Water jet forming enhanced quenching integrated reverse extrusion connection system and method

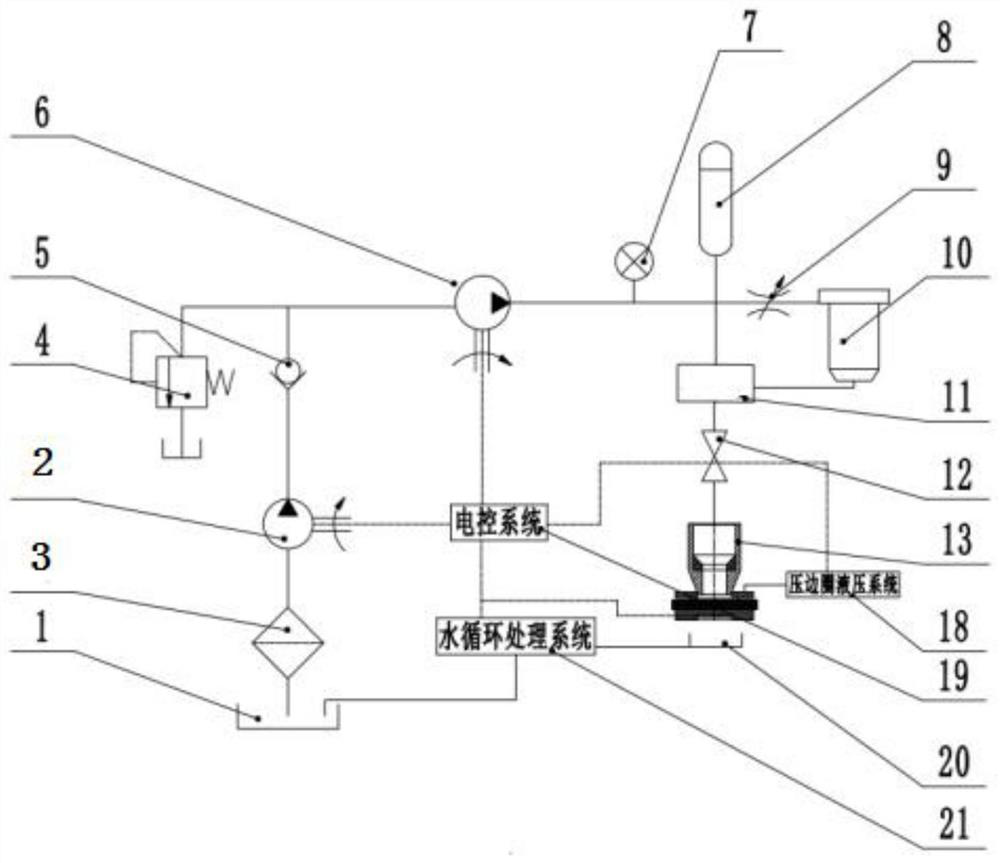

A connection system and reverse extrusion technology, which is applied in the field of integrated reverse extrusion connection system of water jet forming, strengthening and quenching, can solve the problems of reducing production efficiency, high tensile stress, hidden safety hazards, etc., achieving high processing efficiency and increasing plasticity. Flowability, the effect of increasing strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] In order to make the technical problems, technical solutions and advantages to be solved by the present invention clearer, the following will describe in detail with reference to the drawings and specific embodiments.

