Patents

Literature

37results about How to "Eliminate reduction" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Display

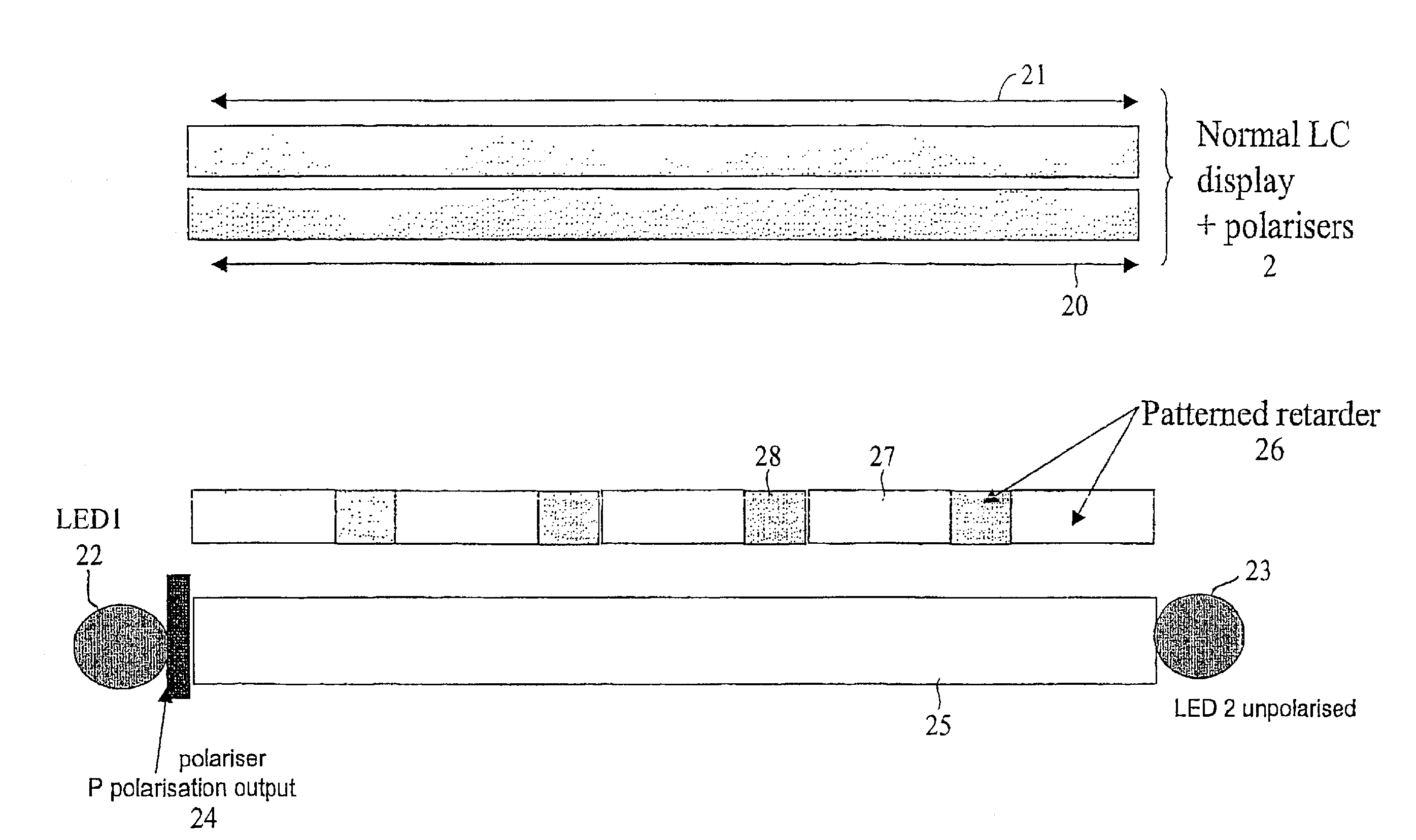

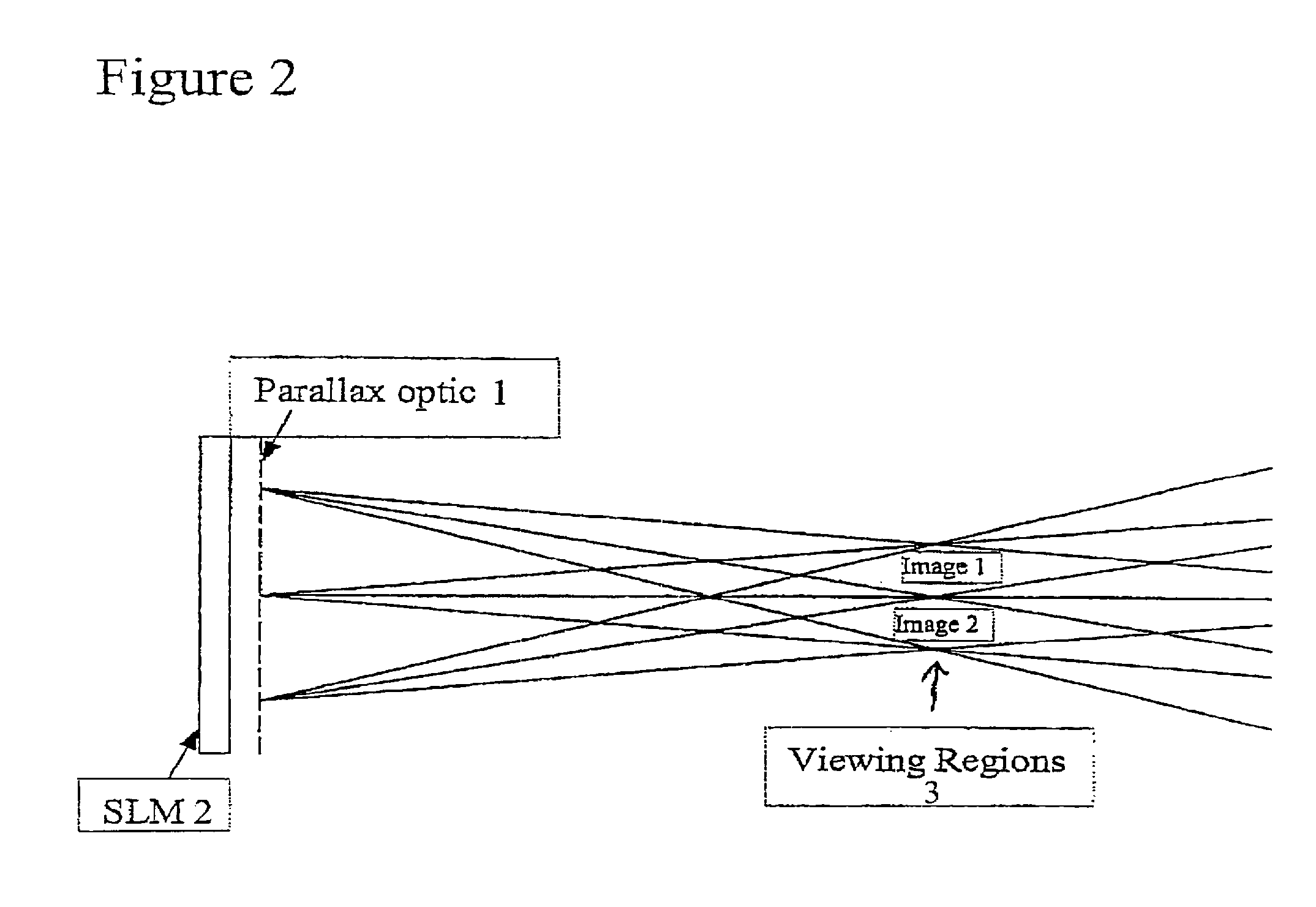

InactiveUS20070013624A1Improve image qualityReduce impactStatic indicating devicesNanoopticsSpatial light modulatorImage resolution

A display is provided having a multiple view mode of operation and a wide angle single view mode. The display comprises a transmissive spatial light modulator which displays spatially multiplexed images in the multiple view mode and a single image with full resolution in the single view mode. The modulator has an input polariser which passes light of a first polarisation. A backlight has a light output surface with alternating first and second regions of parallel strip shape. The backlight is electronically switchable between the multiple view and single view modes. In the multiple view mode, only the first regions emit light containing the first polarisation. In the single view mode, both regions emit light containing the first polarisation.

Owner:SHARP KK

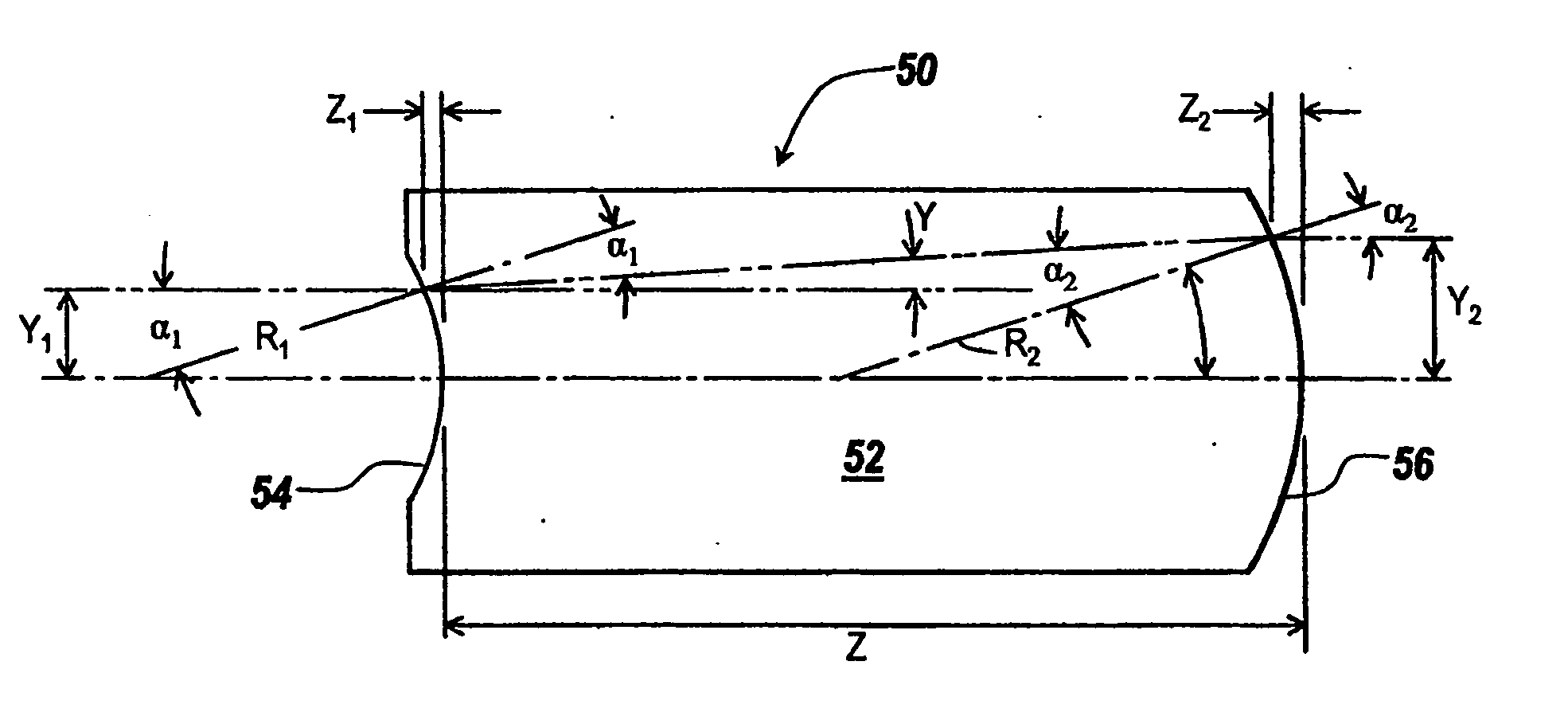

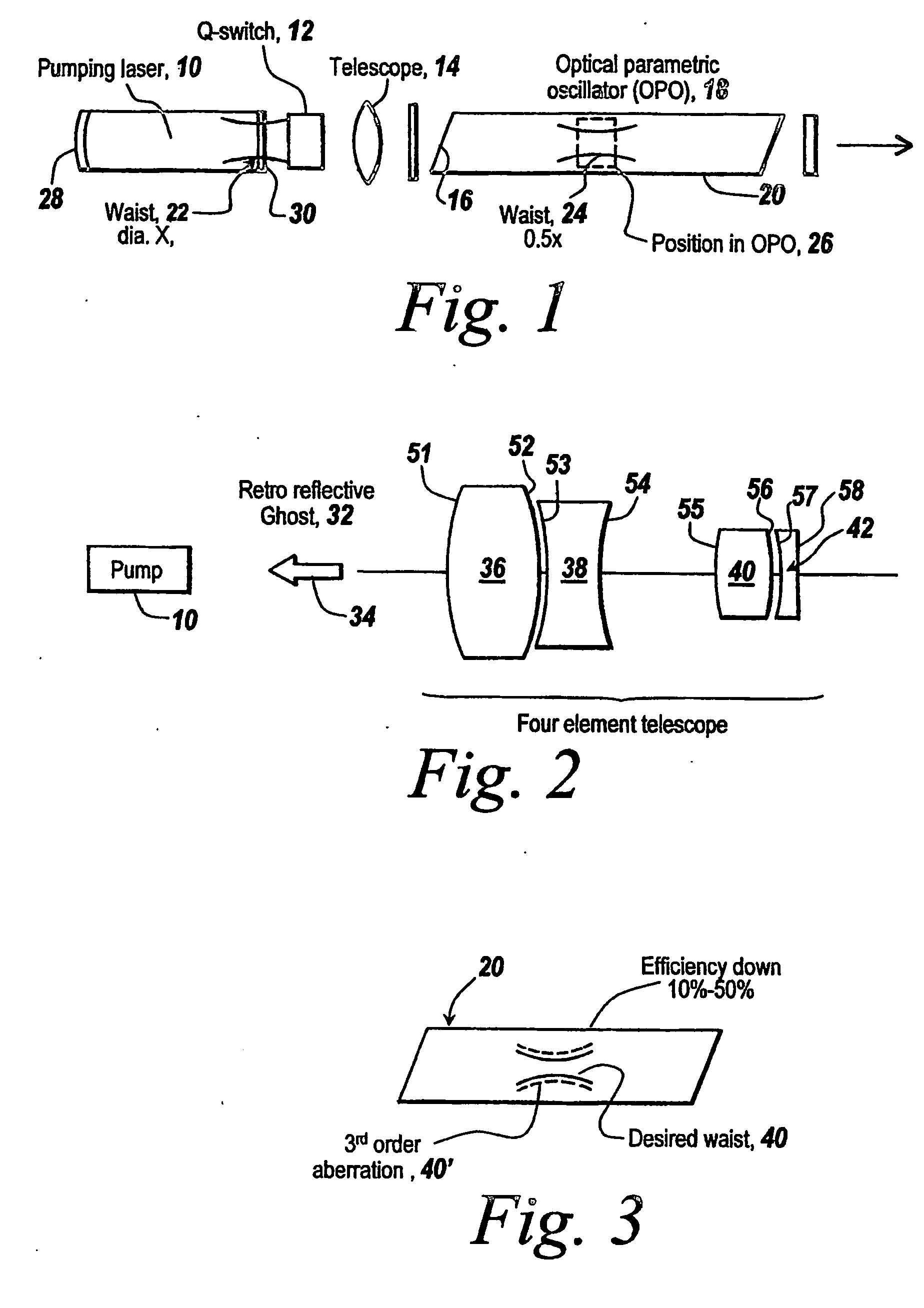

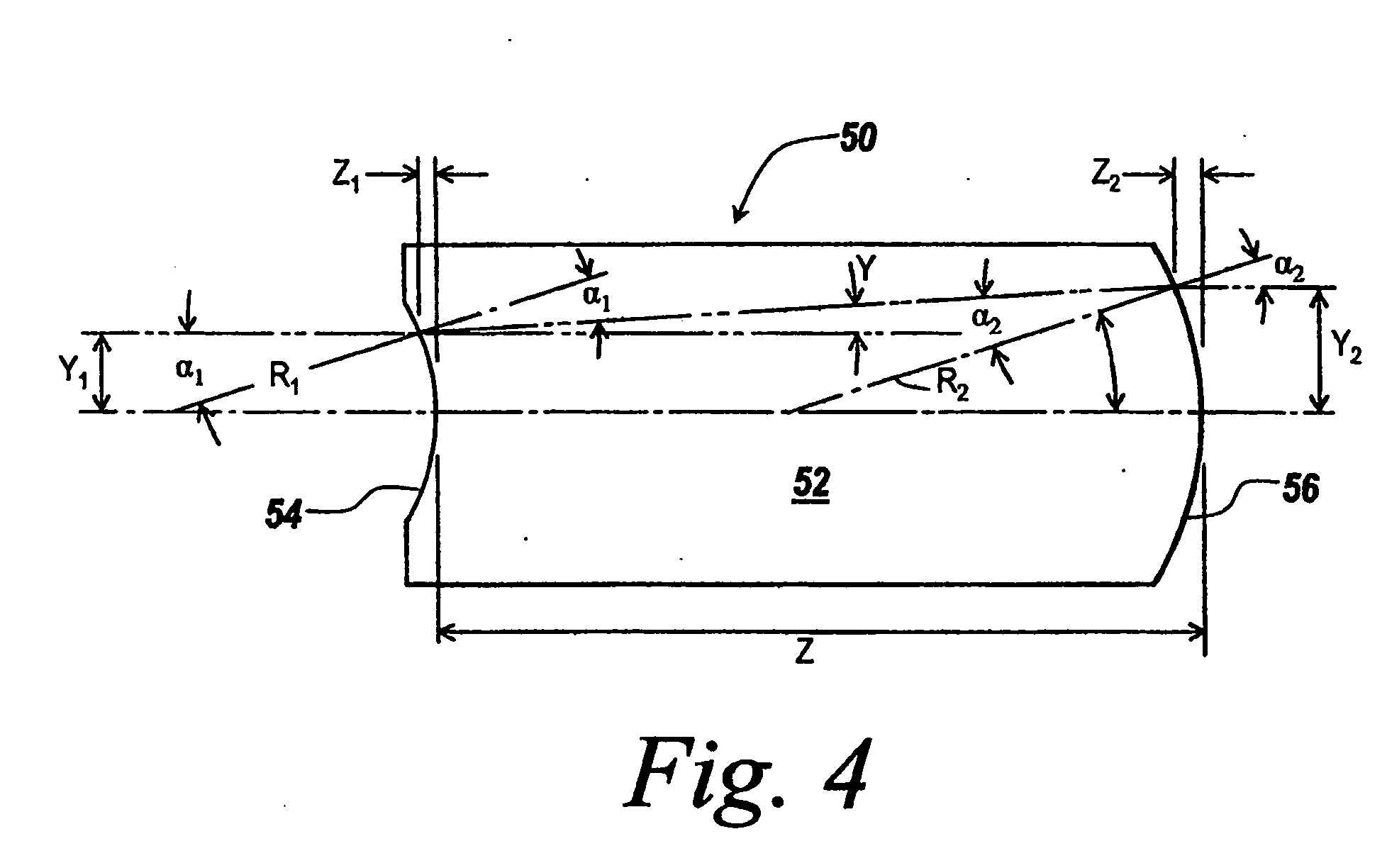

Singlet telescopes with controllable ghosts for laser beam forming

A singlet telescope is provided for reshaping the laser beam to a larger or smaller diameter while maintaining the inherent quality of the beam. Applications for the singlet telescope include intercavity expansion to accommodate the damage thresh-old of various components, expansion of beams to match the size of different wavelengths for final collimation, and shrinking of beams to provide high irradiance for nonlinear processes such as optical parametric oscillation and frequency doubling, with the above applications usually requiring low power magnification or demagnification. Problems involving the utilization of these telescopes over wide temperature ranges and ghost reflections in which a light is reflected back to a pumping laser are minimized with the singlet construction, with the ghost reflections potentially creating damage of components including self-damage or breakdown of air, as well as damage to a Q-switched resonator which causes pre-lasing.

