Metal piece manufacturing method and low-pressure casting forging machine used for achieving metal piece manufacturing method

A technology of low-pressure casting and manufacturing methods, which is applied in the field of low-pressure casting and forging presses, which can solve the problems that castings cannot meet high-strength requirements, achieve the effects of dense metal structure, eliminate pores, and increase strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0025] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

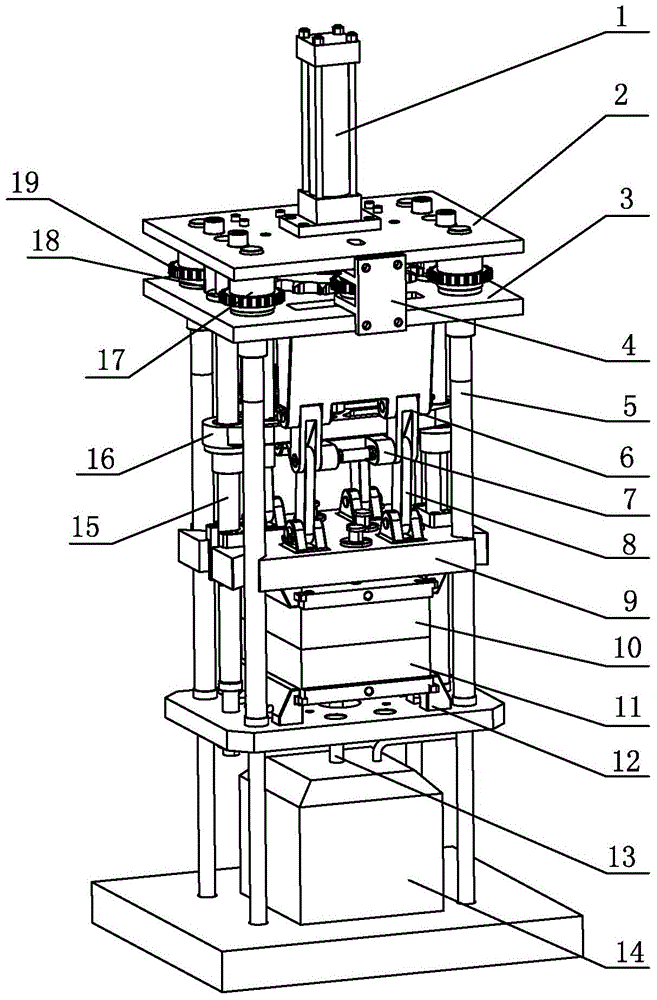

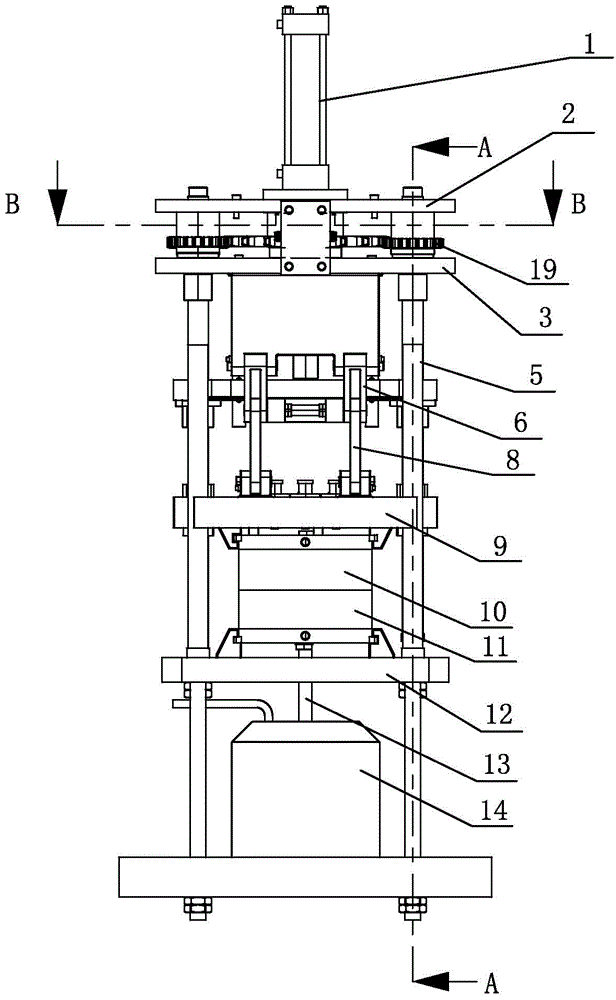

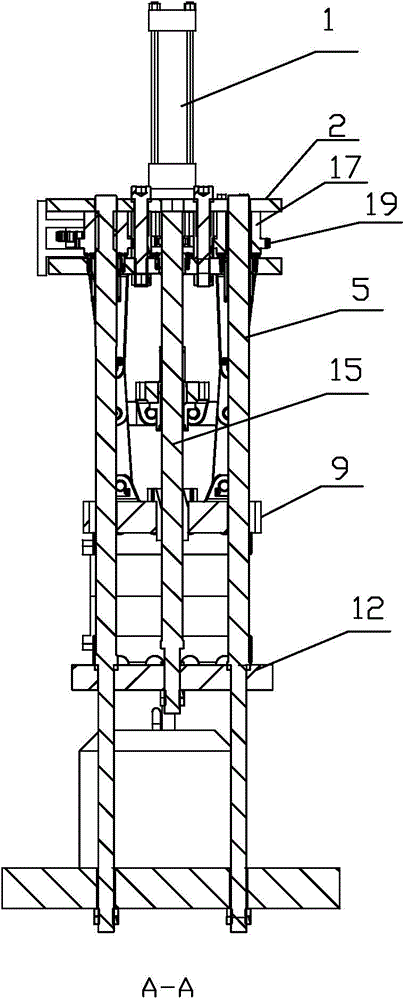

[0026] Such as Figure 1 to Figure 6 Shown:

[0027] The manufacturing method of the metal parts of the present invention comprises two stages of low-pressure casting and forging in the manufacturing process; in the low-pressure casting stage, a low-pressure casting device is used to realize the filling of molten metal in the mold cavity, and the mold cavity is composed of an upper mold 10 and a lower mold cavity. The half cavity of the mold 11 is combined, the lower mold 11 is fixed, the upper mold 10 is driven up and down by the driving mechanism through the five-hinge mechanism of the crank arm, and the joint surfaces of the upper mold 10 and the lower mold 11 are separated by a certain distance in the low...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com