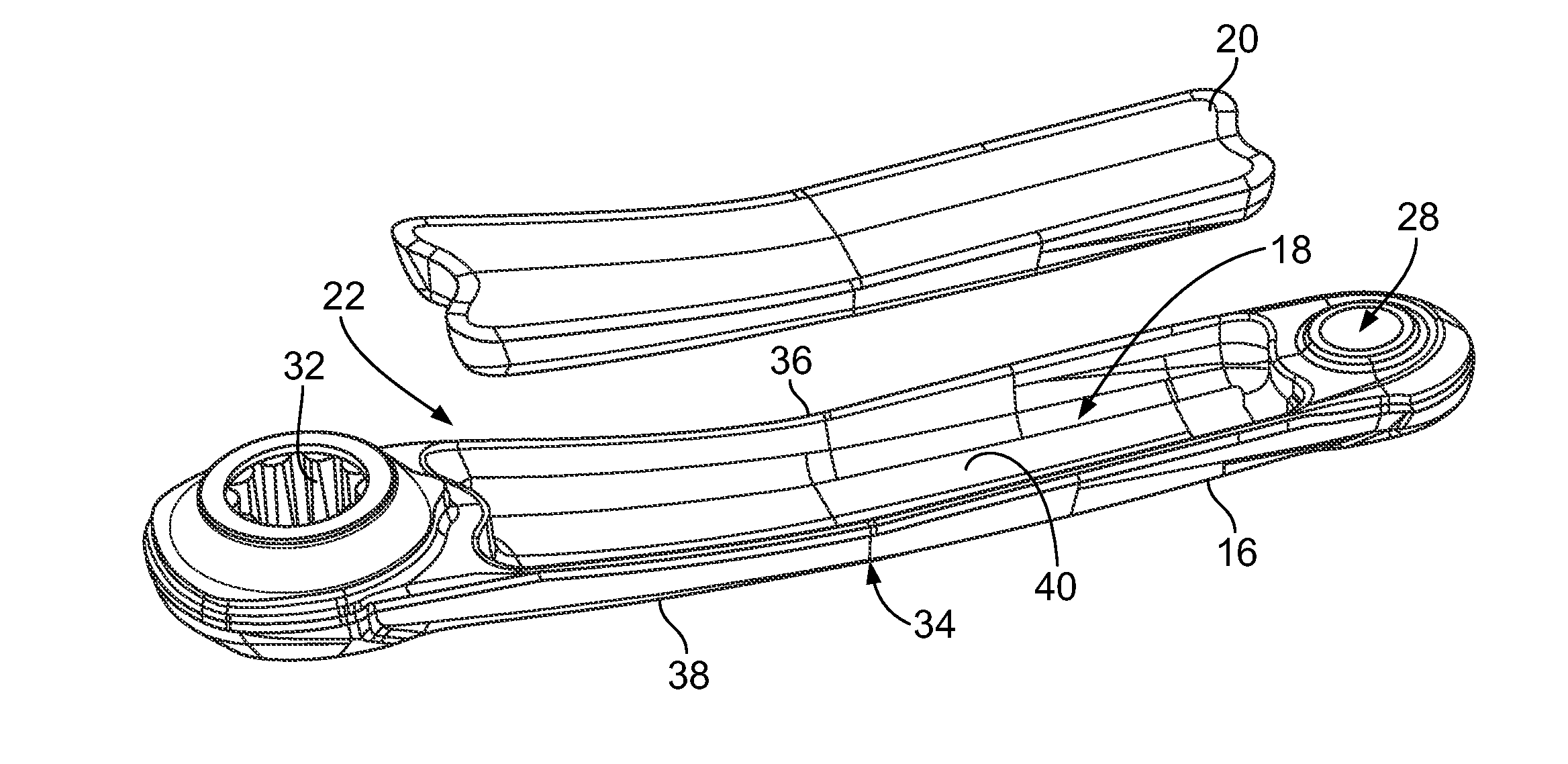

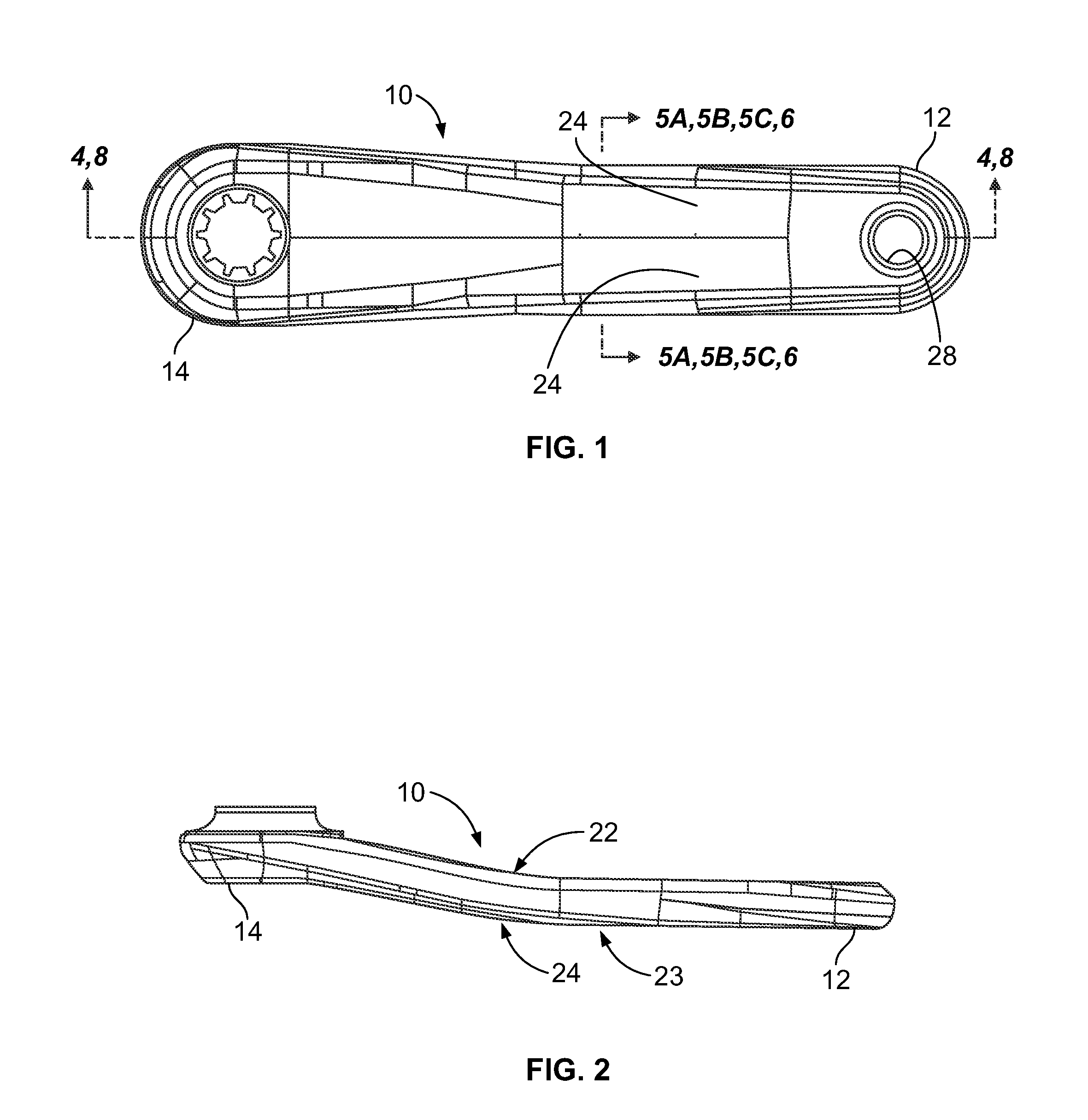

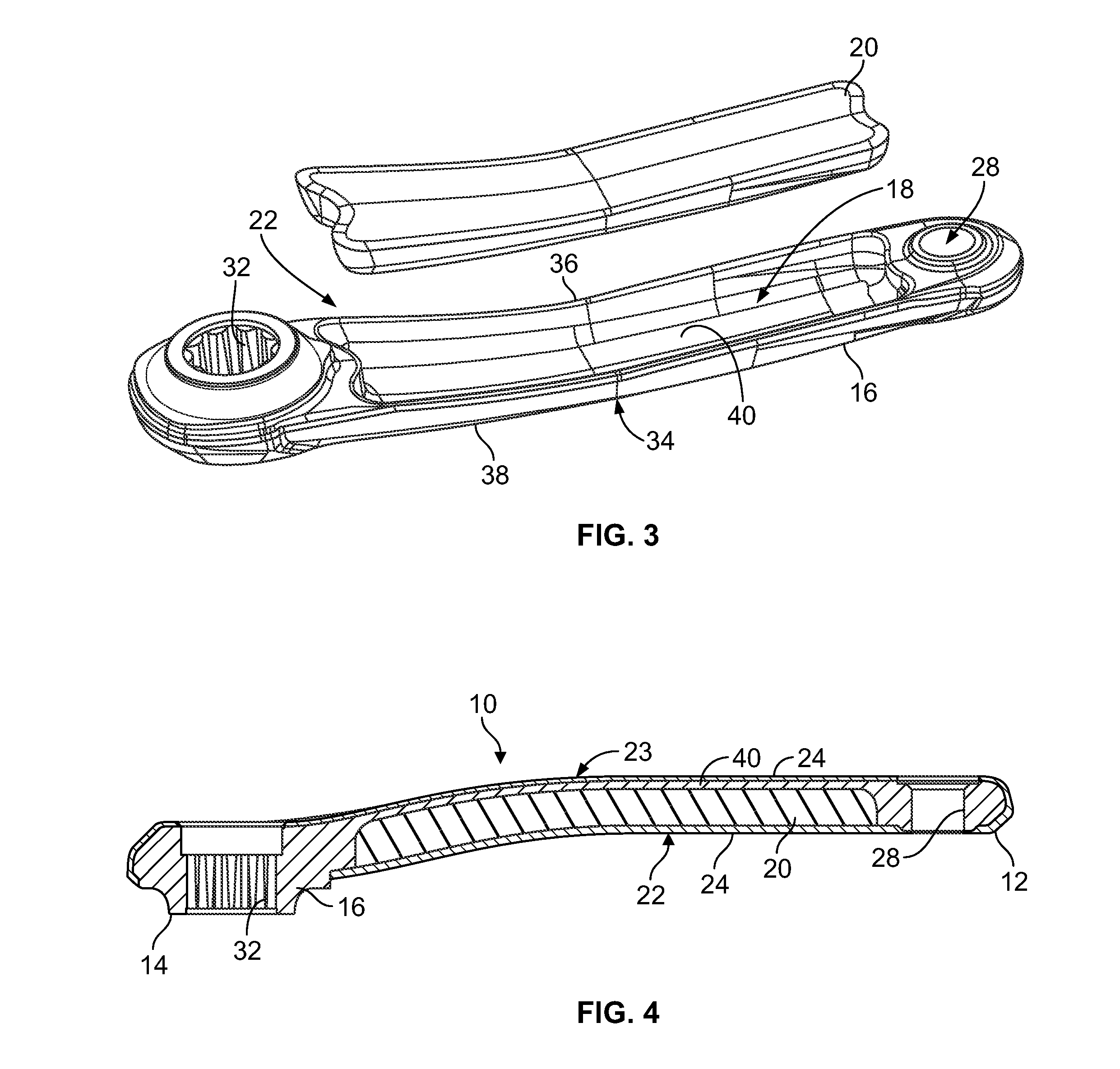

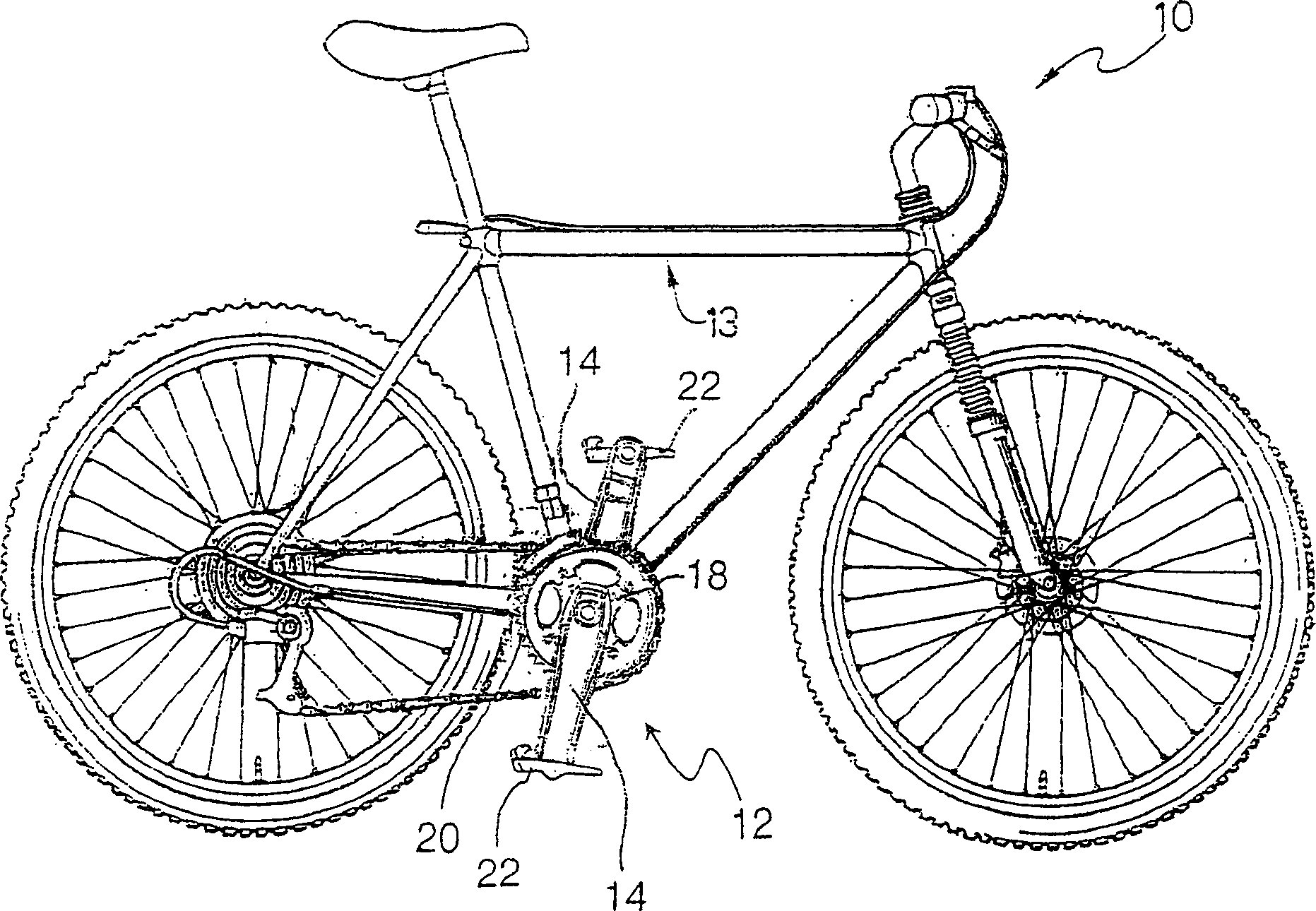

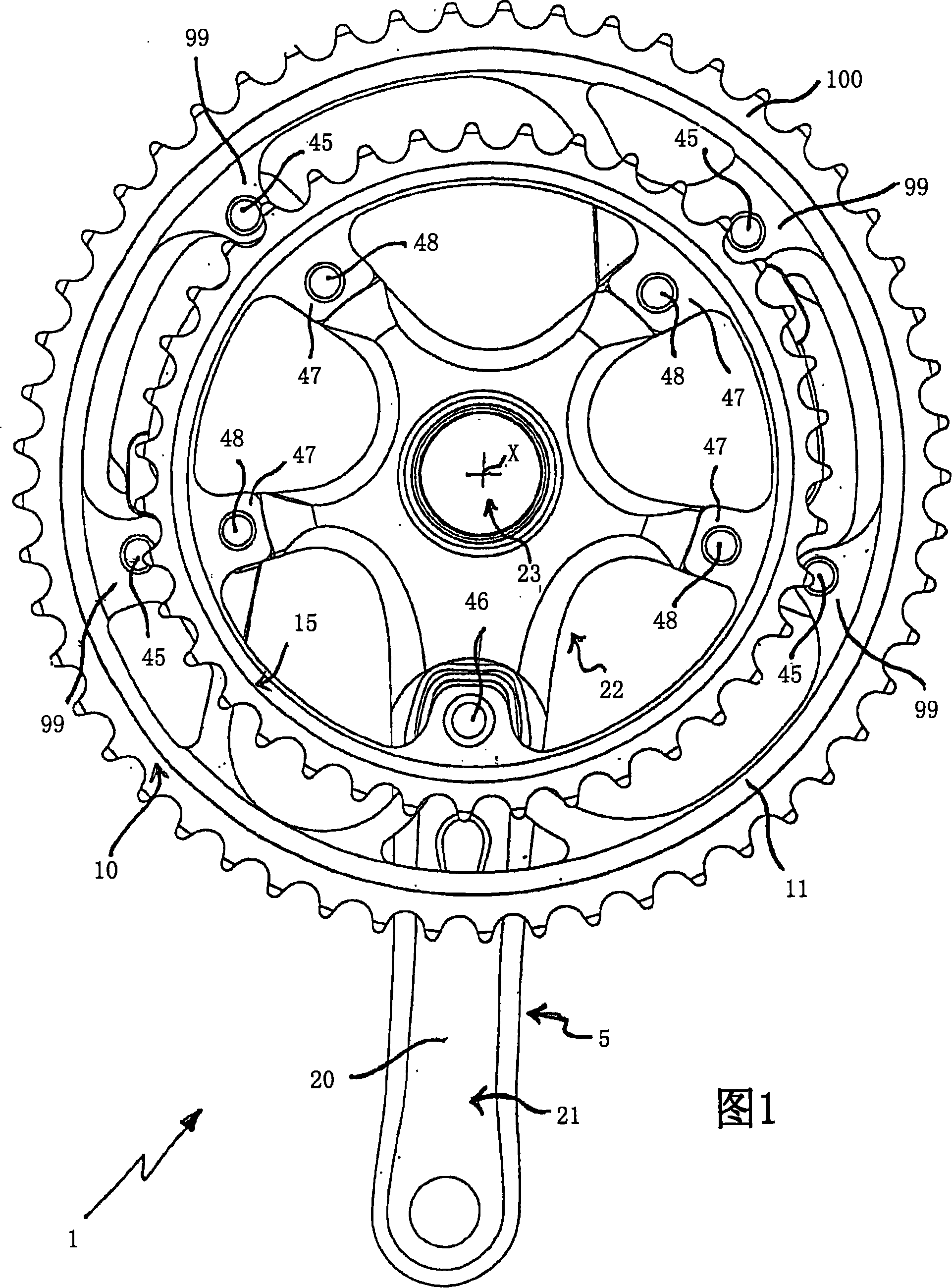

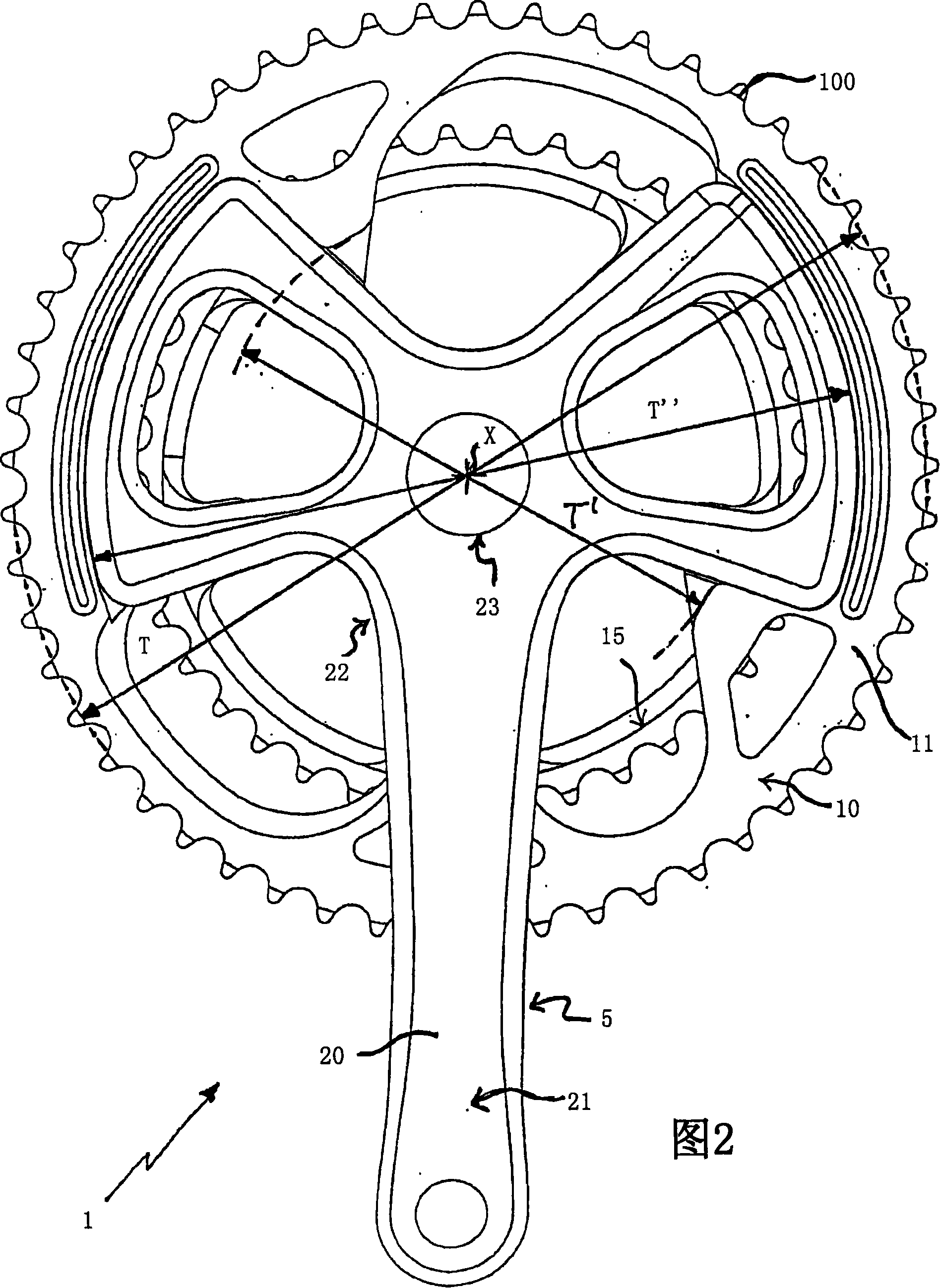

Bicycle crank arm assembly

ActiveUS20150175241A1High strengthStrong and light constructionMechanical apparatusVehicle cranksFiber-reinforced compositeCrank Arm Assembly

A bicycle crank arm including a support member. The support member includes a first end sized and shaped to receive a pedal and a second end opposite the first end. The second end is sized and shaped to receive a spindle and a middle portion extends between the first and second ends, wherein the middle portion includes at least one recess. An insert is disposed in each of the one or more recess and an outer shell that covers the support member and insert, wherein the outer shell is made of fiber reinforced composite.