Owner:BAE SYST INFORMATION & ELECTRONICS SYST INTERGRATION INC

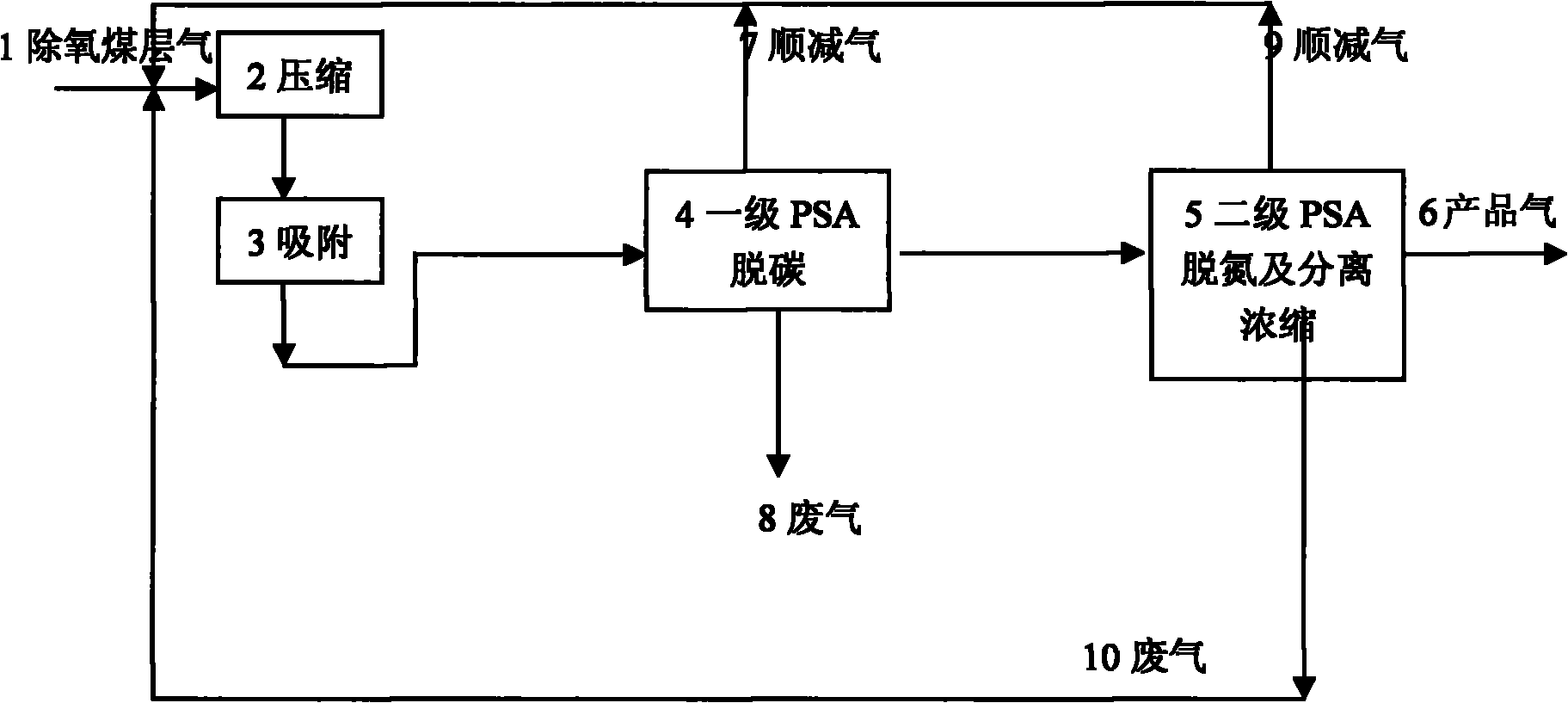

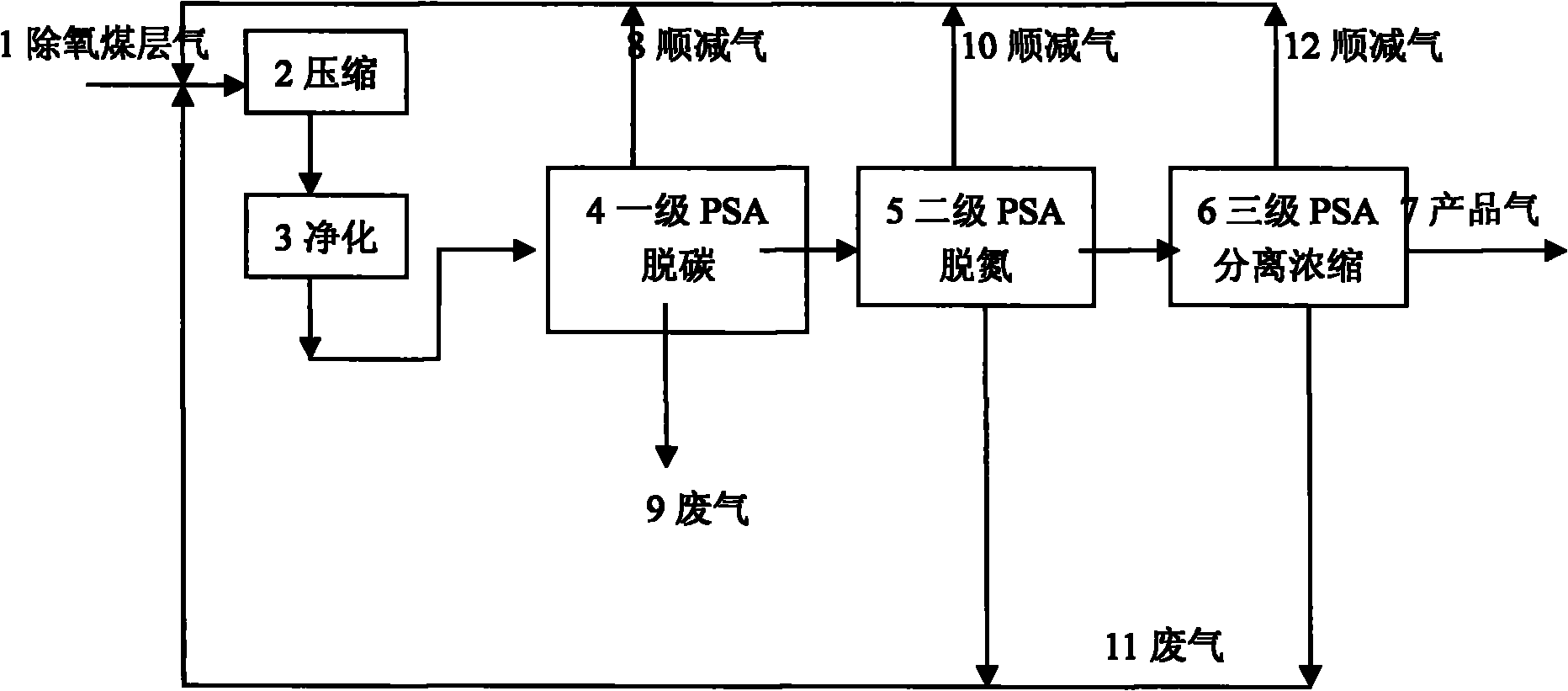

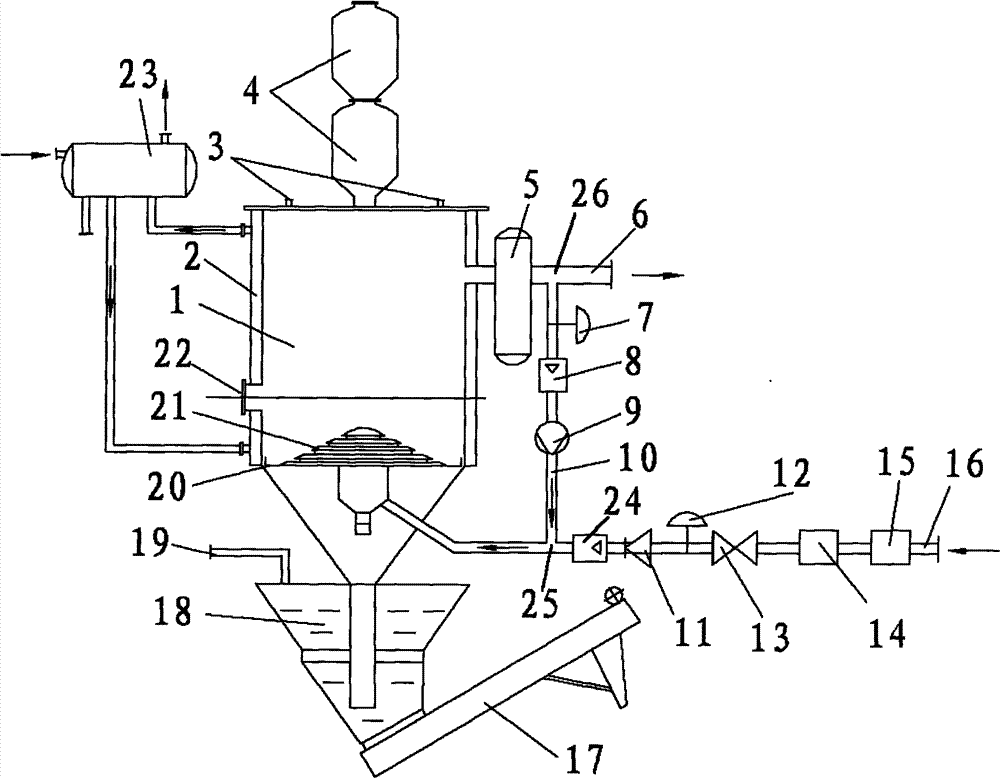

Method for deoxidizing coal bed gas and separating methane by concentration

ActiveCN101921642AReduce consumptionReduce consumption costGaseous fuelsMolecular sieveOxygen content

The invention discloses a method for deoxidizing coal bed gas and separating methane by concentration. By using the method, the coal bed gas having 20 to 50 percent of CH4 can be deoxidized, and the requirement on the oxygen content in raw material gas is low, so that the raw material gas can be deoxidized when the oxygen content is 10.6 to 15 percent, and the times of circulated deoxidization can be obviously reduced compared with that of the conventional method. Therefore, energy consumption and production cost can be lowered, deoxidization time can be shortened, and production efficiency can be further improved. The method is characterized by wide application range, low investment consumption, complete and fast deoxidization, and good application prospect in the field of coal bed gas deoxidization. The concentration of the methane in the coal bed gas can be improved from 20 to 50 percent in the raw material gas to 80 to 90 percent by the method. CH4 concentration, decarbonization and denitrification can be performed by the method with only one carbon molecular sieve, so that the concentration separation efficiency is obviously improved, and the method has great significance andapplication value in the aspect of industrialized popularization of the coal bed gas.

Owner:CCTEG CHINA COAL RES INST

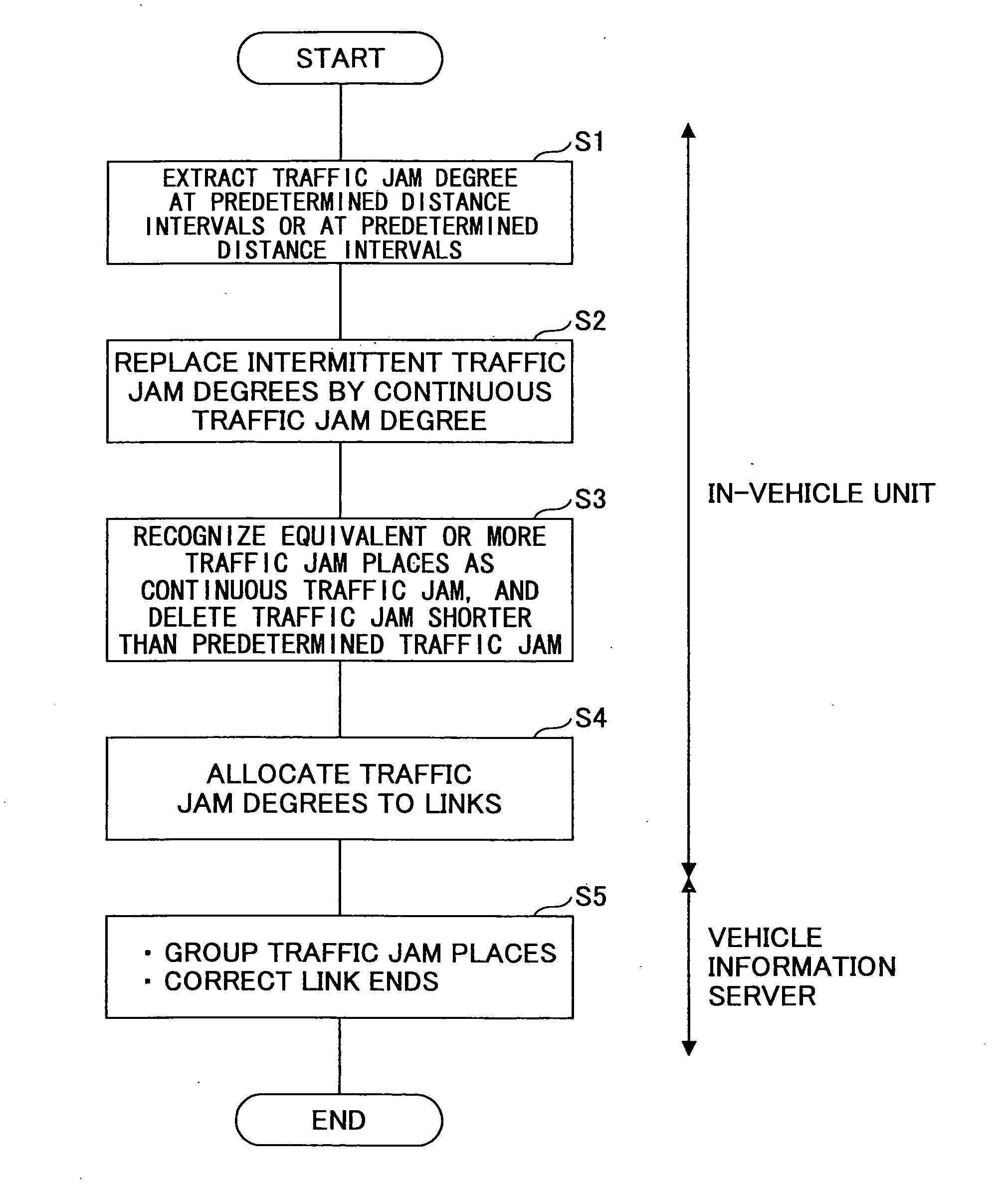

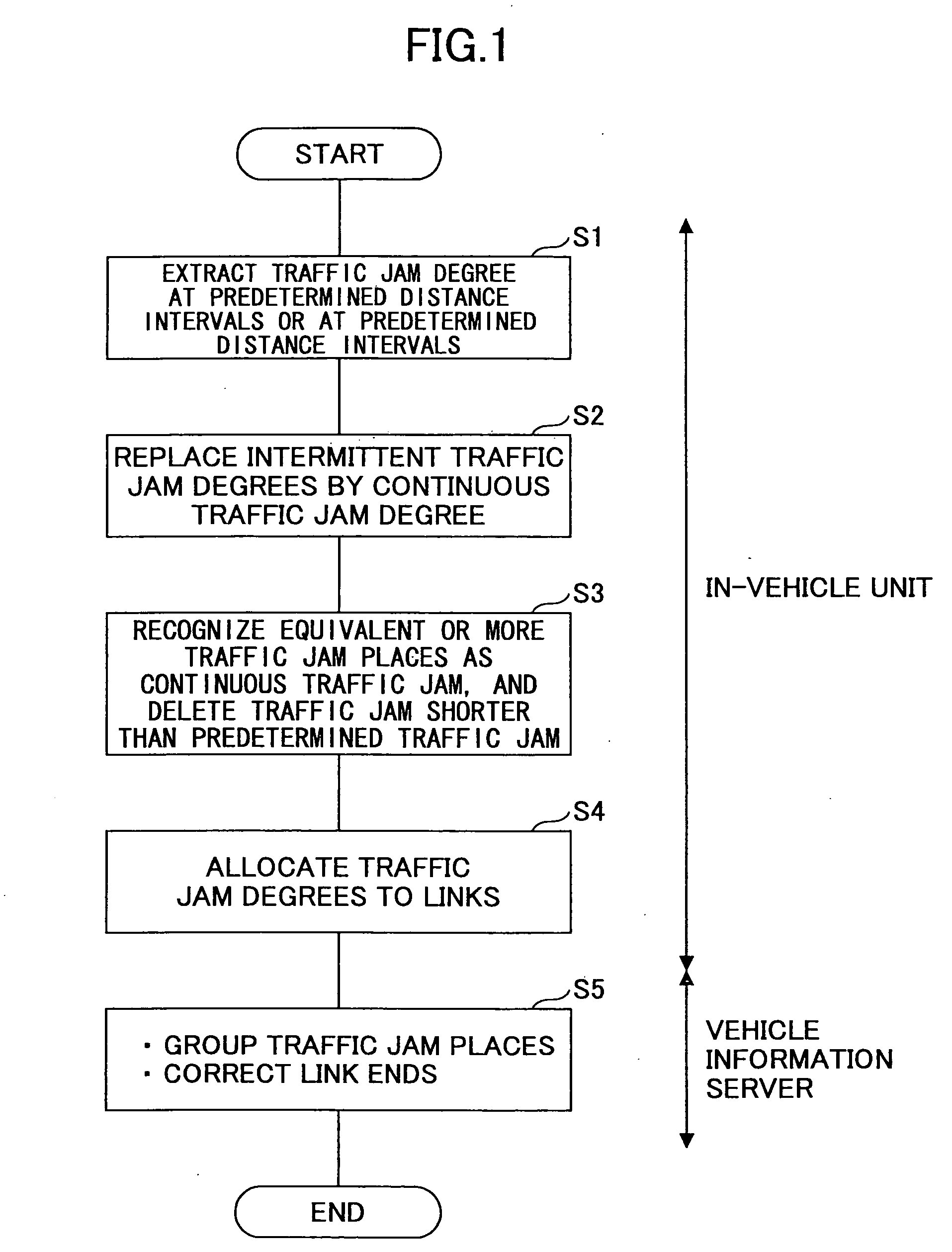

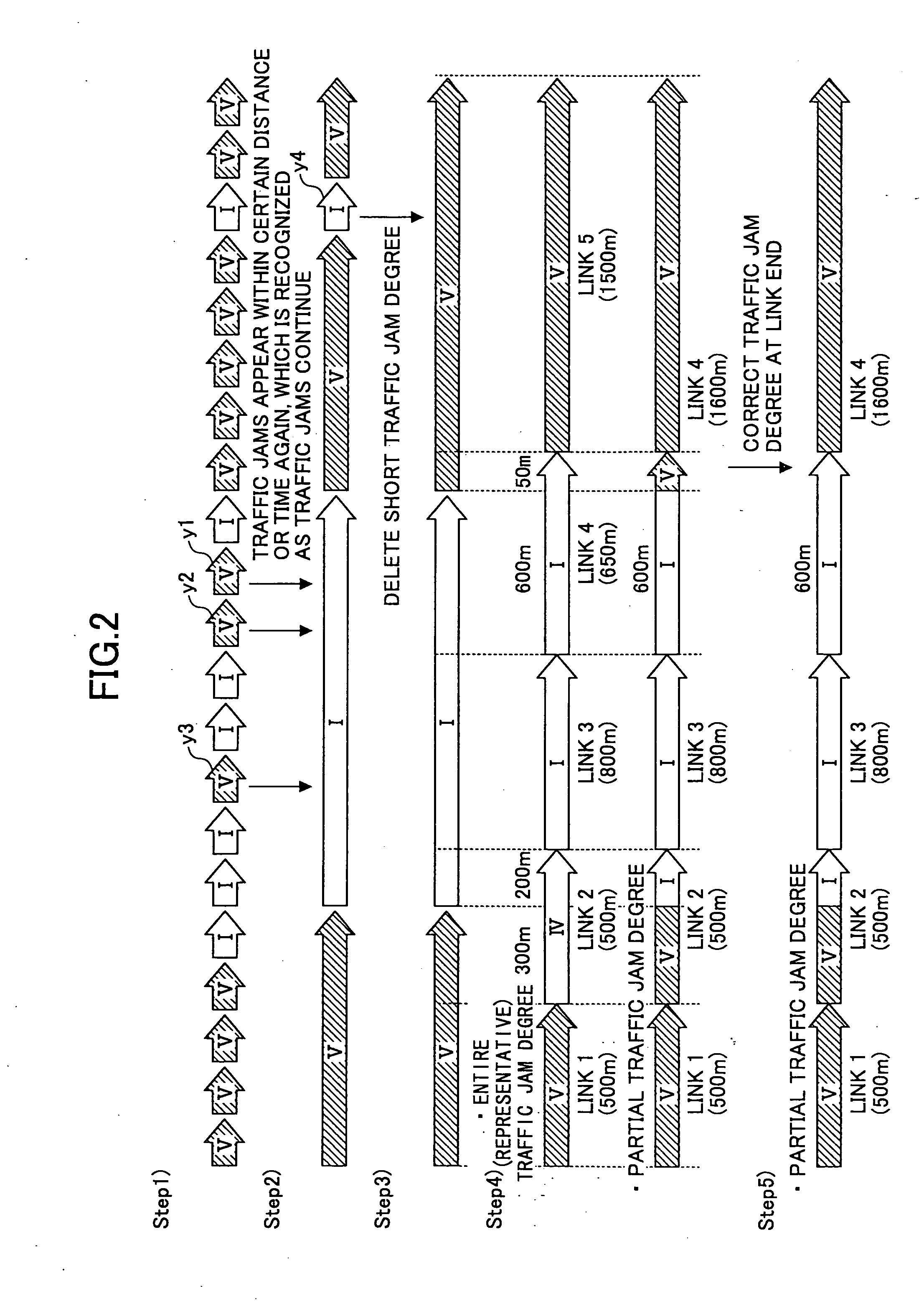

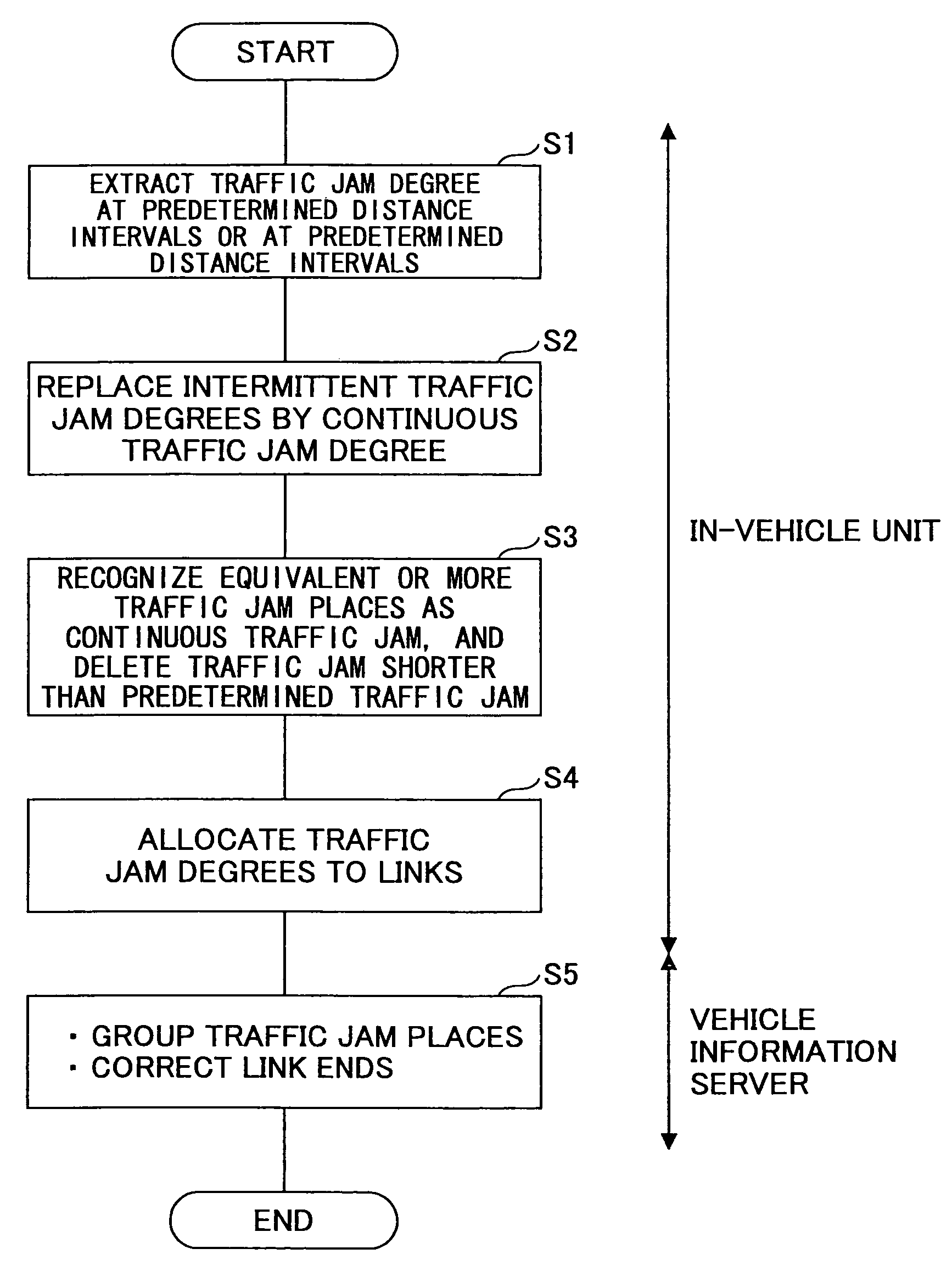

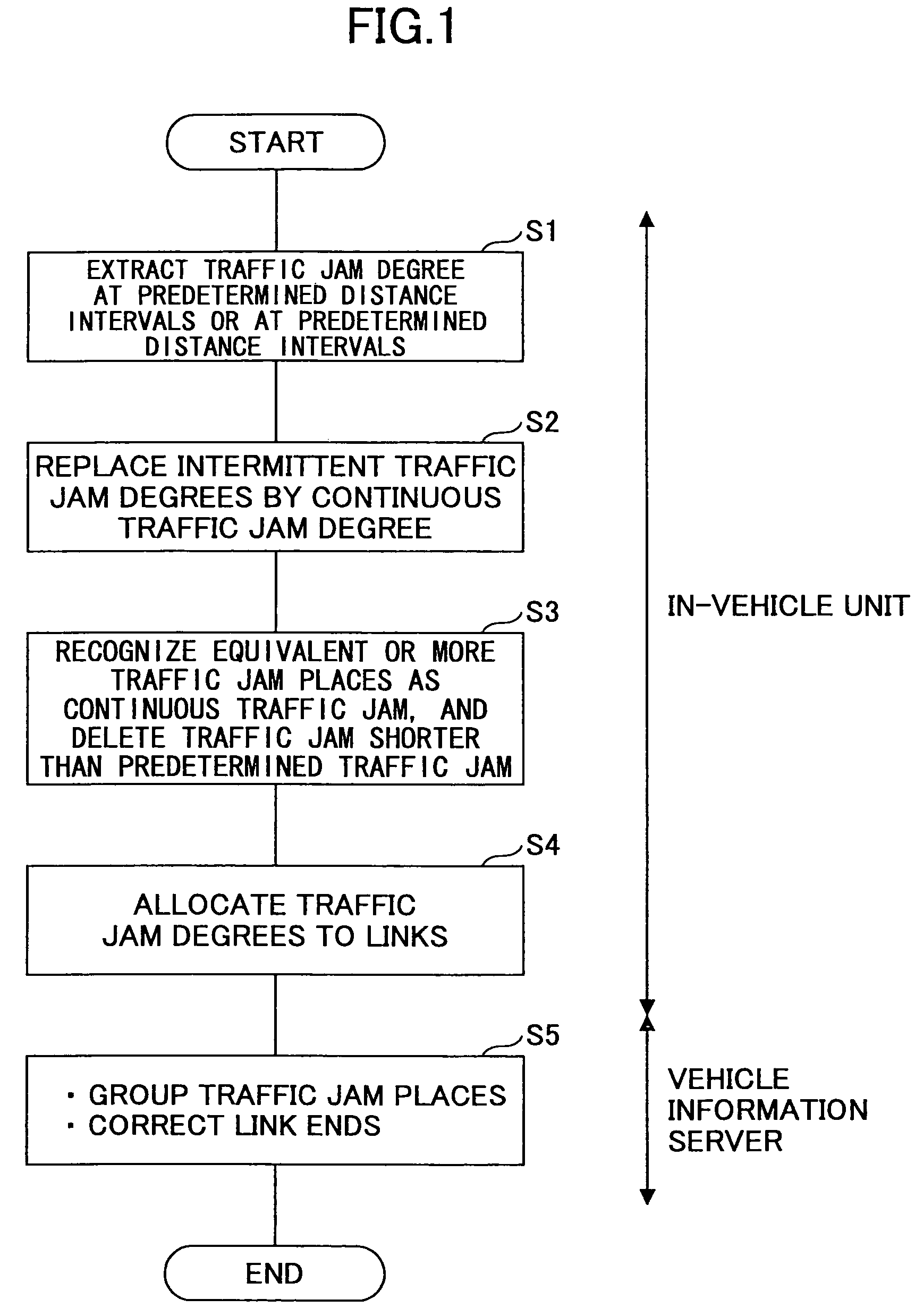

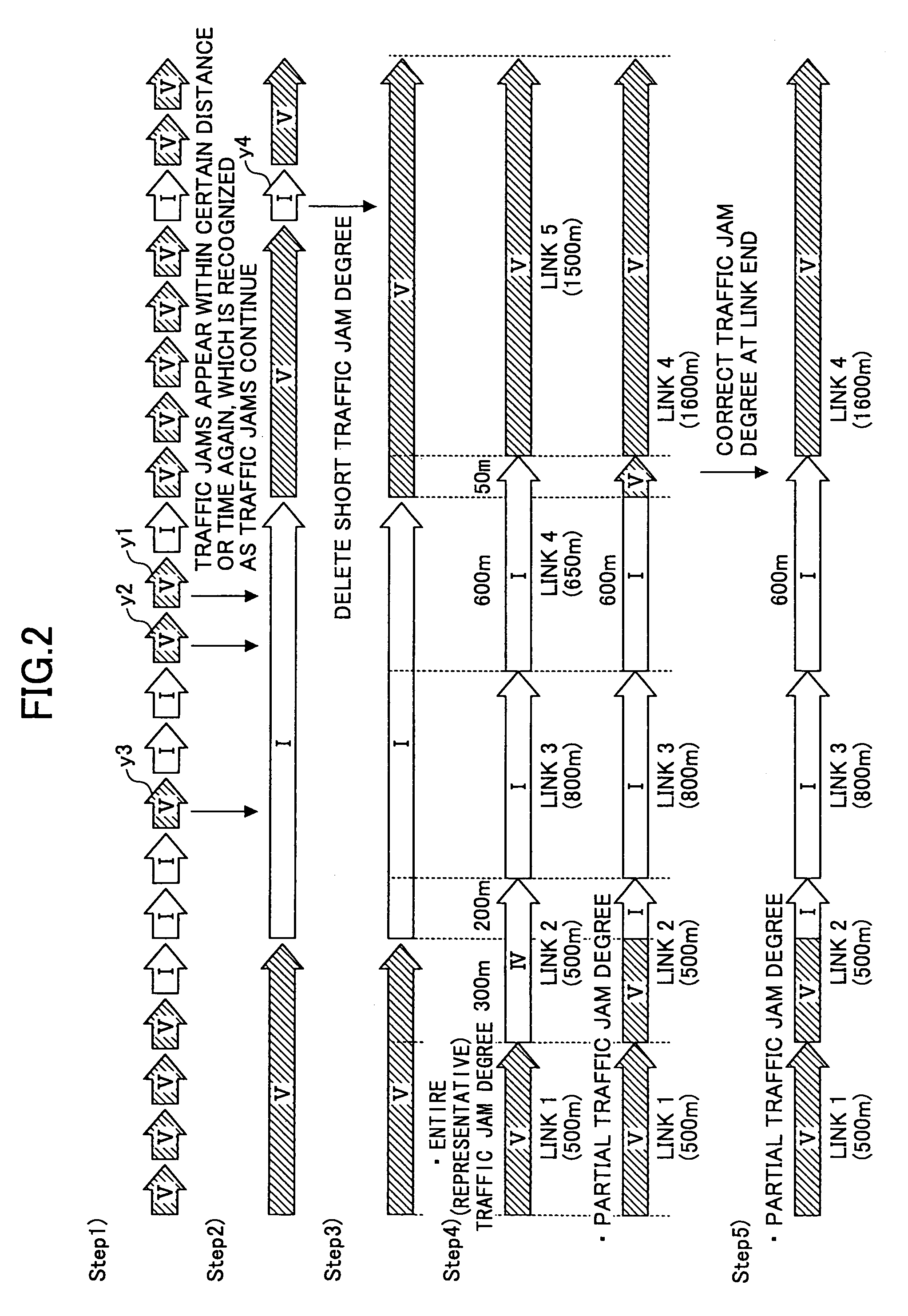

Traffic information generation method, traffic information generation device, and navigation system

