Driving mechanism for isolating switch

A technology of driving mechanism and isolating switch, which is applied in the direction of contact driving mechanism, air switch parts, etc., to achieve the effect of improving reliability, small reserved space, and reducing volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

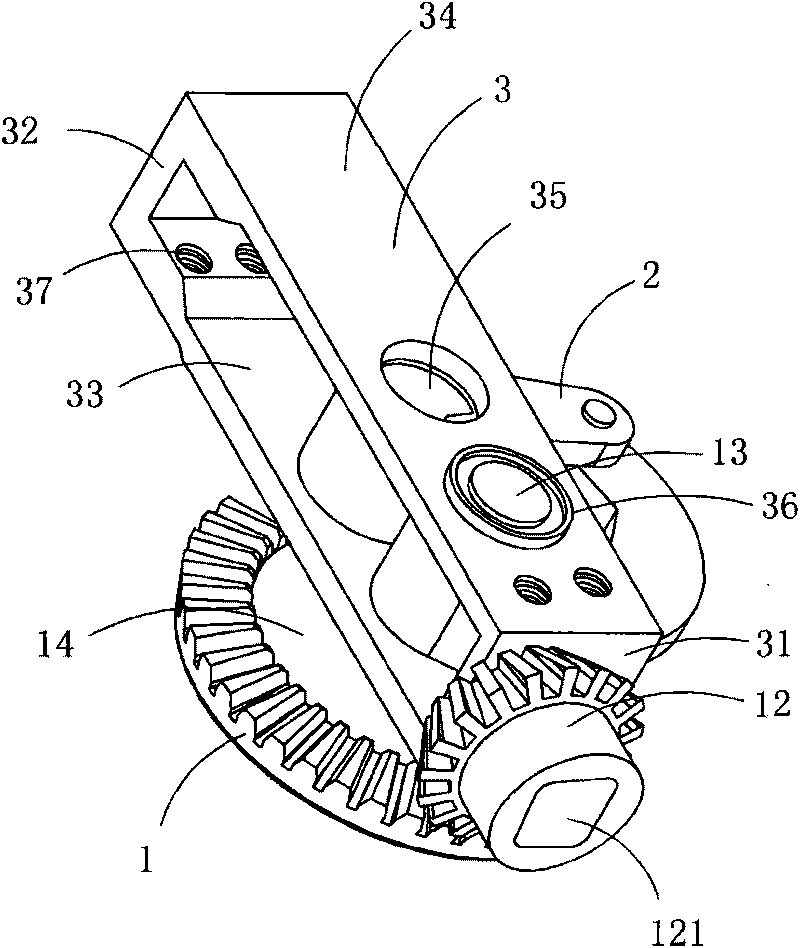

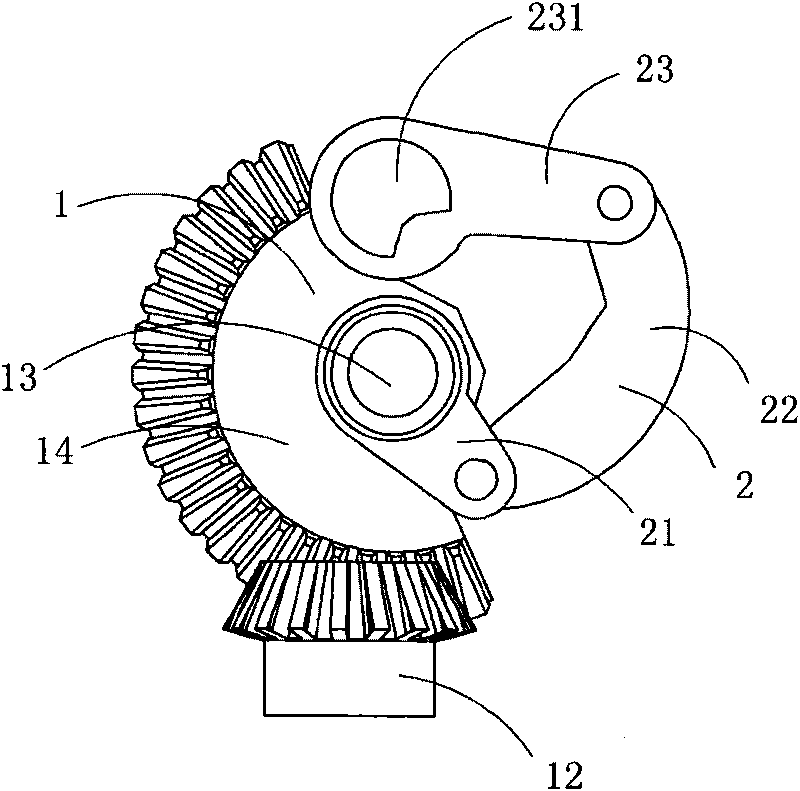

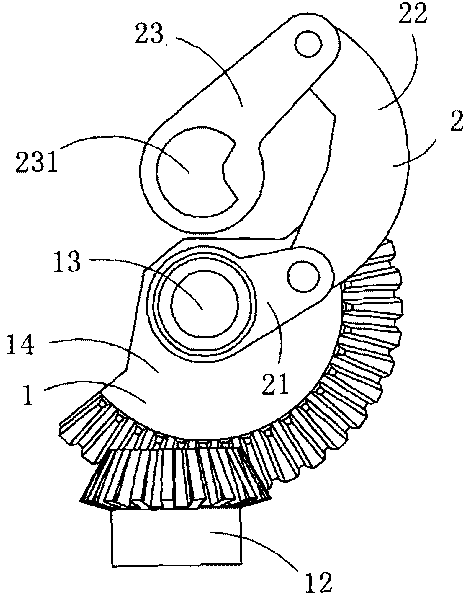

[0016] Figure 1 to Figure 3 A specific embodiment of the invention is shown in which, figure 1 It is a schematic diagram of a three-dimensional structure of the present invention; figure 2 for figure 1 A side view of the drive mechanism shown with the mounting bracket removed; image 3 for figure 2 A schematic diagram of the driving mechanism shown in use.

[0017] This embodiment is a driving mechanism for a disconnector installed in a high-voltage switchgear, see figure 1 , including a gear transmission assembly 1 , a crank arm assembly 2 and a mounting frame 3 . The gear transmission assembly 1 is a vertical axis bevel gear transmission assembly.

[0018] See Figure 1 to Figure 2 , the vertical axis bevel gear transmission assembly includes a first bevel gear 12 that rotates circumferentially along a first rotating shaft (covered in the figure and cannot be seen), is driven by the first bevel gear 12 and rotates circumferentially along a second rotating shaft 13 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com