Owner:SRAM CORPORATION

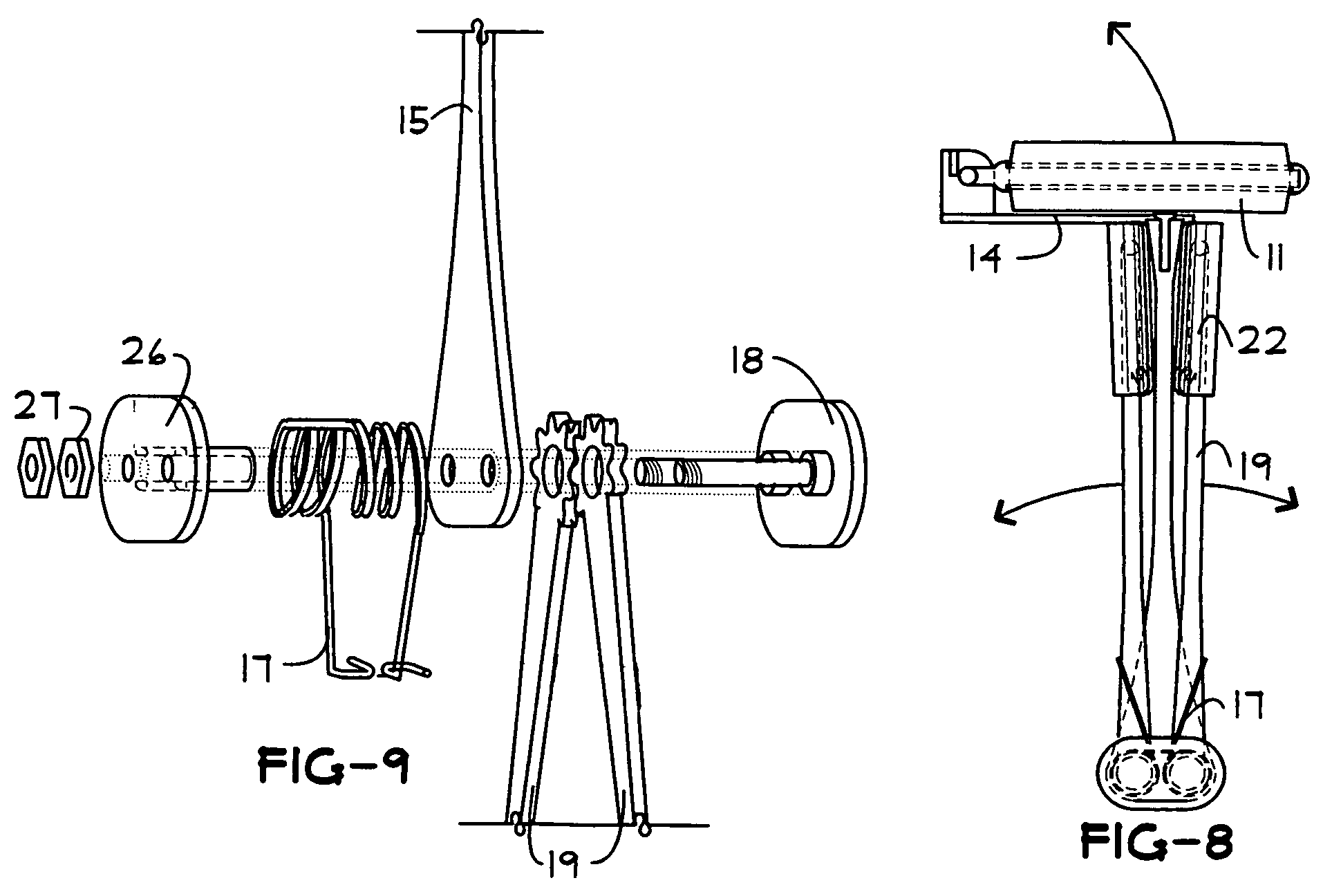

Rotatable container interior cleaning mechanism

InactiveUS20110277262A1Maximize contactPrevent slidingLiquid surface applicatorsCarpet cleanersHand heldCrank Arm Assembly

A hand-held, collapsible, self-adjusting mechanism, which is an improvement to the Spatula, for removing the remaining contents inside a plurality of containers. The device consists of three attached arms, two lower arms geared around their pivot ends to each other to keep their rotation symmetrical in relation to a drive arm, and pressurized with a double torsion spring to rotate towards said drive arm to apply pressure to a swiveling attachment receiver at the opposite end which makes contact with the inside walls of a container. The drive arm has a foldable crank arm assembly which allows you to quickly rotate and slide the mechanism in and out within a container with one hand while the other hand supports said container thus removing the contents from the walls of the container without difficulty or a mess.

Owner:SMETANA MATTHEW J

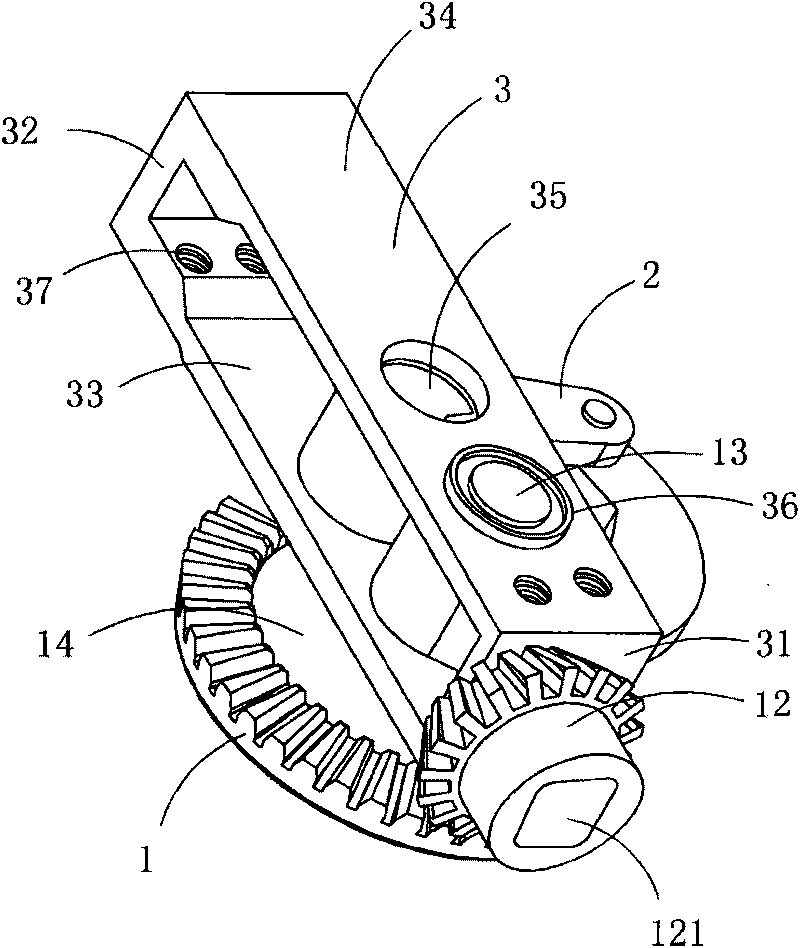

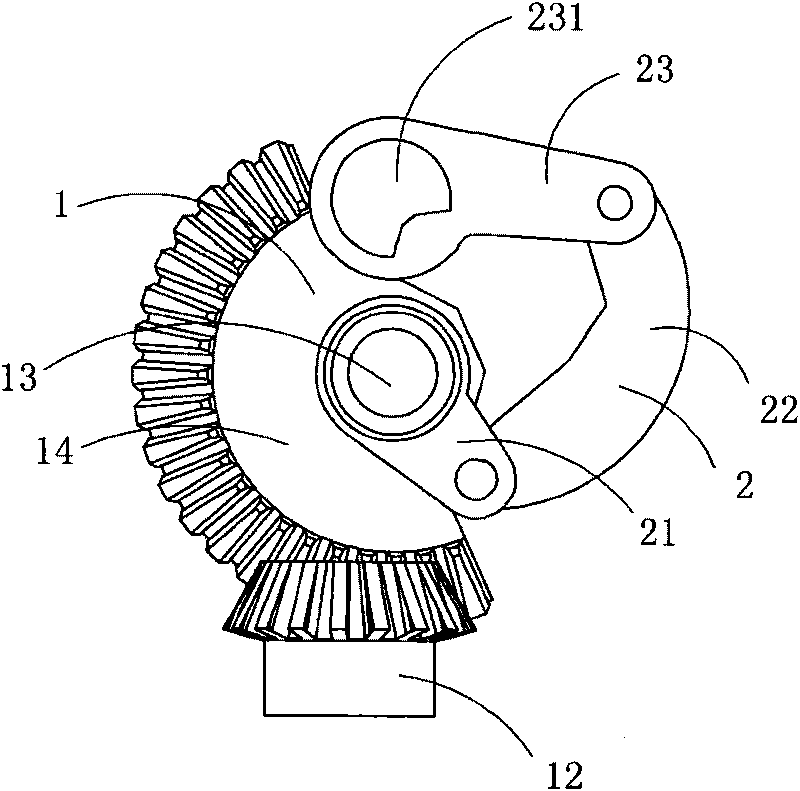

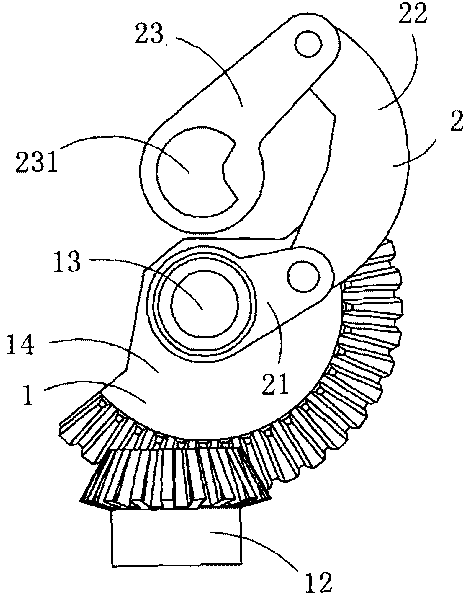

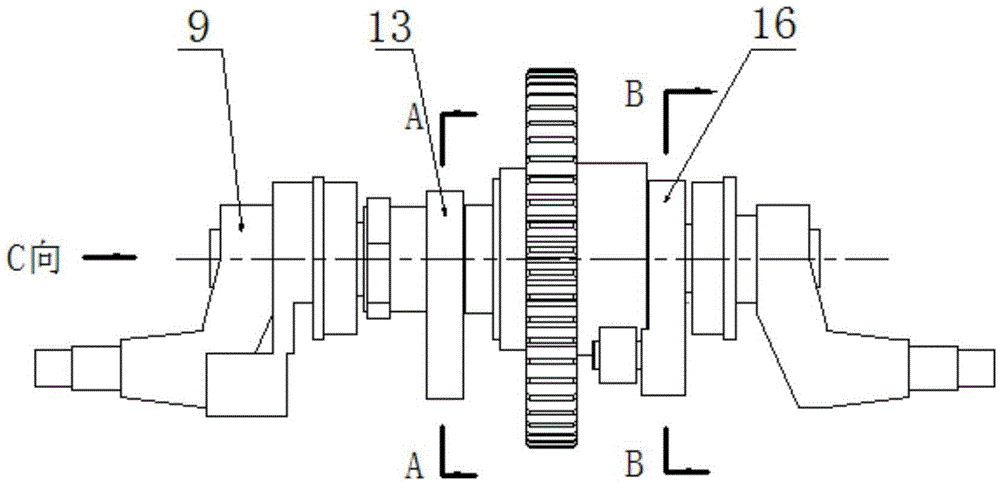

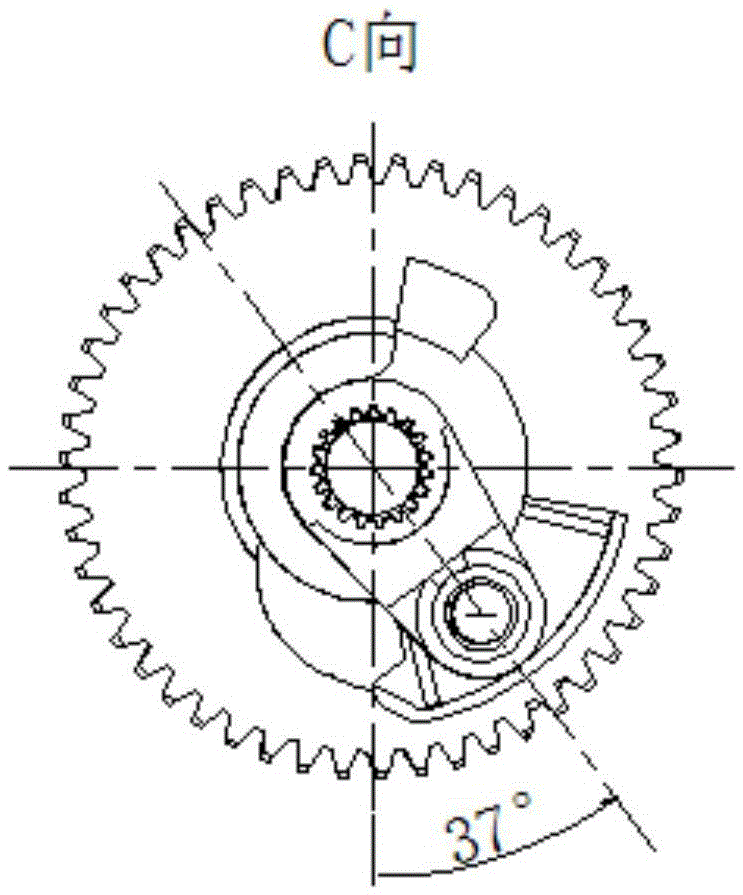

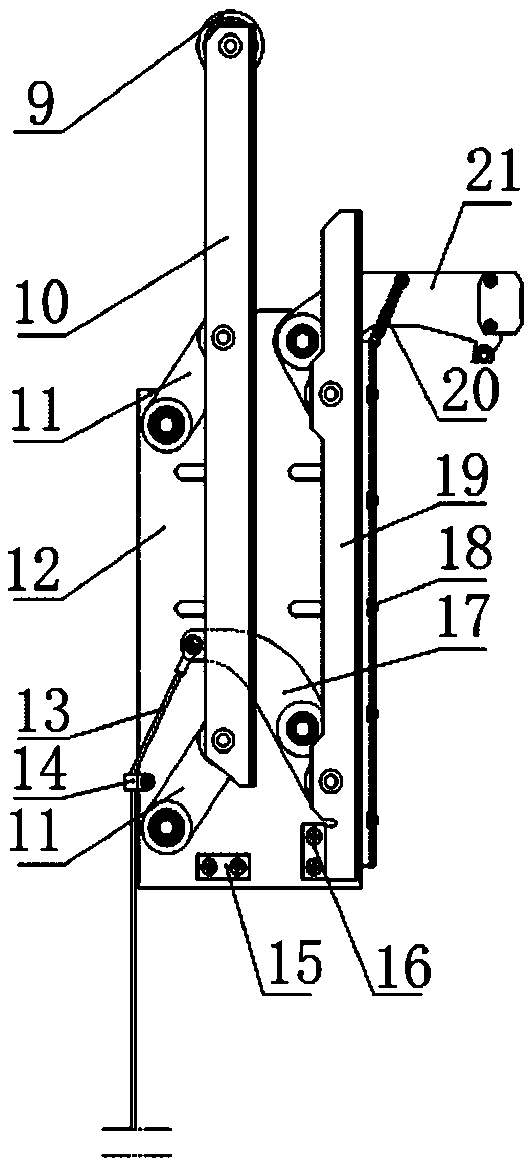

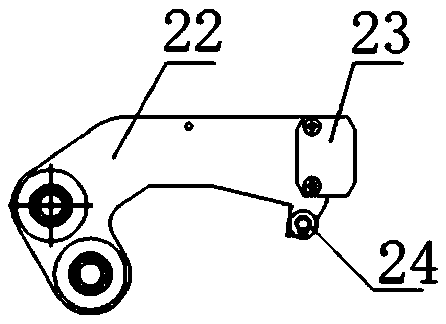

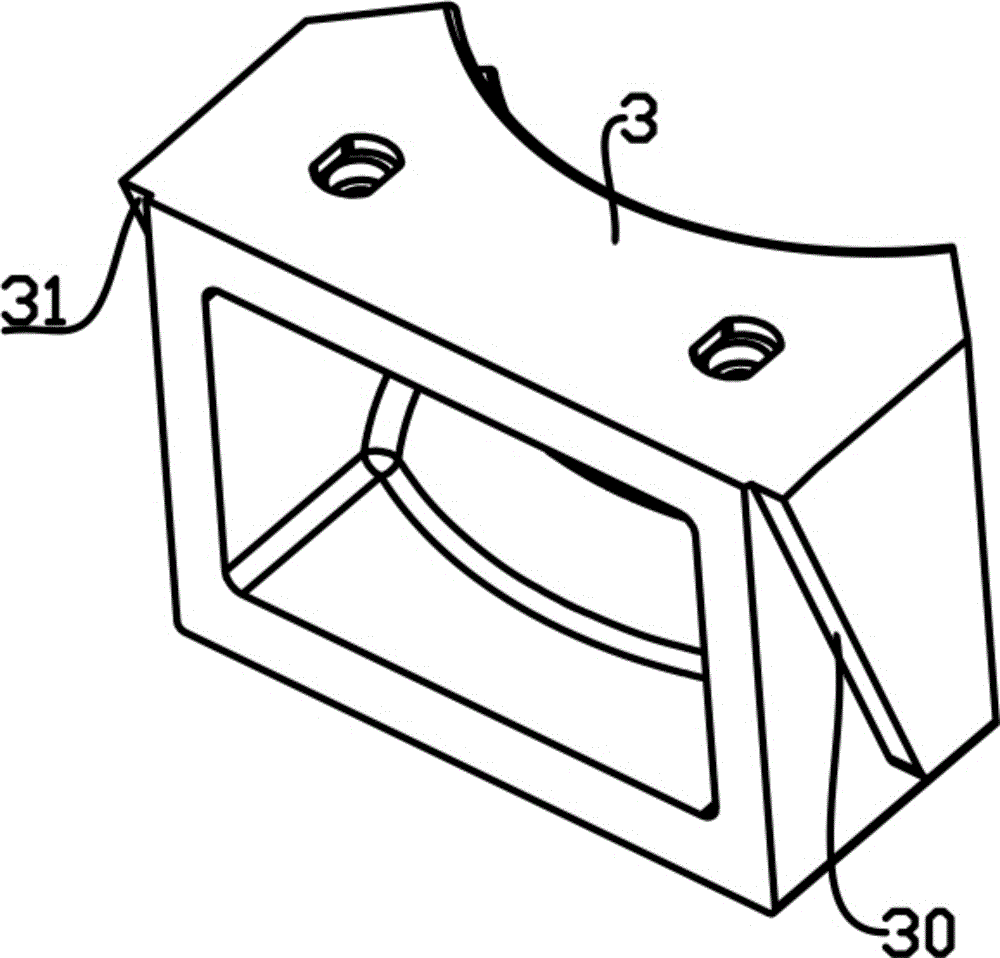

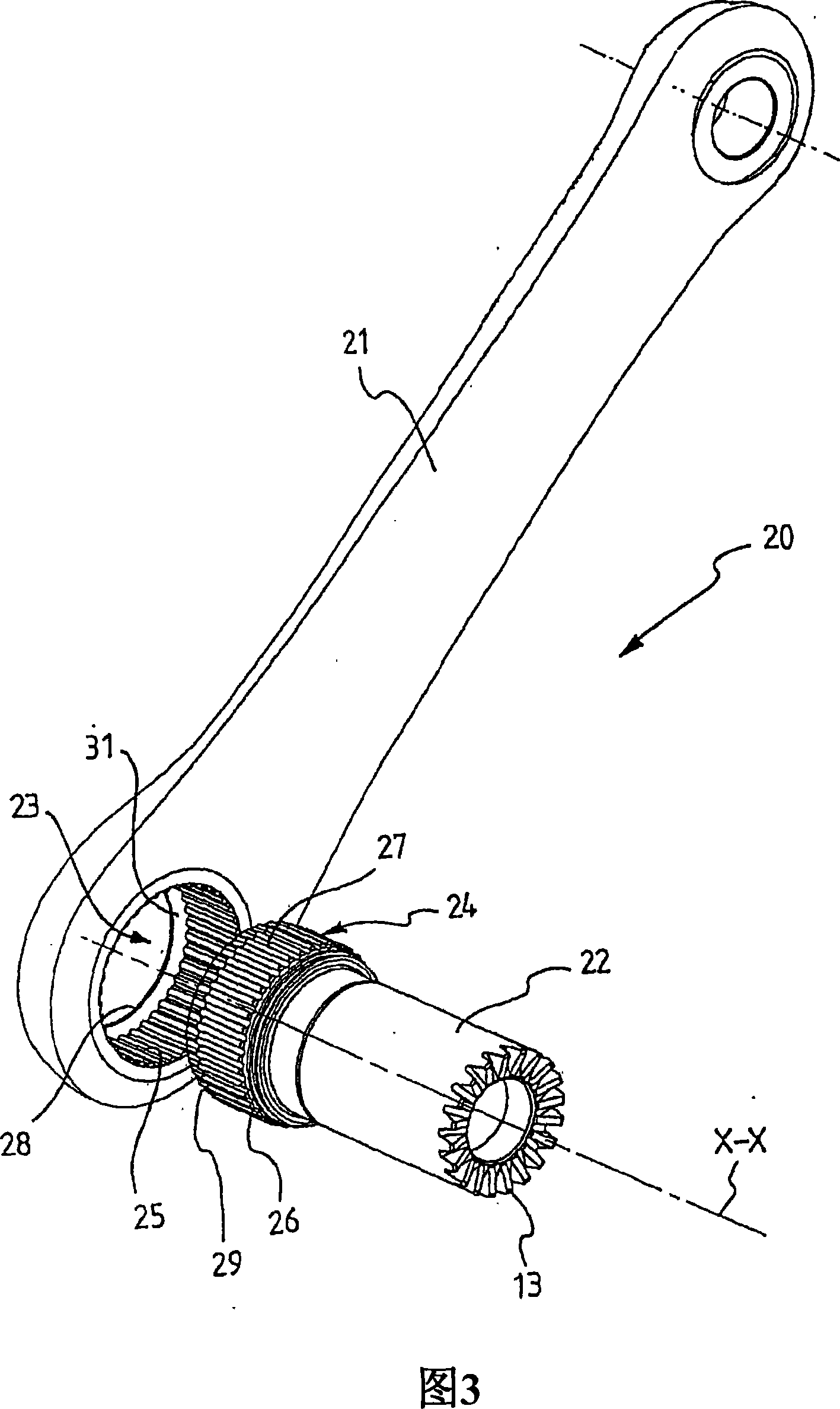

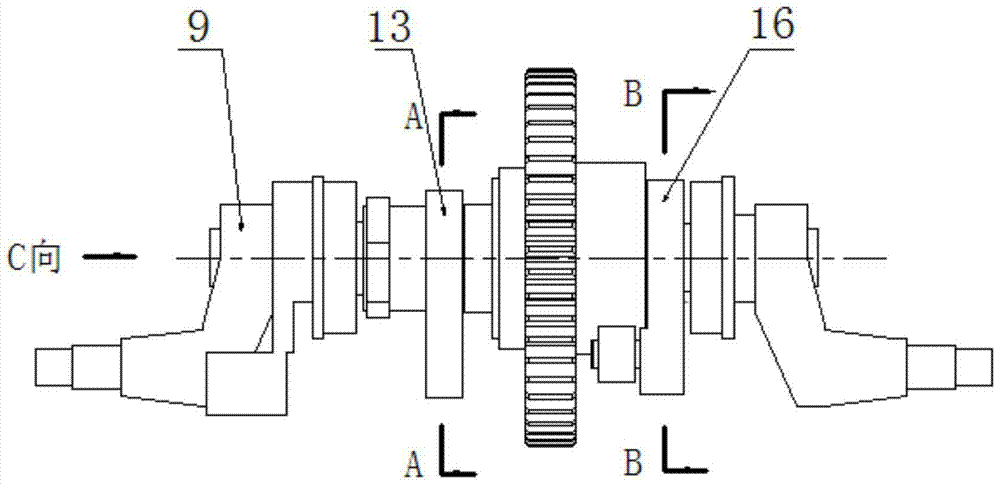

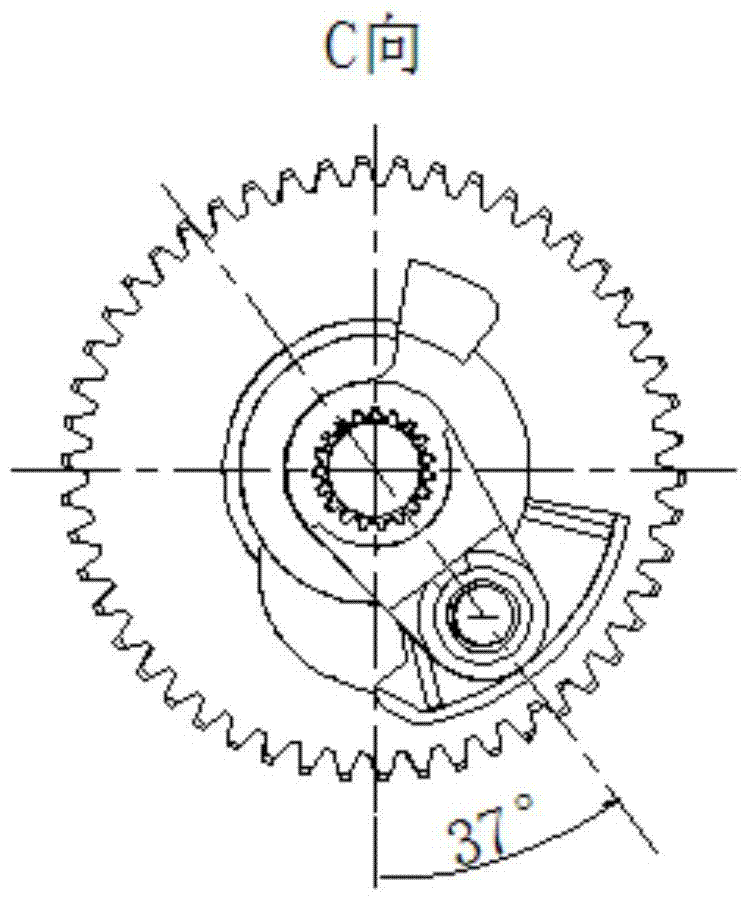

Driving mechanism for isolating switch

ActiveCN101763977AReduce volumeReduce headroomContact driving mechanismsAir-break switch detailsGear wheelCrank Arm Assembly