ActiveUS20100138141A1Eliminate reductionControlling traffic signalsAnalogue computers for vehiclesTraffic congestionEngineering

Owner:AISIN AW CO LTD +1

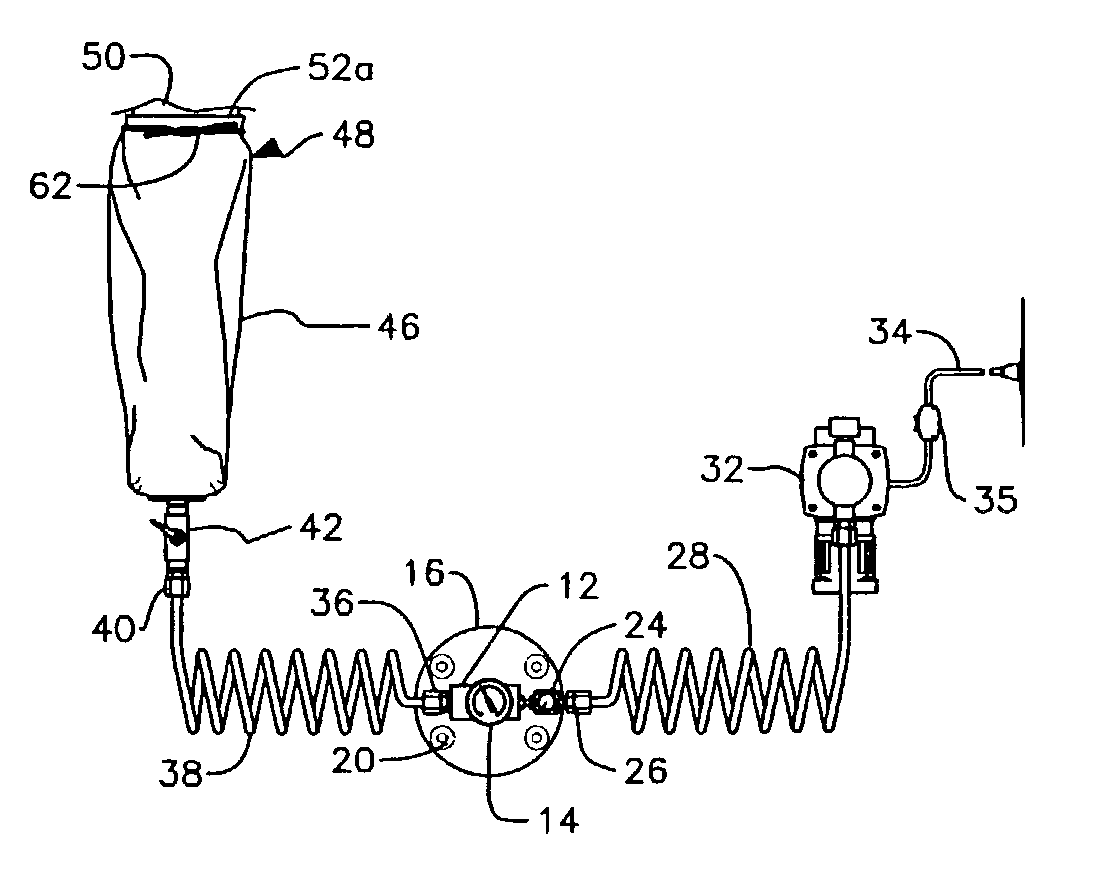

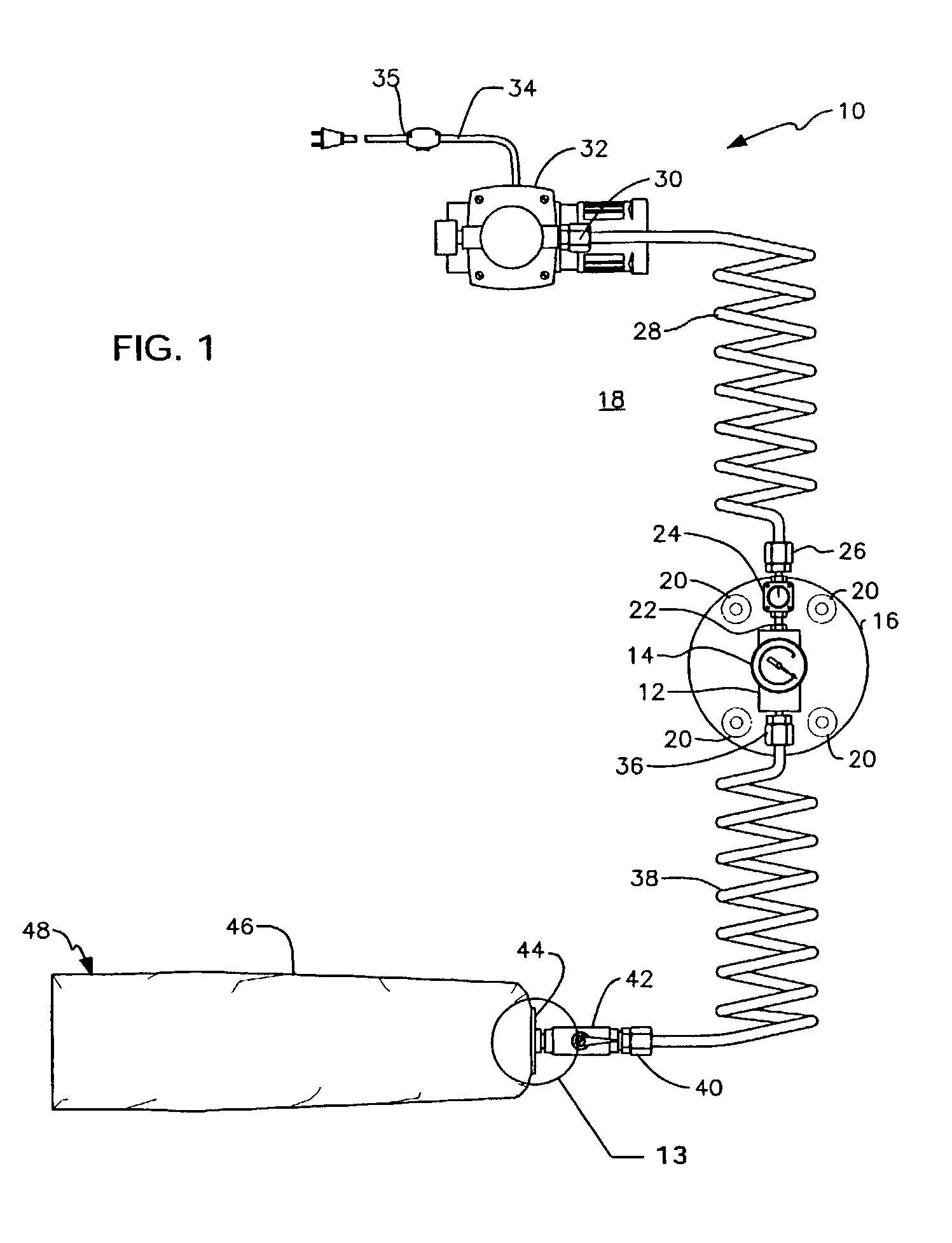

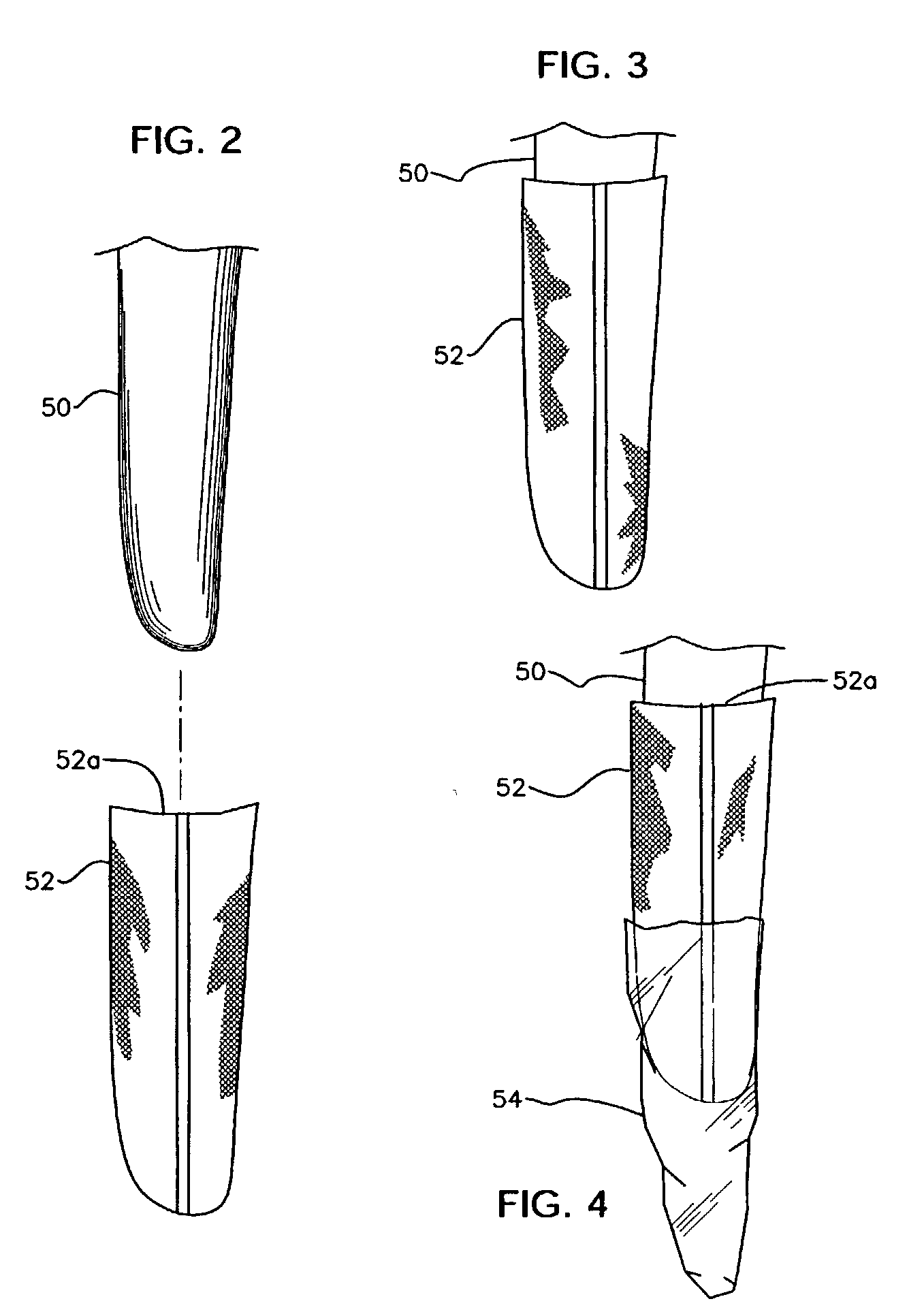

Apparatus for casting a prosthetic socket under vacuum

InactiveUS6991444B1Reduce difficultyIncrease comfortOther chemical processesConfectioneryUrologyBandage

A prosthetic socket is made by wrapping water-soaked plaster bandages around a residual limb or around a prosthetic liner within which is disposed a residual limb, and positioning a vacuum wick in overlying relation to the plaster bandages. The residual limb, prosthetic liner, plaster bandages, and vacuum wick means are then inserted into a vacuum bladder. The vacuum bladder is sealed and a predetermined vacuum is applied internally to the bladder until the plaster hardens into a negative cast. The residual limb is manipulated through the vacuum bladder to modify the geometry of the plaster before the plaster hardens. The negative cast is removed from the residual limb and a positive cast is produced by pouring plaster into the negative cast. A thermoplastic sheet is thermoformed over the positive cast or a carbon-epoxy matrix is laminated over the positive cast. This eliminates reduction and modification of a hard positive cast.

Owner:LAGHI ALDO A

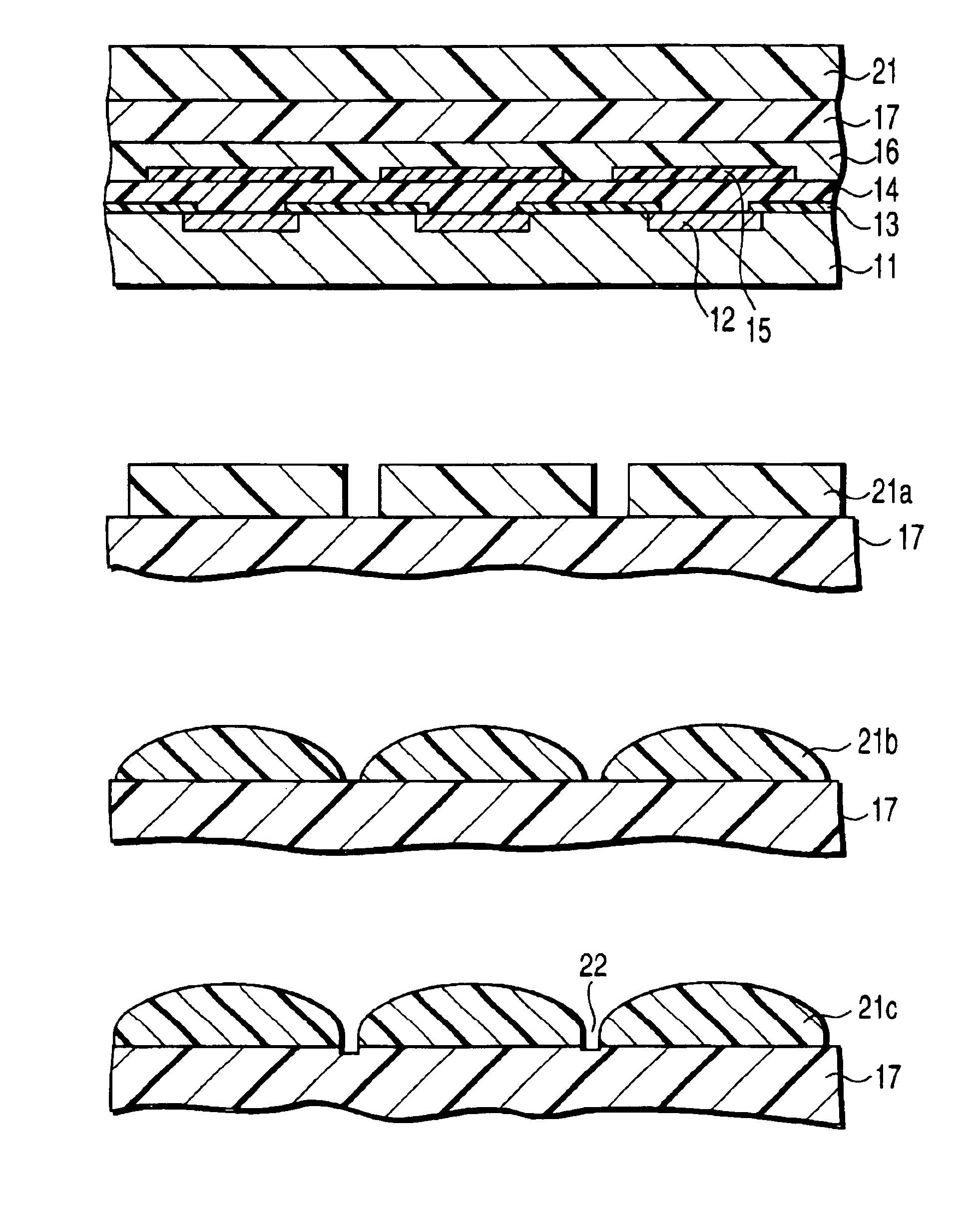

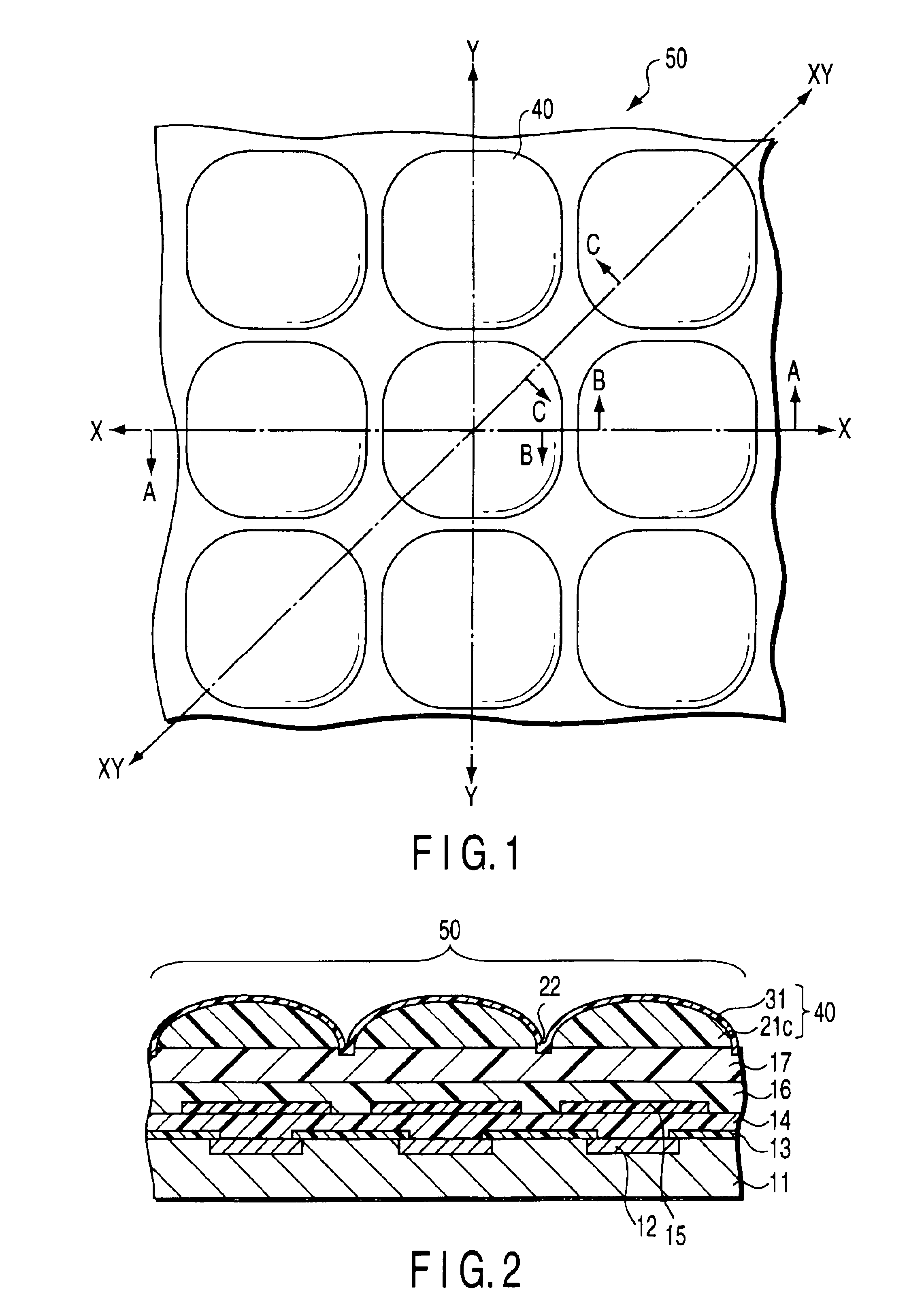

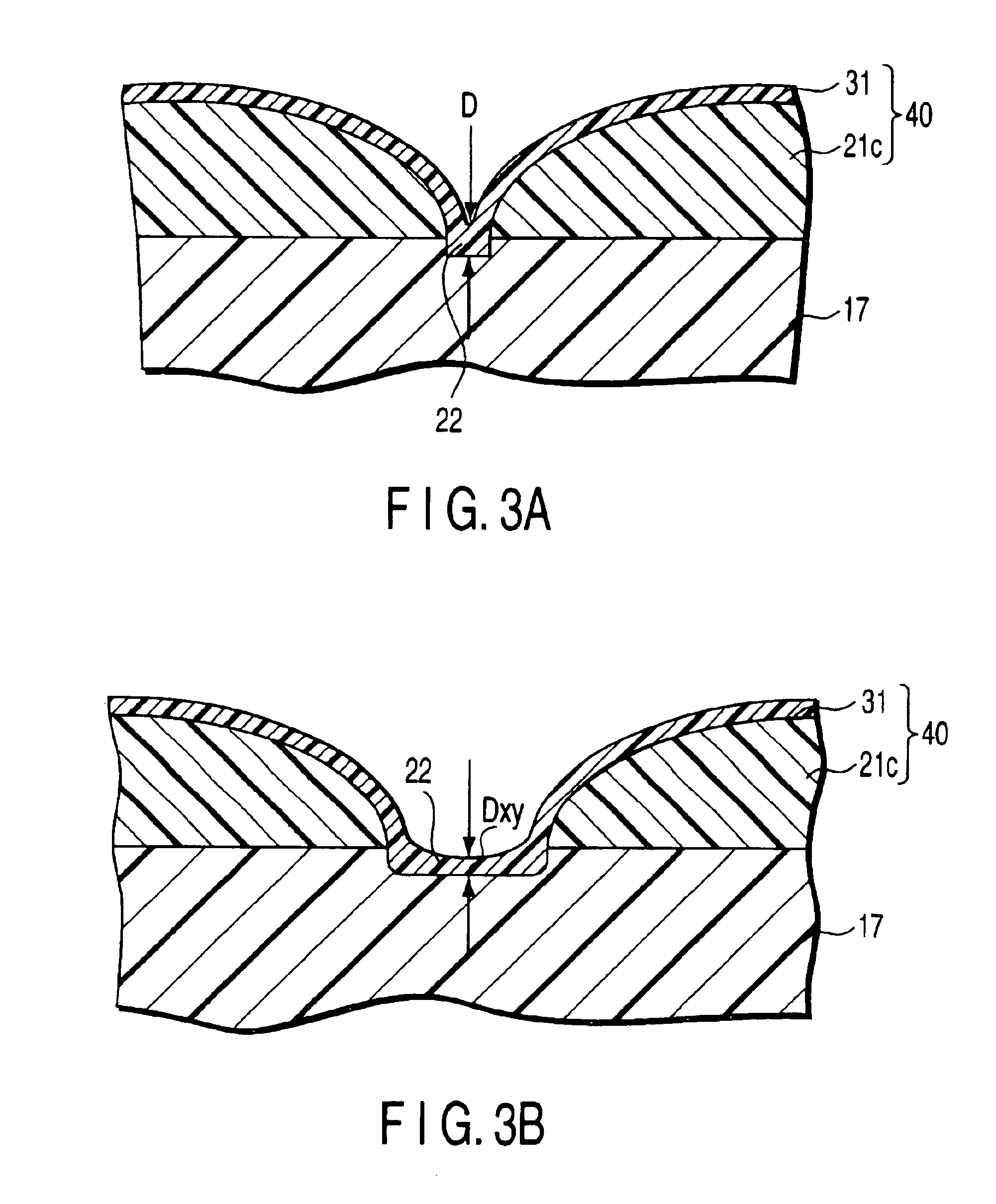

Solid image-pickup device having a micro lens array and method of manufacturing the same

InactiveUS6950140B2Solve the low opening rateHigh rateTelevision system detailsSolid-state devicesResistEngineering

A photovoltaic element, a light shielding portion, a planarized layer, a color filter, another planarized layer and an undercoat layer are formed successively on a semiconductor substrate, followed by forming resin lenses. The undercoat layer positioned between adjacent resin lenses is subjected to an etching treatment with the resin lenses used as a resist mask so as to form ditches extending in the X- and Y-directions and other ditches extending in the XY-direction. Further, a transparent resin layer having a predetermined thickness is formed to cover the resin lenses and the ditches, thereby obtaining a solid image-pickup device comprising a micro lens array including a plurality of micro lenses.