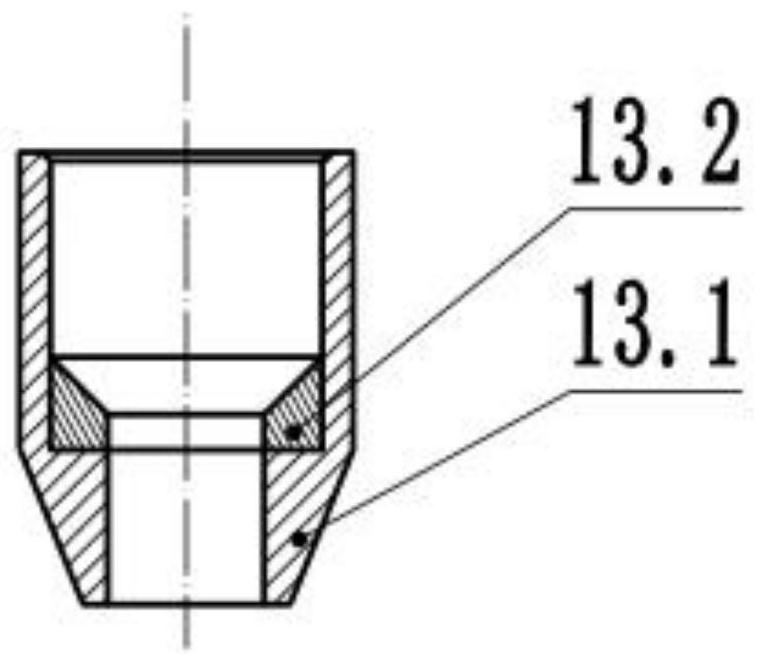

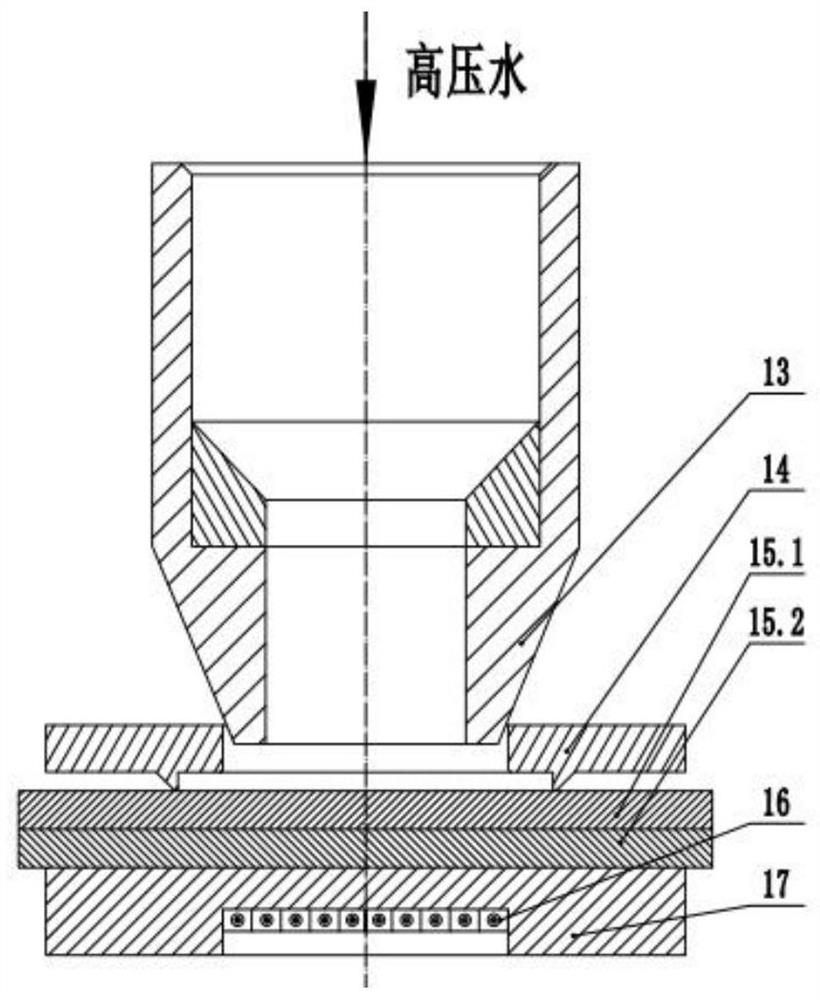

[0038]Aiming at the existing problems, the present invention provides a water jet forming, strengthening and quenching integrated reverse extrusion connection system, including: a connection device, the connection device includes a nozzle 13, a connection tool, and the exterior of the nozzle is a nozzle housing 13.1 , the nozzle housing 13.1 is hollow inside and has a ring-shaped artificial sapphire 13.2 fixed inside; the connection tool is located directly below the nozzle 13, including a blank holder 14 and a lower die 17; the blank holder 14 is located on the connection tool In the upper part, there is a circular through hole in the middle of the blank holder 14 and there is an annular protrusion on the lower side of the blank holder 14, and the blank ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com