The invention discloses a driving mechanism for an isolating switch, comprising a gear transmission assembly, a crank arm assembly and a mounting frame, wherein the gear transmission assembly is a vertical shaft bevel gear transmission assembly comprising a first bevel gear and a second bevel gear; the first bevel gear rotates around a first rotating shaft, and the second bevel gear is driven by the first bevel gear and rotates around a second rotating shaft; the first rotating shaft and the second rotating shaft are vertically arranged; the basic shape of the mounting frame is a rectangular framework formed by combining a front wall, a rear wall, a left wall and a right wall; the crank arm assembly comprises a supporting arm fixed on the second rotating shaft, a transmission arm used fordriving an externally connected operation spindle to rotate and a connecting arm used for connecting the supporting arm and the transmission arm; both ends of the connecting arm are respectively connected with the supporting arm and one end of the transmission arm; and when the first bevel gear rotates, the second bevel gear is driven to rotate so as to further drive the supporting arm to rotate,and the externally connected operation spindle is driven to rotate through the connecting arm and the transmission arm. The driving mechanism is suitable for a high-voltage switch cabinet and can effectively reduce the volume of the switch cabinet.

Owner:华精科技股份有限公司

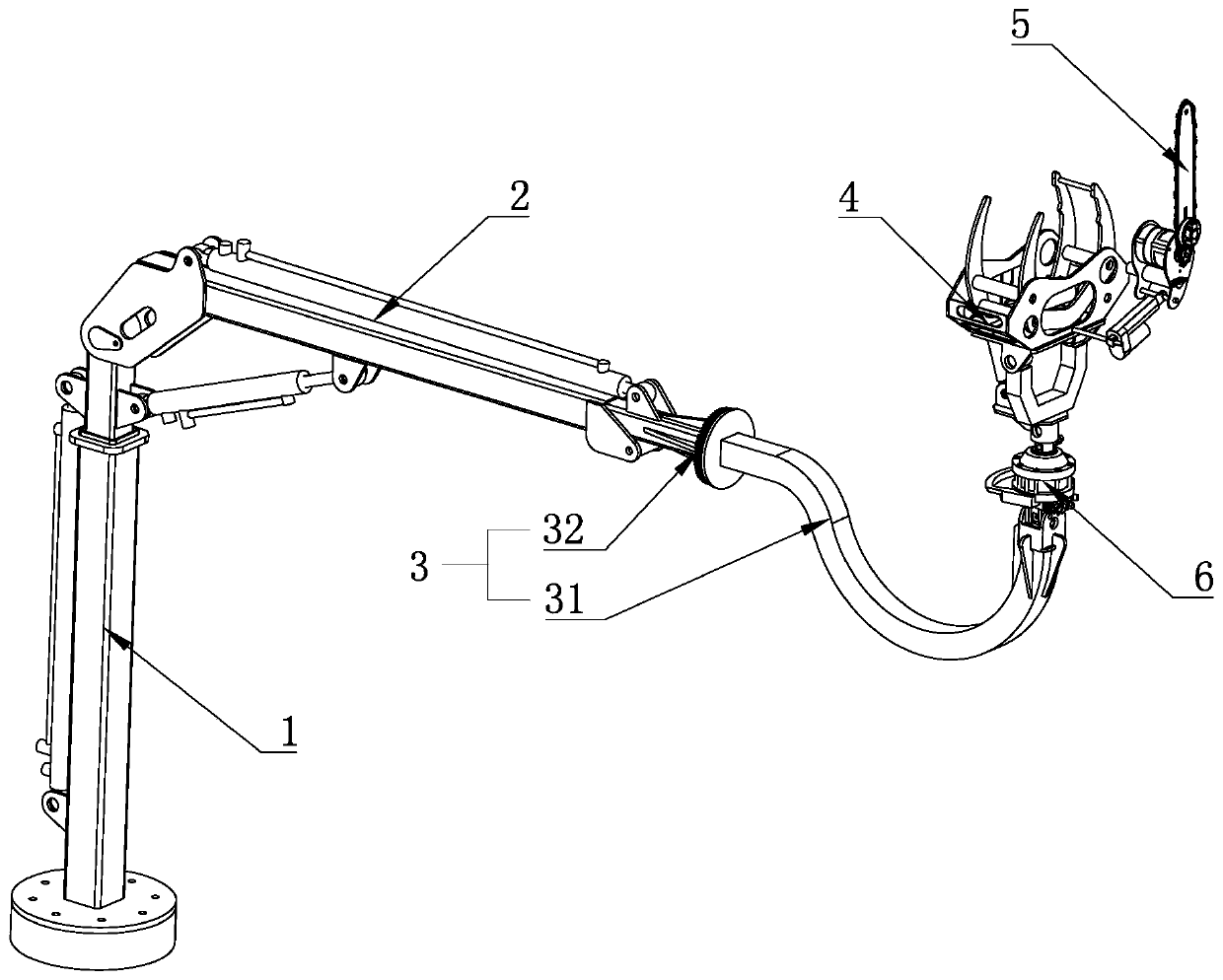

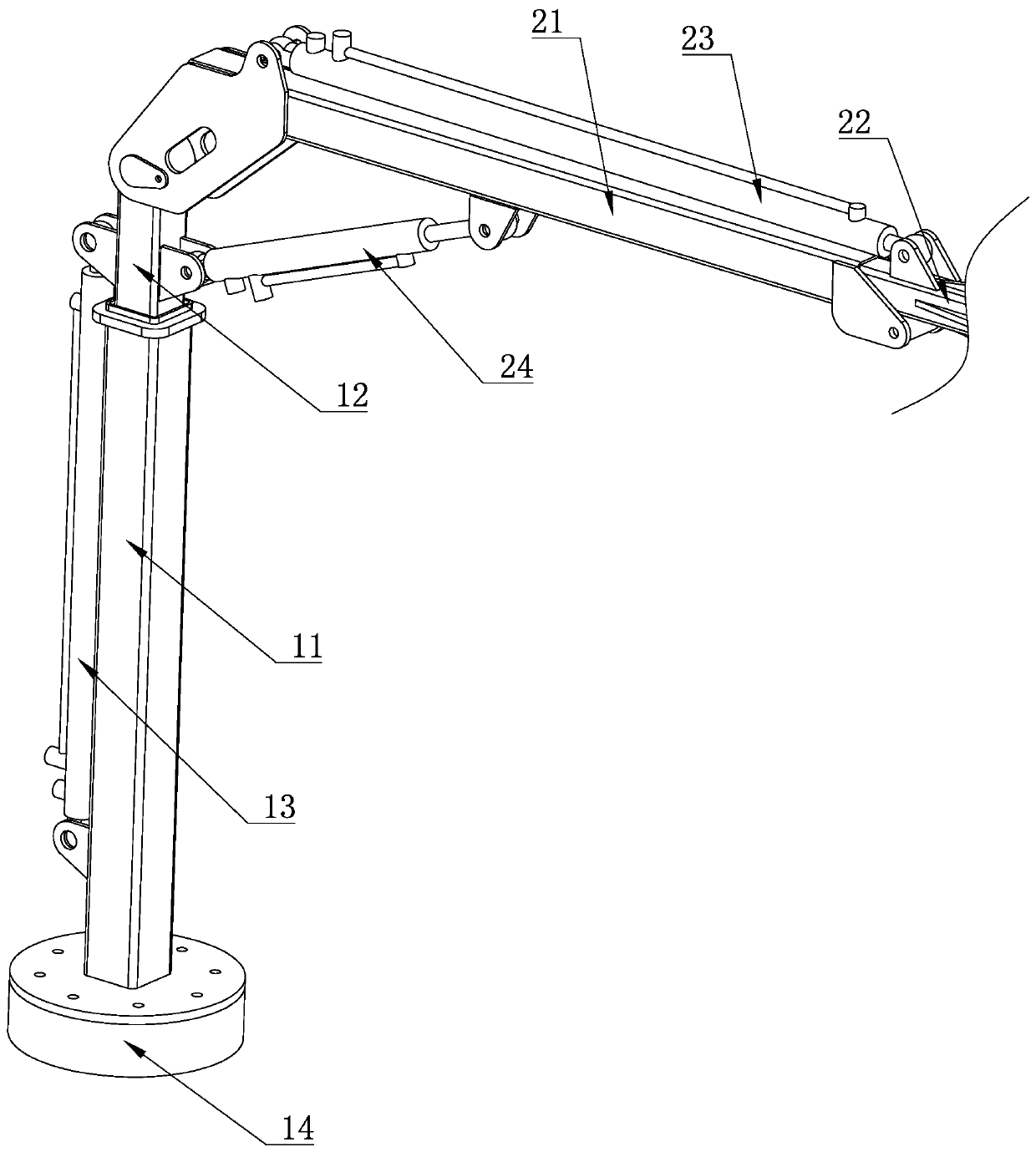

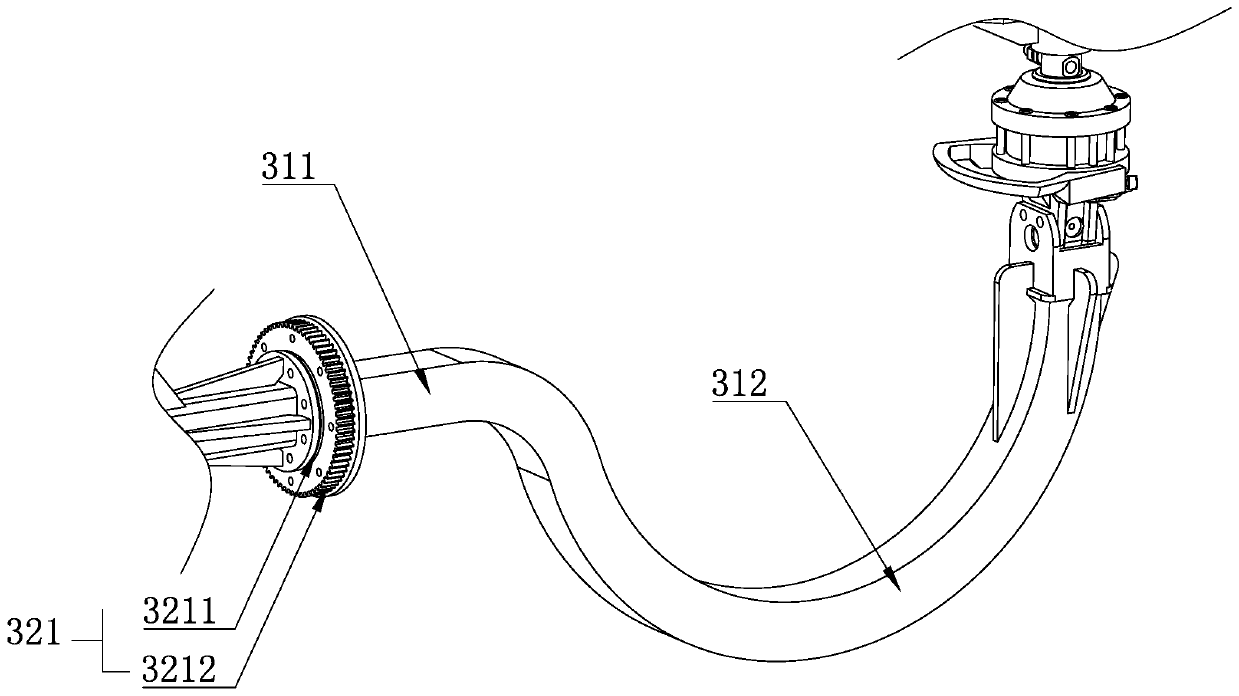

Tree trunk lateral branch pruning mechanical hand

PendingCN110073832AAvoid safety accidentsImprove pruning efficiencyGripping headsCuttersTree trunkEngineering

The invention discloses a tree trunk lateral branch pruning mechanical hand. The mechanical hand comprises an arm frame device and a pruning device, wherein the arm frame device comprises a support seat assembly, a straight arm assembly and a crank arm assembly; the support seat assembly is used for regulating the vertical lifting height; the straight arm assembly is used for regulating the horizontal extending length; the crank arm assembly is used for avoiding tree trunks; the straight arm assembly is connected between the support seat assembly and the crank arm assembly; the crank arm assembly is connected with the pruning device. The mechanical hand is regulated to the position of lateral branches required to be pruned through the arm frame device; then, the lateral branches are tightly clamped and cut by the pruning device; finally, through the combination of the pruning device and the arm frame device, the lateral branches cut from the tree trunks are piled to a defined position;the manual cutting and carrying are not needed in the whole process; safety accidents caused by the manual cutting and carrying are prevented; high safety and reliability are realized.