Owner:TOPPAN PRINTING CO LTD

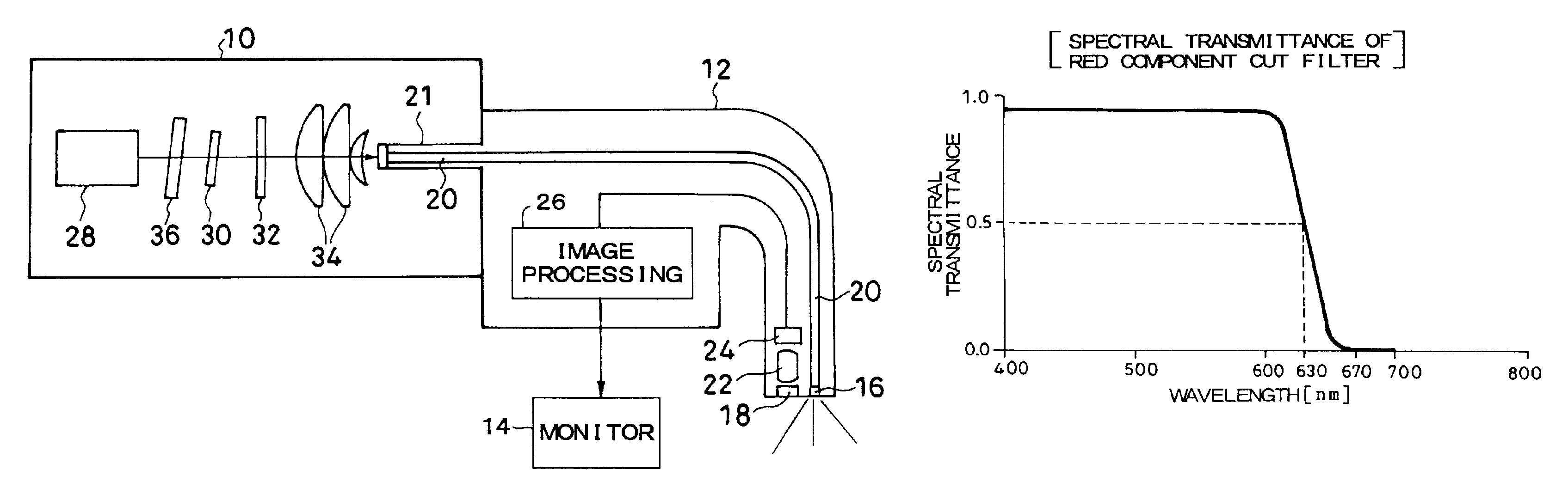

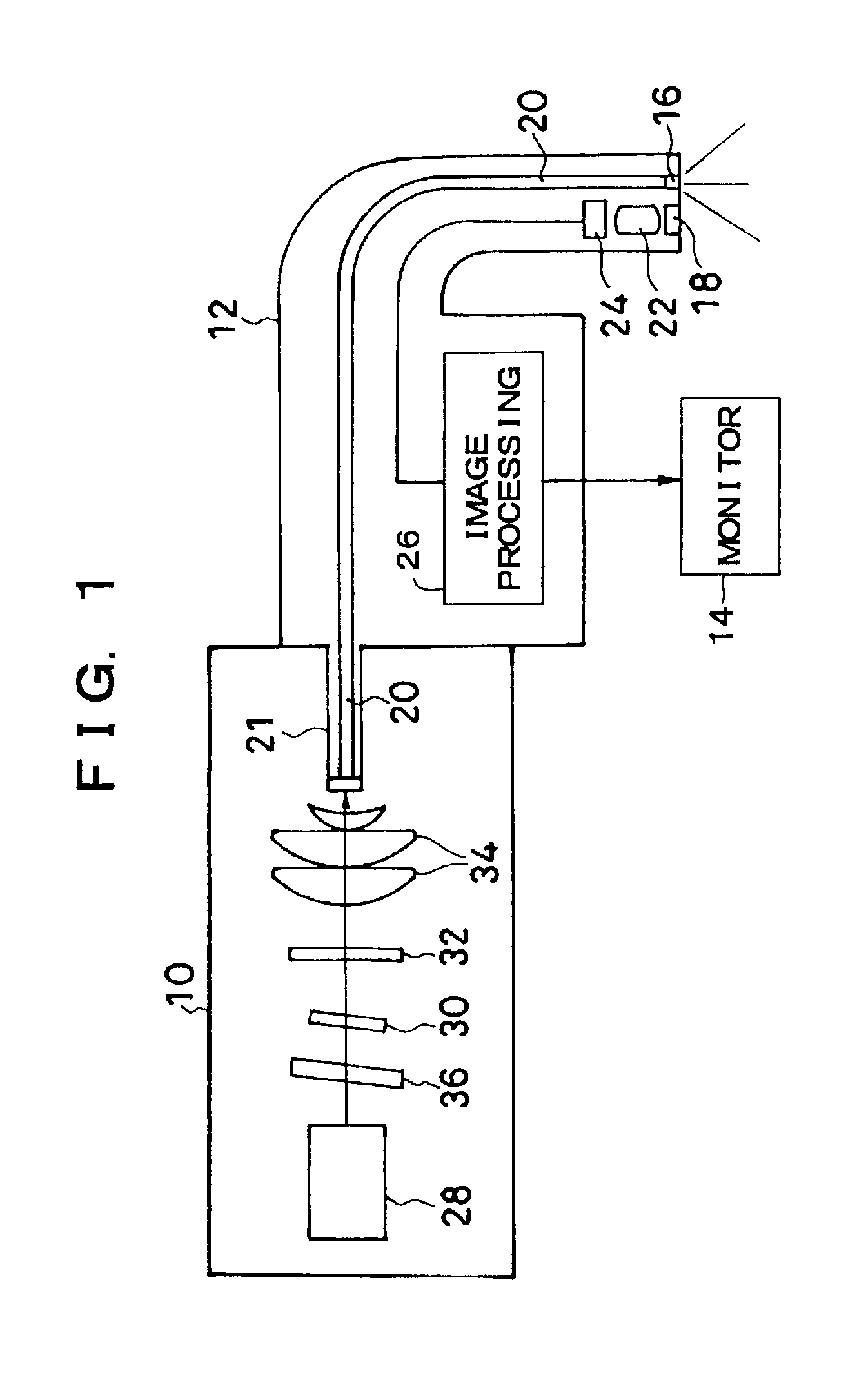

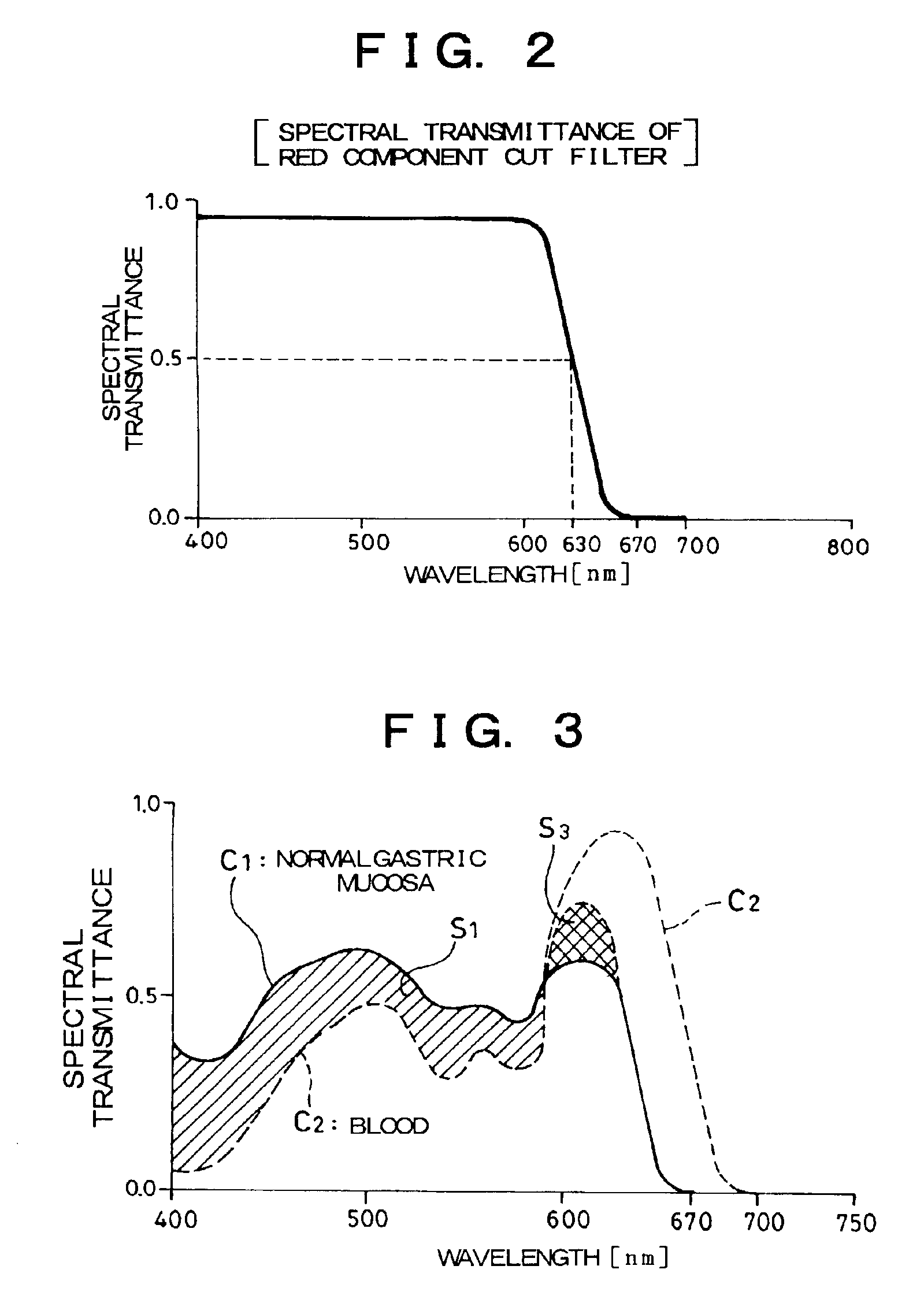

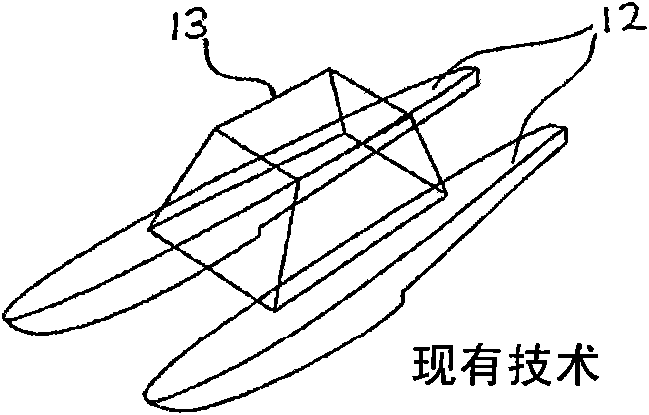

Endoscope having red component cut filter

An endoscope includes a red component cut optical filter having a characteristic that a spectral transmittance becomes half at 630 nm and zero at 670 nm, for example between a light source and an infrared cut filter, to remove a long wavelength component mainly in a red band of illumination light. This restrains scattering of light on a long wavelength side of red light, and allows taking images of mucosa, blood vessels, and other tissue in good contrast in an object to be observed and satisfactorily observing them on a monitor. Further, reduction in light amount resulting from cutting a red component with the filter is eliminated by light amount control with an aperture and gain control of a signal.

Owner:FUJI PHOTO OPTICAL CO LTD

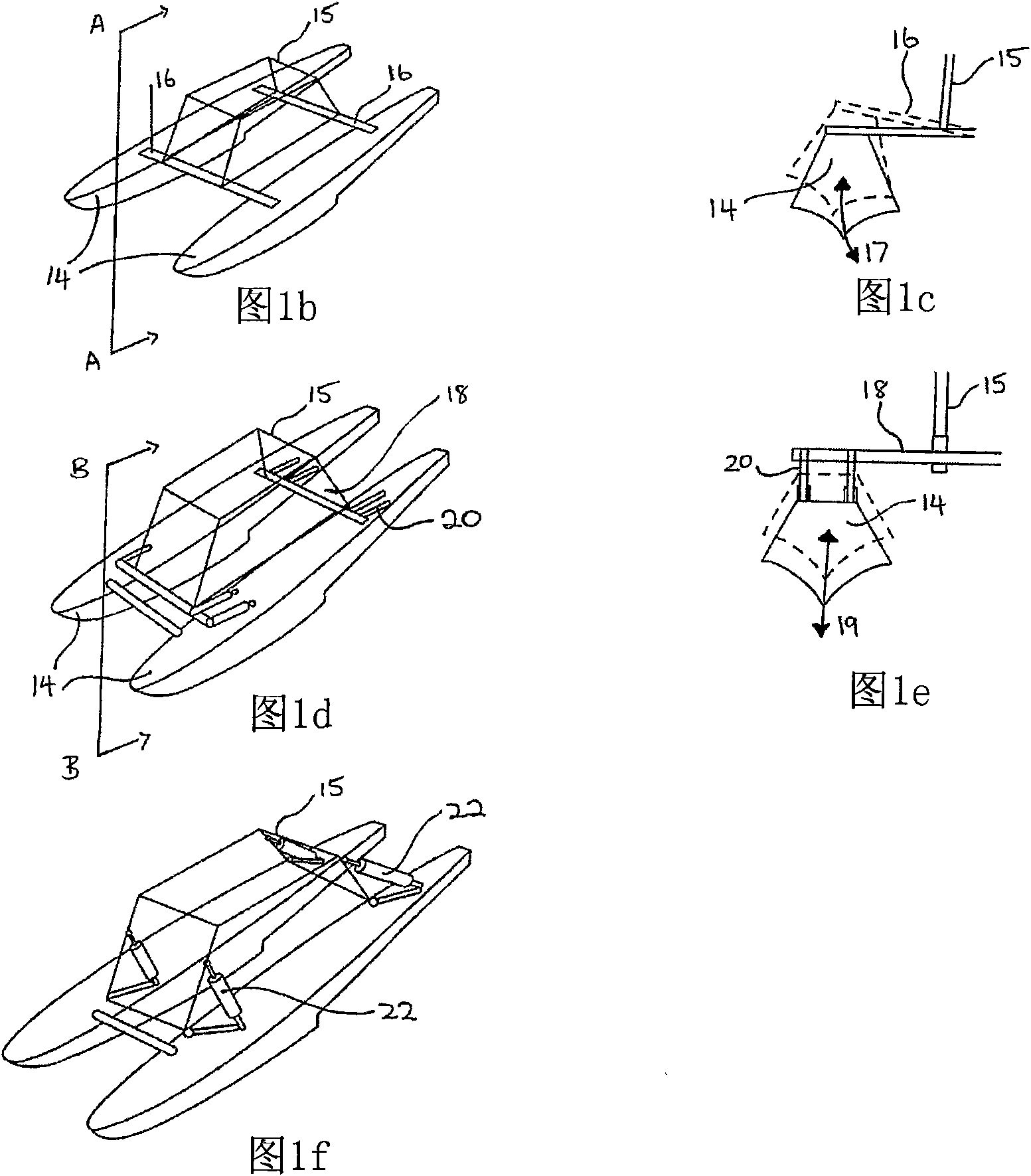

Improvements in aircraft

InactiveCN101678895AInhibition formationSmall surface areaConvertible aircraftsFloatsSolid surfaceFuselage

Owner:TIGERFISH AVIATION PTY LTD

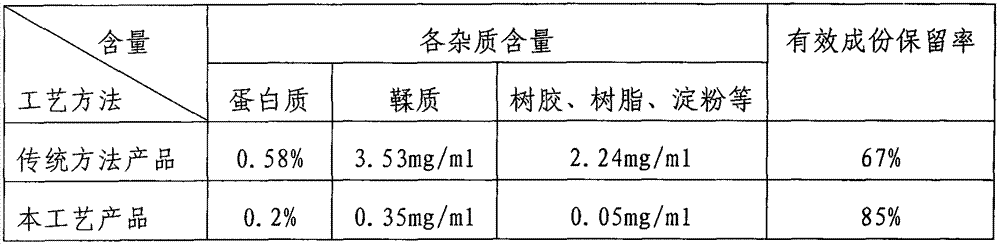

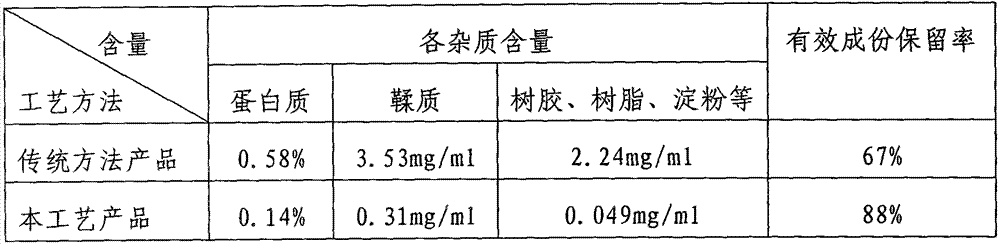

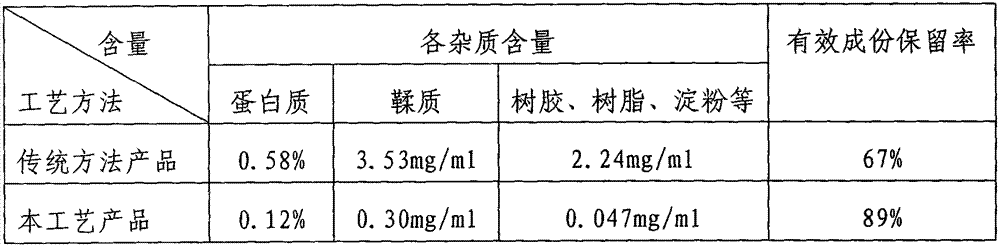

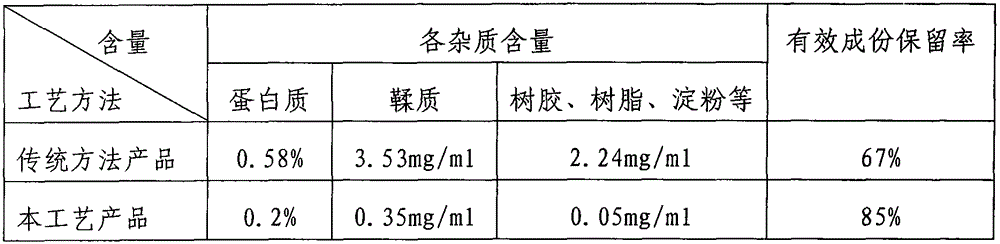

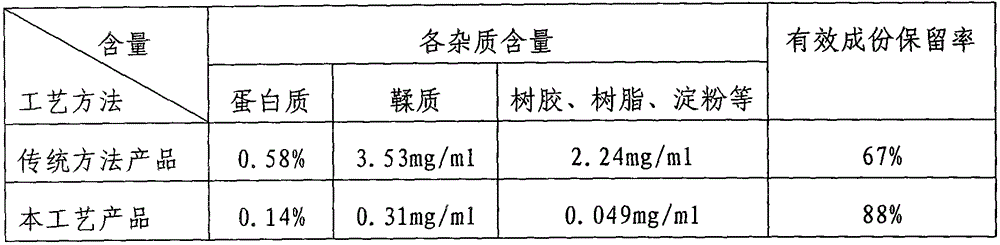

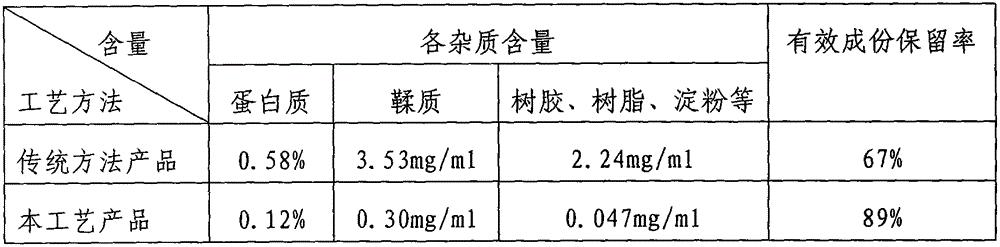

Technology for preparing salviae miltiorrhizae oral liquid with ceramic membrane

ActiveCN103494879ASolving Clarity IssuesEnsure clarityPlant ingredientsUltrafiltrationFiltration technique

A technology for preparing salviae miltiorrhizae oral liquid with a ceramic membrane is characterized by comprising the following steps of decoction, concentration, centrifugal filtration through a high-speed centrifuge, primary filtering by ceramic membrane with the hole diameter of 150000-180000 molecular weight, secondary filtering by ceramic membrane with the hole diameter of 80000-120000 molecular weight, ultrafiltration by ceramic membrane with the hole diameter of 20000-50000 molecular weight, nanofiltration concentration by ceramic membrane with the hole diameter of 300-450 nanometers, concentrating medicine liquid to the amount 2.5-3.5 times that of medicinal materials, final preparation and embedment sterilization. Heating processes in the whole technology course are reduced, ceramic membrane filtering with different molecular weights and refining under normal temperature are carried out, impurities are effectively removed, effective constituents are reserved to the maximum degree, an extracting technology is shortened, pollution is lowered, energy is saved, clean production is achieved, the technology accords with traditional Chinese medicine theoretical system, an ultrafiltration membrane filtering technology is used, degerming and pyrogen effect is good, and the clarity of medicine liquid is guaranteed and improved.

