Square-tapered rotary mixer

A technology of rotating mixers and mixers, which is applied in the direction of mixers with rotating containers, mixers, mixing methods, etc., can solve the problem of insufficient radial and axial mixing promotion and unsatisfactory mixing effect of the mixture , It is difficult to meet the problems of industrial mixing and other problems, and achieve the effect of low energy consumption, low cost and good mixing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] Next, specific embodiments of the present invention will be described in detail with reference to the drawings. In the present invention, descriptions of known technologies, even if they are related to the present invention, may be omitted if they are considered unnecessary when they would make the characteristics and description of the present invention unclear.

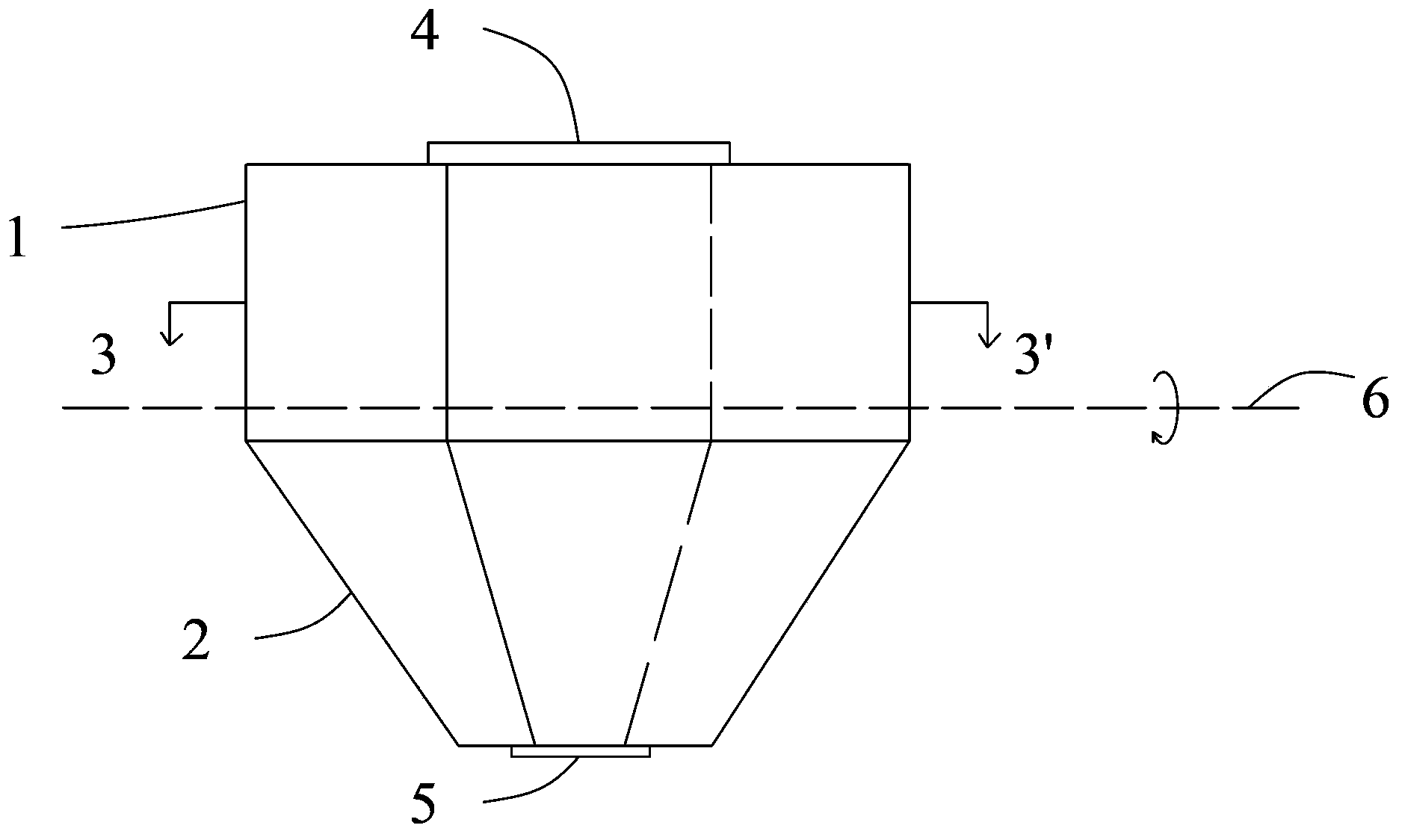

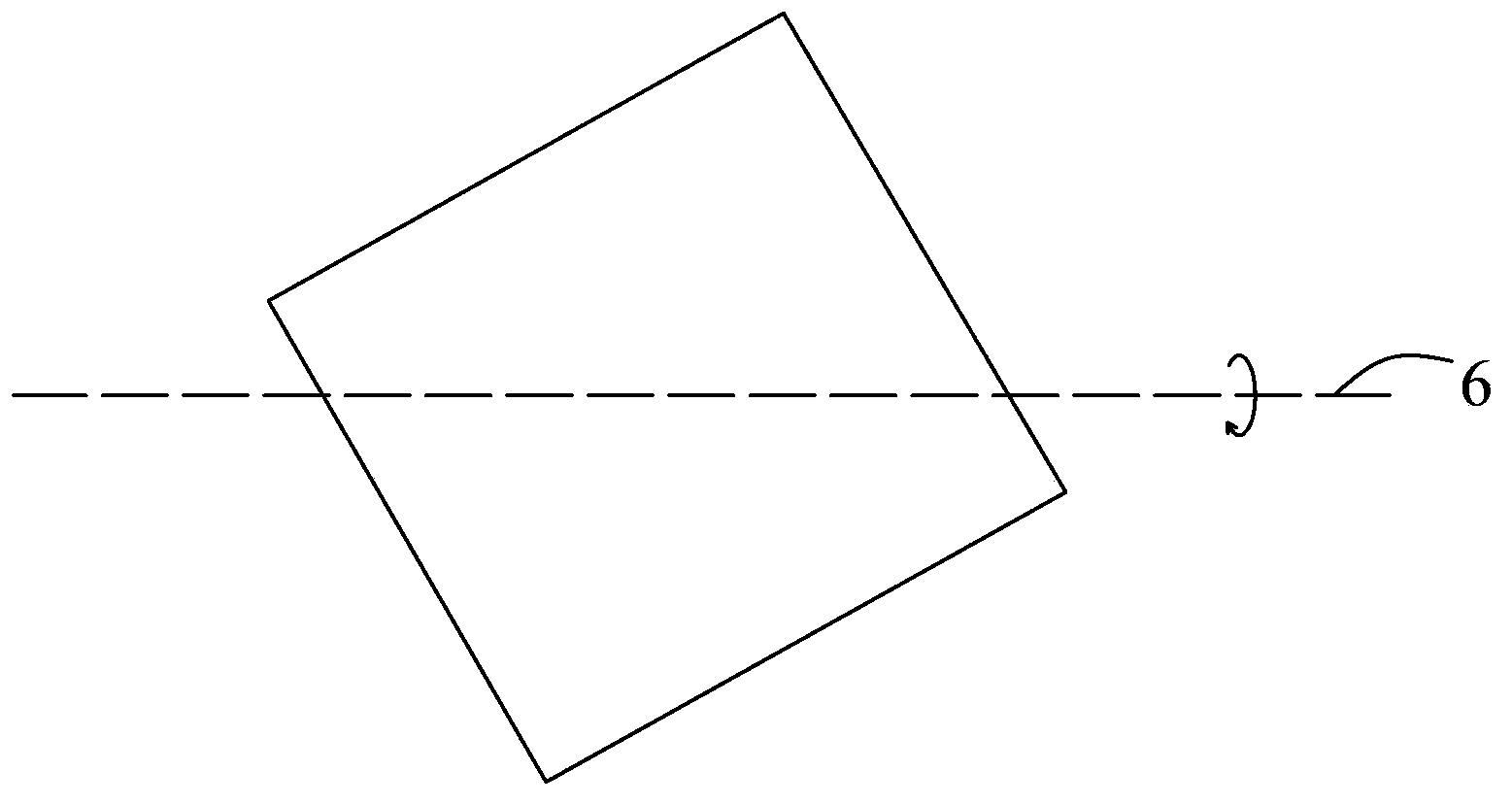

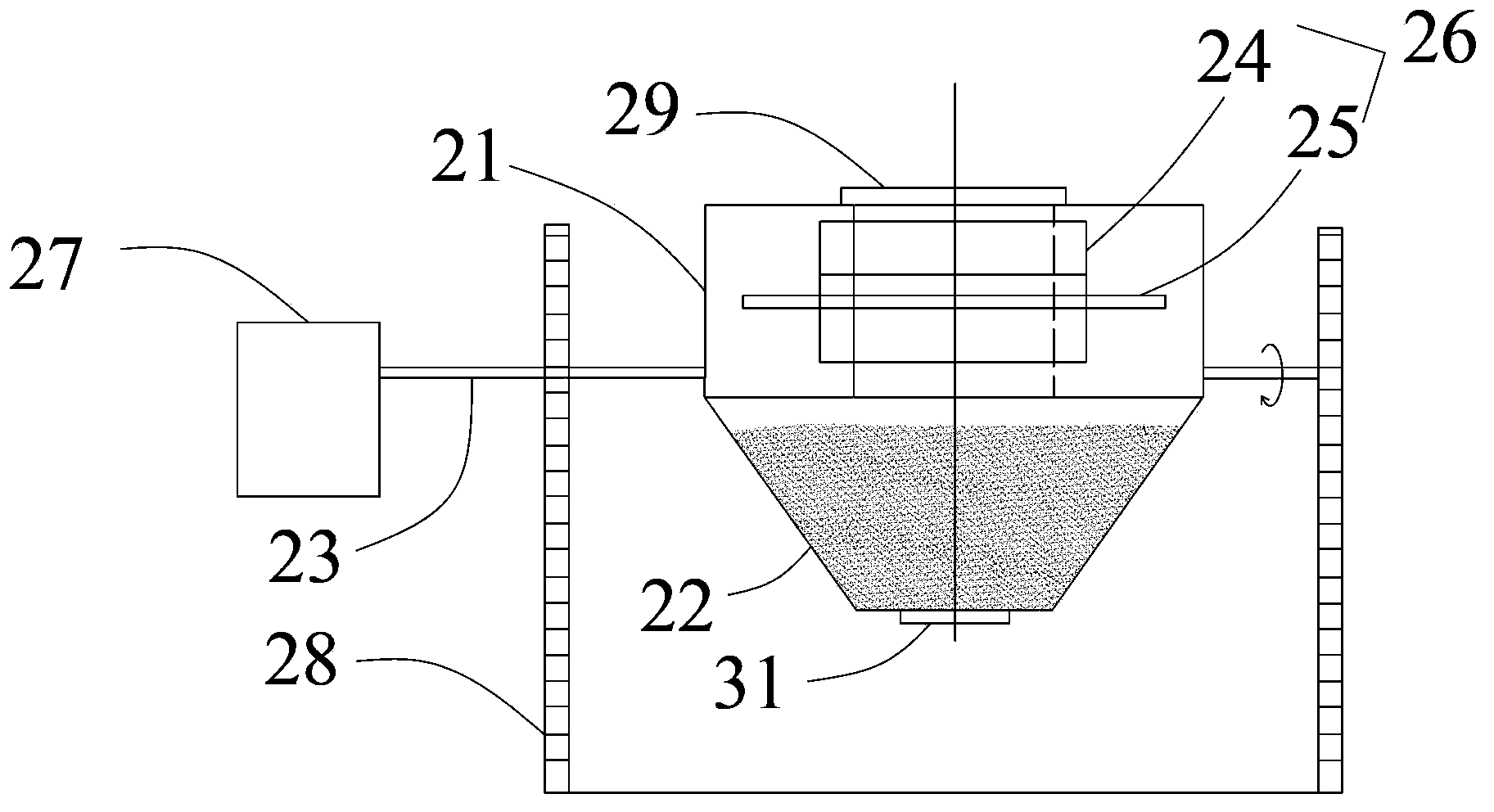

[0047] mixer 10 For the existing square cone mixer, such as figure 1 ( figure 1 is the structural schematic diagram of the existing square cone mixer) and figure 2 ( figure 2 As shown in the top sectional view obtained along the direction 3 of the existing square cone mixer), mixer 10 It is composed of a mixer body composed of an upper cube 1 and a lower pyramid 2, and a rotating shaft 6 that provides the rotational power of the mixer; the top of the cube 1 has an inlet 4, and the bottom of the pyramid has an outlet 5; wherein, The material enters from the inlet 4, and the mixer is placed vertically ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com