Owner:ZHEJIANG YAT ELECTRICAL APPLIANCE CO LTD

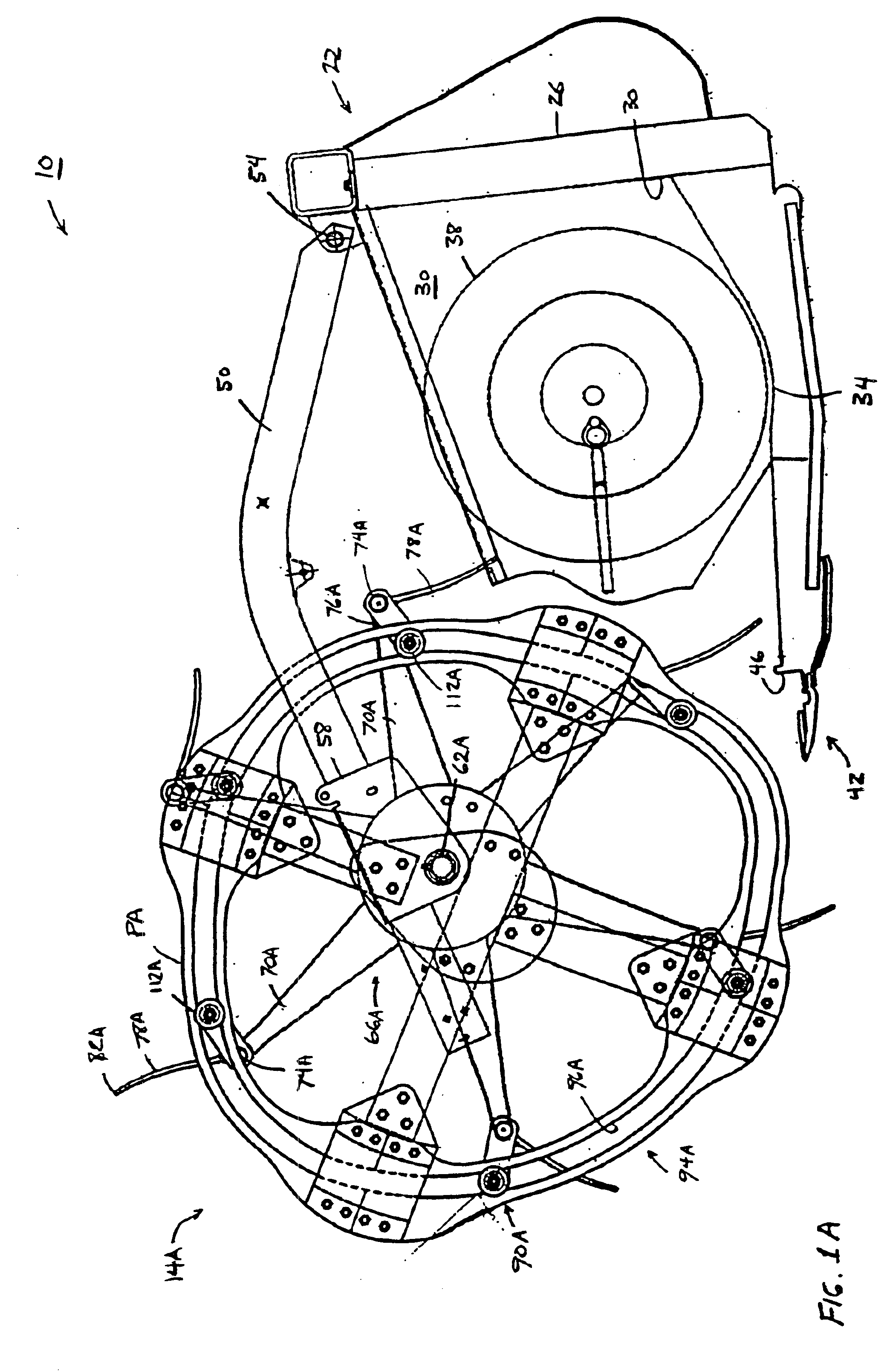

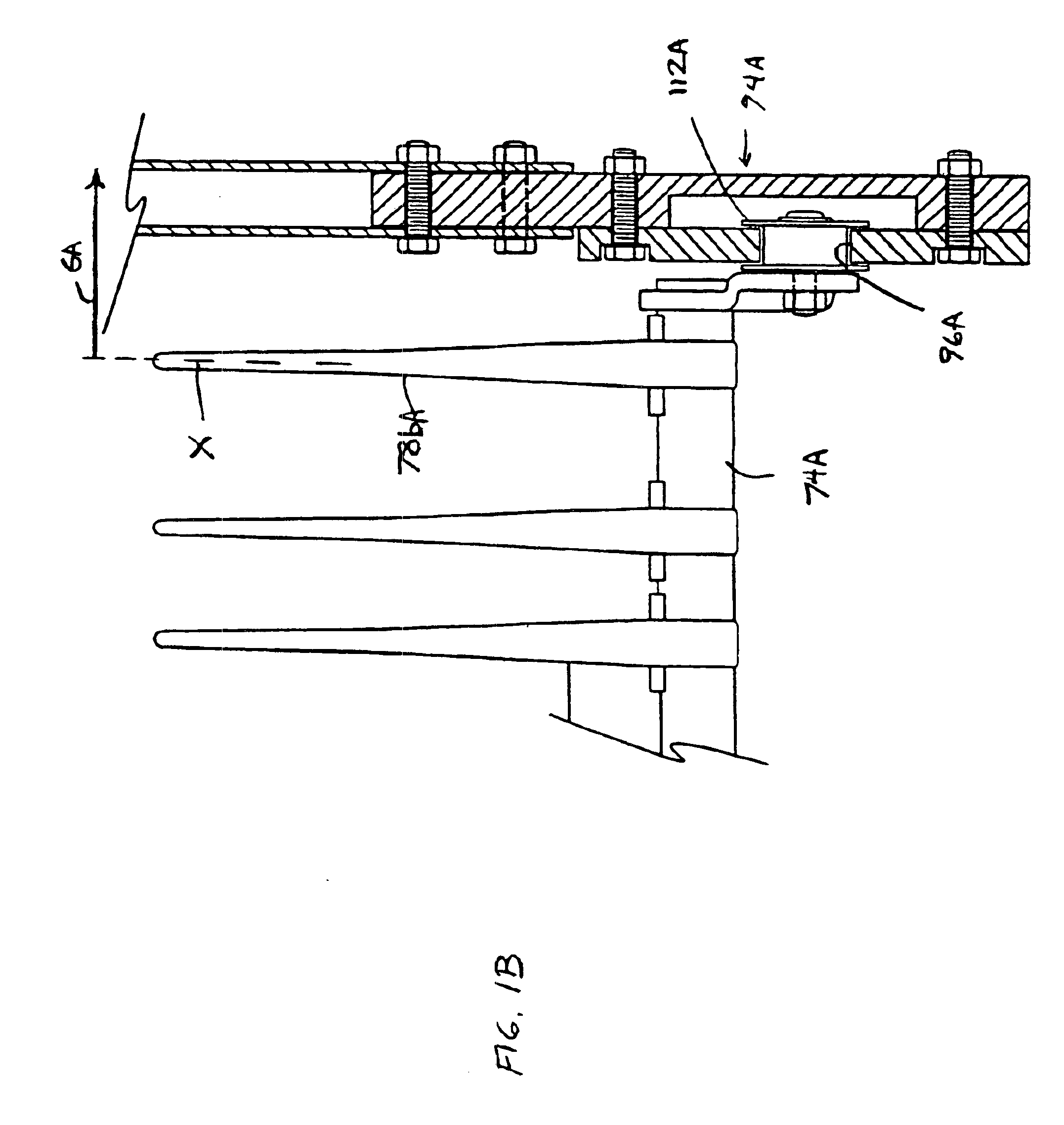

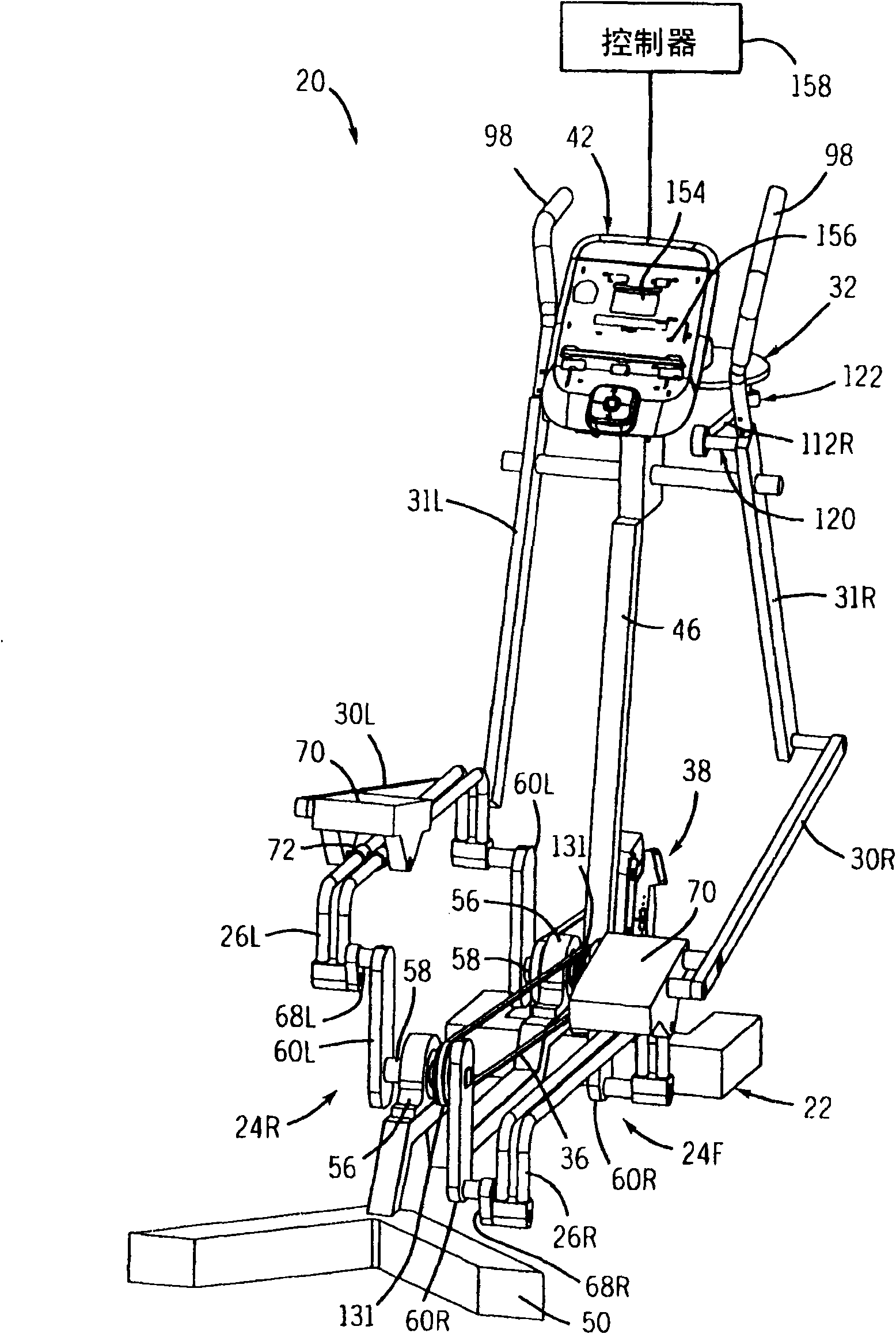

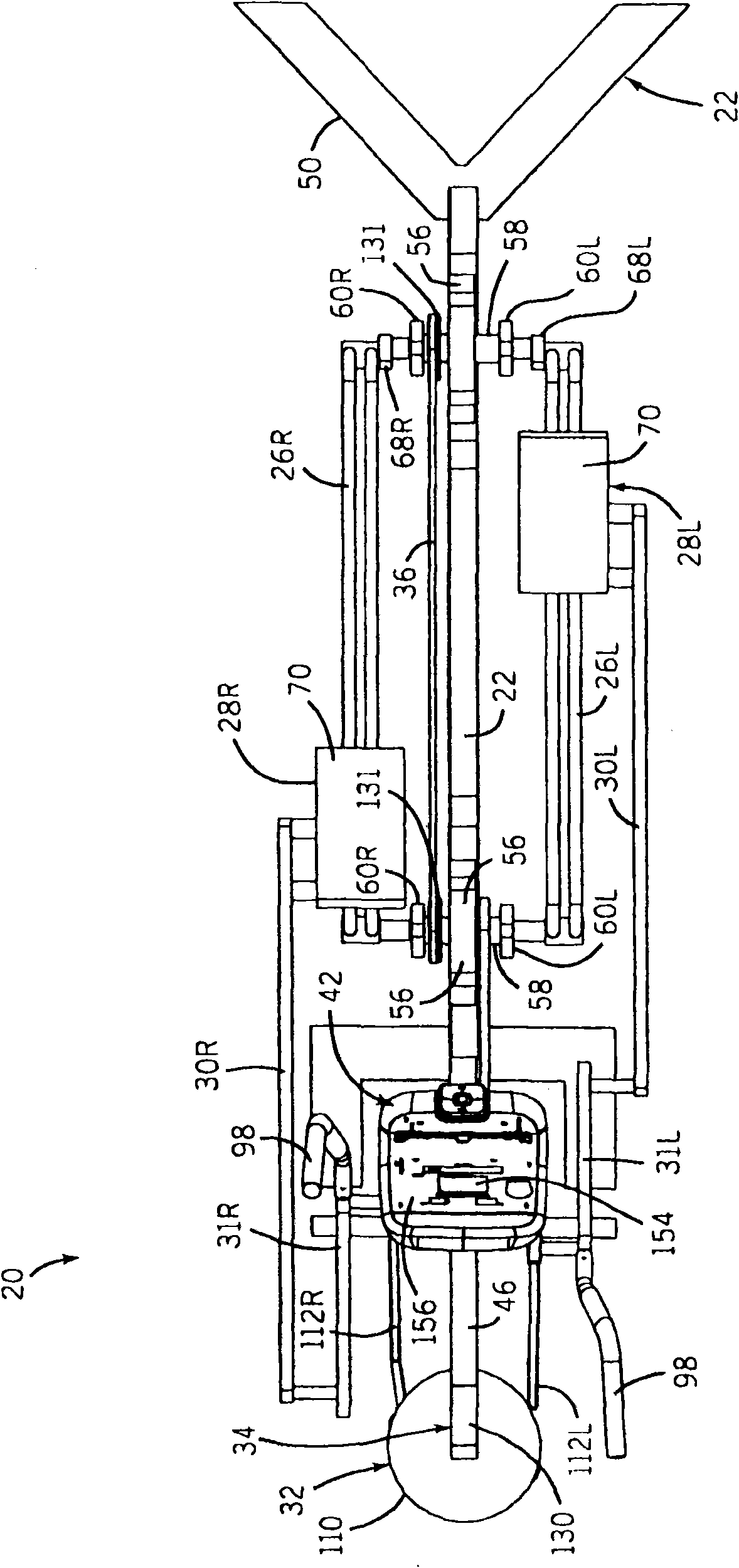

Stationary bike

InactiveUS20050239610A1Accurately and dynamically simulates bicyclingSimple designMechanical apparatusMovement coordination devicesEngineeringCrank Arm Assembly

A stationary exercise bicycle is provided having a frame, a resistance member, a drive assembly, a right pedal, a left pedal, a seat and an adjustable seat mechanism utilizing a rack. Assembly and disassembly of a three piece crank arm assembly is accomplished without requiring the assembling and disassembling of the entire drive assembly. The stationary exercise bicycle also provides a variety of users with an optimum seat position and with a convenient latch mechanism to adjust the position of the seat.

Owner:BRUNSWICK CORPORATION

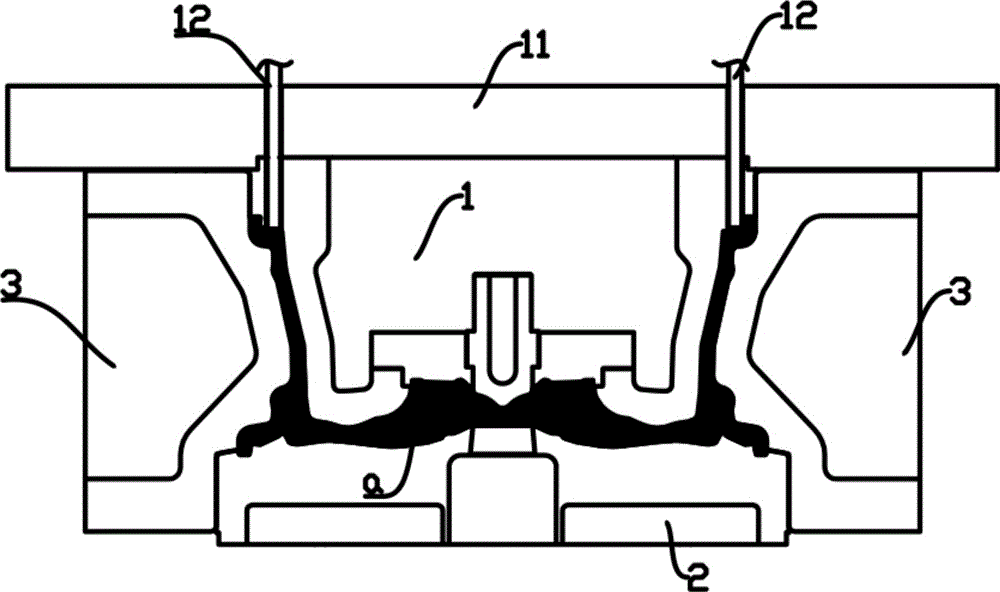

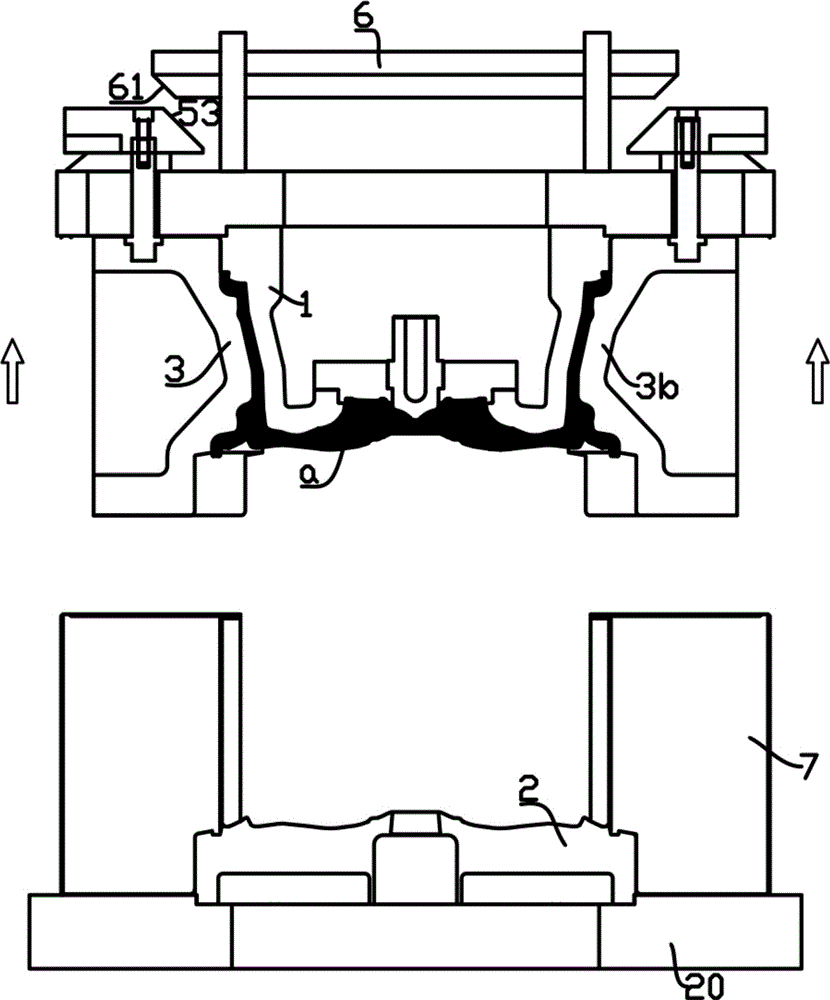

Metal piece manufacturing method and low-pressure casting forging machine used for achieving metal piece manufacturing method

The invention provides a metal piece manufacturing method and a low-pressure casting forging machine used for achieving the metal piece manufacturing method and belongs to the metal casting technology. The manufacturing process of the method includes a low-pressure casting stage and a forging stage. The low-pressure casting forging machine used for achieving the metal piece manufacturing method comprises a low-pressure casting device, a support, an upper die driving mechanism, a crank arm five-hinge mechanism and a control system. The low-pressure casting device comprises an upper die and a lower die, wherein a die cavity is formed by oppositely combining the upper die and the lower die. A sealing guide face is formed between joint faces of the upper die and the lower die. The support is composed of a lower die installation piece, a driving mechanism installation rack and supporting rods and is of a frame type. The lower die is installed through the lower die installation piece. The upper die is installed through an upper die installation piece. The crank arm five-hinge mechanism comprises a first rotating arm, a second rotating arm, a moving arm and two supporting rotating arms. The first rotating arm is hinged to the corresponding supporting rotating arm, so that a crank arm assembly is formed and respectively hinged to the upper die installation piece and the driving mechanism installation rack. The control system controls the upper die driving mechanism to move. The low-pressure casting and high-pressure forging processes are achieved and strength of a metal piece is improved.

Owner:浙江文源智能科技有限公司

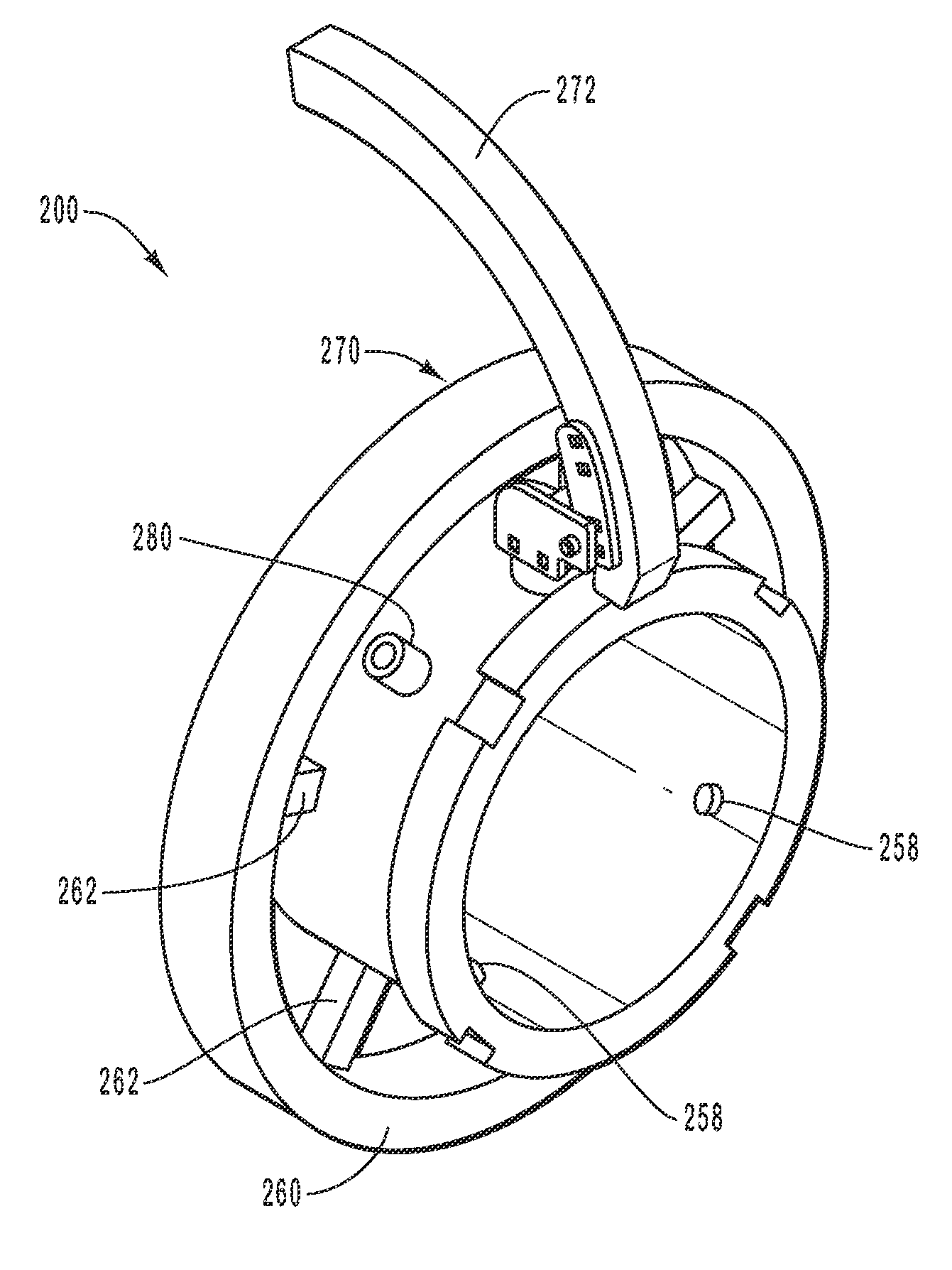

Fluid system coupling with pivoting handle actuating member

ActiveUS20100013216A1Easy to engagePreventing intentional and accidental disengagementSleeve/socket jointsEngine sealsLine tubingLocking mechanism

A fluid system component is provided that includes first and second elements configured to be removably engaged with each other to define a fluid passageway. The first element defines at least one groove. Correspondingly, the second element includes at least one engagement member configured to be received in a corresponding groove. The presence of a line pressure in the passageway substantially forecloses disengagement of the first and second elements until the fluid pressure in the fluid passageway has decreased to a predetermined magnitude. A handling and locking mechanism for selectively securing the second element relative to the first element is included. The locking mechanism includes a pin controlled by a crank arm assembly adjacent a collar handle. The crank arm assembly includes a crank arm handle that rotates to withdrawn the pin from the second element and which facilitates rotation of the first element relative to the second element.

Owner:HILTAP FITTINGS

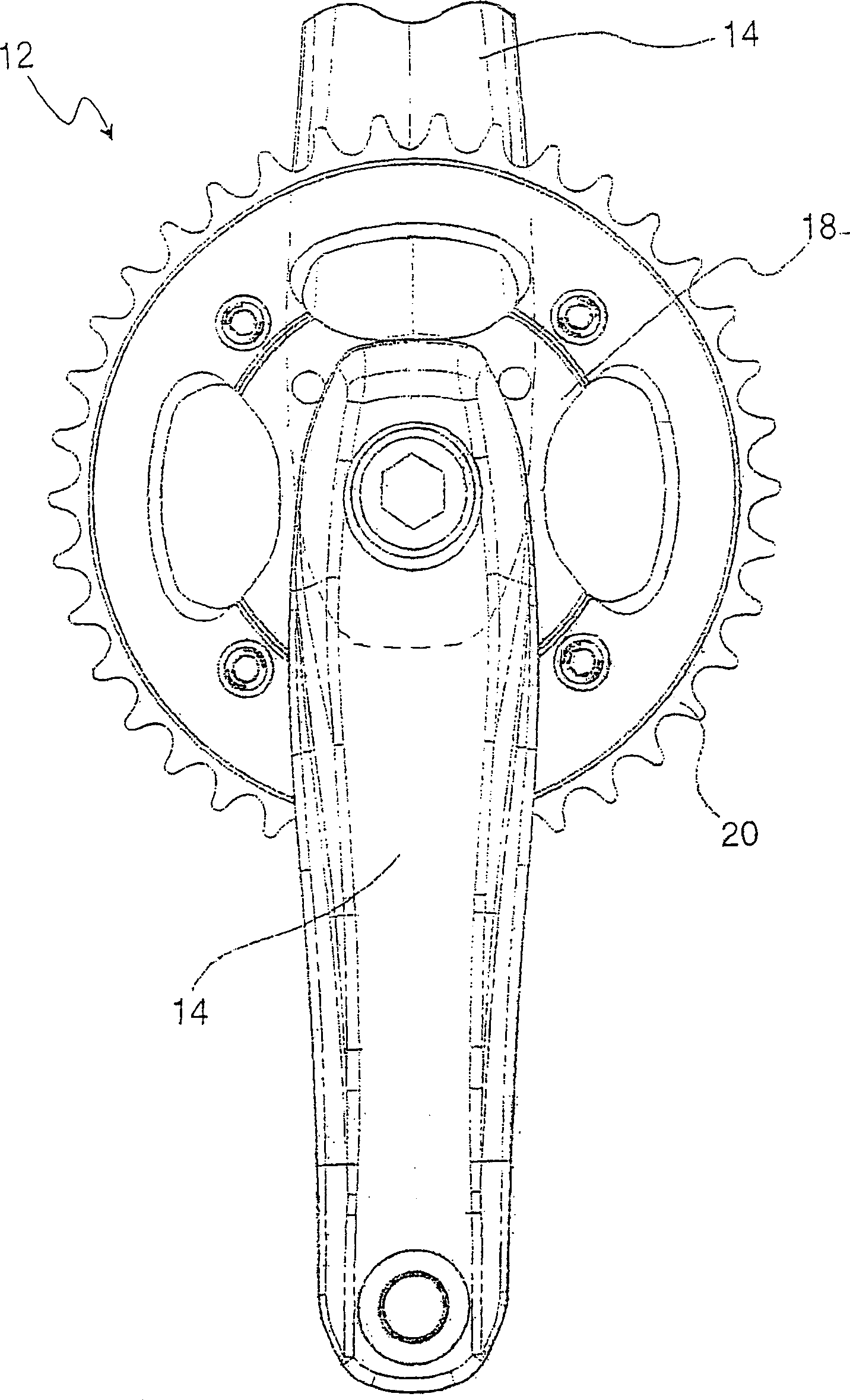

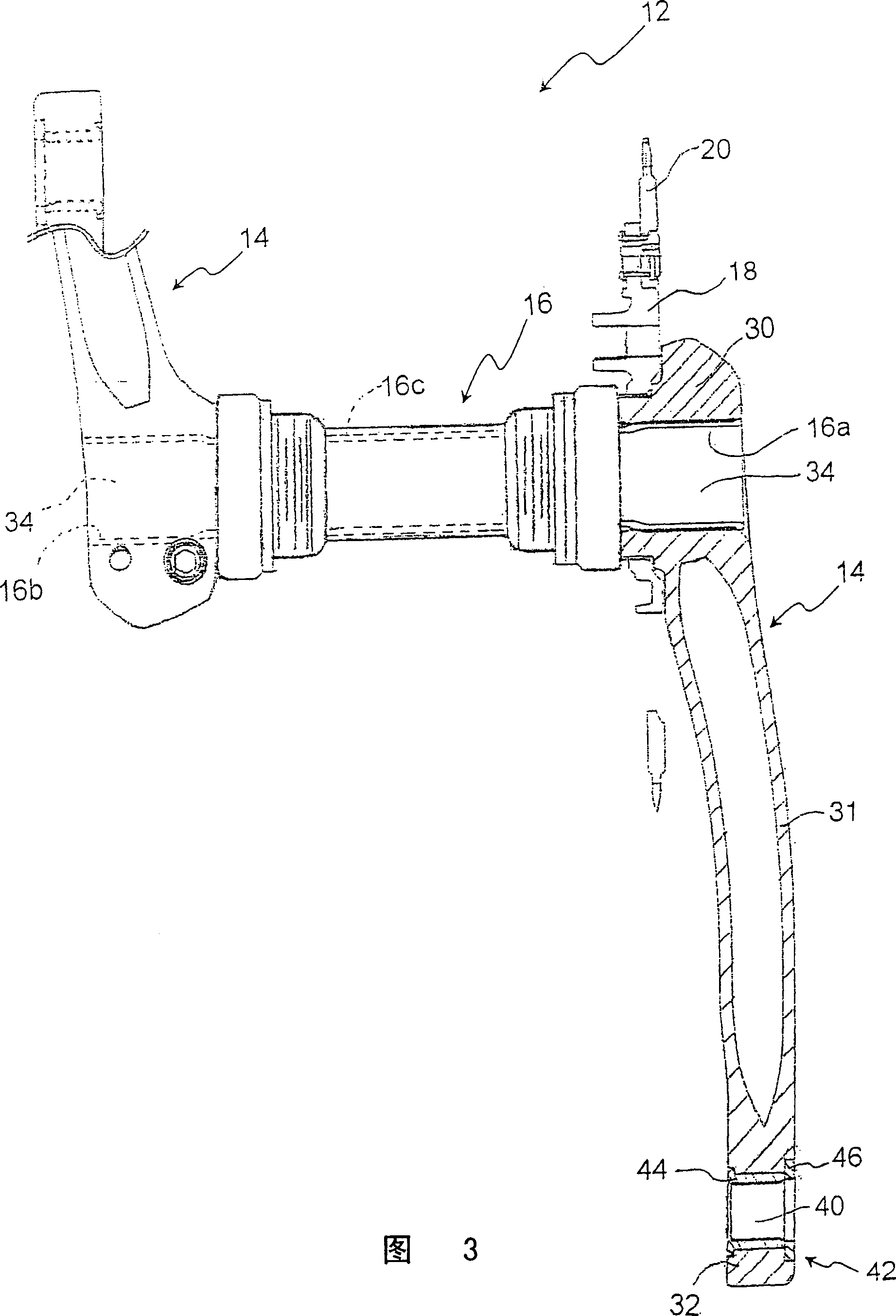

Crank web assembly of bicycle

A bicycle crank arm assembly is provided with a bicycle crank arm (14) with a first end configured to be coupled to an axle (16c) of a bottom bracket (16) and a second end with a pedal attachment bore (40) for receiving a bicycle pedal shaft. A tubular member (44) is press fitted into the bore of the bicycle crank arm (14). The tubular member (44) has an external circumferential surface with serrations that surface is non-releasably press fitted into the pedal attachment bore (40) of the bicycle crank arm (14), and an internally threaded surface adapted to be coupled to the bicycle pedal shaft. The crank arm (14) preferably has a counterbore at one axial end of the pedal attachment bore (40) with a washer (46) disposed therein such that the washer (46) partially overlaps the tubular member (44).