Owner:江苏恒沣药业有限公司

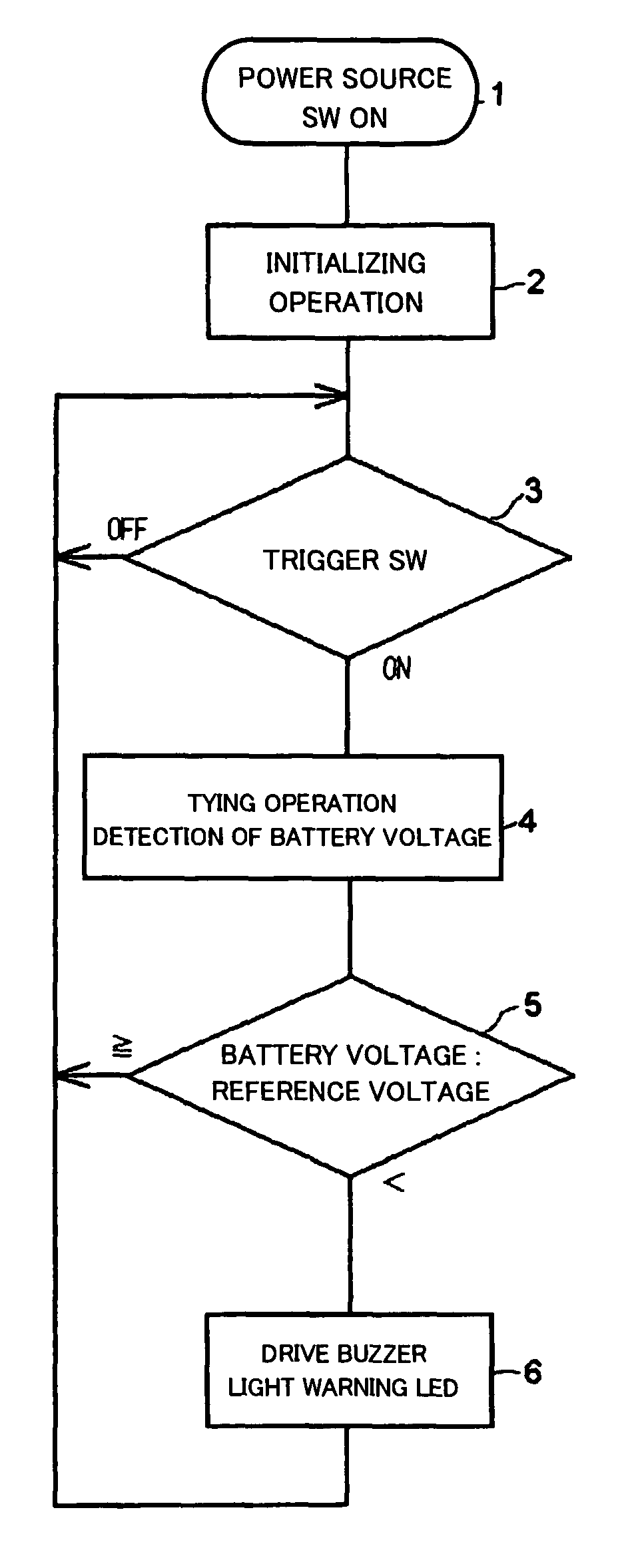

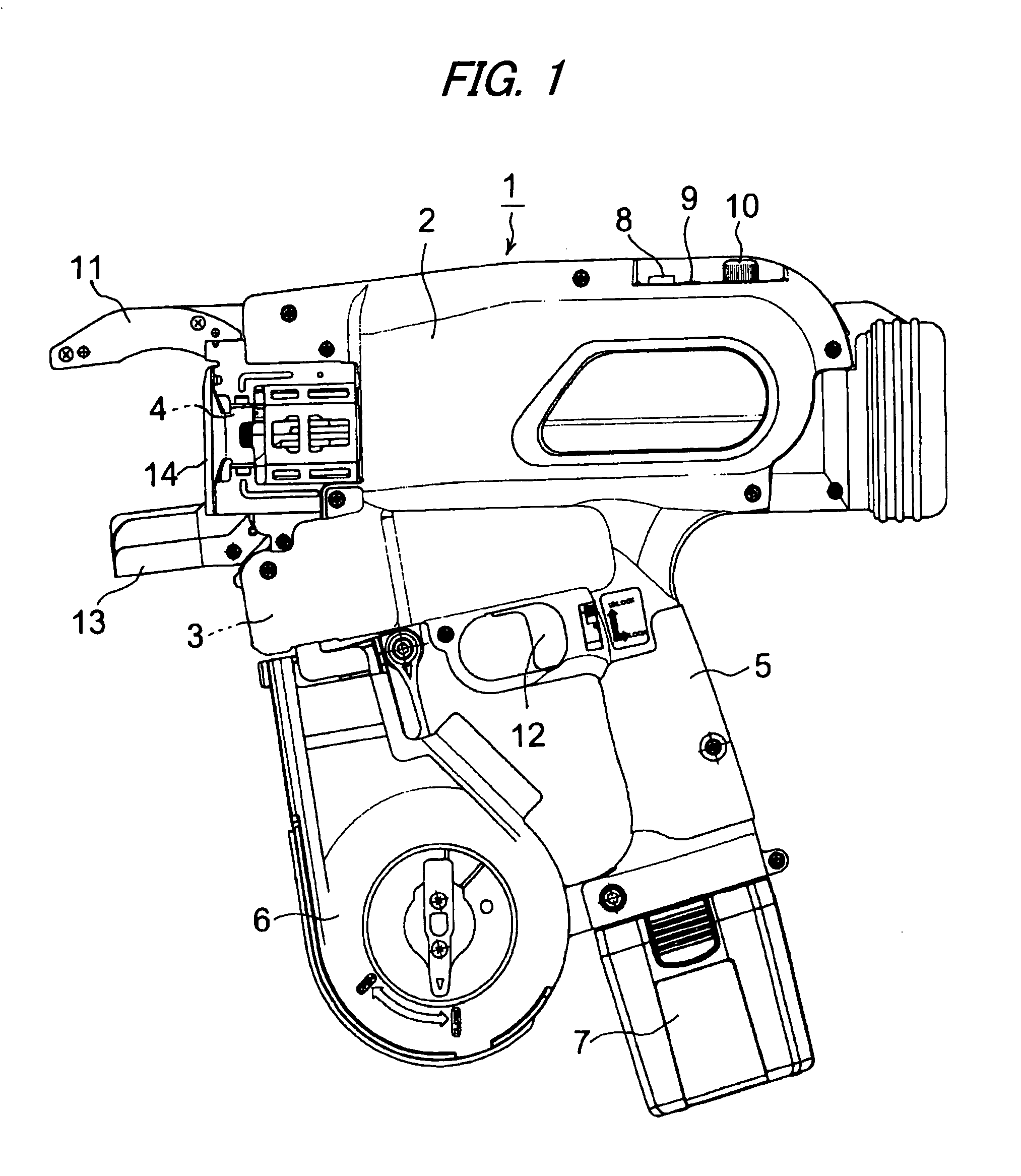

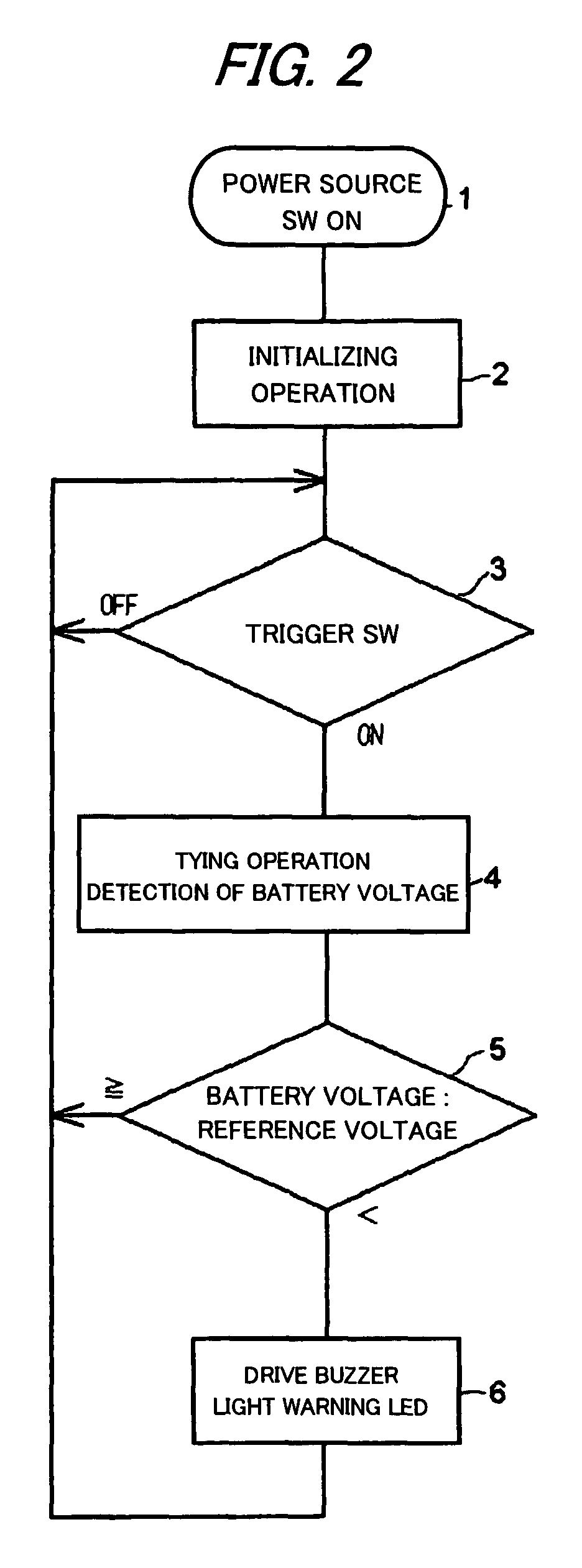

Rechargeable electric tool

ActiveUS7817053B2Shorten the timeEliminate reductionCurrent/voltage measurementSecondary cells charging/dischargingElectrical batteryVoltage reference

A rechargeable electric tool includes a warning device which monitors a voltage of a power source battery and indicates a warning by means of an LED or a buzzer when the power source voltage is reduced to be equal to or lower than a reference voltage. The tool is configured such that, even when the warning is indicated, a control to interrupt a power supply to a motor is not performed, thereby enabling a usual operation in response to an activating operation on a trigger switch.

Owner:MAX CO LTD

Water-borne aluminum foil working fluid

Owner:FOSHAN SHUNDE FUYANSHENG LUBRICANT

Traffic information generation method, traffic information generation device, and navigation system

ActiveUS8433504B2Eliminate reductionControlling traffic signalsAnalogue computers for vehiclesEngineeringNavigation system

Owner:AISIN AW CO LTD +1

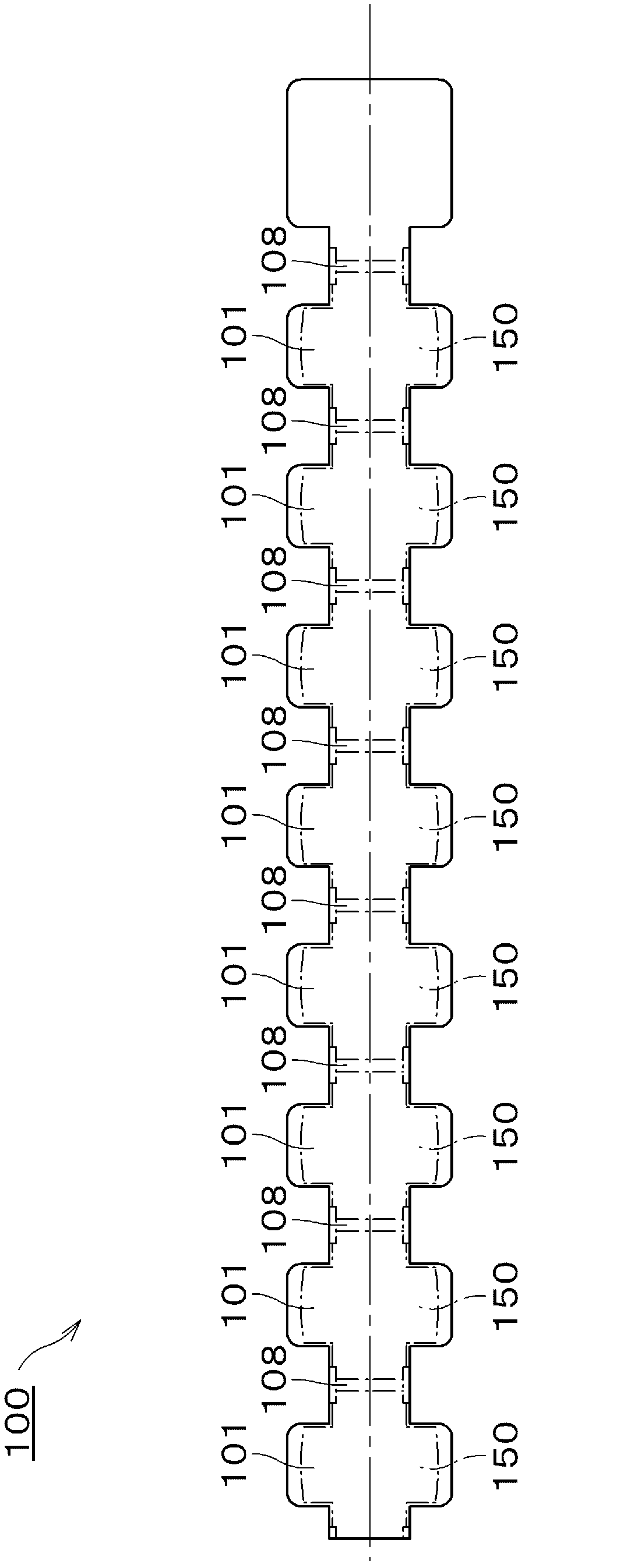

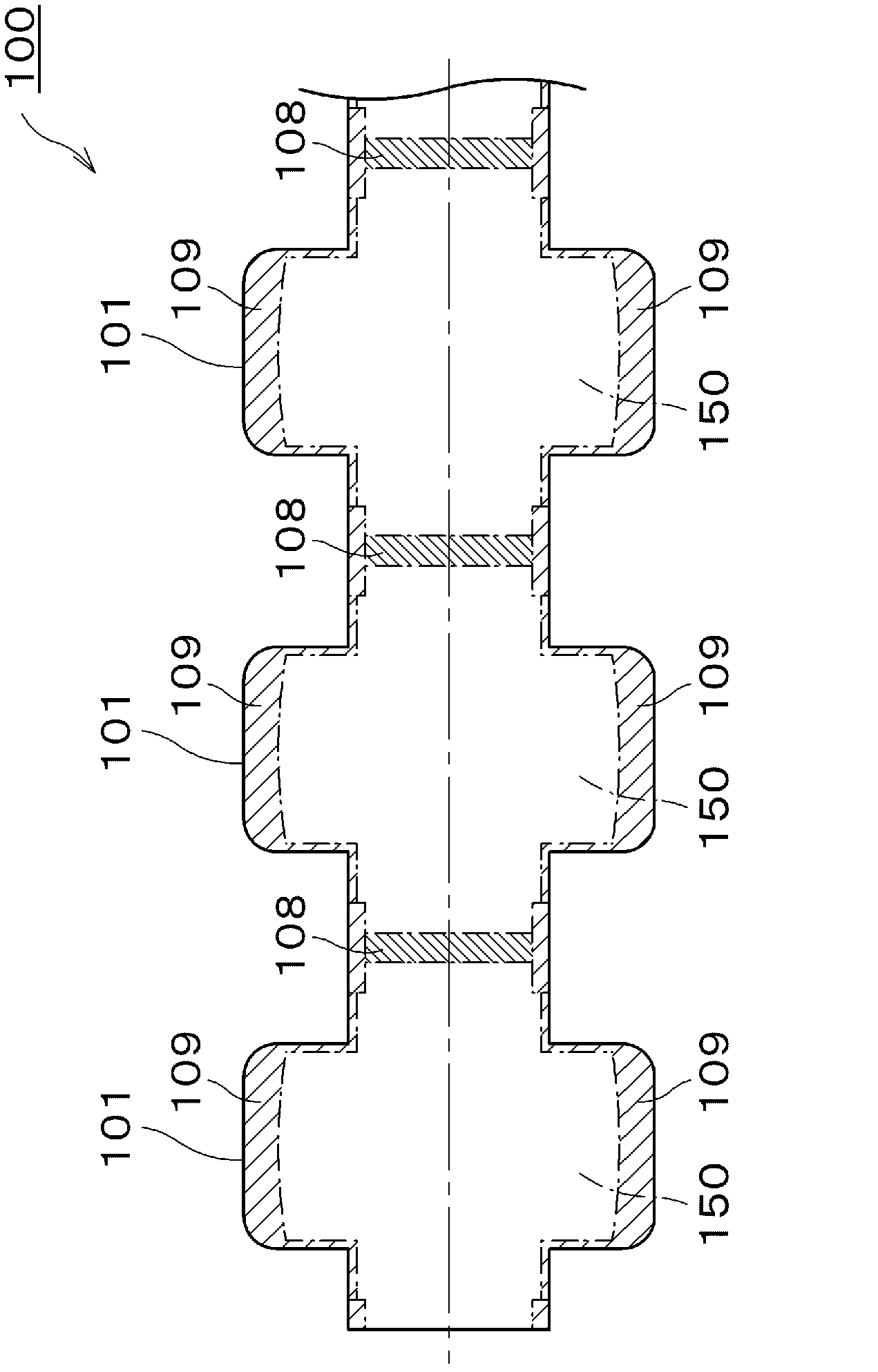

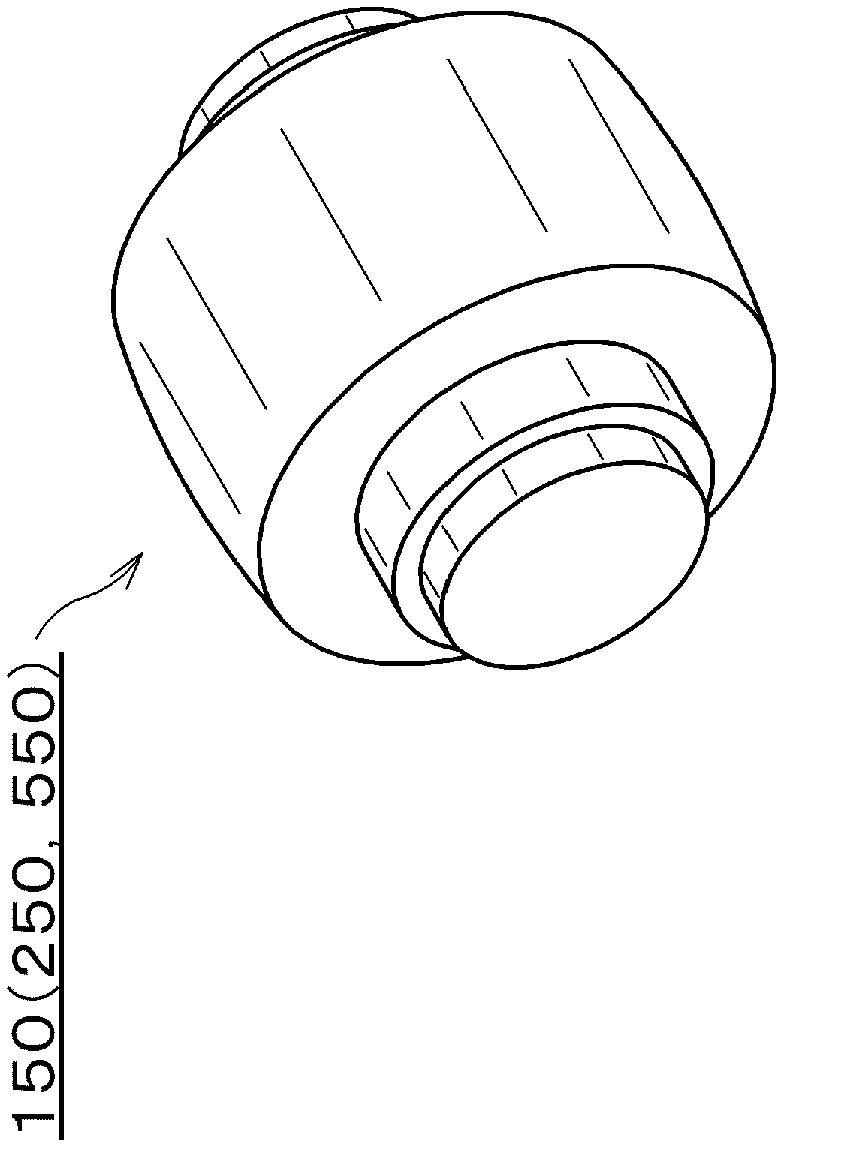

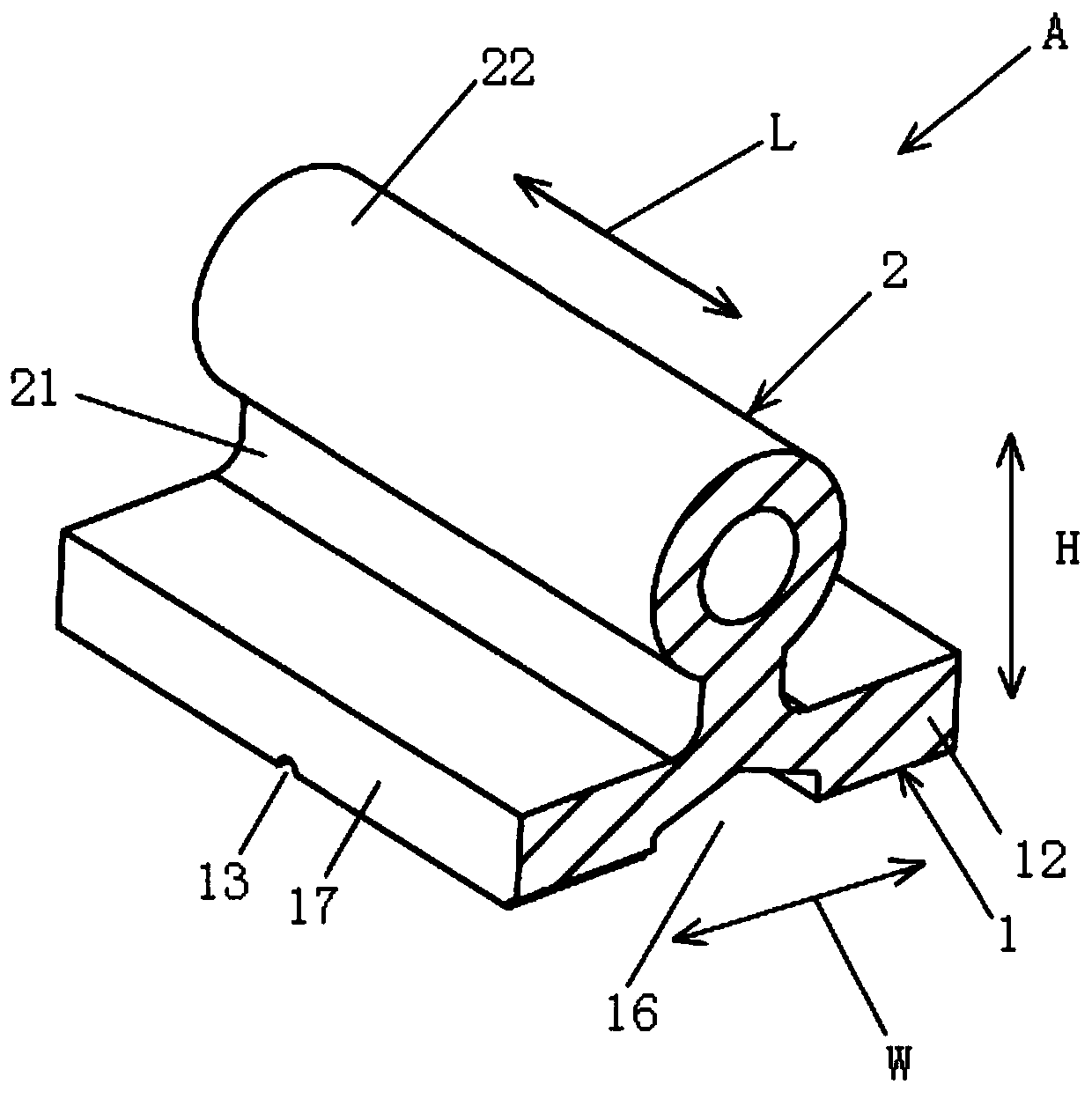

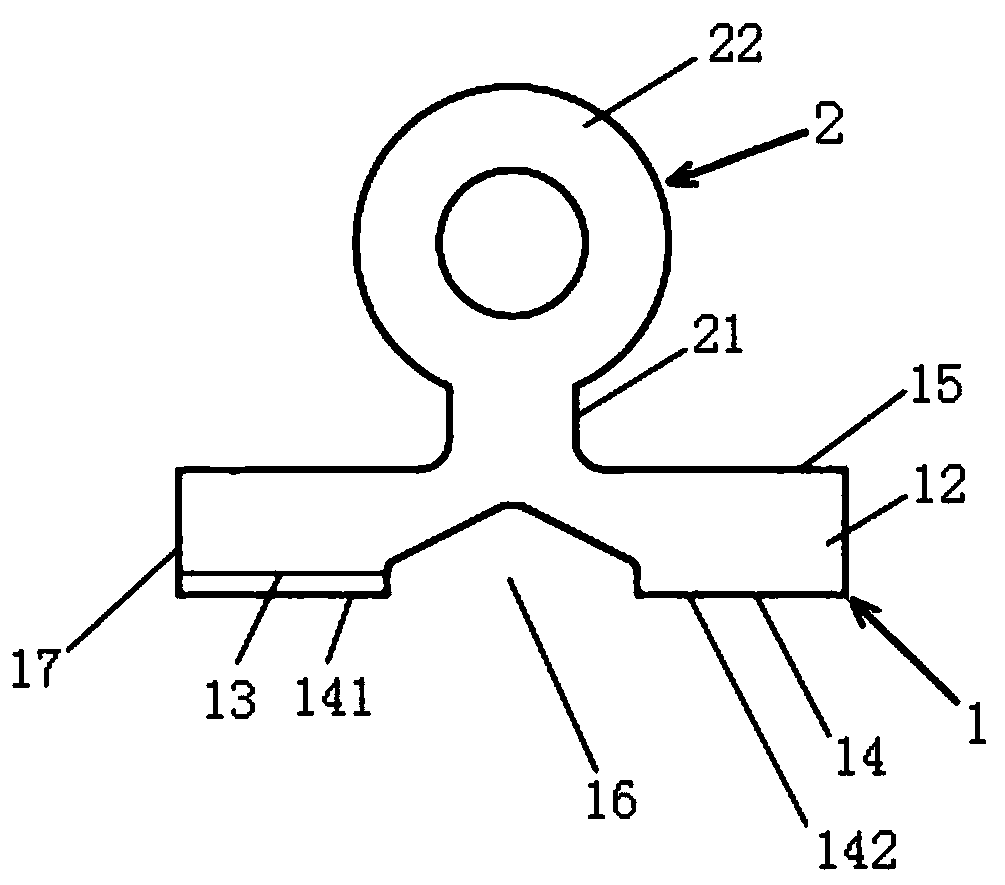

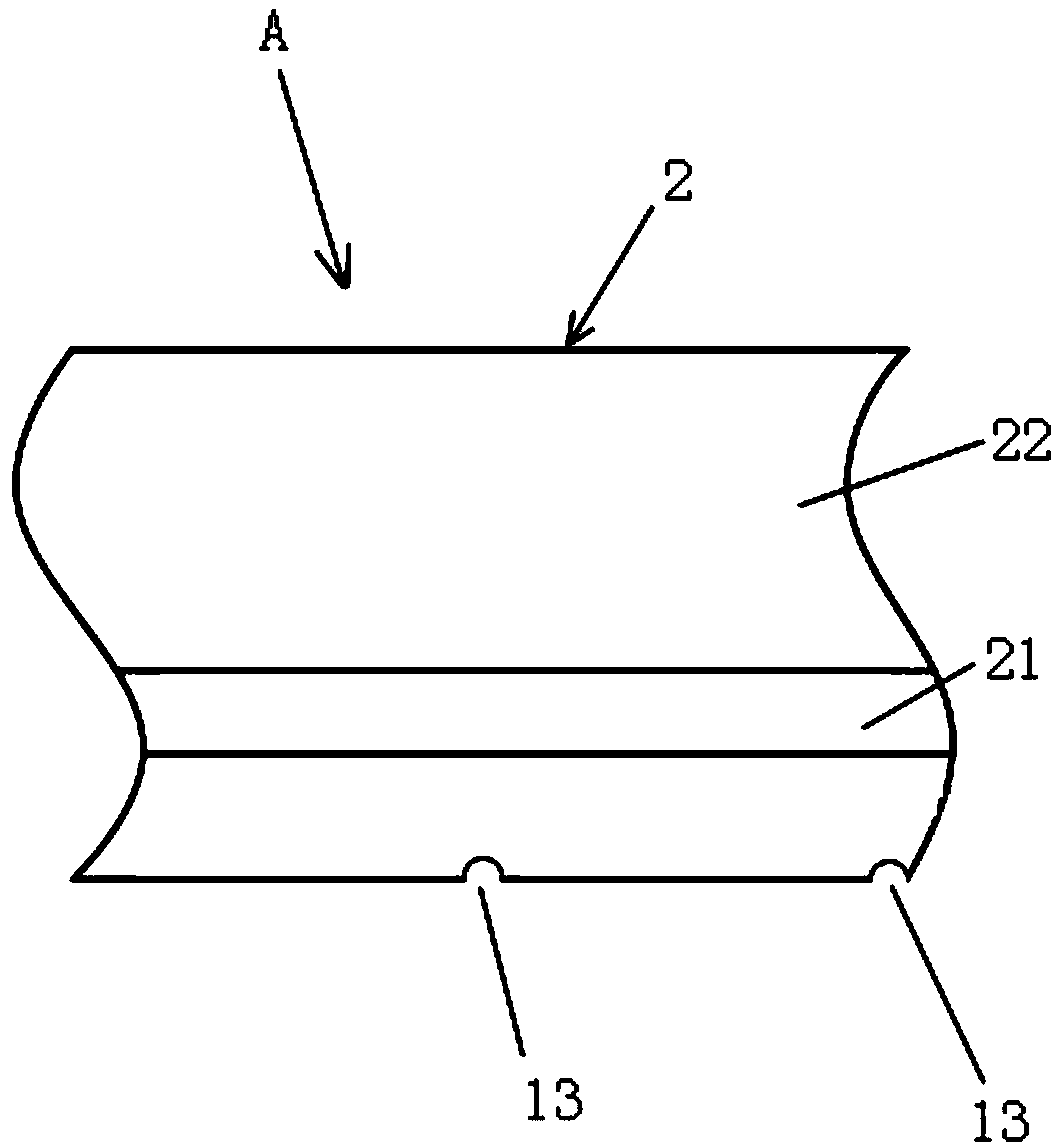

Workpiece material and grasping mechanism

InactiveCN102574207AReduce removal partReduce wasteSleeve/socket jointsFoundry mouldsMaterial removalSwarf

Provided is a workpiece material and a grasping mechanism which are capable of performing accurate positioning, even if a dimension error in an axial direction is caused, while reducing a handling time that is not involved in a working and reducing the overall time required to obtain a plurality of work completion members, and which reduce a load of the disposal of discharged swarf with less waste of a material. A workpiece material (100) has a shape obtained by integrally molding a plurality of formed materials (101) that is to be a product by a material removal work. A grasping mechanism (110) is provided with a free movement means (120) for causing a grasping unit (112) and the workpiece material (100) to be relatively freely moved and is provided with a positioning means for defining an axial-direction grasping position of the grasping unit (112) and the workpiece material (100).

