Side-mounted high-voltage vacuum circuit breaker

A vacuum circuit breaker, side-mounted technology, applied in the direction of high-voltage air circuit breakers, high-voltage/high-current switches, circuits, etc., can solve the problem of high prices, unavailable switch cabinets and ring network cabinets, and the price of switch cabinets and ring network cabinets Problems such as high and low, to achieve the effect of reducing manufacturing costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

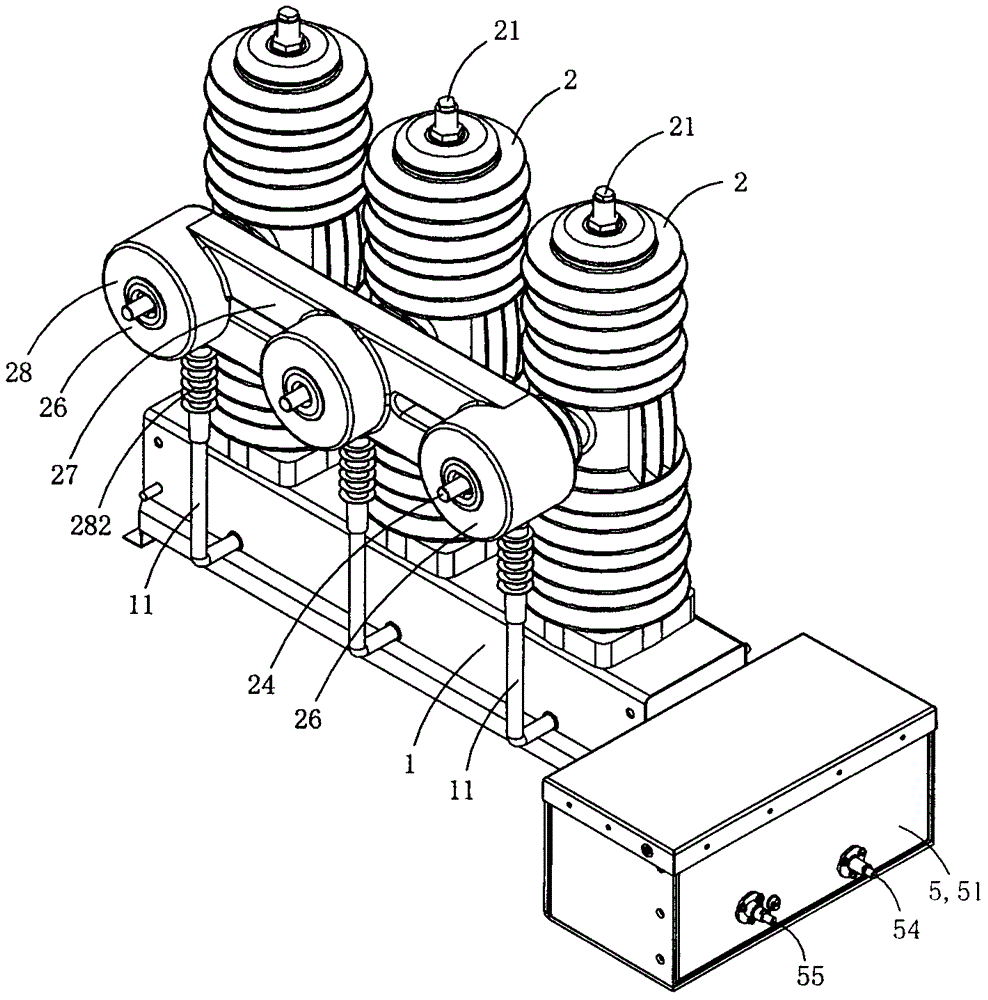

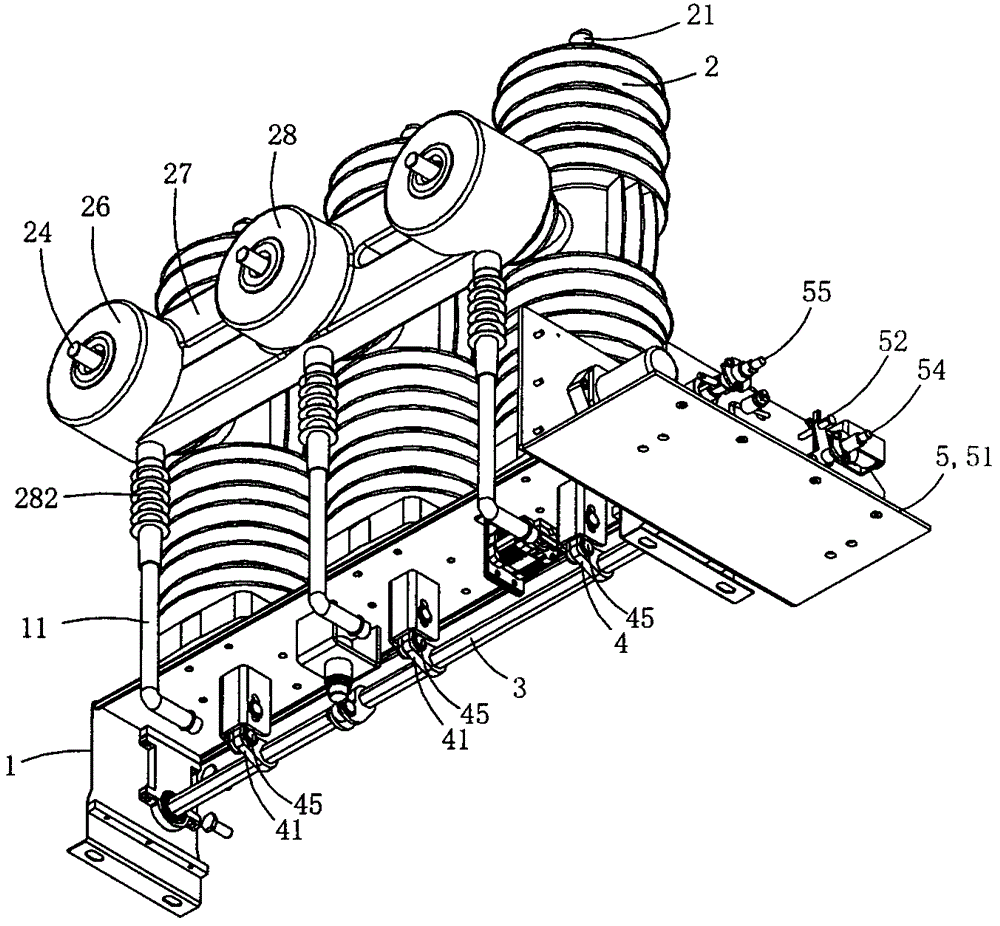

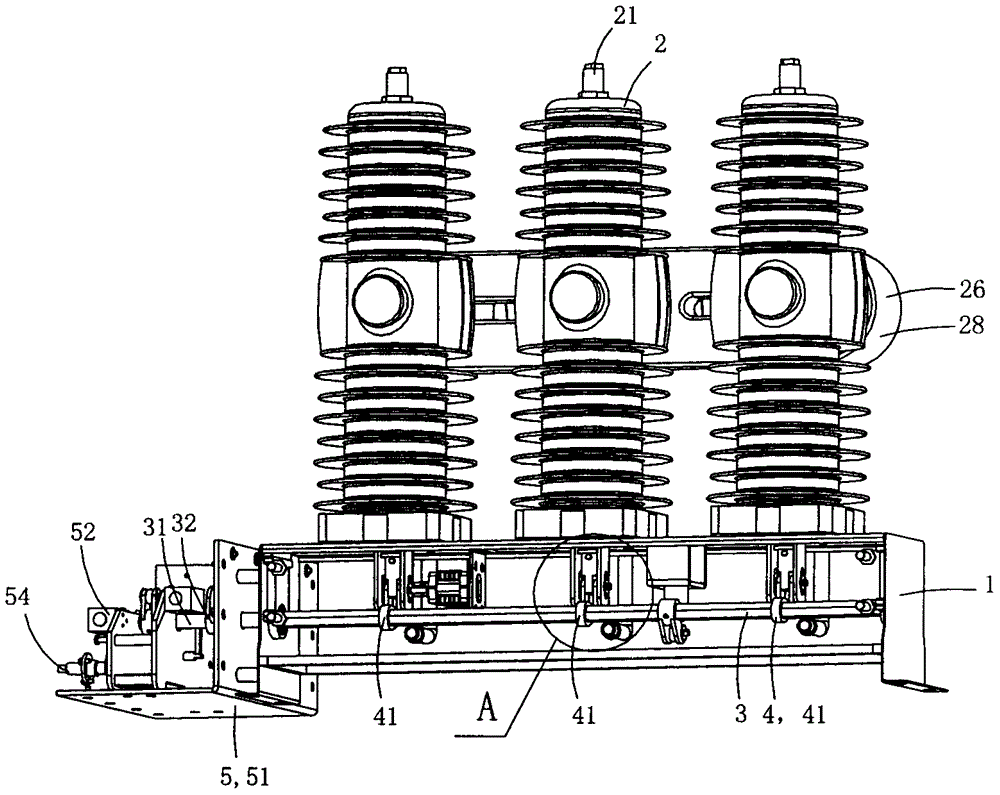

[0021] Figure 1 to Figure 8 One specific embodiment of the invention is shown.

[0022] This embodiment is a side-mounted high-voltage vacuum circuit breaker, see Figure 1 to Figure 8 As shown, it includes a base 1 and three poles 2 arranged on the base; each pole is sequentially provided with a power-in terminal 21, a vacuum interrupter 22 with a static contact and a moving contact along the direction from top to bottom. And the insulating pull rod 23 connected with the moving contact; the middle part of each pole is also provided with a power outlet terminal 24 electrically connected to a corresponding moving contact; each power input terminal and a static contact of a corresponding vacuum interrupter Electrical connection; the base is provided with the opening and closing main shaft 3, and three crank arm assemblies 4 arranged on the opening and closing main shaft, and each crank arm assembly is connected with a corresponding insulating pull rod; An operating mechanism ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com