Bicycle crank arm assembly

A bicycle and crank arm technology, applied in the field of bicycle crank arm components, can solve problems such as inaccuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

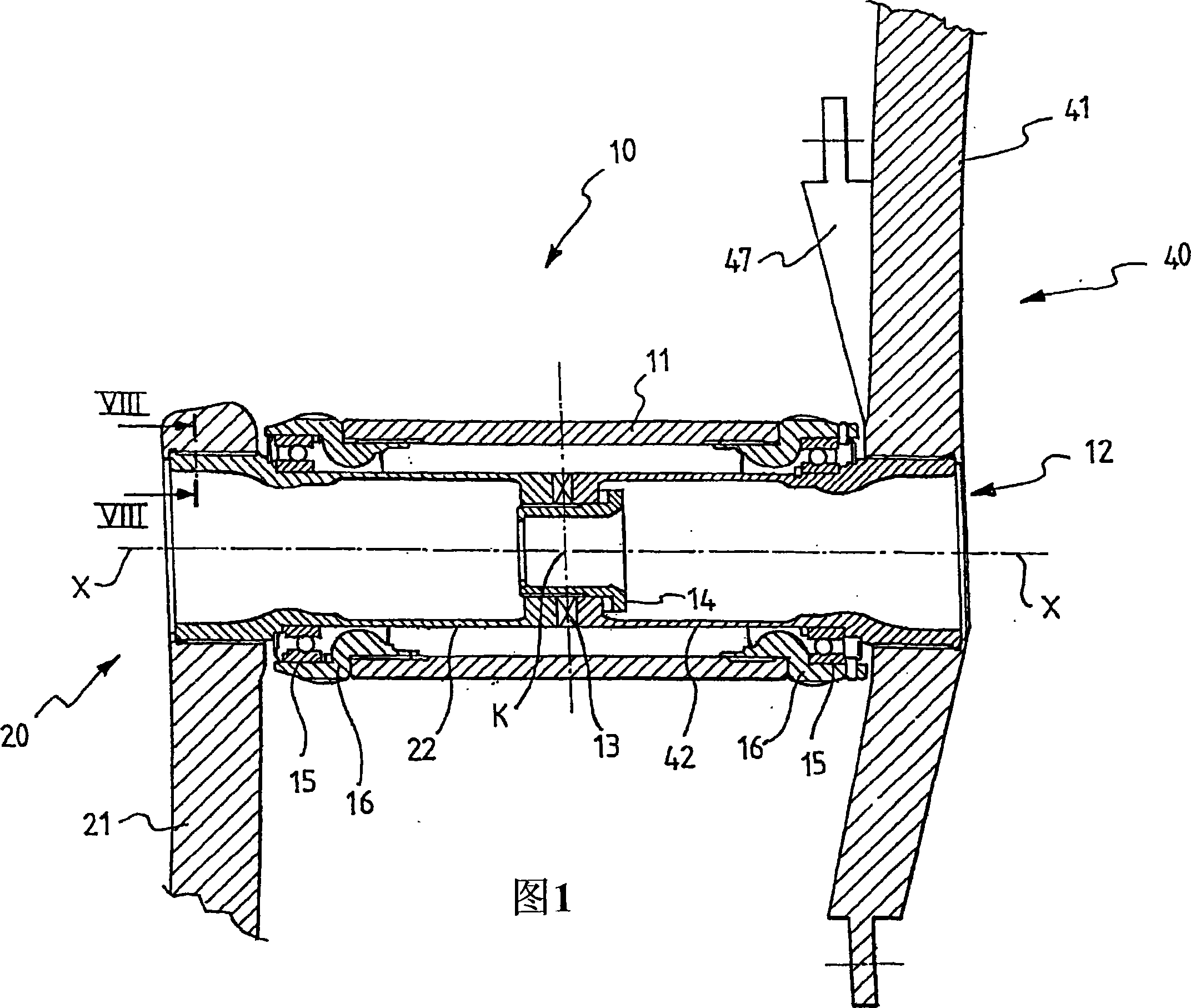

[0035] In the figures, the bottom bracket assembly of the bicycle transmission is generally indicated by 10; only the frame box 11 of the bicycle supporting the bottom bracket assembly 10 is shown.