Owner:CITIZEN WATCH CO LTD

Sealing part, foamed forming mould and manufacturing method of foamed forming body

ActiveCN107461495AEfficient replacementReduced and easy to removeEngine sealsDomestic articlesEngineeringMechanical engineering

Owner:TOYOTA BOSHOKU KK +1

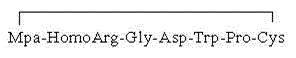

Novel reduction-oxidation system for preparing Eptifibatide

InactiveCN105001304AEliminate reductionReduce the difficulty of purificationPeptide preparation methodsCombinatorial chemistryPeptide synthesis

The invention relates to the field of polypeptide synthesis and particularly relates to a novel reduction-oxidation system for preparing Eptifibatide. According to the technical scheme of the invention, the novel reduction-oxidation system for preparing Eptifibatid is provided to solve the problems of high crude peptide purification difficulty and low product yield due to dimer impurities that easily occur during the cracking process of Eptifibatide. According to the technical scheme of the invention, the linear peptides of Eptifibatid are synthesized based on the Fmoc solid-phase synthesis method. Firstly, the reduction reaction of intermolecular disulfide bonds of dimer impurities in the linear peptide solution is realized by DTT, and then the pH value of the solution is regulated. An oxidizing agent is added and subjected to oxidization reaction so as to form intermolecular disulfide bonds, so that a crude peptide product of Eptifibatid is obtained. Finally, the crude peptide product is subjected to chromatography purification, salt transferring and freeze-drying to obtain the pure peptide product of Eptifibatid. The preparation method is simple to operate and the obtained pure peptide product is high in both purity and yield. Therefore, the method is suitable for scale-up production.