Owner:SHIMANO INC

Hose reel cart with multi-position crank handle

ActiveUS7959101B2Reduce the amount of bendingEliminate needFilament handlingFire rescueGear wheelEngineering

The present invention relates to hose reel carts for handling and storage of flexible hoses, such as garden or air hoses. The hose reel cart is primarily constructed of plastic components having a centrally rotatable spool for winding of the flexible hose, a frame for supporting the spool and a multi-position crank arm assembly allowing the consumer to place the crank handle in a lowered position or a raised position. The crank remotely drives the spool, for winding the hose, through a series of gears located within the crank arm assembly. The device may further include a reciprocating guide assembly that operates during rotation of the spool to rewind the hose into a compact configuration.

Owner:SUNCAST TECH

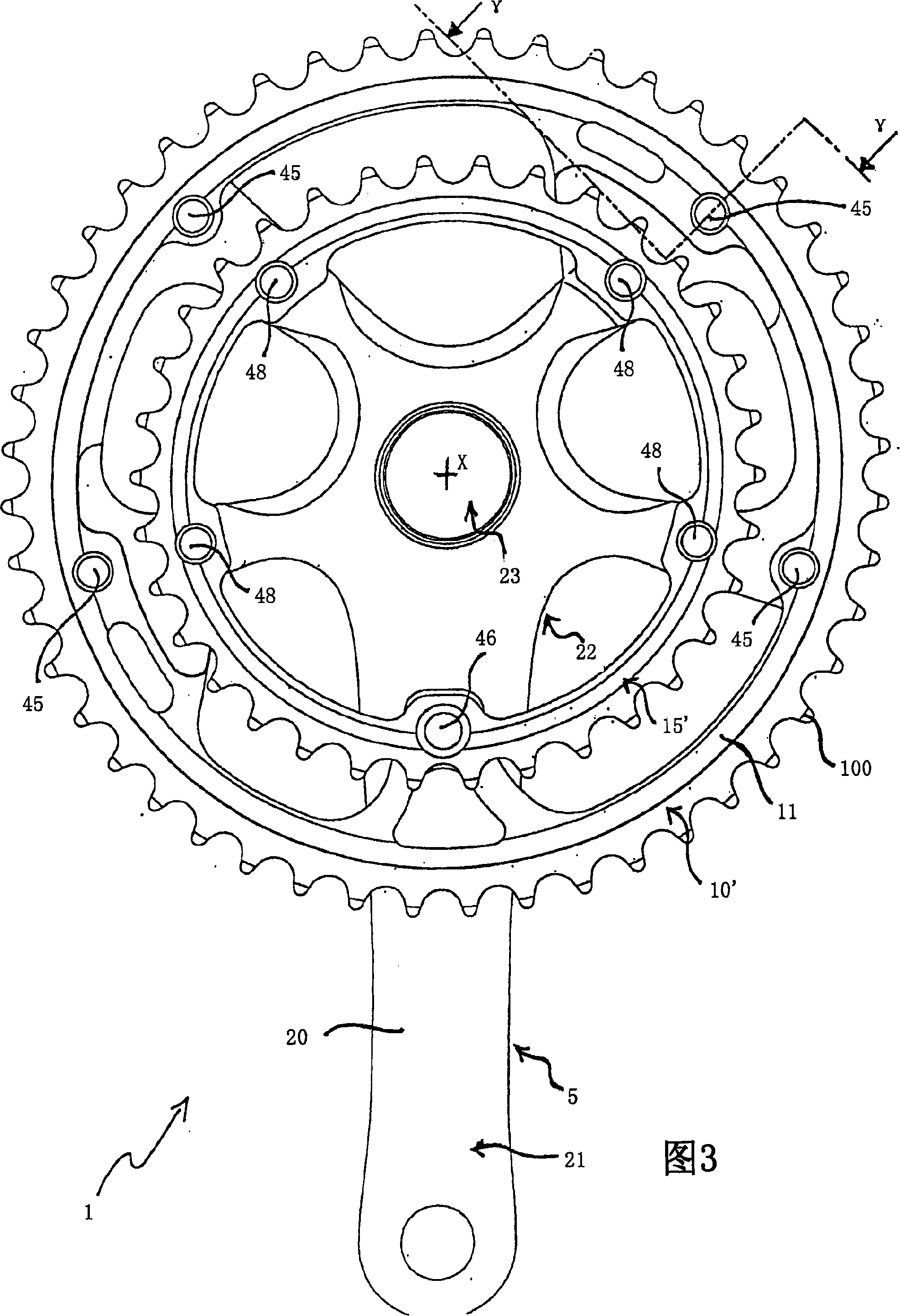

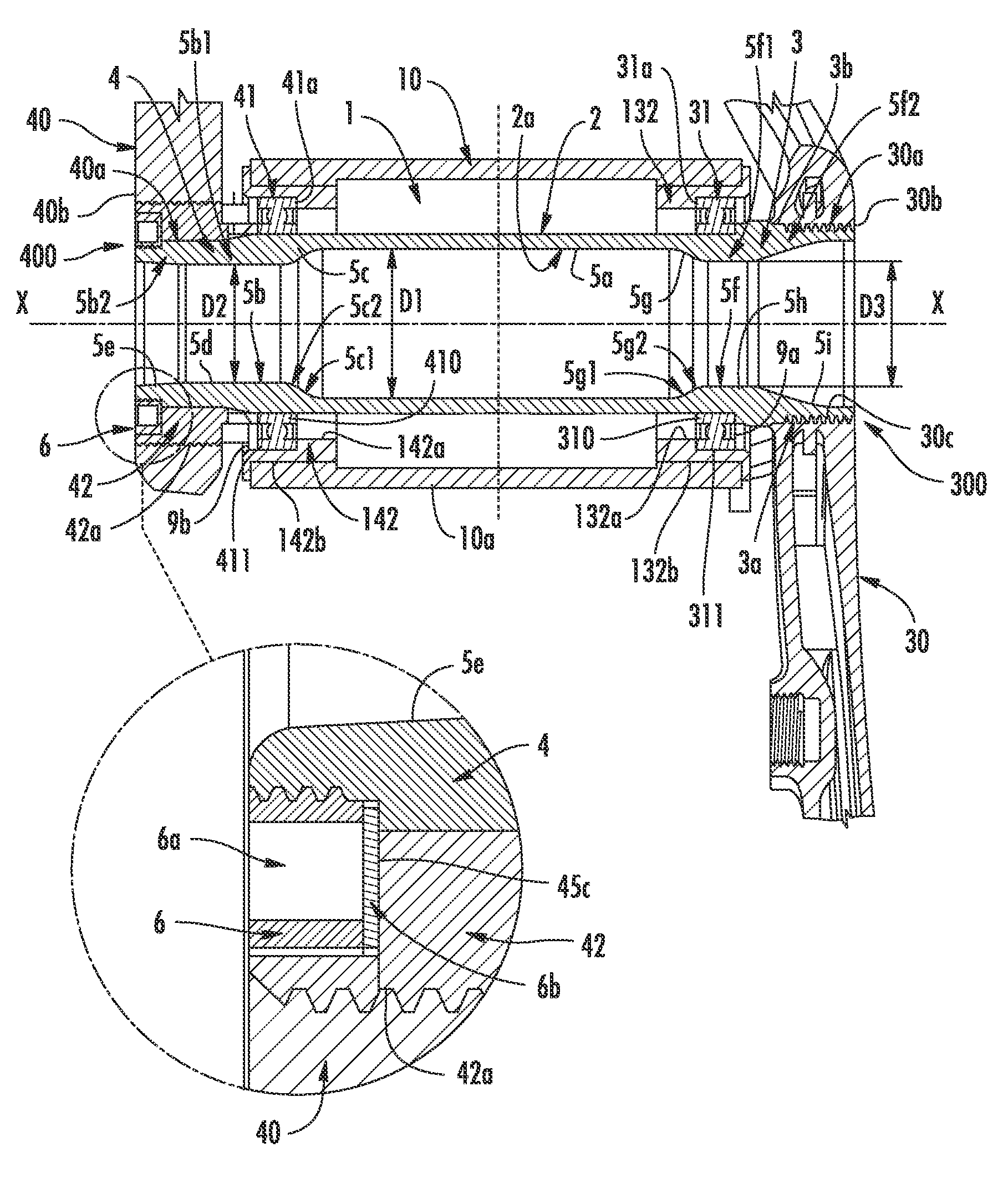

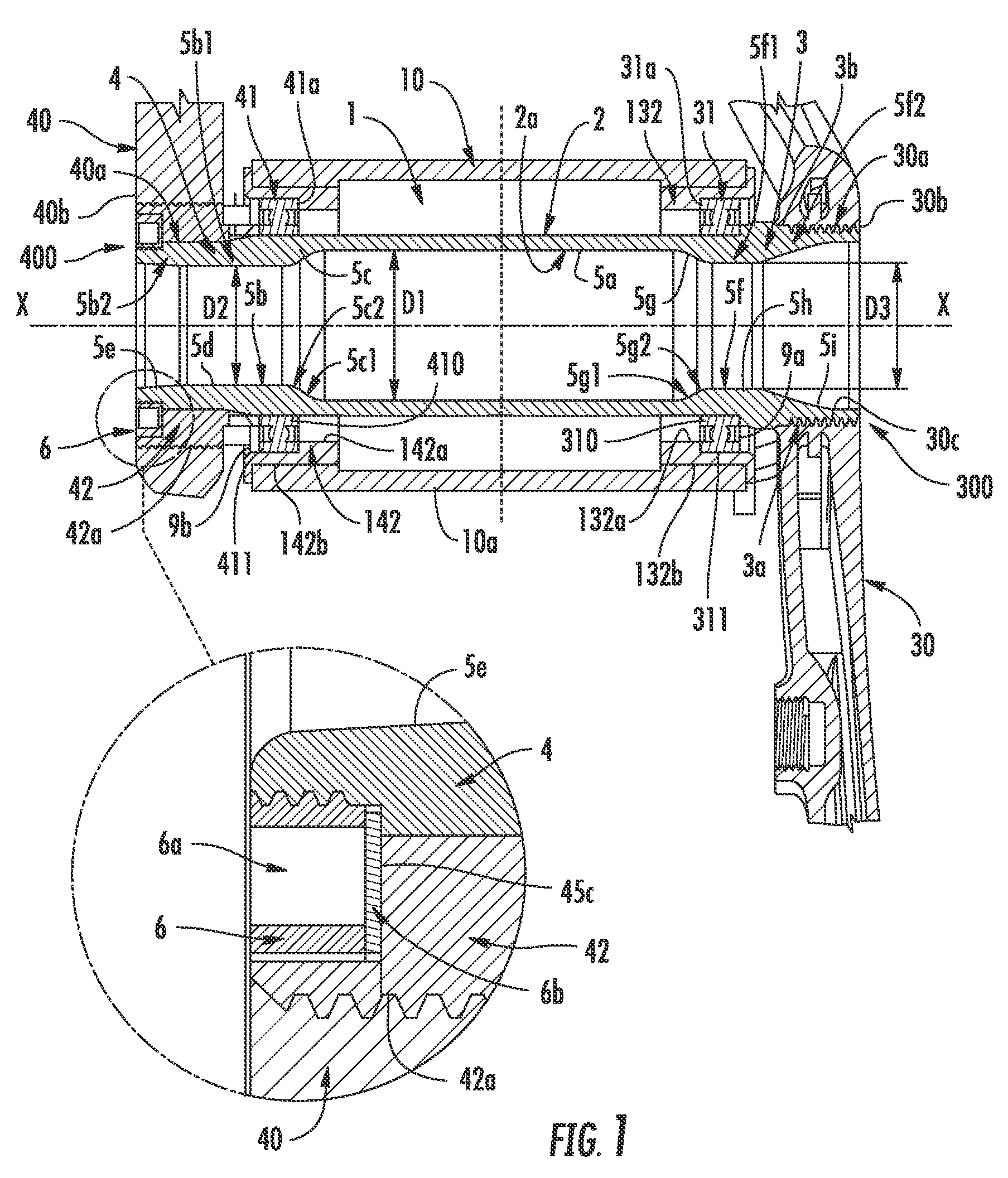

Right crank arm assembly for a bicycle and crank arm and front sprocket thereof

ActiveCN101121432AFaster and easier disassemblyVehicle cranksChain/belt transmissionVehicle frameCoupling

A right crank arm assembly (1) for a bicycle, comprises a right crank arm (5) and at least one front sprocket (10) coupled with the crank arm at at least one coupling portion (44) of the crank arm. The front sprocket (10) has an inner side adapted, in use, to face towards the frame of the bicycle and an outer side opposite the inner side. The assembly (1) comprises at least one first crank arm element (30) which acts in contact with the front sprocket (10) on one of said sides and at least one second crank arm element (35) which acts in contact with the front sprocket (10) on the other of said sides. The contact action of the crank arm elements on the two opposite sides of the front sprocket prevents the twisting deformation of the front sprocket during pedalling. Such a deformation wouldcause a reduction in the transmission efficiency of the right crank arm assembly.