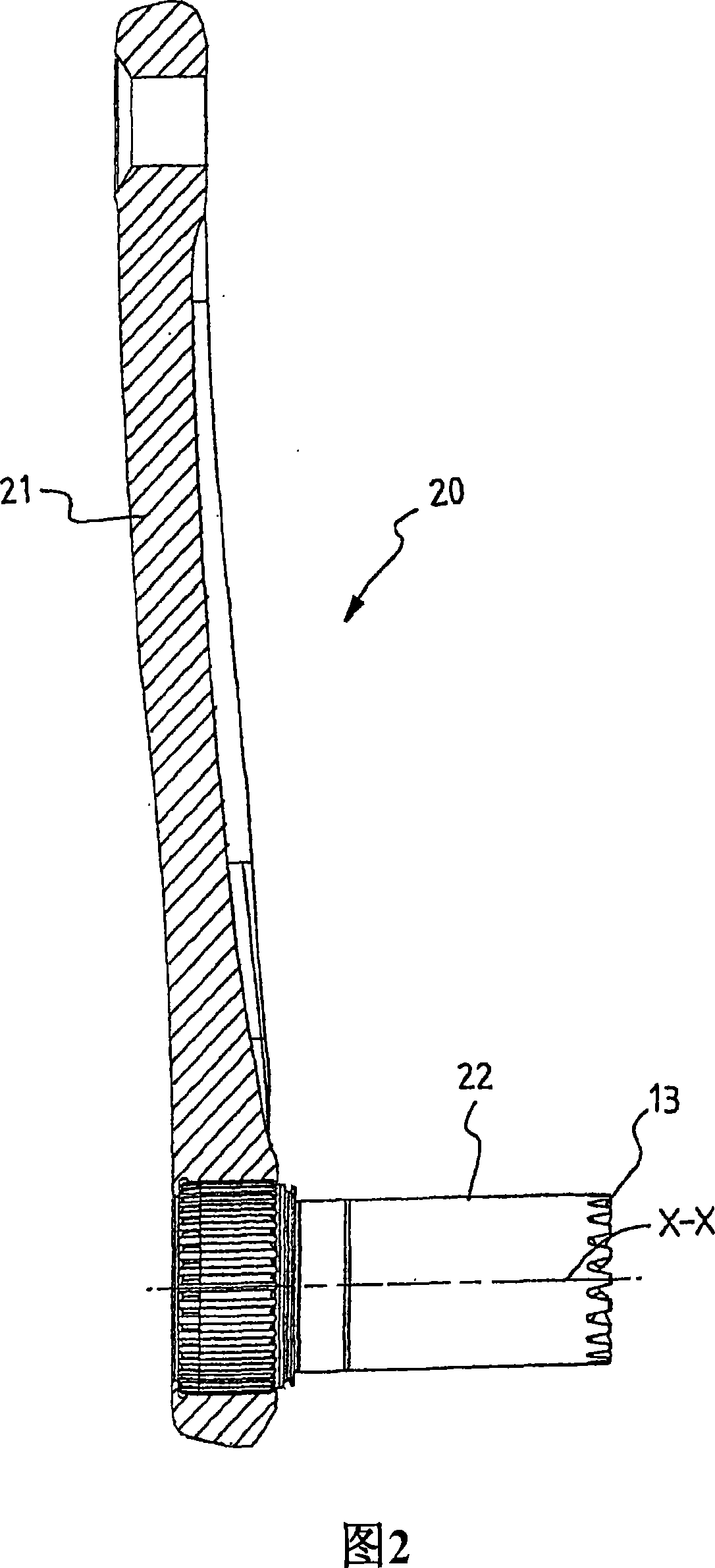

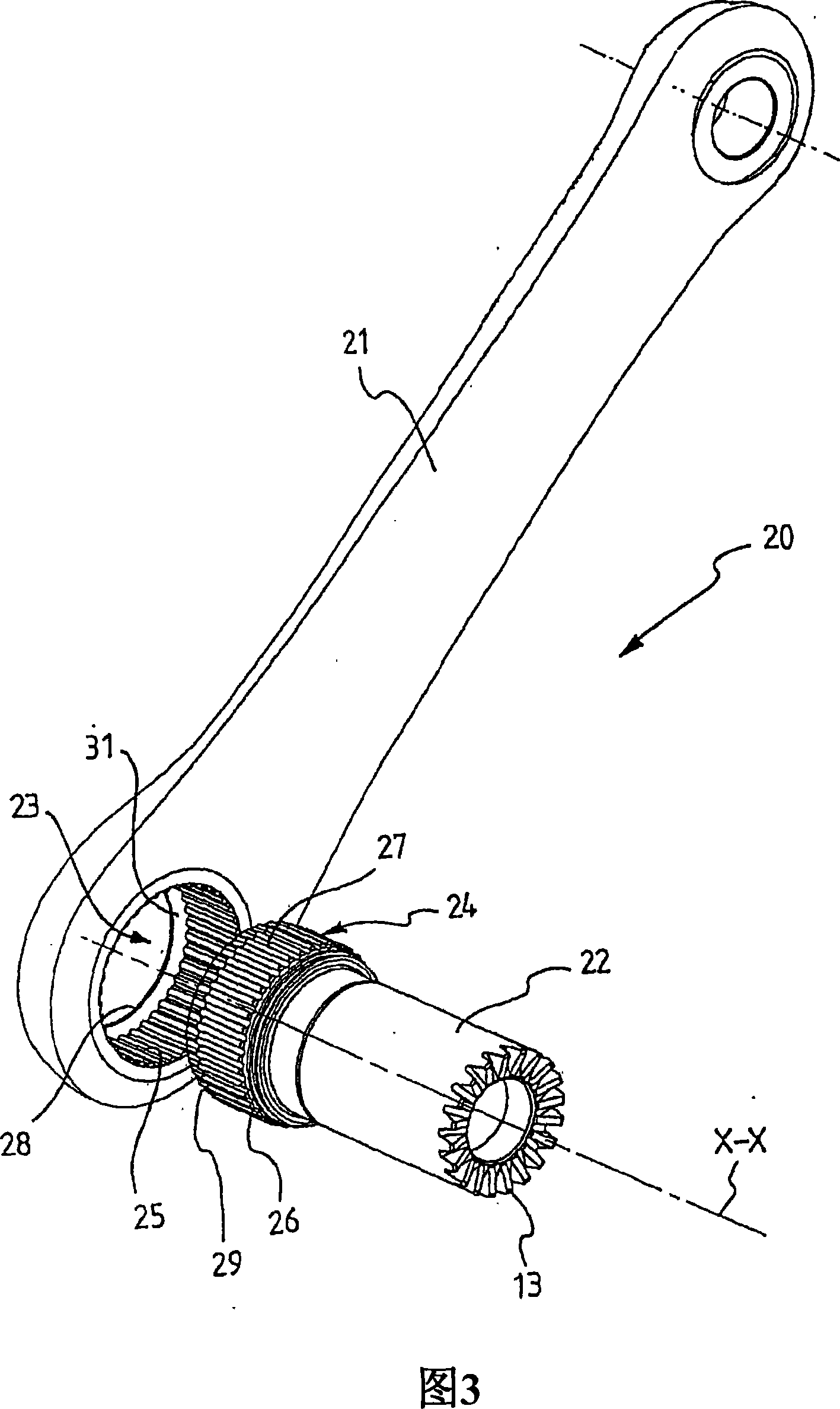

[0036] With particular reference to FIG. 1 , bottom bracket assembly 10 includes two crank arm assemblies 20 and 40 , left and right, each of which includes crank arms 21 and 41 and shaft portions 22 and 42 , respectively. The two shaft parts 22 and 42 are substantially identical to each other and rotate integrally by coupling with the front teeth 13 and the lock nut 14, which are only diagrammatically shown because they are conventional in nature, thus In use a shaft assembly, indicated generally at 12, is formed. It should be noted that in other embodiments (not shown) two different shaft parts may be provided and that one of the two parts may even be omitted, while the other may comprise the entire shaft.

[0037] The right crank assembly 40 differs from the left crank assembl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com