Owner:JINAN KANGHE MEDICAL TECH

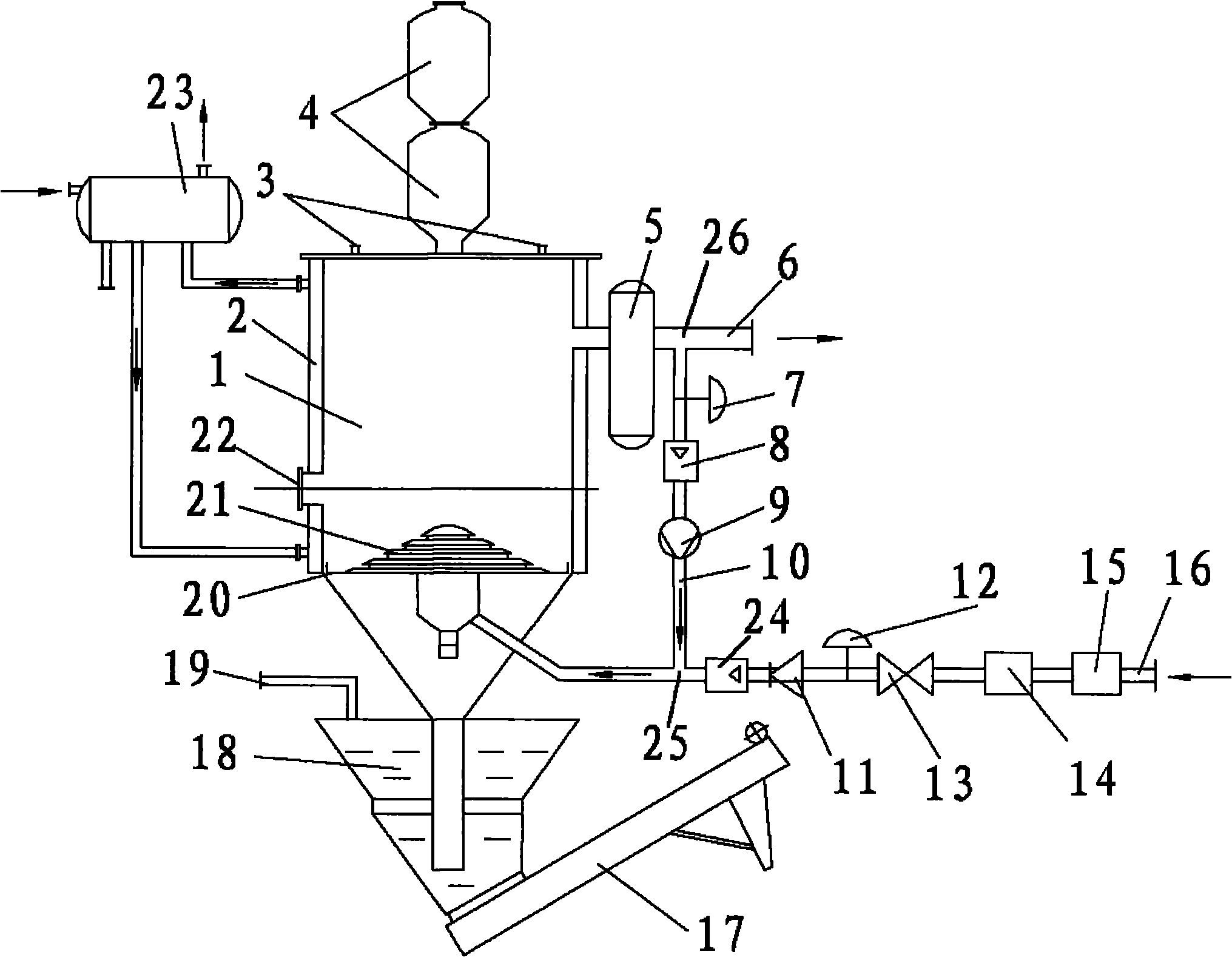

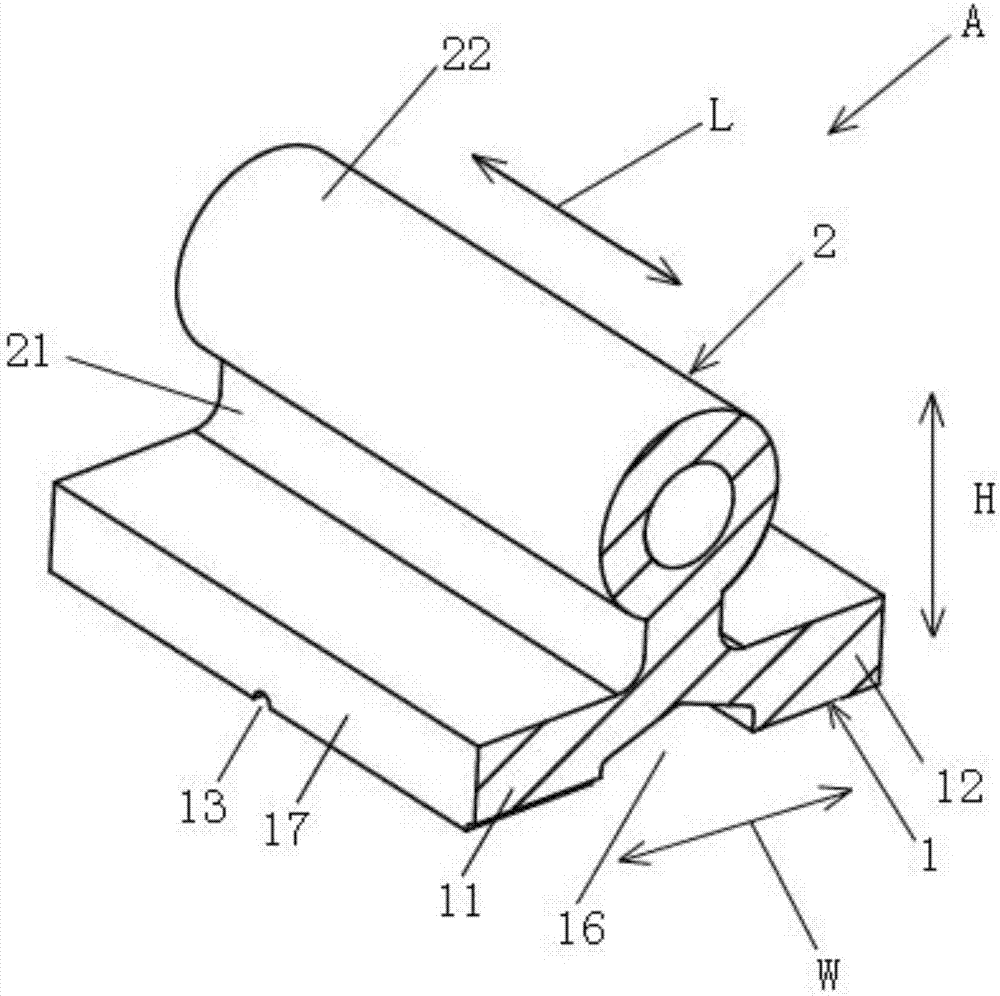

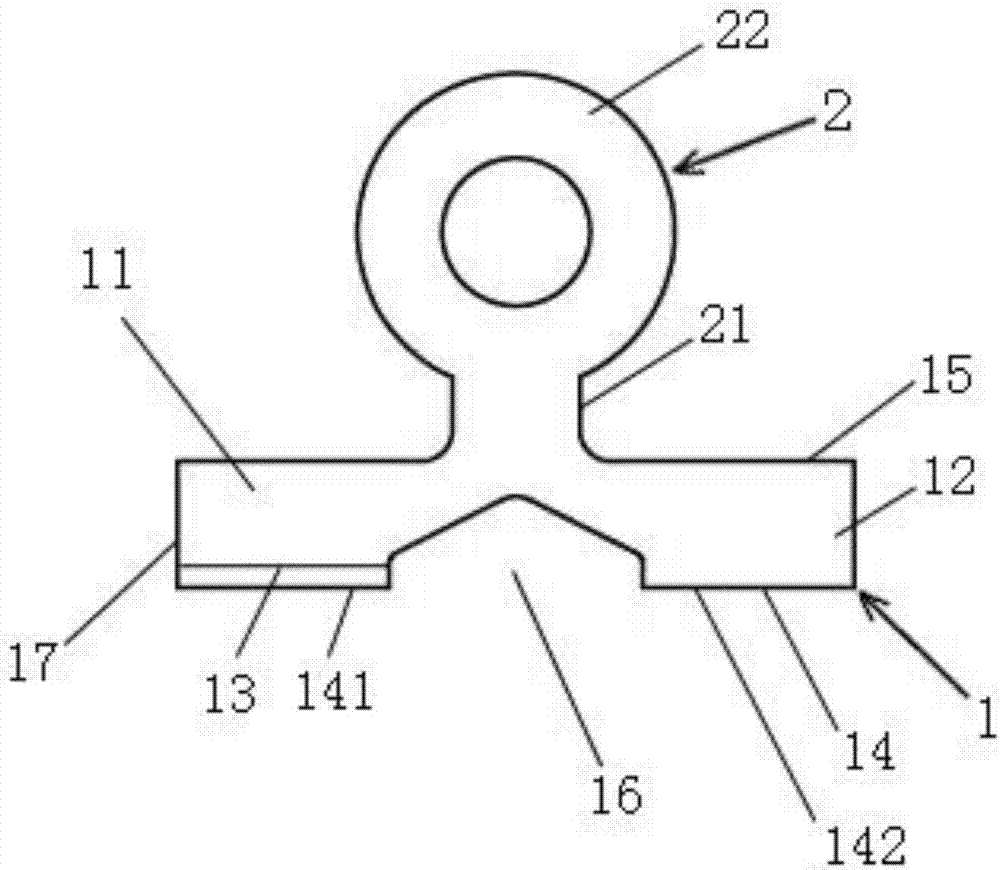

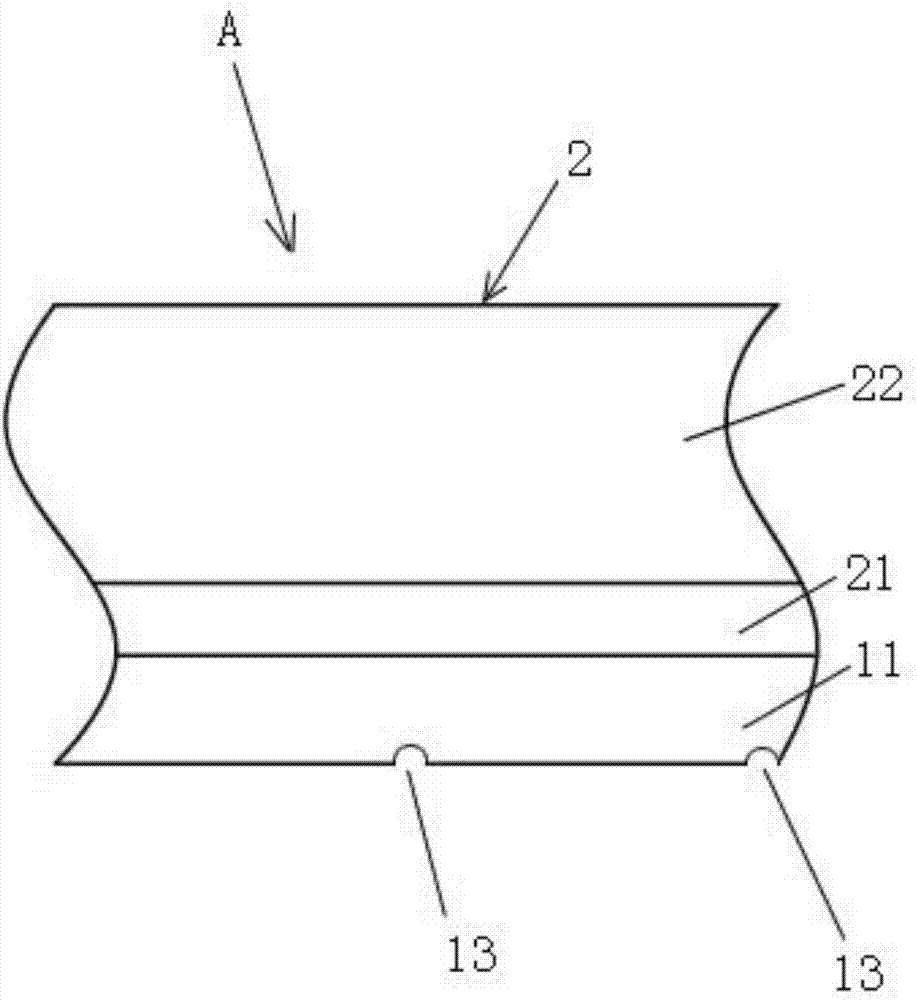

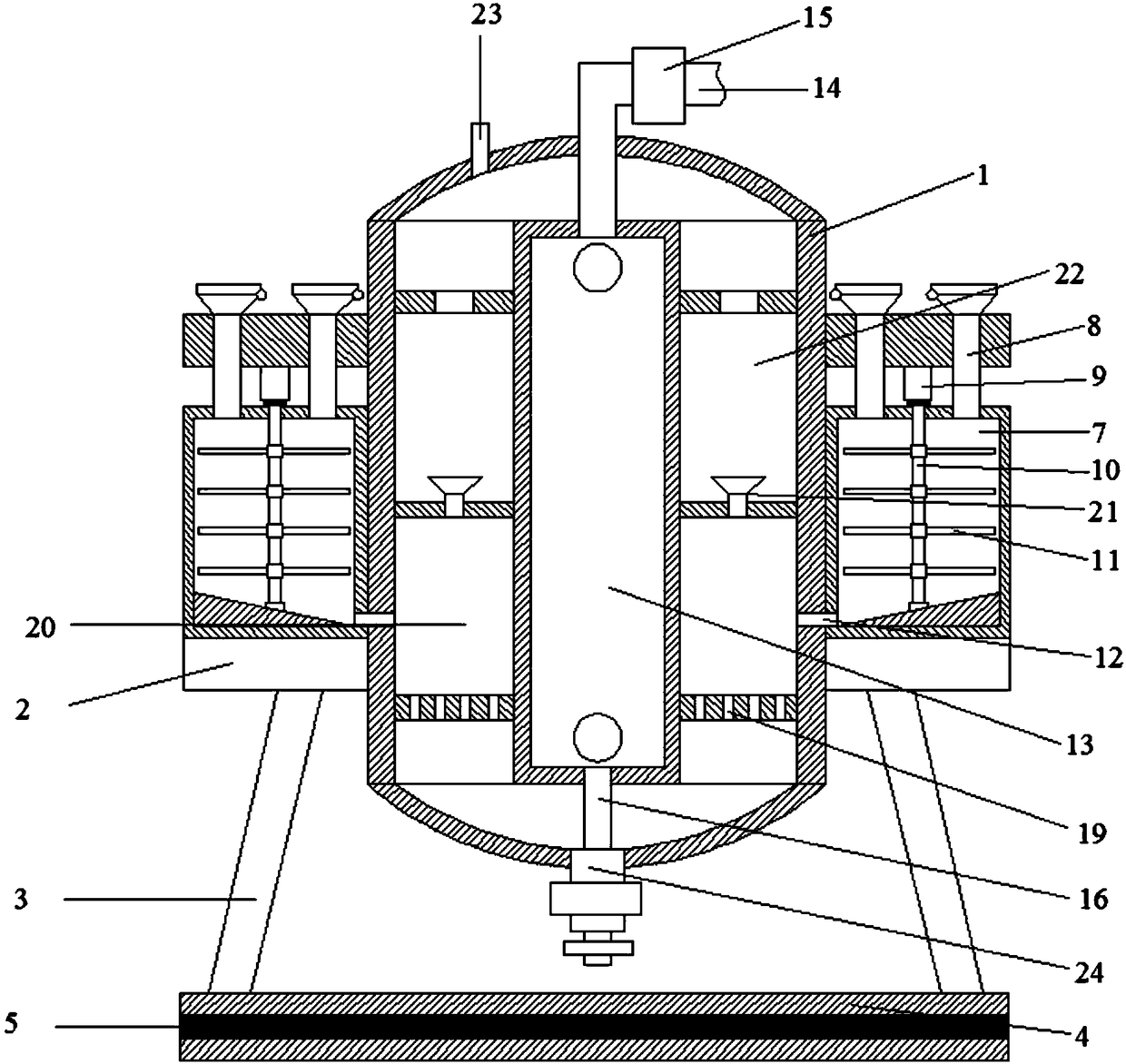

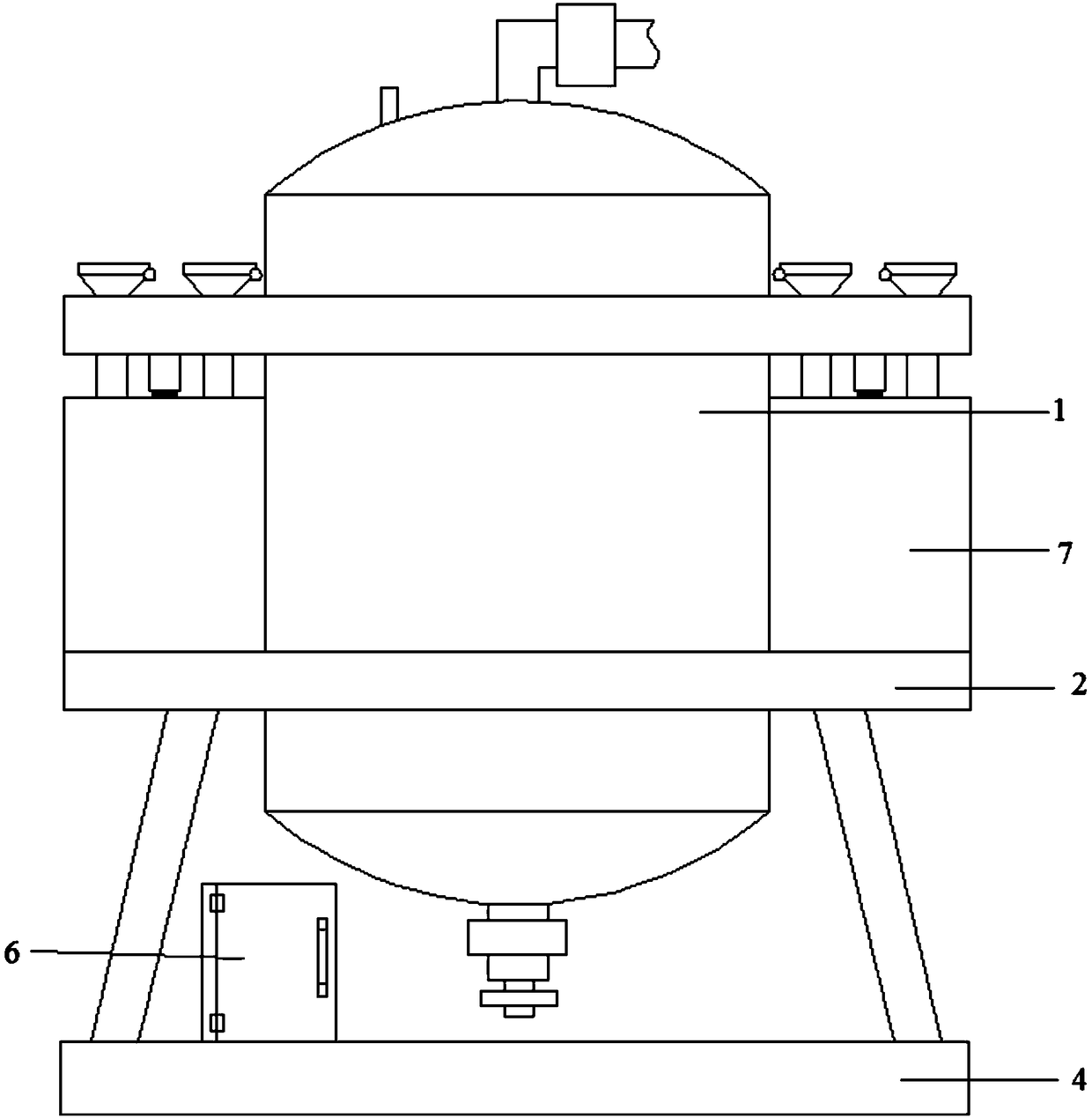

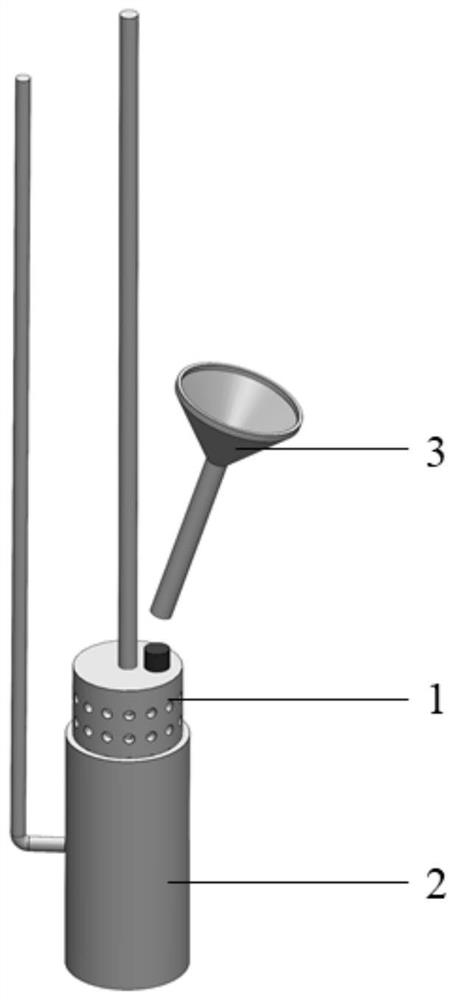

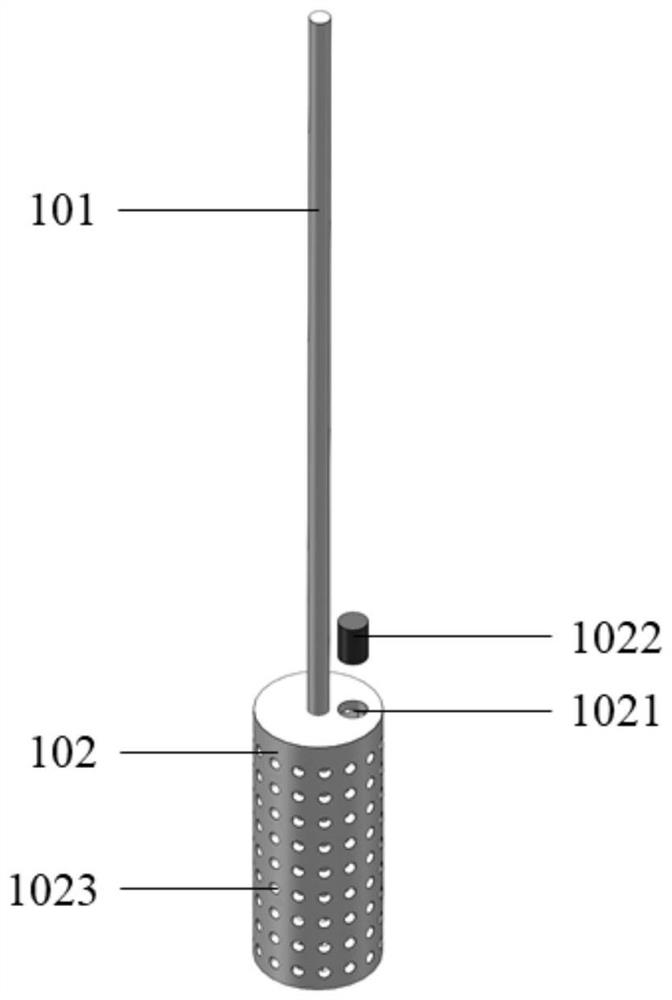

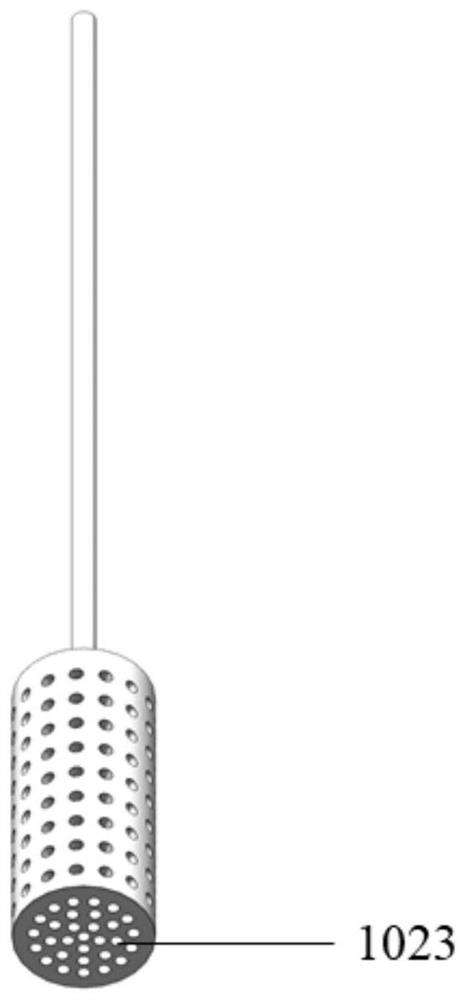

Fixed bed coal seam gas non-catalytic deoxidization method and device

ActiveCN101914402BSolving security problems in enrichmentAvoid security issuesGaseous fuelsFixed bedEngineering

The invention discloses a fixed bed coal seam gas non-catalytic deoxidization method and a fixed bed coal seam gas non-catalytic deoxidization device. The device comprises a fixed bed coal seam gas deoxidization device body including a furnace body (1), wherein the side wall of the furnace body (1) is provided with a water jacket (2) enclosing the side wall of the furnace body; the upper part of the water jacket (2) is connected with an air inlet of a steam pocket (23) through a pipeline; and a water inlet pipe on the lower part of the water jacket is connected with a water outlet of the steam pocket (23). The device deoxidizes the coal seam gas, can effectively control the deoxidization temperature and reduce the oxygen content in the coal seam gas to less than 0.5 percent, and maximallyreduces methane decomposition to make the methane loss less than 5 percent.

Owner:CCTEG CHINA COAL RES INST

A kind of rosemary antioxidant popping beads and its application in cigarette filter sticks

ActiveCN108338406BImprove stabilityImprove adsorption capacityTobacco smoke filtersBiotechnologyHaematococcus

Owner:YUXI KAIYUAN JINLAN BIOTECH CO LTD +1

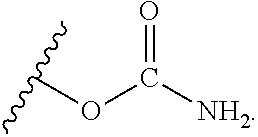

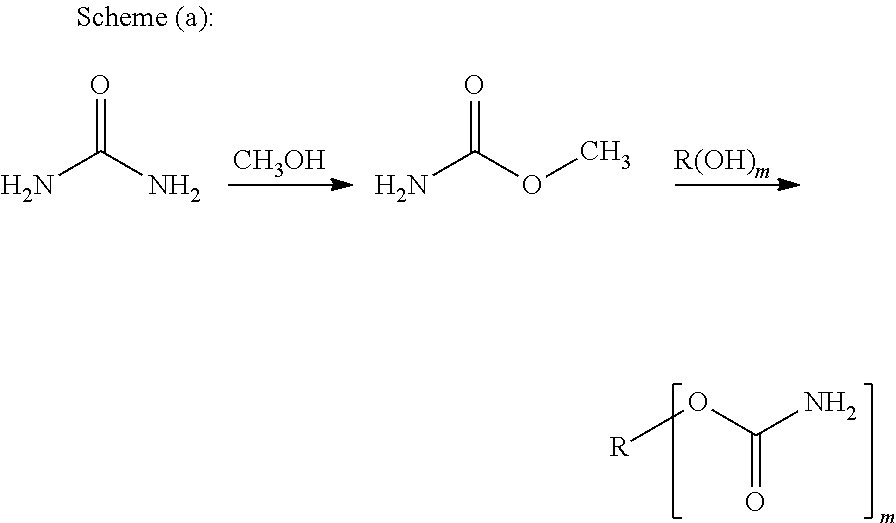

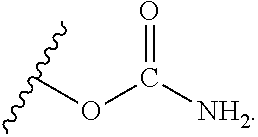

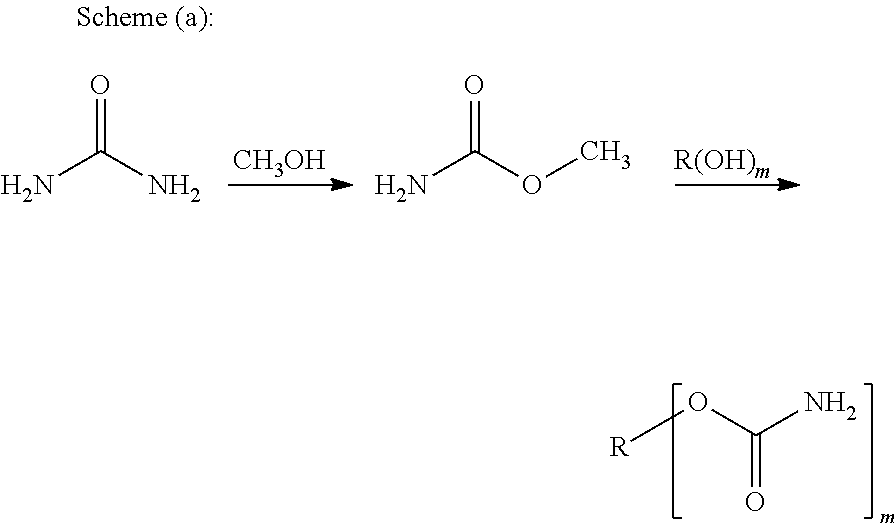

Ambient temperature curable isocyanate-free compositions for preparing crosslinked polyurethanes

ActiveUS20160289386A1Improved performance characteristicsHigh hardnessPolyurea/polyurethane coatingsHemiacetalPigment

The present invention provides a multicomponent composition that is substantially isocyanate-free and comprises a polycarbamate as a first component having a filler, pigment, extender or matting agent and a second component containing an acidic catalyst an alkanol having one OH group, a polyaldehyde and an acetal or hemiacetal of the polyaldehyde. The compositions are shelf stable and useful as two components and avoid problems caused by combining the catalyst with any filler, pigment, extender or matting agent.

Owner:DOW GLOBAL TECH LLC

Ambient temperature curable isocyanate-free compositions for preparing crosslinked polyurethanes

ActiveUS10030104B2Extended validity periodEliminate reductionPolyurea/polyurethane coatingsHemiacetalPigment

The present invention provides a multicomponent composition that is substantially isocyanate-free and comprises a polycarbamate as a first component having a filler, pigment, extender or matting agent and a second component containing an acidic catalyst an alkanol having one OH group, a polyaldehyde and an acetal or hemiacetal of the polyaldehyde. The compositions are shelf stable and useful as two components and avoid problems caused by combining the catalyst with any filler, pigment, extender or matting agent.

Owner:DOW GLOBAL TECH LLC

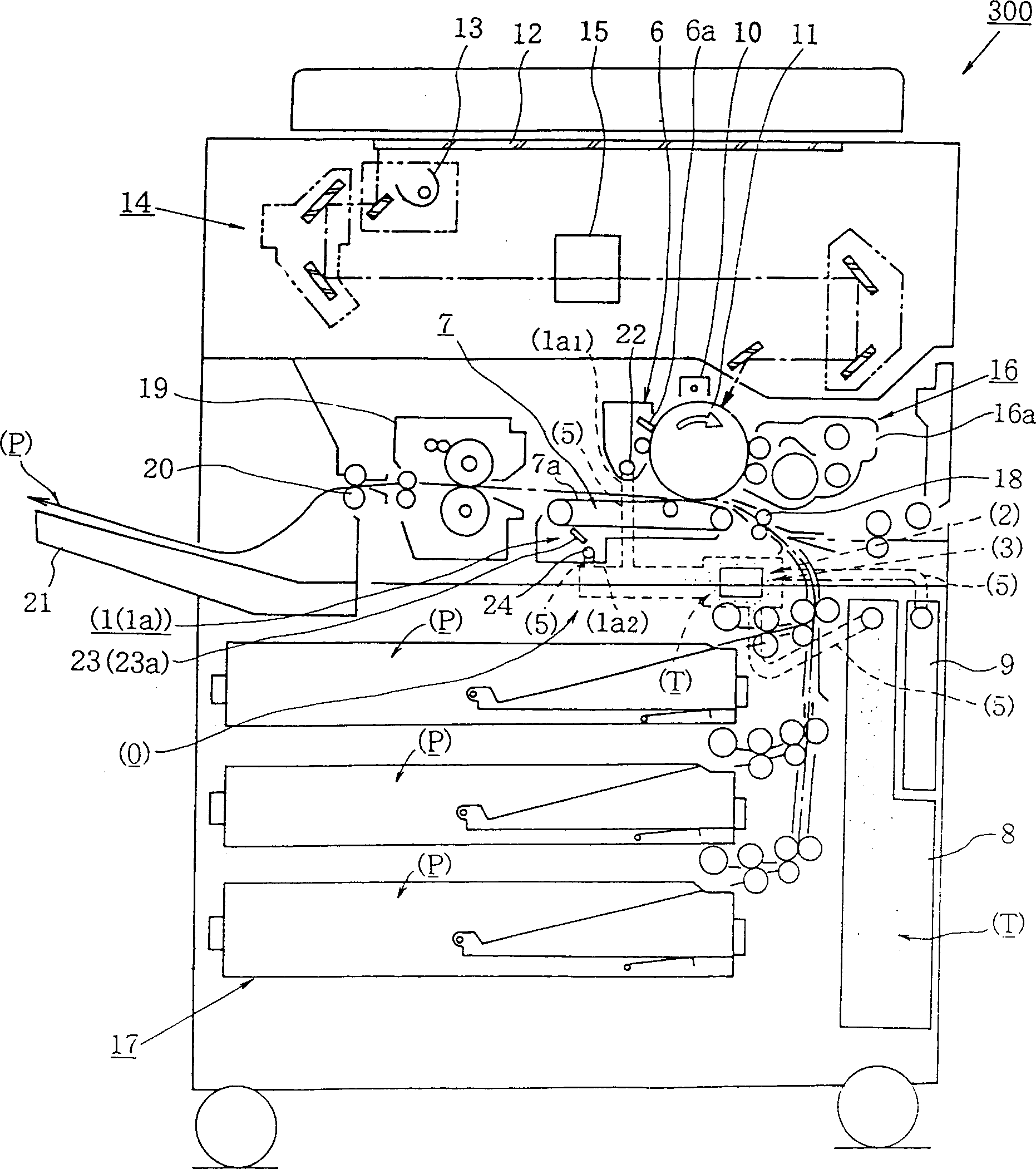

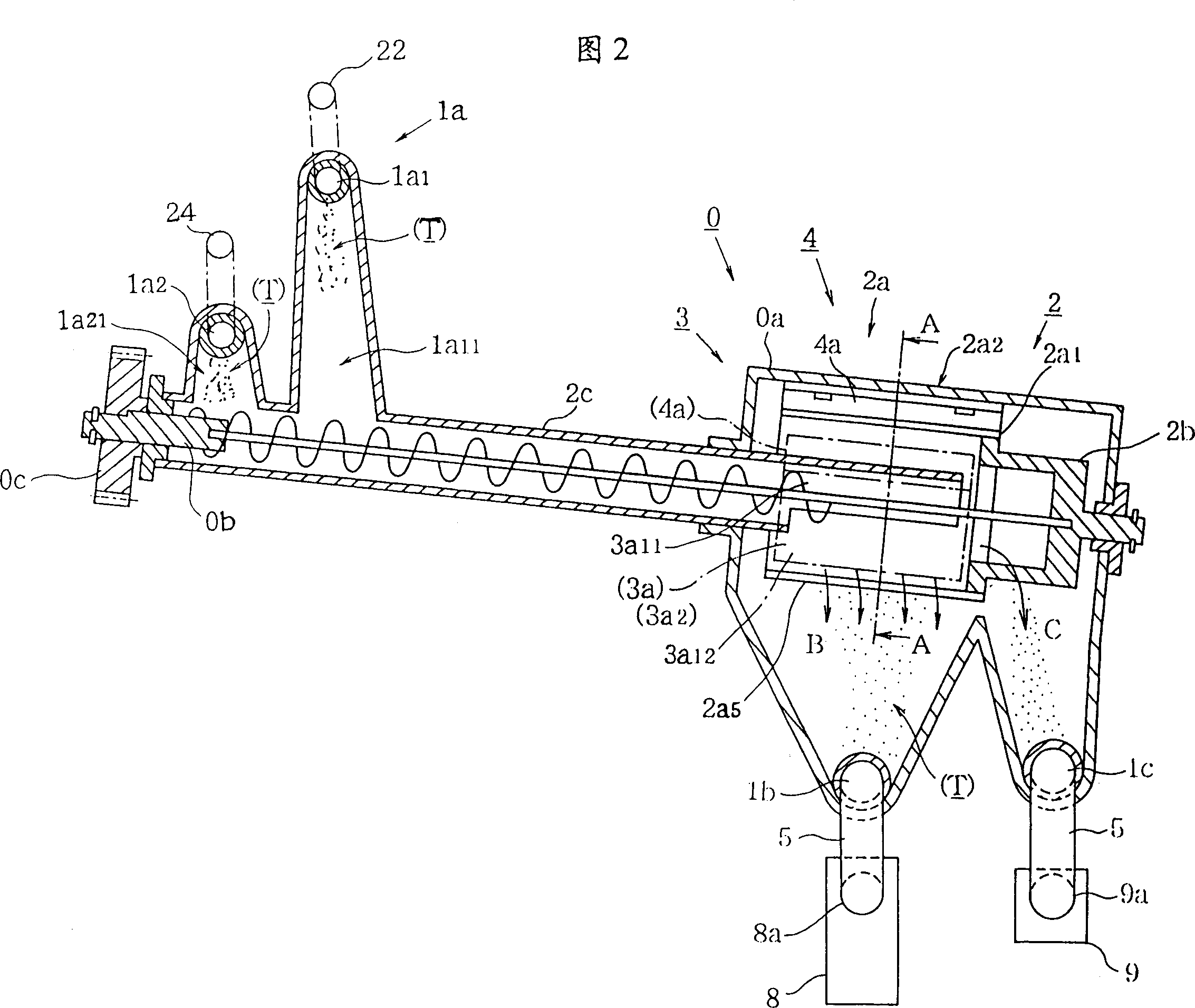

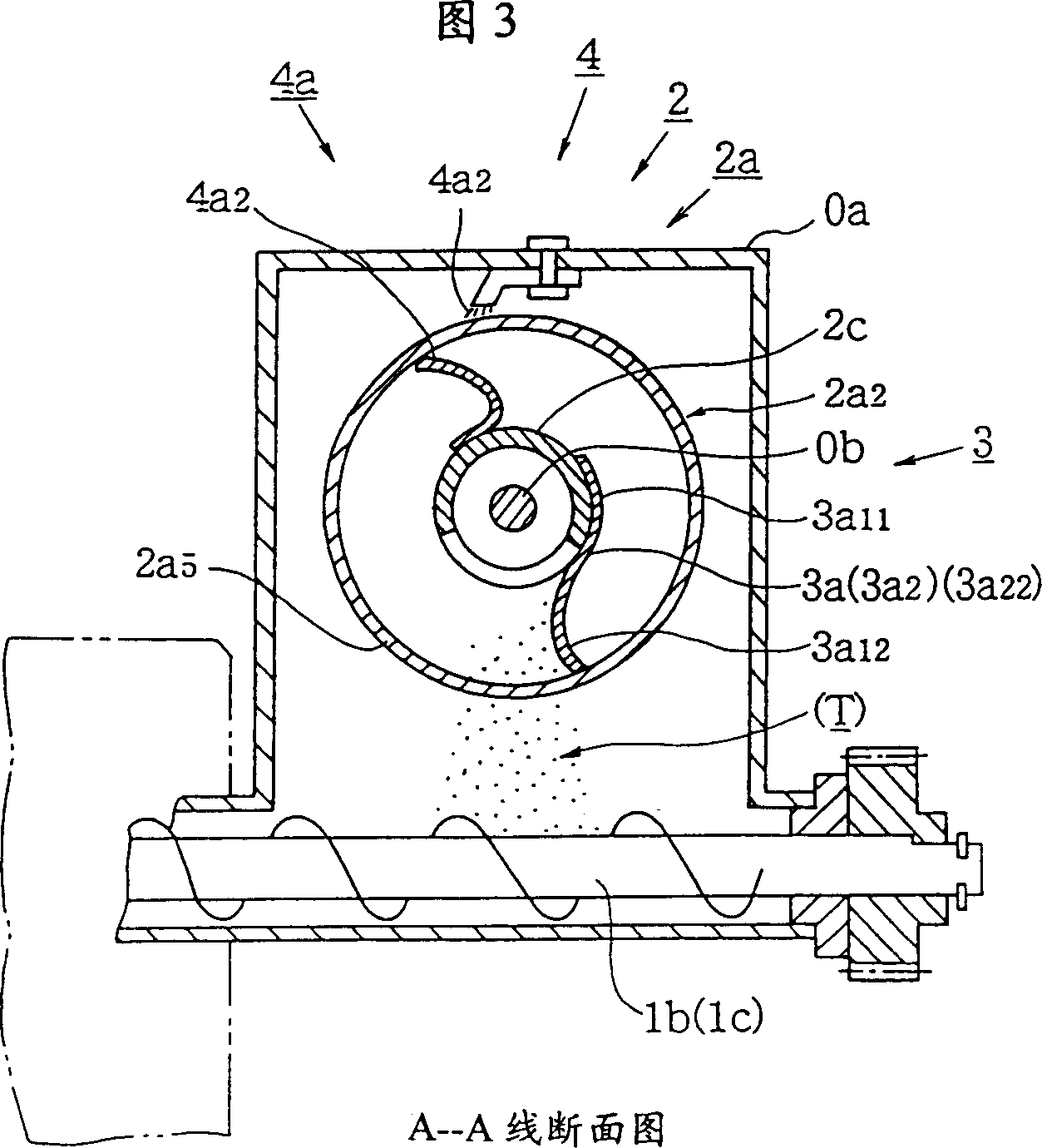

Recirculating powdered in grading plant

InactiveCN1115610CEasy to separateReduce cloggingElectrography/magnetographyElectrical and Electronics engineeringSieve

A toner sorting device includes a device for taking in used toner conveyed from an image forming apparatus and conveying the used toner in one direction, and a device for sifting the used toner conveyed from the intake device to separate reusable toner from the used toner. The sifting device includes a tubular sieve for separating reusable toner from the used toner and a device for holding the sieve so that the sieve is rotatable. The sieve has an opening for receiving the used toner conveyed from the intake device to be moved into the sifting device and an opening for discharging the remaining toner separated from the reusable toner and remaining inside the sifting device. The toner sorting device further includes a device for collecting the reusable toner separated from the used toner by the sifting device and a device for collecting the remaining toner discharged from the sifting device. The toner sorting device further includes a device for accelerating sifting of the used toner by the sifting device.

Owner:RICOH KK

Sealing member, foam molding die, and manufacturing method of foam molding

ActiveCN107461495BEfficient replacementReduced and easy to removeEngine sealsDomestic articlesMechanical engineeringEngineering

Owner:TOYOTA BOSHOKU KK +1

A novel reduction-oxidation system for preparing eptifibatide

InactiveCN105001304BEliminate reductionReduce the difficulty of purificationPeptide preparation methodsDisulfide bond reductionFreeze-drying

The invention relates to the field of polypeptide synthesis and particularly relates to a novel reduction-oxidation system for preparing Eptifibatide. According to the technical scheme of the invention, the novel reduction-oxidation system for preparing Eptifibatid is provided to solve the problems of high crude peptide purification difficulty and low product yield due to dimer impurities that easily occur during the cracking process of Eptifibatide. According to the technical scheme of the invention, the linear peptides of Eptifibatid are synthesized based on the Fmoc solid-phase synthesis method. Firstly, the reduction reaction of intermolecular disulfide bonds of dimer impurities in the linear peptide solution is realized by DTT, and then the pH value of the solution is regulated. An oxidizing agent is added and subjected to oxidization reaction so as to form intermolecular disulfide bonds, so that a crude peptide product of Eptifibatid is obtained. Finally, the crude peptide product is subjected to chromatography purification, salt transferring and freeze-drying to obtain the pure peptide product of Eptifibatid. The preparation method is simple to operate and the obtained pure peptide product is high in both purity and yield. Therefore, the method is suitable for scale-up production.

Owner:JINAN KANGHE MEDICAL TECH

Energy saving boiler capable of fully combusting

InactiveCN108151304AEffective secondary ignitionEffective re-ignition, which effectively removesSolid fuel combustionWater heatersWater storageCombustion

The invention discloses an energy saving boiler capable of fully combusting. The energy saving boiler comprises a boiler body; support rings are arranged at the upper and lower ends of the outer sideof the boiler body; support legs are arranged at four corners of the lower side of the support ring at the lower end; a base plate is arranged on the lower sides of the support legs; a crushing cavityis formed between the support rings; charging ports are formed in the left and right ends of the upper side of the crushing cavity; a motor is arranged between the charging ports; a crushing shaft isarranged on the lower side of the motor; crushing blades are arranged on the left and right sides of the crushing shaft; a water storage cavity is formed in the boiler body; a water adding pipe is arranged on the upper side of the water storage cavity; a drainage pipe is arranged on the lower side of the water storage cavity; a connecting pipe is arranged on the back side of the water storage cavity, and is provided with a pump; a fire grate is arranged at the lower end between the boiler body and the water storage cavity; a combustion cavity is formed in the upper side of the fire grate; anexhaust cover is arranged on the upper side of the combustion cavity; a secondary combustion cavity is formed in the upper side of the exhaust cover; an exhaust pipe is arranged at the left end of theupper side of the boiler body; and a slag discharge pipe is arranged on the lower side of the boiler body. The energy saving boiler can effectively guarantee complete combustion of equipment, accelerates the heating speed of the equipment, and achieves the energy saving effect of the equipment.