Owner:CAMPAGNOLO SRL

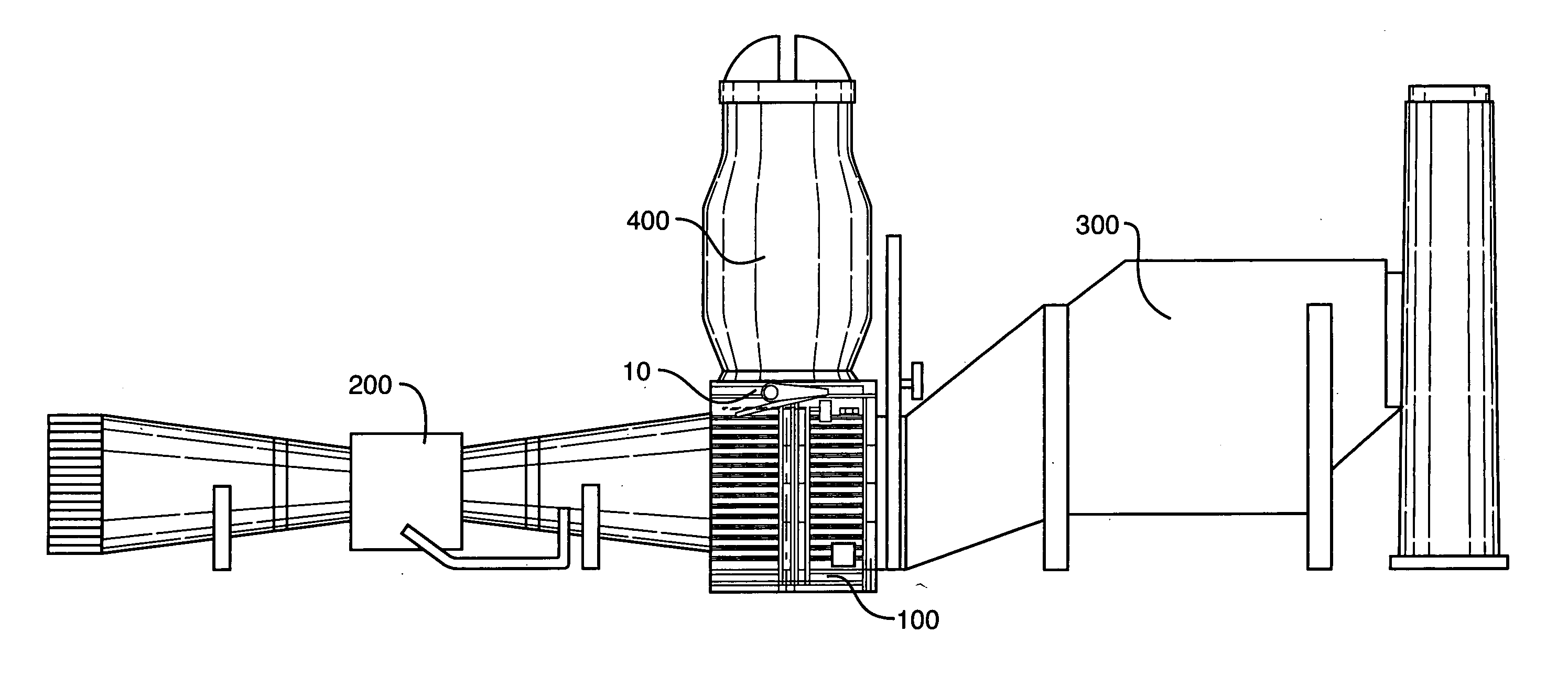

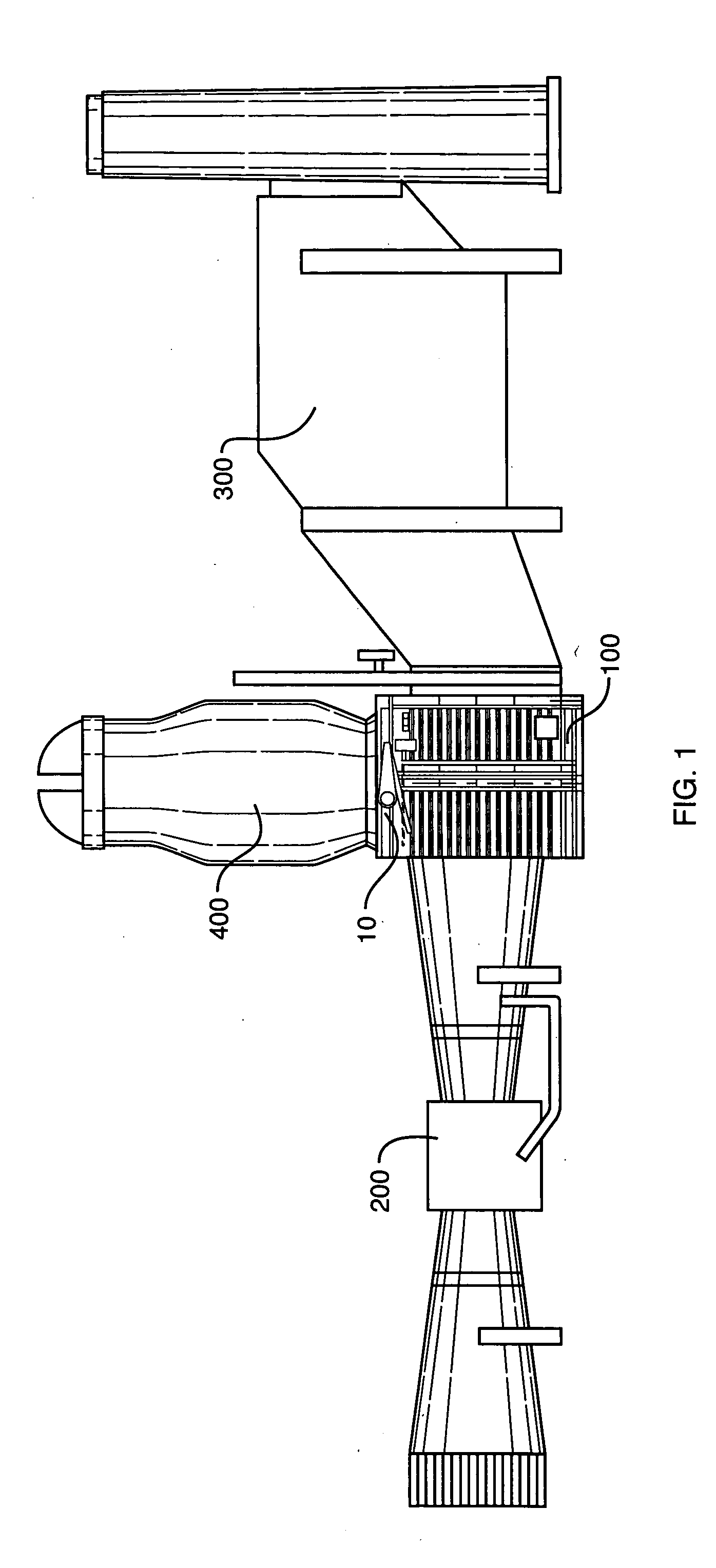

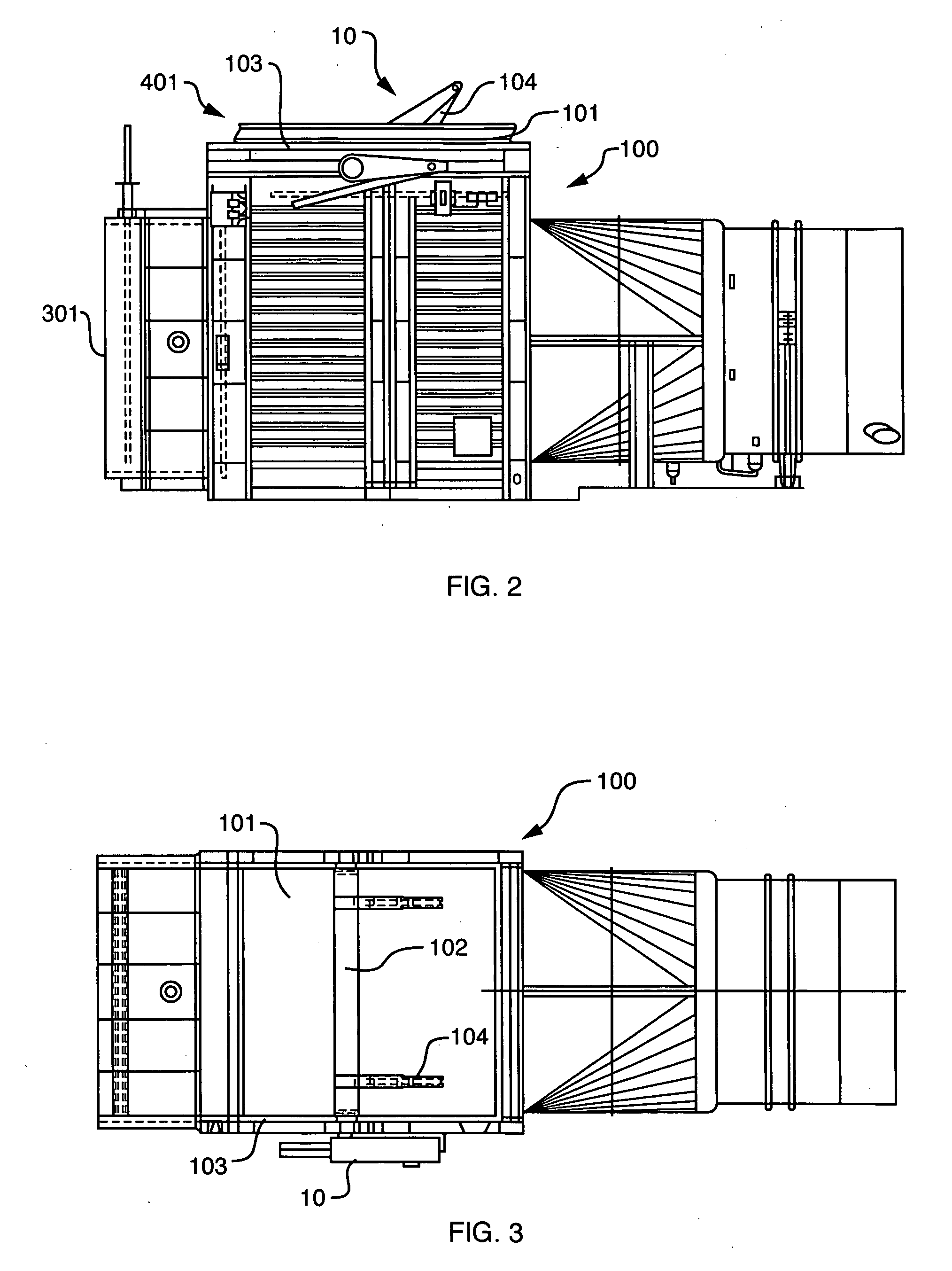

Actuation system for fluid flow diverter

InactiveUS20050166981A1Minimal complexityMinimal thermal impactOperating means/releasing devices for valvesMultiple way valvesLinear motionBall screw

An actuation system for causing movement of a fluid flow diverter. The actuation system includes a drive frame assembly, a crank arm assembly and a ball screw assembly working in combination as an electromechanical device suitable for movement of diverter devices of a wide range of sizes. The drive frame assembly is connected to the diverter. The crank arm assembly is attached to the diverter's diverting component, such as a damper flap. The crank arm assembly is connected to the ball screw assembly such that movement of the ball screw forces pivotal movement of the crank arm and, in turn, the diverter's diverting component. A variable speed motor causes linear movement of a ball screw along a fixed rod, with the crank arm assembly connected to the movable ball screw. A drive lockout assembly ensures that movement of the ball screw occurs only under controlled conditions.

Owner:BACHMANN INDUSTRIES

Rotatable container interior cleaning mechanism

InactiveUS8479343B2Maximize contactPrevent slidingBrush bodiesHollow article cleaningHand heldEngineering

A hand-held, collapsible, self-adjusting mechanism, which is an improvement to the Spatula, for removing the remaining contents inside a plurality of containers. The device consists of three attached arms, two lower arms geared around their pivot ends to each other to keep their rotation symmetrical in relation to a drive arm, and pressurized with a double torsion spring to rotate towards said drive arm to apply pressure to a swiveling attachment receiver at the opposite end which makes contact with the inside walls of a container. The drive arm has a foldable crank arm assembly which allows you to quickly rotate and slide the mechanism in and out within a container with one hand while the other hand supports said container thus removing the contents from the walls of the container without difficulty or a mess.References CitedU.S. Patent Documents2,065,866 A * December 1936 Clift15:2457,182,377 B2294 / 75,674,042 B65B 69 / 00414 / 4206,424,812 B1399 / 2623,934,300 15 / 2445,626,683134 / 85,732,434 15 / 93.15,491,868 15 / 236.09D262,428 D7 / 1504,106,193 30 / 1722,188,1142,065,8861,228,437, 1,184,606, 1,180,23015 / 104.18US 2005 / 0264017 A1Foreign Patent DocumentsSU001774860* November 1992 294:7EP0854099 (A1)B65D88 / 68

Owner:SMETANA MATTHEW J

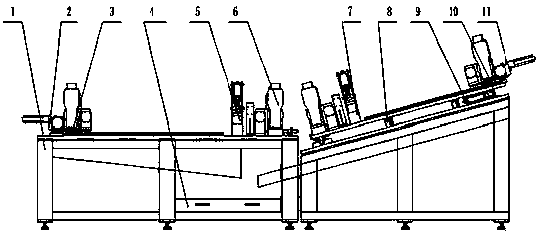

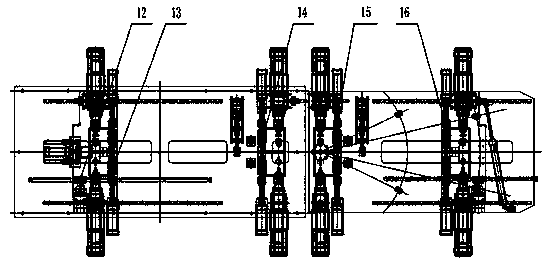

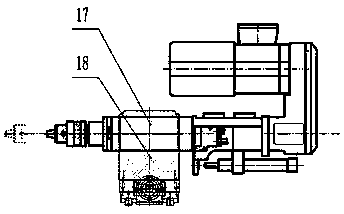

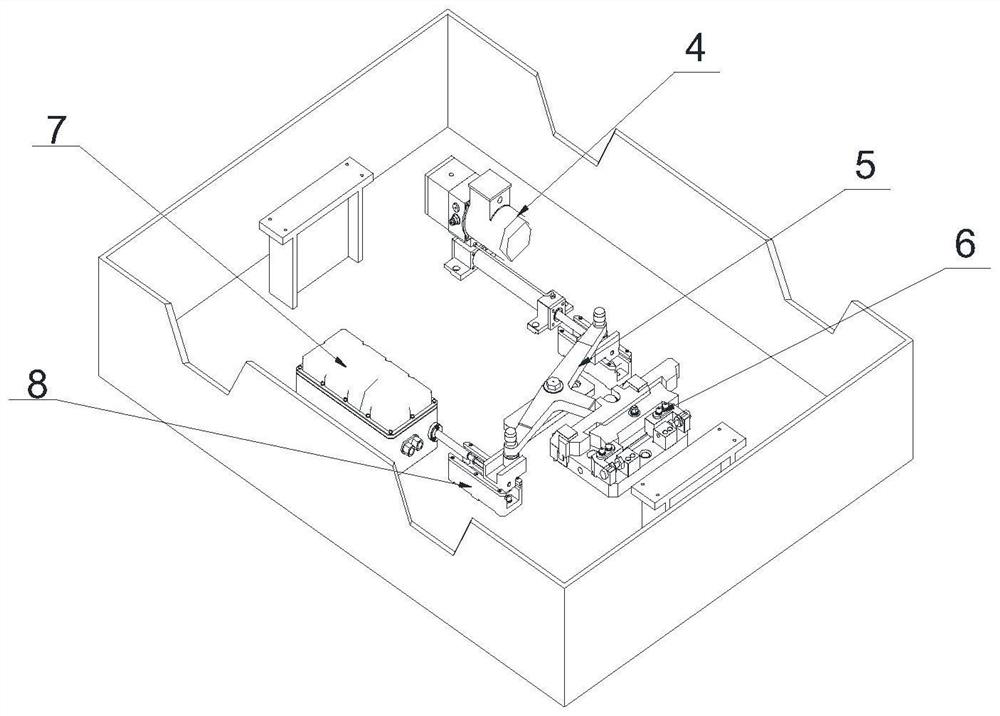

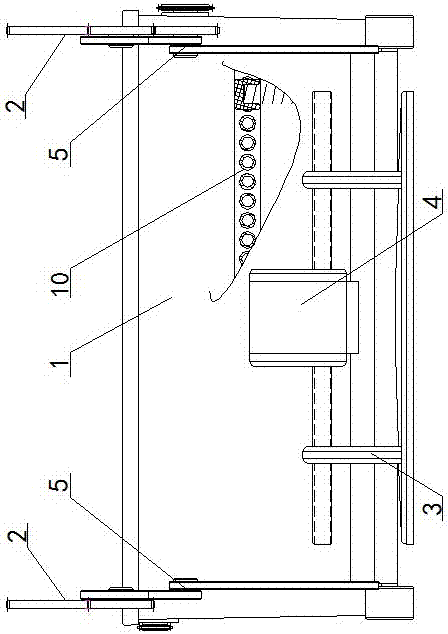

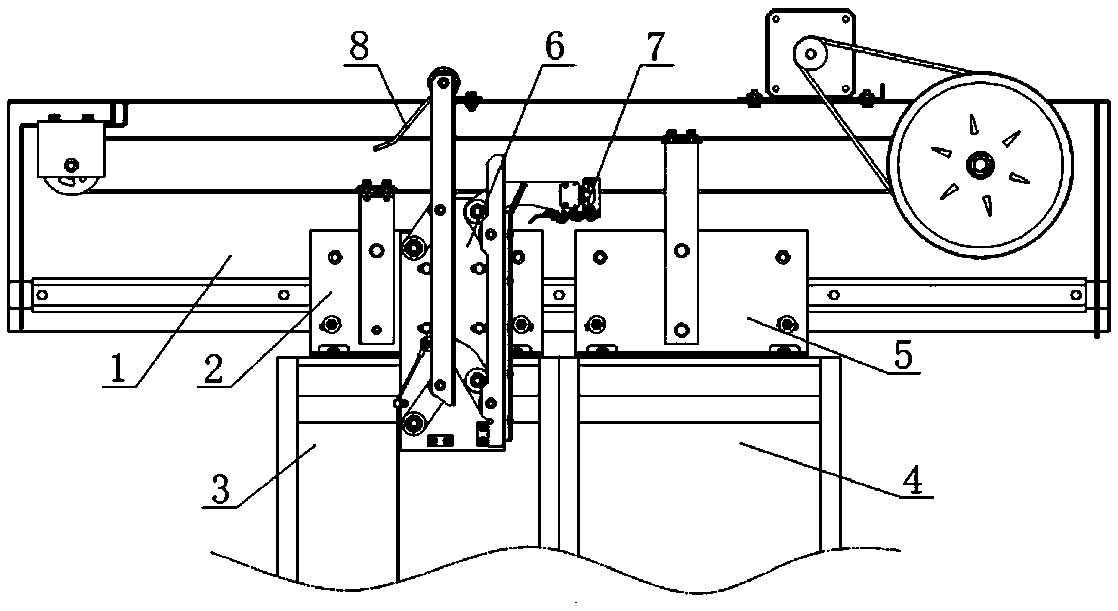

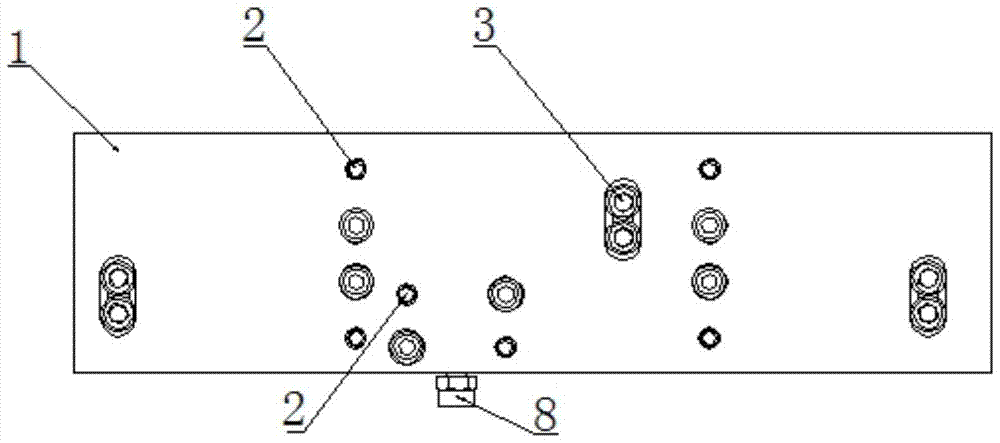

Full-automatic multi-station hole-drilling machine tool

InactiveCN104338960AShorten working timeReduce manufacturing costWork clamping meansLarge fixed membersElectronic control systemElectrical control

The invention discloses a full-automatic multi-station hole-drilling machine tool which comprises a rack as well as a horizontal power sliding platform mechanism, an inclined power sliding platform mechanism, an inclined platform rotary mechanism, a horizontal workpiece pressing mechanism, an inclined workpiece pressing mechanism, a position adjusting power mechanism and a workpiece positioning mechanism which are arranged on the rack, a chip removal mechanism, and an electronic control system for connecting the mechanisms. The full-automatic multi-station hole-drilling machine tool has two processing modes of a left crank arm and a right crank arm, eight hole-drilling power heads are adopted, and holes can be automatically formed in a sunshade crank arm assembly on eight stations through drilling. By adopting pressing devices of the machine tool, components of the sunshade crank arm assembly can be tightly compressed and combined together, and rivet holes are in optimal positions. The working time is shortened, and the product quality and the production efficiency are improved.

Owner:李明军

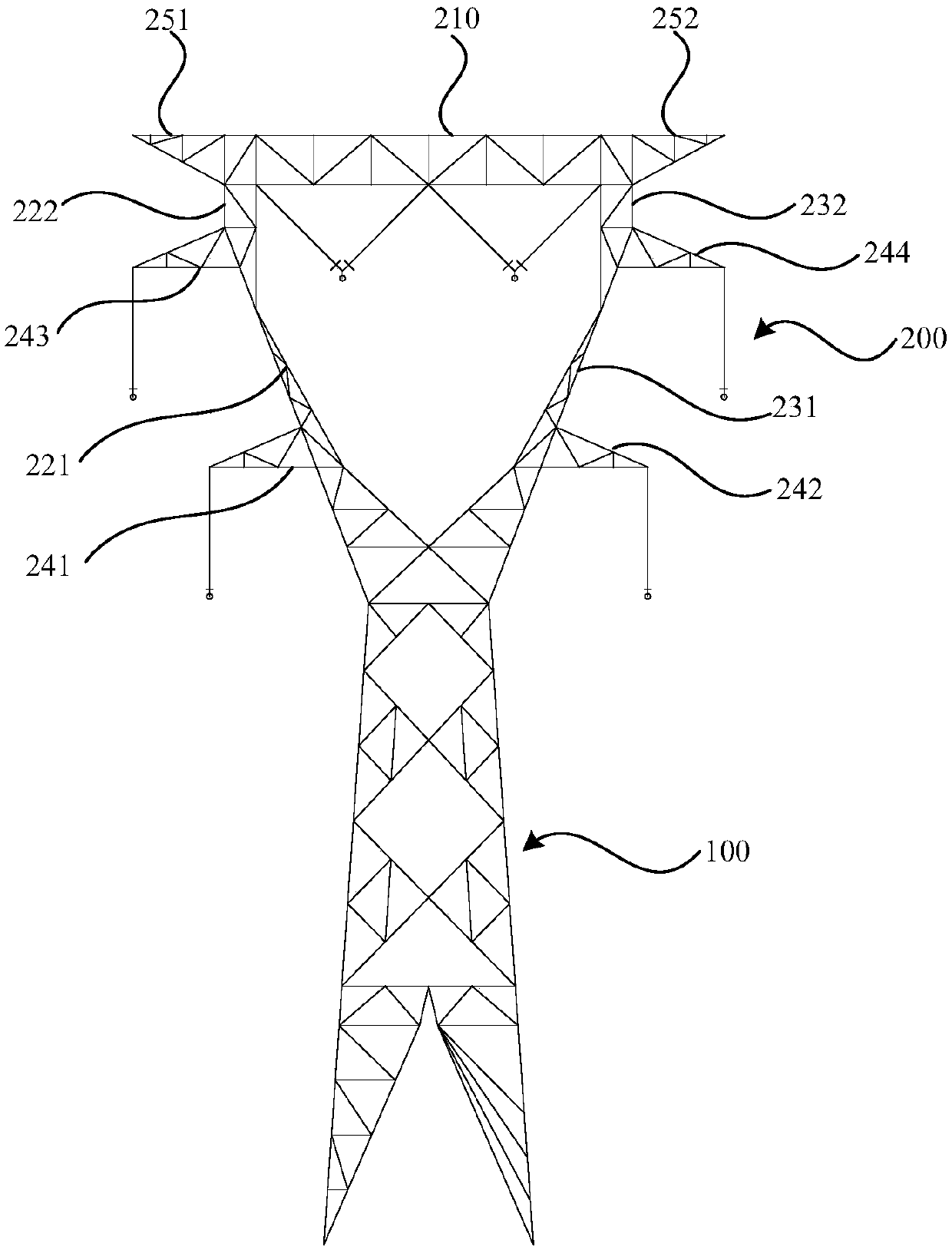

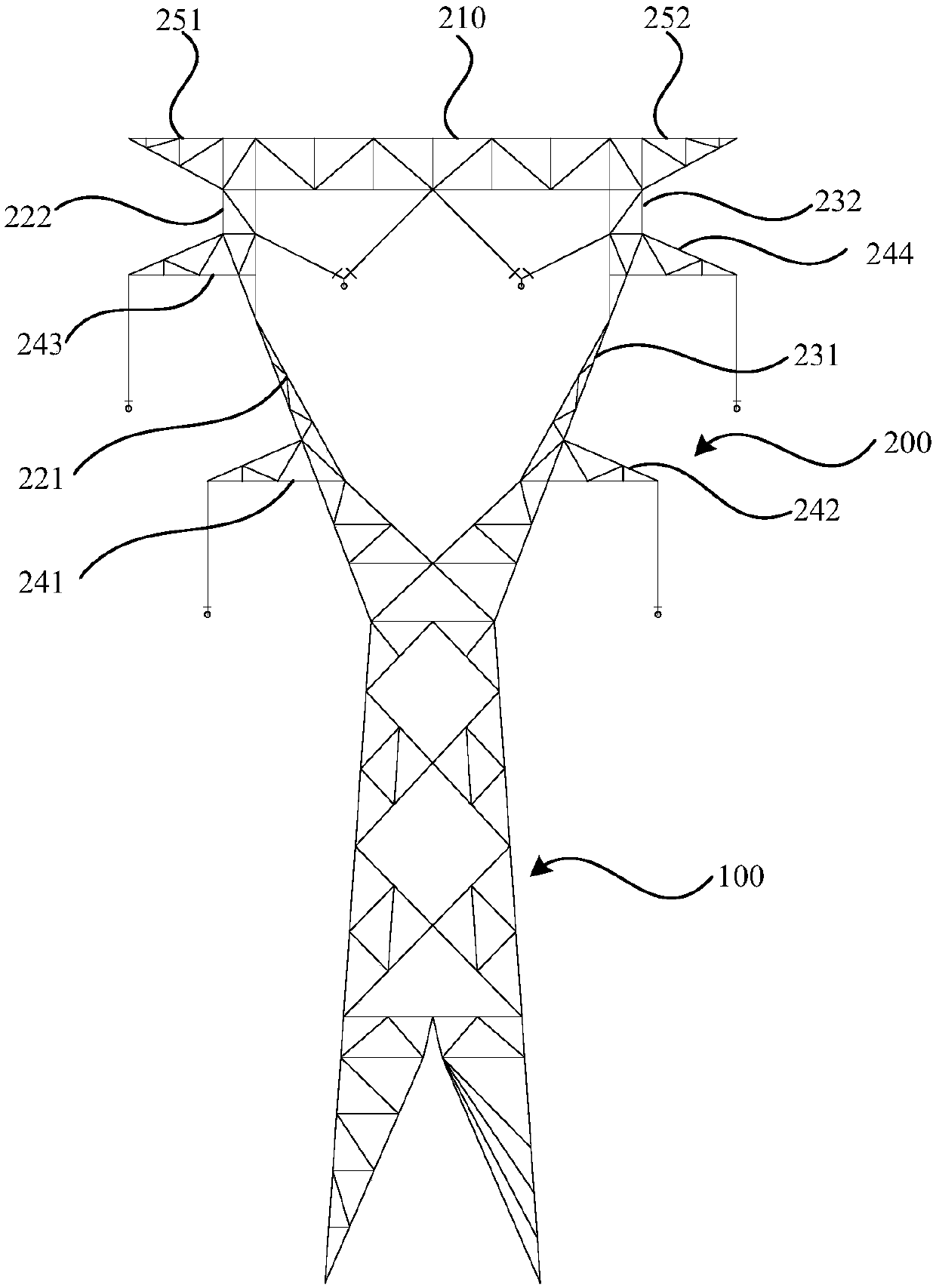

Double-loop cat-head tower and tower head structure thereof

The invention discloses a double-loop cat-head tower and a tower head structure thereof. The tower head structure comprises a first conducting-wire cross arm and a crank arm assembly, wherein the first conducting-wire cross arm can be extended and retracted in the length direction of the first conducting-wire cross arm; the crank arm assembly comprises a first crank arm and a second crank arm; oneend of the first crank arm is connected with one end of the first conducting-wire cross arm, and one end of the second crank arm is connected with the other end of the first conducting-wire cross arm; the other end of the first crank arm is rotatably and relatively connected with the other end of the second crank arm so that the first conducting-wire cross arm can horizontally move up and down; the crank arm assembly further comprises a first locking mechanism used for locking relative rotating motion of the first crank arm and the second crank arm, or the first crank arm can be extended andretracted in the length direction of the first arm, and the first crank arm can be extended and retracted in the length direction of the second arm so that the first conducting-wire cross arm can horizontally move up and down; and the crank arm assembly further comprises a second locking mechanism used for locking and loosing the extending and retracting motion of the first crank arm and the second crank arm. According to the double-loop cat-head tower and the tower head structure thereof, the height of a tower head can meet different erecting requirements.

Owner:广东天联电力设计有限公司

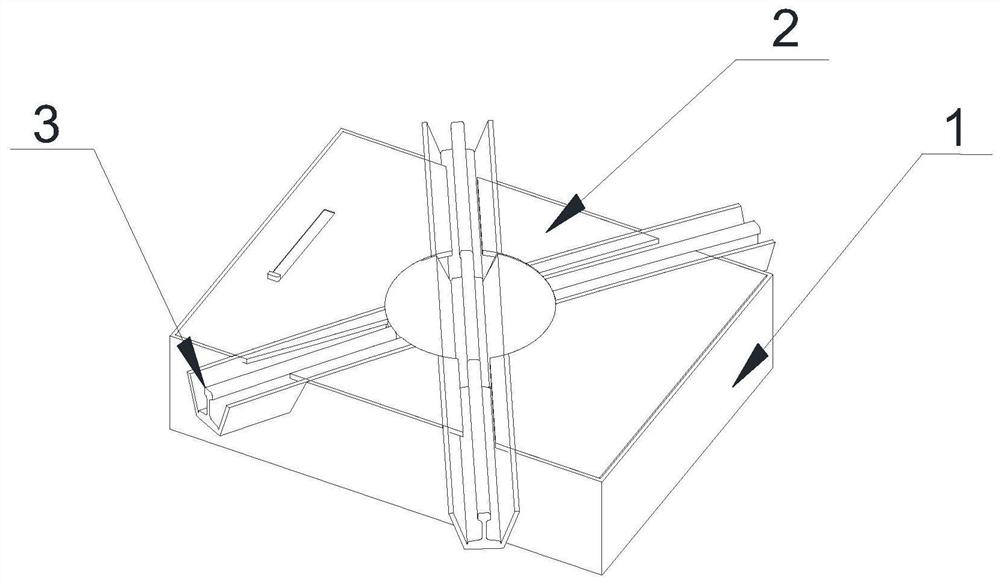

Novel circular electro-hydraulic point switch special for monorail train

ActiveCN112498415ATo achieve the function of locking the turnoutSimple structureMonorailsElectric devices for scotch-blocksCrank Arm AssemblyMonorail

The invention discloses a novel circular electro-hydraulic point switch special for a monorail train, and belongs to the technical field of urban traffic monorail trains. In order to solve the problems that in the prior art, the road conditions of monorail railways are complex, and the rail changing condition of crossed rails frequently occurs, the novel circular electro-hydraulic point switch special for the monorail train is provided and comprises a machine shell, machine covers, an electro-hydraulic driving unit, a locking mechanism and an indicating mechanism, and the machine shell is connected with the machine covers; wherein an integral turnout is clamped between the machine covers, a T-shaped crank arm assembly is fixedly connected to the integral turnout, sliding block assemblies are clamped to the two ends of the T-shaped crank arm assembly, the sliding block assemblies are fixedly connected with the electro-hydraulic driving unit and the indicating mechanism through connecting rods respectively, and the T-shaped crank arm assembly is clamped to the locking mechanism in the vertical direction. The switch machine can be installed under the ground, switch the position of a turnout, change the opening direction of the turnout, lock the turnout and reflect the position information of the turnout, and great convenience is brought to road traffic.

Owner:CRSC WANQUAN SIGNAL EQUIP

Mop machine realizing automatic operation

InactiveCN107960954ASimple structureEasy to operateCarpet cleanersFloor cleanersGear wheelCrank Arm Assembly

The invention discloses a mop machine realizing automatic operation. The mop machine is characterized in that gear plates are fixedly and symmetrically connected to two sides of a washing barrel upwards, crank arm assemblies and a transmission mechanism for driving the crank arm assemblies to rotate are connected to the washing barrel, plate type duster cloth is driven by the crank arm assemblies,and the plate type duster cloth works in a manner of mopping the floor outside the washing barrel, rotating to a scrubbing plate in the washing barrel along with the rotation of a crank arm, being soaked in stored water to be scrubbed, or being lifted to the water surface along with the scrubbing plate to be rubbed to be dry. Compared with the prior art, the mop machine realizing automatic operation has the advantages of automatic cleaning for floor mopping and automatic cleaning of a mop, the structure is simple, the operation is convenient and reliable, and the beneficial effects are obvious.

Owner:FUZHOU GENGYUN PATENT DEV +1

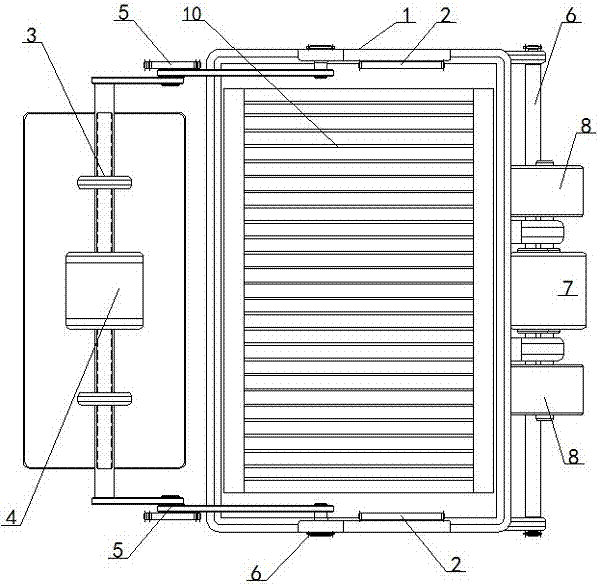

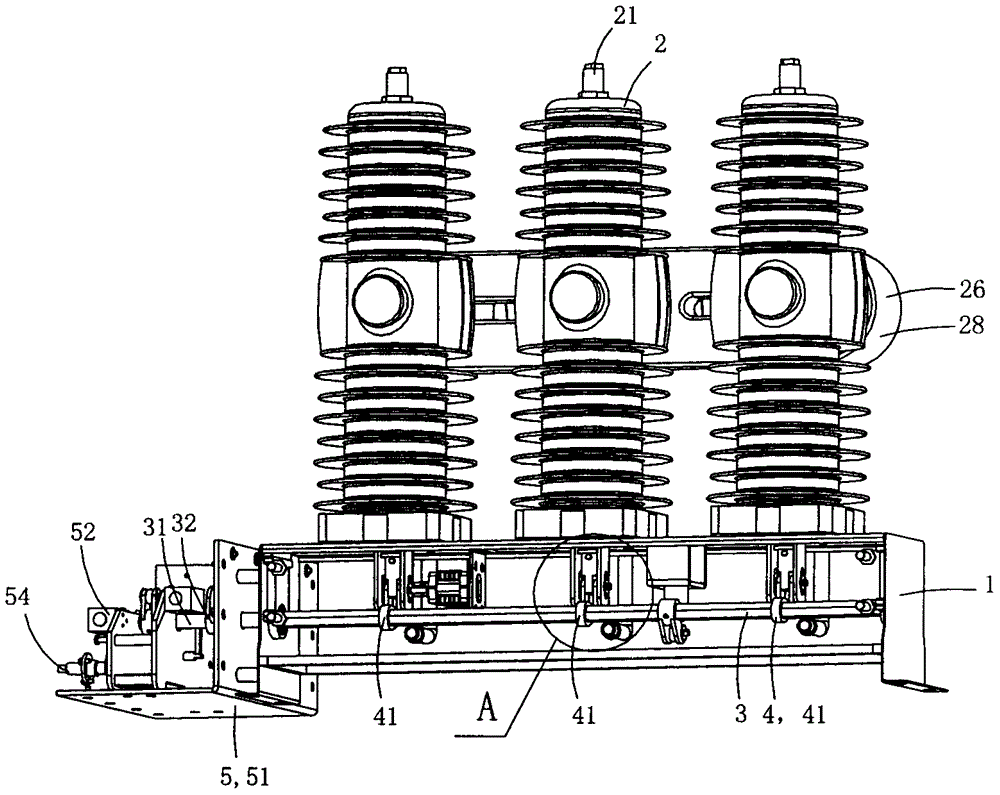

Side-mounted high-voltage vacuum circuit breaker

InactiveCN105719890AReduce manufacturing costHigh-tension/heavy-dress switchesAir-break switchesHigh pressureCrank Arm Assembly

The invention discloses a side-mounted high-voltage vacuum circuit breaker, which includes a base and three poles; an operating mechanism for driving the opening and closing main shaft to rotate is provided on the outside of the base shell; The transmission crank arm on the main shaft of the gate, the reinforced limit plate with a limit slide hole fixed on the top wall of the base, the transmission plate, the upper pin shaft and the lower pin shaft; the lower end of the transmission plate passes through the lower pin shaft and the transmission crank arm Rotationally connected, the upper end of the transmission plate is connected with the bottom end of a corresponding insulating rod through the upper pin shaft; the upper pin shaft is located in the limit slide hole of the reinforced limit plate; The plate drives the insulating pull rod; the operating mechanism drives the opening and closing main shaft to reciprocate; under the cooperation limit of the upper pin shaft and the limit slide hole, the opening and closing main shaft synchronously drives the three insulating pull rods along the up and down direction through the three crank arm components. Reciprocating movement for opening and closing action. The invention can be applied in traditional switch cabinets and ring network cabinets.

Owner:苏刚印

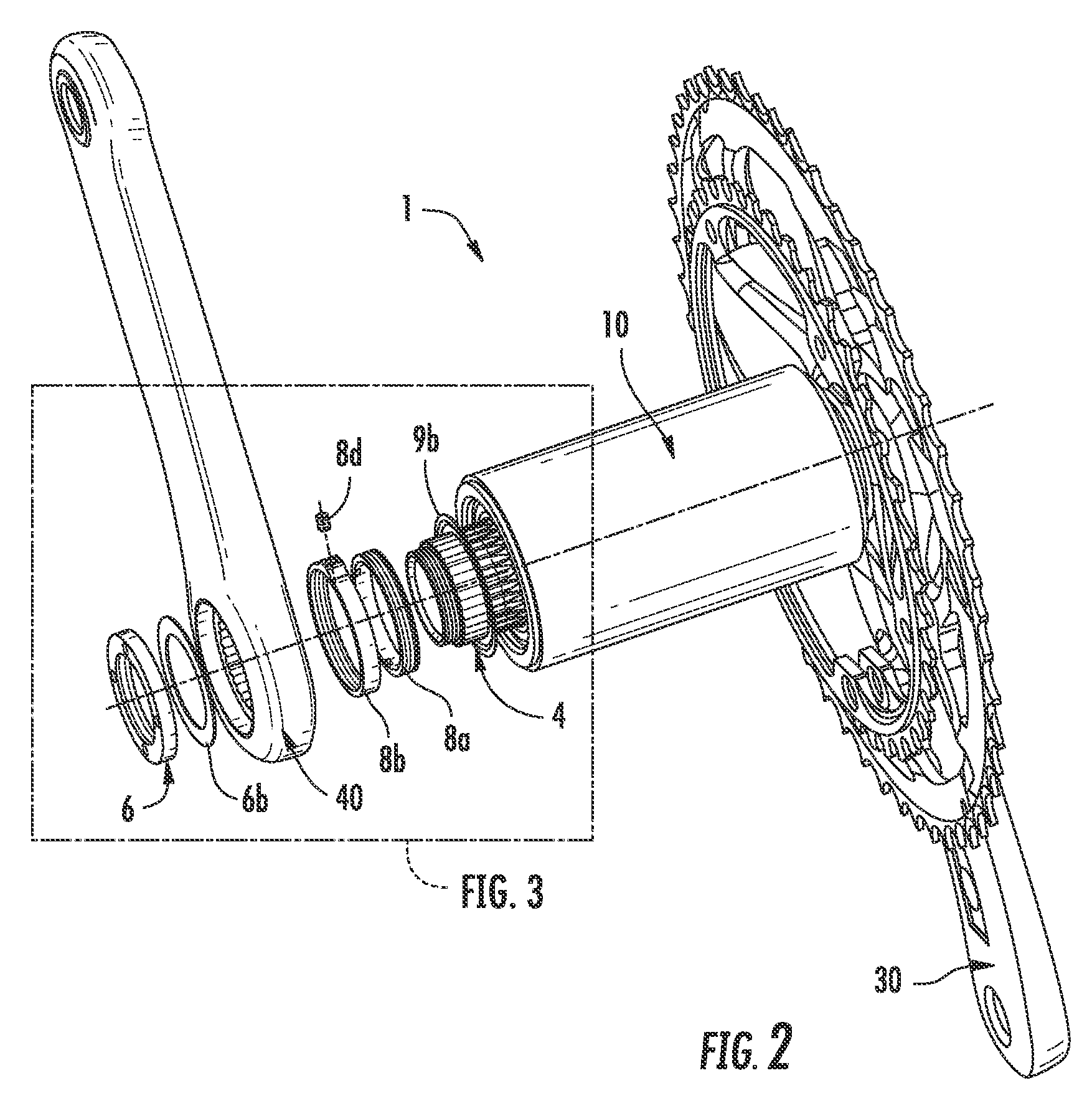

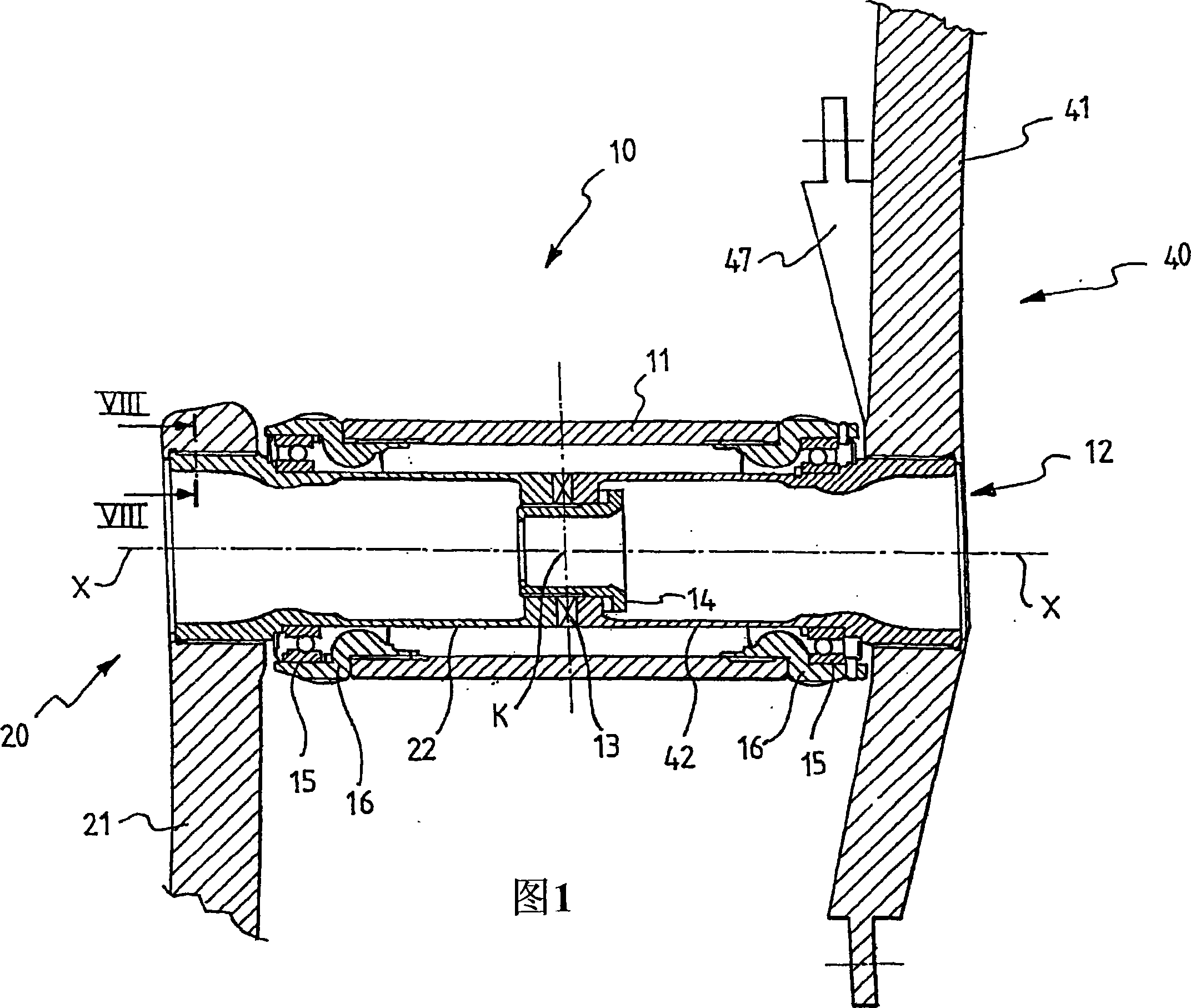

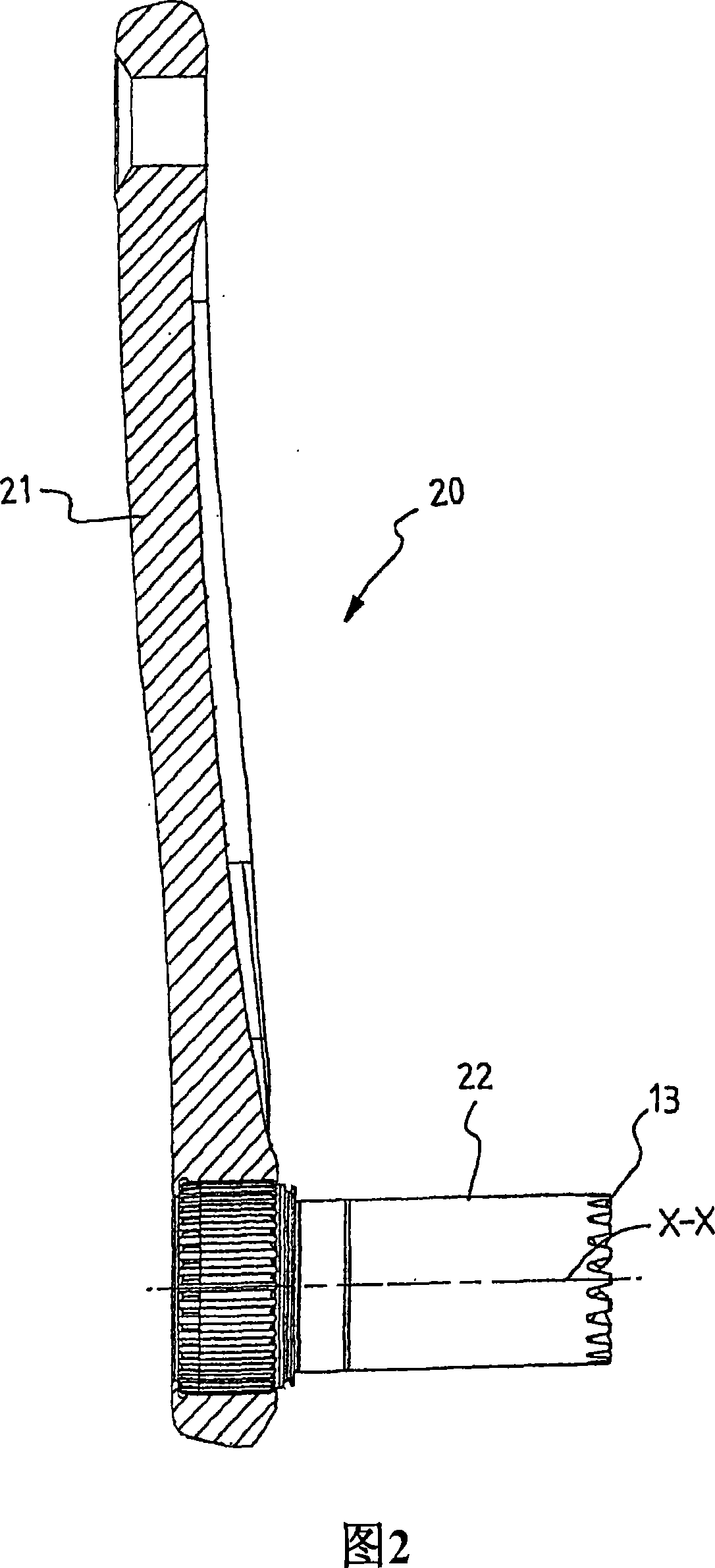

Bottom bracket assembly of a bicycle and left crank arm assembly thereof

ActiveUS8925948B2Reduce accumulationFoot-driven leversMechanical apparatusCrank Arm AssemblyMechanical engineering

A bicycle bottom bracket assembly that reduces the accumulation of dirt and / or corrosive substances inside the shaft extending between the crank arms of the assembly. The bottom bracket assembly includes a shaft having a through-cavity that extends along its longitudinal direction; a crank arm is associated with each end portion of the shaft, and the through-cavity extends unobstructed through the crank arms and the shaft.

Owner:CAMPAGNOLO SRL

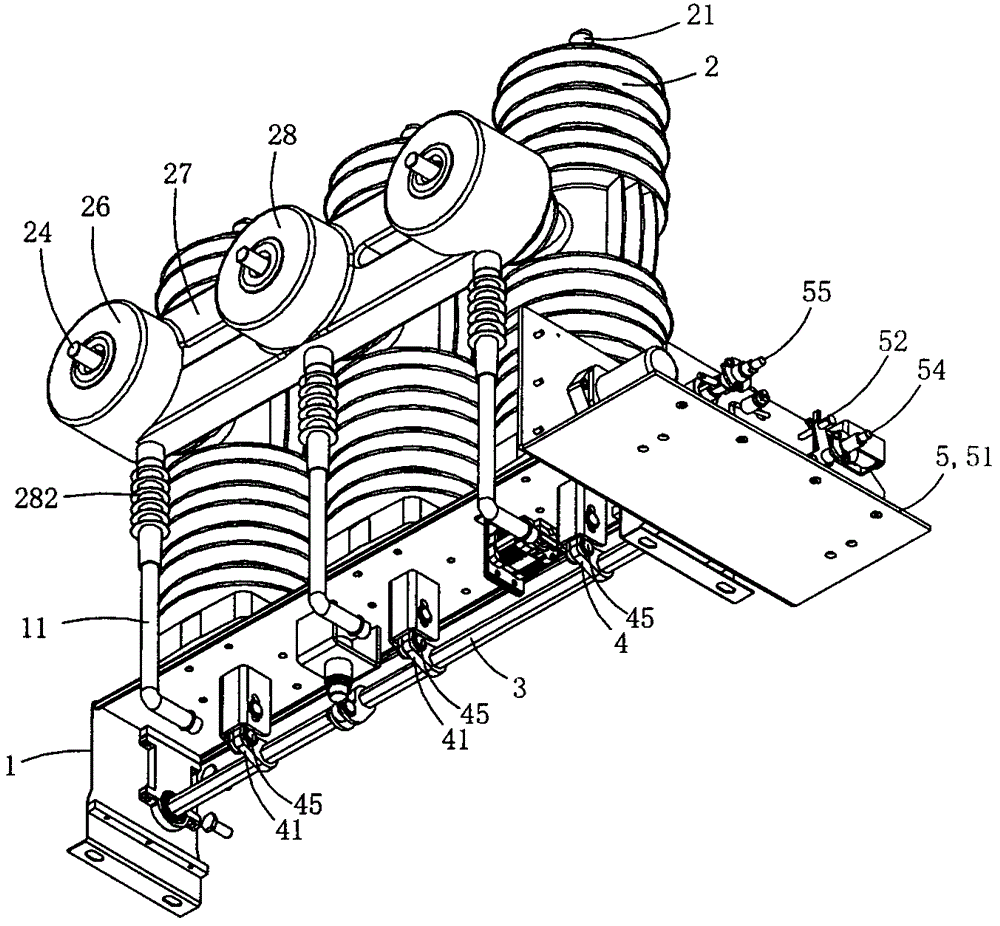

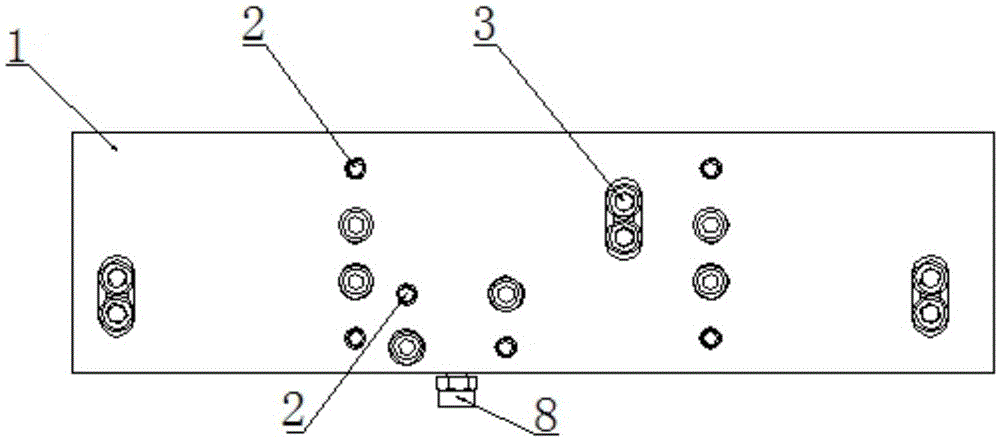

Tool for assembling energy storage component of circuit breaker and assembling method thereof

ActiveCN105428164AAssembly precisionQuick assemblyEmergency protective device manufactureCrank Arm AssemblyCam

The invention discloses a tool for assembling an energy storage component of a circuit breaker. The energy storage component of the circuit breaker is provided with an energy storage shaft on which a first spring crank arm, a first bearing, a cam, a gear assembly, an energy storage crank arm assembly, a second bearing and a second spring crank arm are successively arranged. The tool is provided with a base board. The base board is provided with two supporting boards which are respectively used for supporting the first bearing and the second bearing. The base board is provided with spacing blocks which respectively suppress the first spring crank arm and the second spring crank arm at the sides of the two supporting boards. The base board is provided with a spacing block for suppressing the assembling position of the energy storage crank arm and a block for suppressing the position of the cam between the two supporting plates. The tool for assembling the energy storage component of the circuit breaker has advantages of simple structure, low manufacture cost, accurate and quick assembling of the energy storage component, simple operation and high operation efficiency.

Owner:ANHUI SENYUAN ELECTRICAL

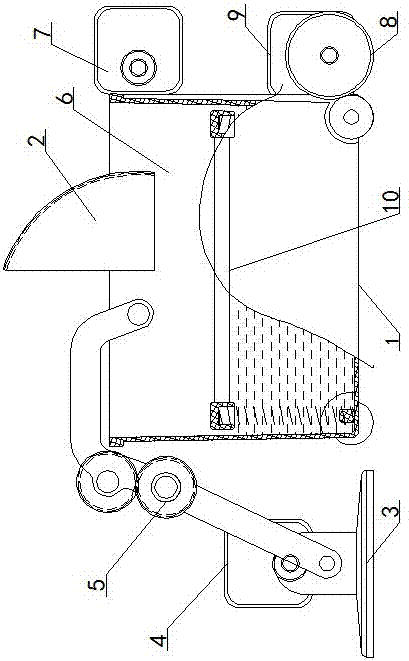

Door vane of elevator door and unlocking device

ActiveCN107720505AImprove securityImprove economyBuilding liftsSustainable buildingsStructural engineeringCrank Arm Assembly

The invention provides a door vane of an elevator door and an unlocking device. The door vane of the elevator door includes a door vane bottom plate, a left blade, a right blade, a lower crank arm assembly and a latch hook assembly. The left blade is installed on one side of the door vane bottom plate in the vertical direction and hinged to the door vane bottom plate through a connecting rod. Theright blade is installed on the other side of the door vane bottom plate in the vertical direction and the upper end of the right blade is hinged to the latch hook assembly and the door vane bottom plate through a rotation shaft. The lower end of the right blade is hinged to the lower bending arm assembly and the door vane bottom plate through a rotation shaft. The upper end of the left blade is provided with a rolling wheel. The latch hook assembly is elastically connected with the door vane bottom plate through a small tension spring. Through the adoption of the technical scheme, an elevatorcar is improved in terms of security and economy, the door vane can gradually replace an existing traditional door vane product, the latest standard requirements and the industry development trend are met and the wide application prospect is achieved; and the door vane of the elevator door is simple in structure, easy to install, low in cost and convenient to maintain.

Owner:NINGBO XINDA ELEVATOR FITTINGS FACTORY

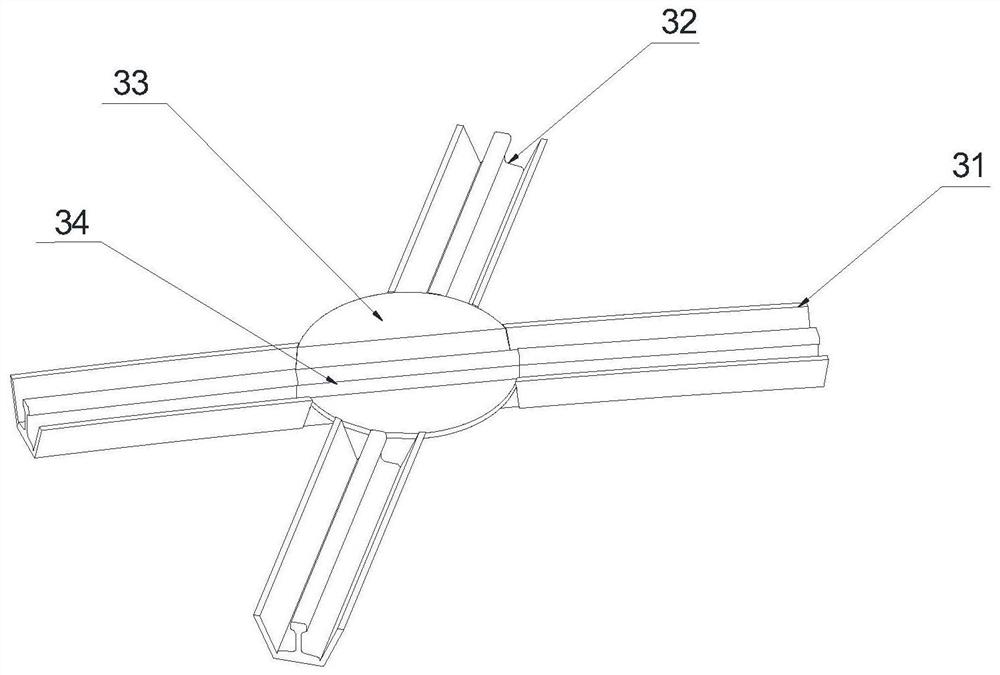

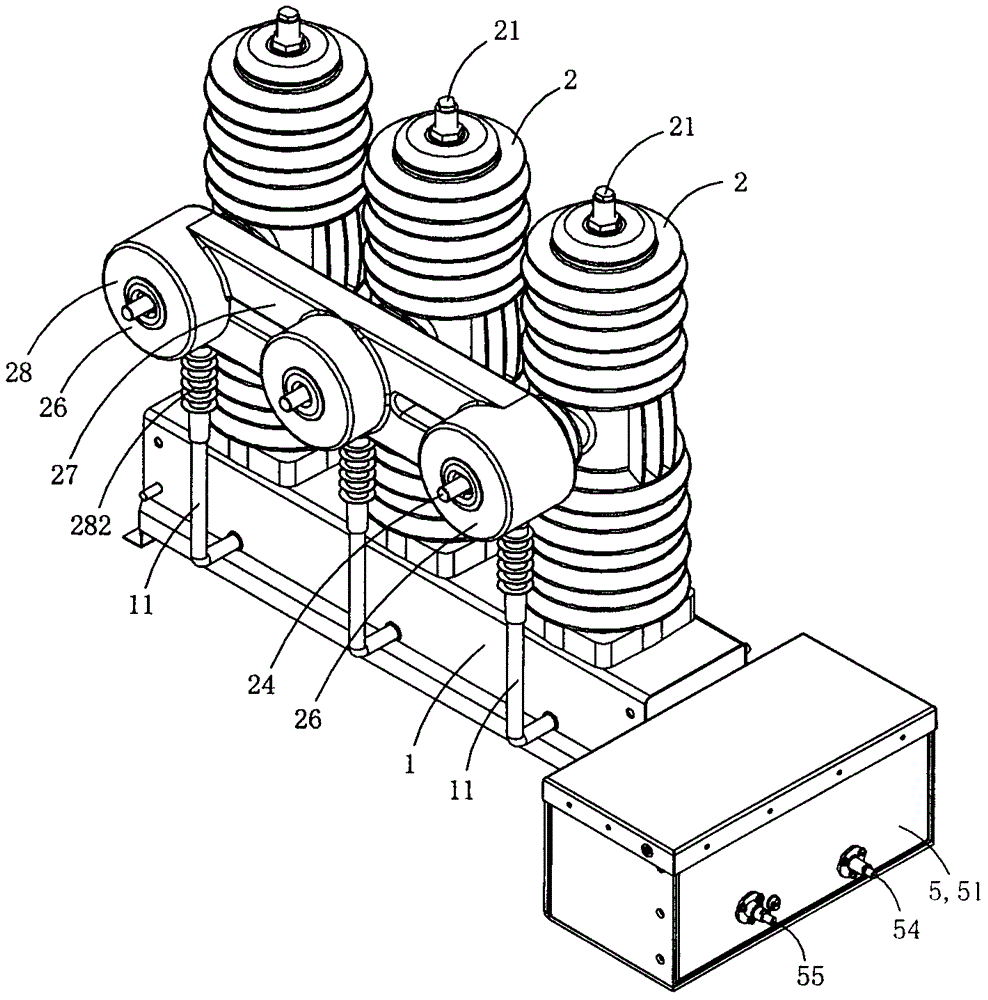

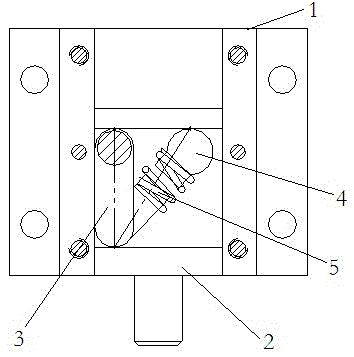

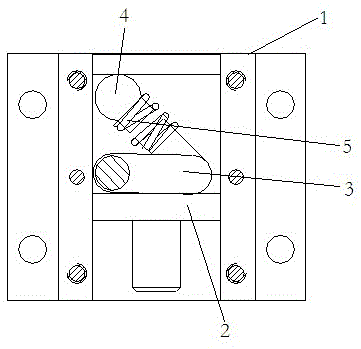

Crank arm assembly and power transmission self-locking mechanism using crank arm assembly

The invention relates to a crank arm assembly and a power transmission self-locking mechanism using the crank arm assembly. The power transmission self-locking mechanism comprises a guide post which can move up and down in a guiding mode. The guide post is provided with a transmission groove. The crank arm assembly is arranged inside the transmission groove and comprises a power input shaft, a connecting shaft, an installing shaft and a jacking head, wherein the connecting shaft is perpendicularly arranged on the power input shaft, and the jacking head is connected to the installing shaft through a spring and used for being in pushing fit with the upper groove wall of the transmission groove in the guide post in a sliding mode. When the crank arm assembly is located at an extending locking station, the upward force is applied to the upper groove wall of the transmission groove through the jacking head, the downward force is applied to the lower groove wall of the transmission groove through the tail end of the connecting shaft, and locking is conducted on the crank arm assembly in the extending position. When the crank arm assembly is located at a retracting locking station, the upward force is applied to the upper groove wall of the transmission groove through the jacking head, the downward force is applied to the lower groove wall of the transmission groove through the outer peripheral face of the connecting shaft, and locking is conducted on the crank arm assembly in the retracting position. According to the crank arm assembly and the power transmission self-locking mechanism using the crank arm assembly, an additional locking mechanism for locking a crank arm in the prior art is omitted, and the structure is simple.

Owner:HENAN PINGGAO ELECTRIC +2

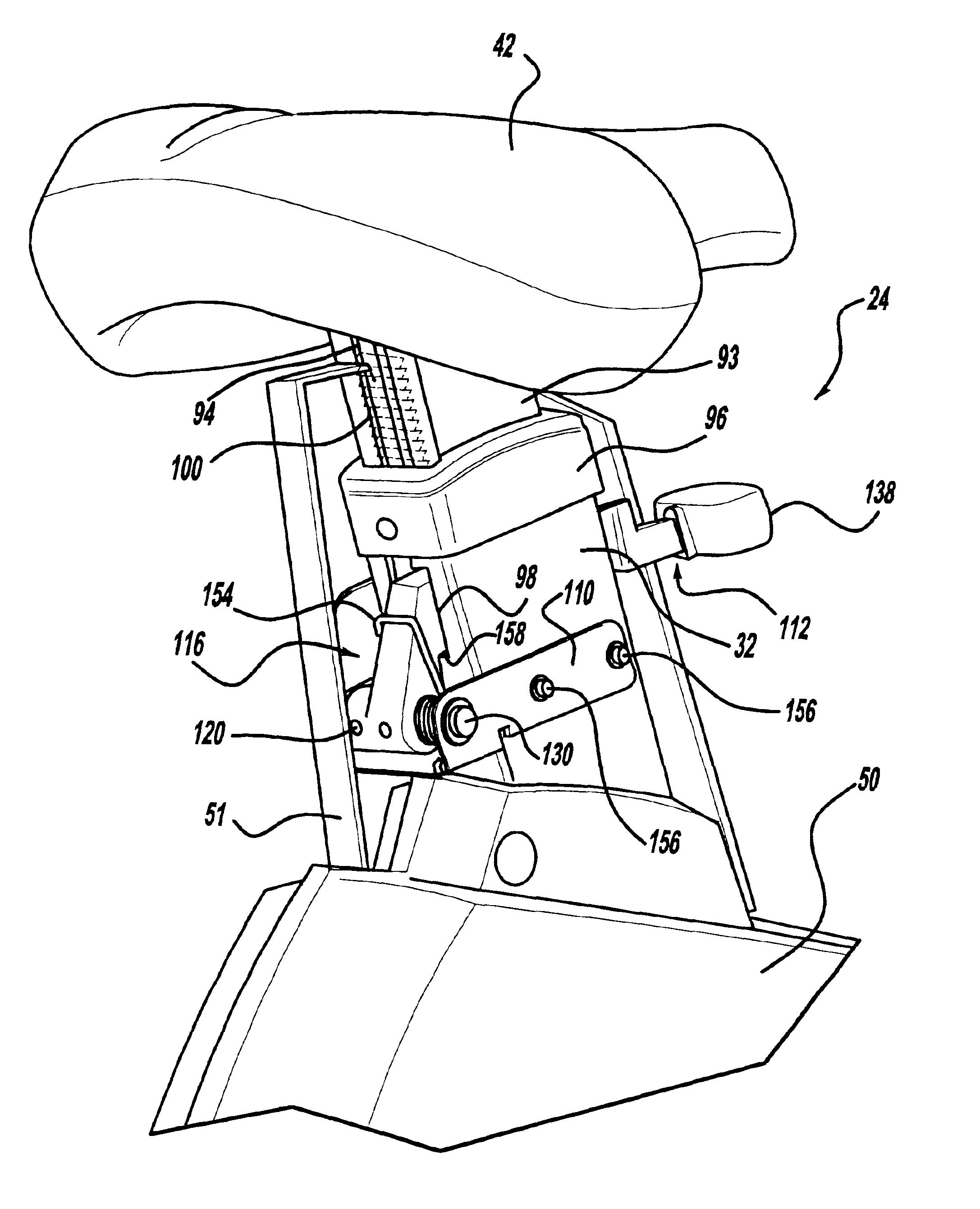

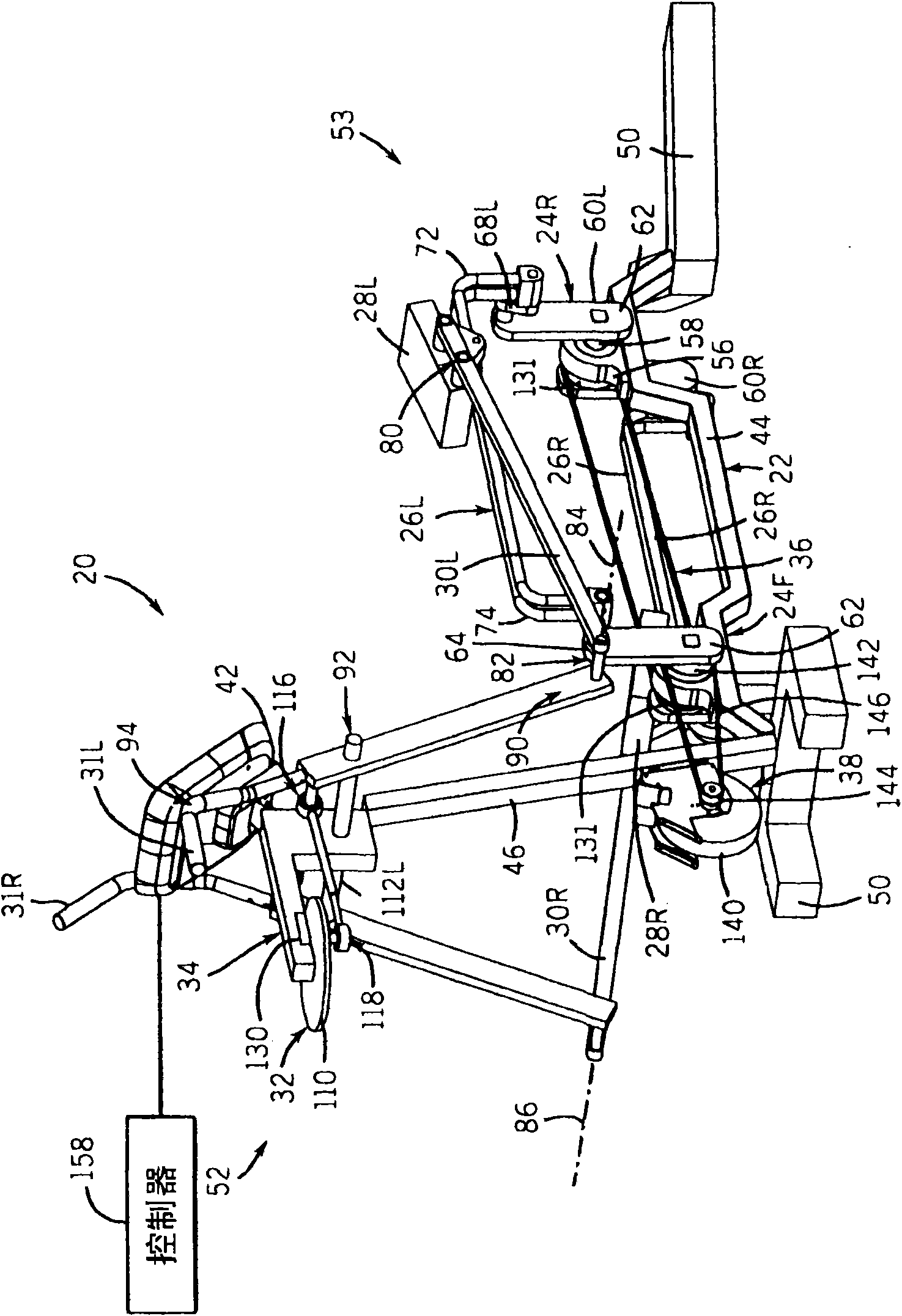

Adaptive motion exercise device with plural crank assemblies

An exercise device includes a first crank arm assembly (24R) and a second crank arm assembly (24F) supporting opposite portions of a guide (26). A first foot pad (28) is coupled to the guide (26) to reciprocate along the guide. A foot pad link (30) has a first end portion (80) pivotably connected to the foot pad (28) and a second end portion (82) pivotably supported about an axis that is movable along one of a plurality of user selectable paths, each of the plurality of user selectable paths having a different length.

Owner:PRECOR

Demolding driving mechanism for casting mold

The invention relates to a demolding driving mechanism for a casting mold. The demolding driving mechanism comprises an upper mounting plate used for positioning and dragging an upper mold, the upper mounting plate is provided with movable holes which are arranged in a long-hole-shaped mode in the internal direction and the external direction, and sliding blocks are arranged on the upper mounting plate; the demolding driving mechanism further comprises driving rods for connecting side molds, the top end of each driving rod is connected with the corresponding sliding block to form a crank arm assembly, the driving rods penetrate through the upper movable holes to extend downwards to enable the bottom ends of the driving rods to be connected with the side molds, and one crank arm assembly is used in each movable hole in a matched mode; guide portions are arranged on the upper mounting plate, each guide portion is provided with an inclined plane which inclines outwards and upwards, and each sliding block is provided with a sliding plane matched with the corresponding inclined plane and arranged on the inclined plane; the demolding driving mechanism further comprises a pushing plate located on the sliding blocks, and the pushing plate can vertically and perpendicularly push the sliding blocks. In this way, the demolding driving mechanism and the mold are connected into a whole to form a two-dimensional demolding device, and separation among the upper mold, the side molds and a casting is achieved.

Owner:FOSHAN NANHAI SUPERBAND MOLD

Bicycle crank arm assembly

A bicycle crank arm assembly is provided having at least one axle portion, a crank arm mounted on the at least one axle portion, the crank arm having a coupling seat and the axle portion a coupling portion coupled to the coupling seat, the coupling seat and the coupling portion being shaped so as to make a shape coupling to ensure that the crank arm can transmit a torque to the axle portion. Between the crank arm and the axle portion adhesive material is applied. The shape coupling ensures that the crank arm and the axle portion are integral in rotation, whereas the gluing ensures the sealing of the coupling area against corrosion phenomena. The gluing also ensures a predetermined minimum force limit necessary to disassemble the crank arm assembly. The crank arm assembly has a low overall weight, a simple assembly process, and a suitable resistance to disassembling.

Owner:CAMPAGNOLO SRL

Tooling for assembling circuit breaker energy storage components and assembly method thereof

ActiveCN105428164BAssembly precisionQuick assemblyEmergency protective device manufactureEngineeringCrank Arm Assembly

The invention discloses a tool for assembling an energy storage component of a circuit breaker. The energy storage component of the circuit breaker is provided with an energy storage shaft on which a first spring crank arm, a first bearing, a cam, a gear assembly, an energy storage crank arm assembly, a second bearing and a second spring crank arm are successively arranged. The tool is provided with a base board. The base board is provided with two supporting boards which are respectively used for supporting the first bearing and the second bearing. The base board is provided with spacing blocks which respectively suppress the first spring crank arm and the second spring crank arm at the sides of the two supporting boards. The base board is provided with a spacing block for suppressing the assembling position of the energy storage crank arm and a block for suppressing the position of the cam between the two supporting plates. The tool for assembling the energy storage component of the circuit breaker has advantages of simple structure, low manufacture cost, accurate and quick assembling of the energy storage component, simple operation and high operation efficiency.

Owner:ANHUI SENYUAN ELECTRICAL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com