Owner:王涛

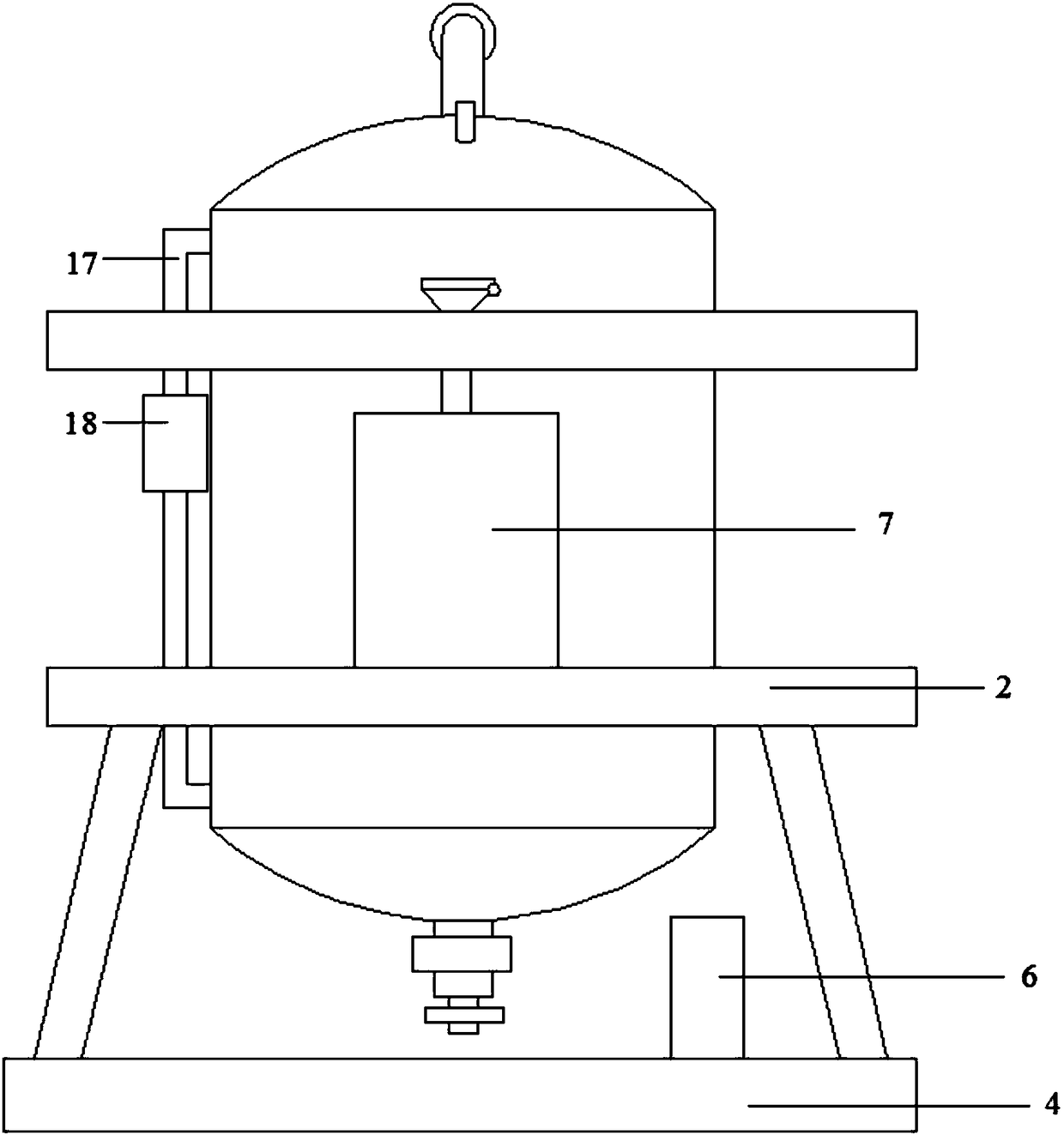

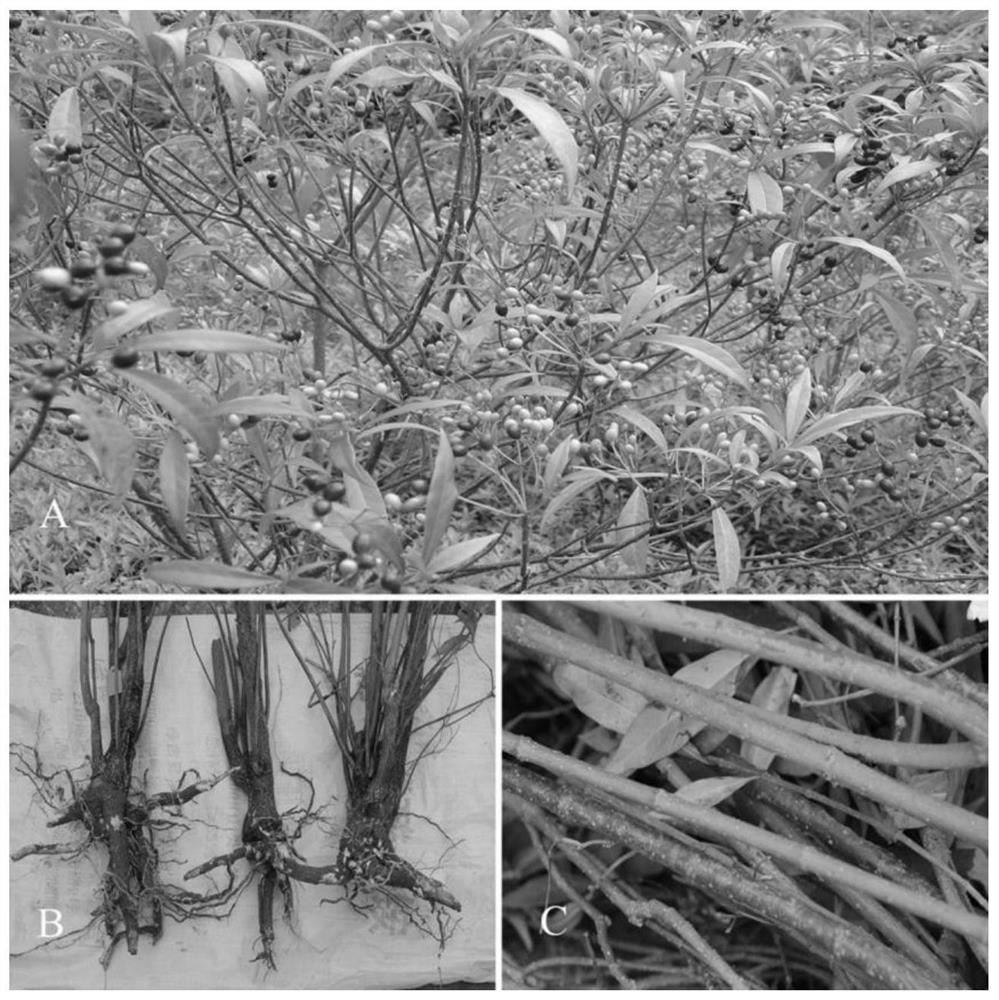

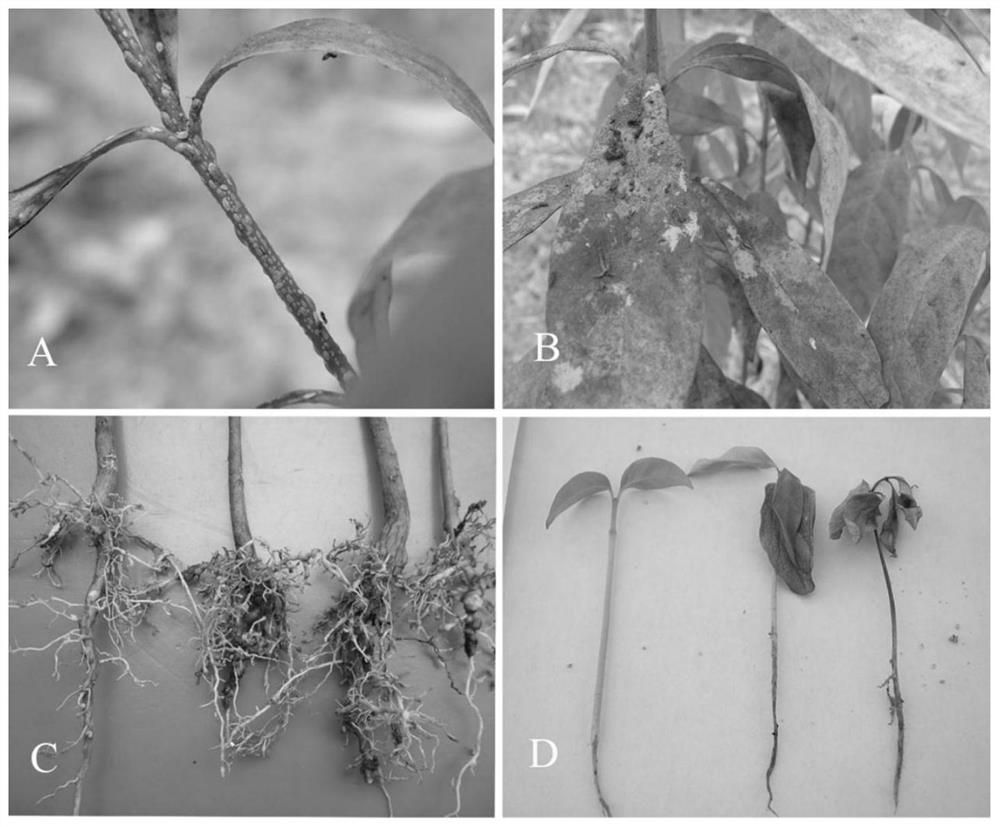

The method of propagation and cultivation of Rauvolwolfia

ActiveCN108925352BImprove fertilityReduce heavy metal contentSeed and root treatmentFertilising methodsBiotechnologyMedicinal herbs

The invention discloses a method for propagation and cultivation of Rauvolfia verticillata(Lour.)Baill.f.rubrocarpa H.T.Chang.mss., which includes the following steps: step 1, preparing a planting field of Rauvolfia verticillata(Lour.)Baill.f.rubrocarpa H.T.Chang.mss.: sowing a mixture of yeast, lactic acid bacteria, cassava powder and crushed eggshell on the planting field one year in advance, mixing the mixture with soil, planting green manure crops on the soil, and tedding the soil once after picking; step 2, breeding the plant of Rauvolfia verticillata(Lour.)Baill.f.rubrocarpa H.T.Chang.mss.: selecting seed propagation or cuttage propagation; step 3, carrying out artificial cultivation and planting: subjected Rauvolfia verticillata(Lour.)Baill.f.rubrocarpa H.T.Chang.mss. to field-planting on the planting field, and after field planting, conducting fertilization in three times, wherein the field planting density is (50-80) cm x (50-80) cm, the light intensity is 50-75% of natural light intensity, and the interval between every two times of fertilization is 2-3 months; step 4, carrying out management of weeding and irrigation in the planting field and control of pests and diseases; and step 5, carrying out harvesting: after field planting for 2-3 years, harvesting the Rauvolfia verticillata(Lour.)Baill.f.rubrocarpa H.T.Chang.mss. in September to November, and conducting natural air-drying. The method not only improves the yield of the Rauvolfia verticillata(Lour.)Baill.f.rubrocarpa H.T.Chang.mss., but also reduces the heavy metal content of medicinal materials of the Rauvolfia verticillata(Lour.)Baill.f.rubrocarpa H.T.Chang.mss., and has good production and medicinal prospects.

Owner:GUANGXI BOTANICAL GARDEN OF MEDICINAL PLANTS

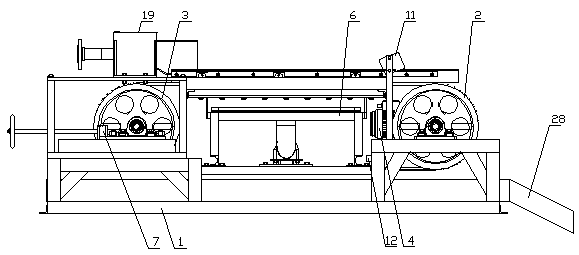

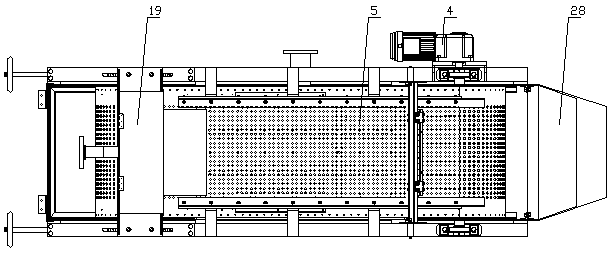

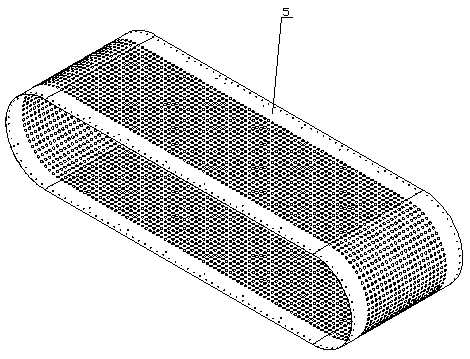

Drilling fluid mud screening and drying treatment method and drilling fluid mud screening device

The invention relates to a mud drying treatment method and a sieving device used for mud drying treatment, which belong to the technical fields of petroleum drilling fluid solid-liquid separation and drilling cuttings drying treatment. The mud drying treatment method comprises the steps of distributing drilling fluid mud through a fluid distribution tank of a feed box, adsorbing through a vacuum box, sweeping through an air knife, and carrying out drying treatment. The separated drilling cuttings moisture content can be effectively reduced, meanwhile, harmful gas and organic volatile impurities in drilling cuttings are effectively removed, and the drilling cuttings can be conveniently collected, stored and transported. In addition, through adjusting an air outlet angle and an air volume of the air knife, different species of materials at different places on a screen can be reversely blown, so that a drying effect of mud is improved, and the method and the device have positive meaning on reducing drilling cuttings pollution on atmosphere and harmfulness of an operation environment.

Owner:YANGTZE UNIVERSITY

Underwater sand rain method device for transparent soil preparation and use method of underwater sand rain method device

PendingCN114878267AReduce bring inEliminate reductionPreparing sample for investigationSoil scienceGeotechnical engineering

The invention discloses an underwater sand rain method device for transparent soil preparation and a use method of the underwater sand rain method device. The device comprises a rotor, a leakage-proof device and a funnel. When the anti-leakage device is used, the rotating head of the rotor is placed in the sleeve of the anti-leakage device, the lower end of the funnel penetrates through the through hole I of the rotating head, the rotating head is filled with the transparent soil preparation material through the funnel, after the rotating head is filled with the transparent soil preparation material, the funnel is removed, and the through hole I is blocked by the rubber plug. The rotating head and the sleeve are placed below the liquid level of the pore liquid in the transparent soil model groove together, and then the leakage-proof device is removed. Standing for a preset time, after bubbles in the transparent soil preparation material are completely discharged, starting a motor, driving a rotating head to rotate at a constant speed, scattering the transparent soil preparation material into the pore liquid, and uniformly stirring with a glass rod. And repeating the operation until the preparation of the transparent soil is completed. Sandy soil is scattered into pore liquid through constant-speed rotation of the rotating head, bubbles brought in in the transparent soil preparation process are effectively reduced, the preparation efficiency is improved, and the test workload is reduced.

Owner:CHONGQING UNIV

A kind of technology of preparation Danshen oral liquid by ceramic membrane

ActiveCN103494879BAvoid easy cloggingReach lossPharmaceutical delivery mechanismPlant ingredientsUltrafiltrationFiltration technique

Owner:江苏恒沣药业有限公司

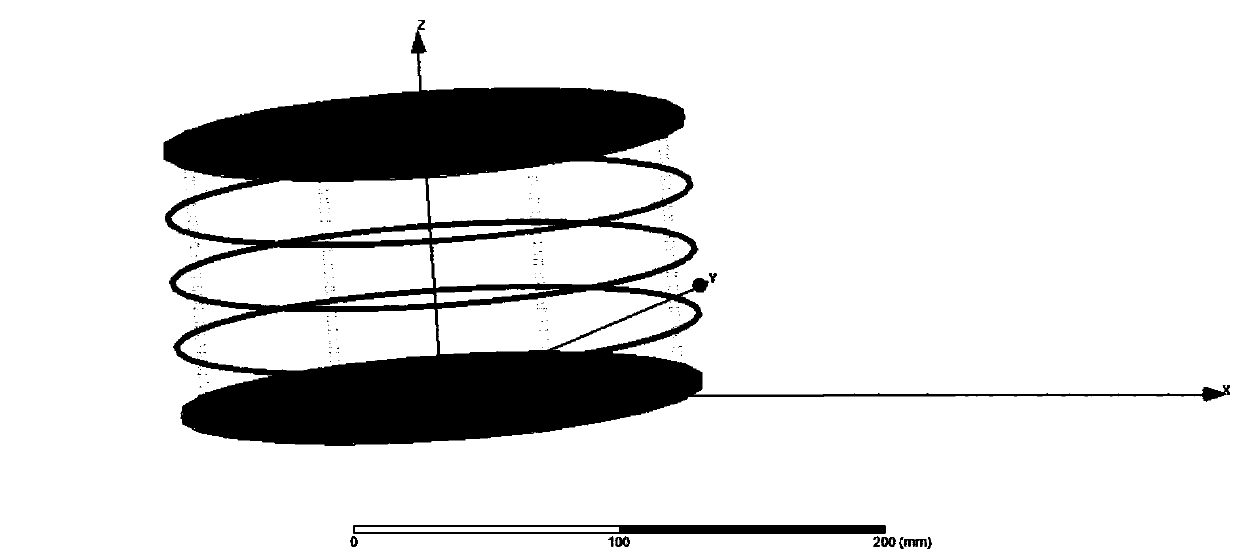

Device and method for calibrating uniformity domain of miniaturized synthetic electric field

PendingCN110579731AEliminate uniform domain reduction problemsEliminate reductionElectrical measurementsEpoxyEdge effects

The invention discloses a device and a method for calibrating the uniformity domain of a miniaturized synthetic electric field, and belongs to the technical field of electromagnetic measurement and calibration. The device comprises two layers of circular plate poles. The edges of the circular plate poles are chamfered, and the space between the two layers of circular plate poles is supported by aplurality of epoxy resin supporting columns with a preset length of d. The epoxy resin supporting columns are provided with a plurality of holes with a hole spacing of d / 4. Single-turn copper wires with preset diameters penetrate through the holes of the epoxy resin supporting columns in the plane parallel to the circular plate poles to form a closed loop, and the joints of the copper wires are connected by welding. By utilizing the thought of a small grading ring, the problem of uniformity domain reduction caused by the edge effect due to great reduction of the radius of the parallel pole plates and equal-proportion reduction of the distance between the parallel pole plates is resolved under the condition of ensuring enough test space.

Owner:CHINA ELECTRIC POWER RES INST +2

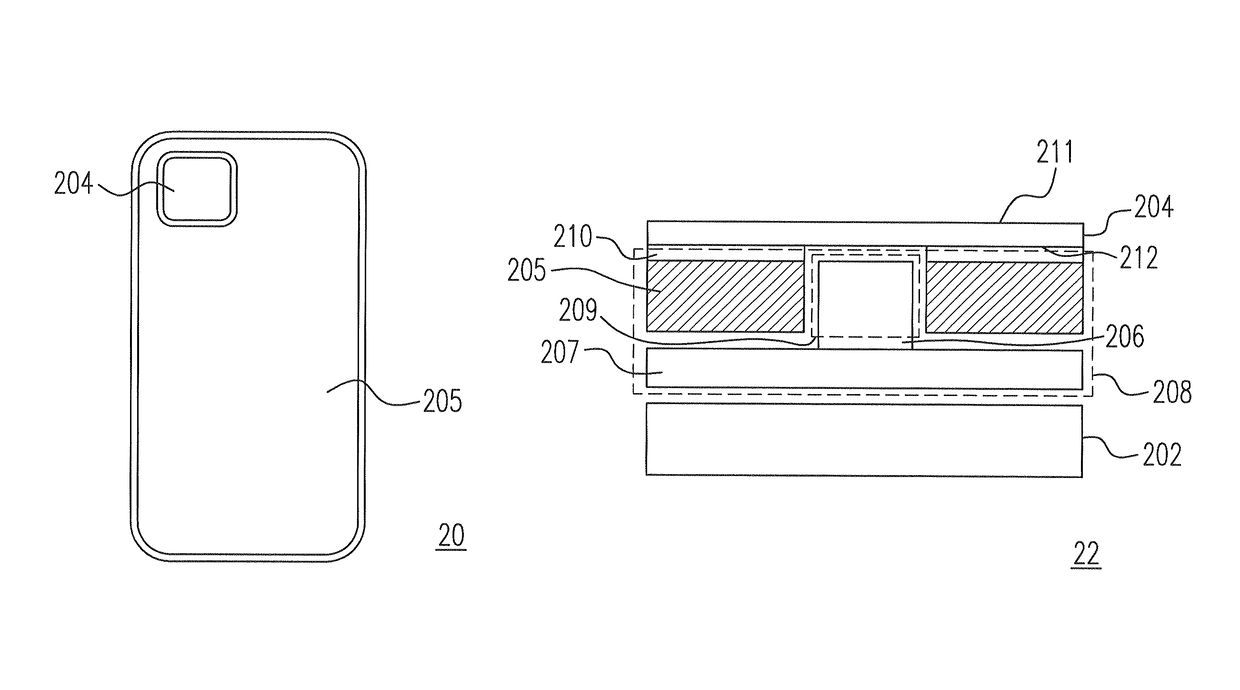

Using sapphire lens to protect the lens module

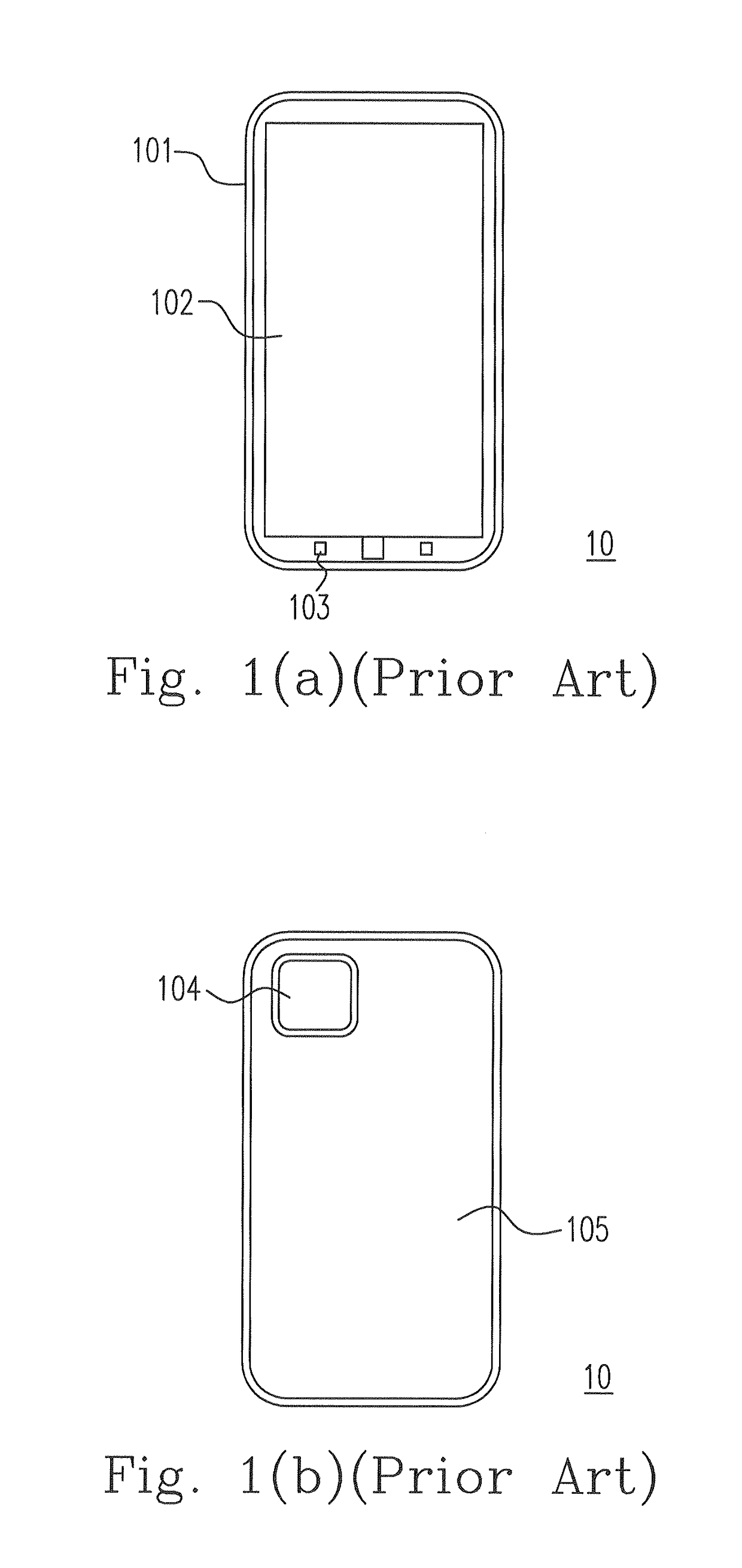

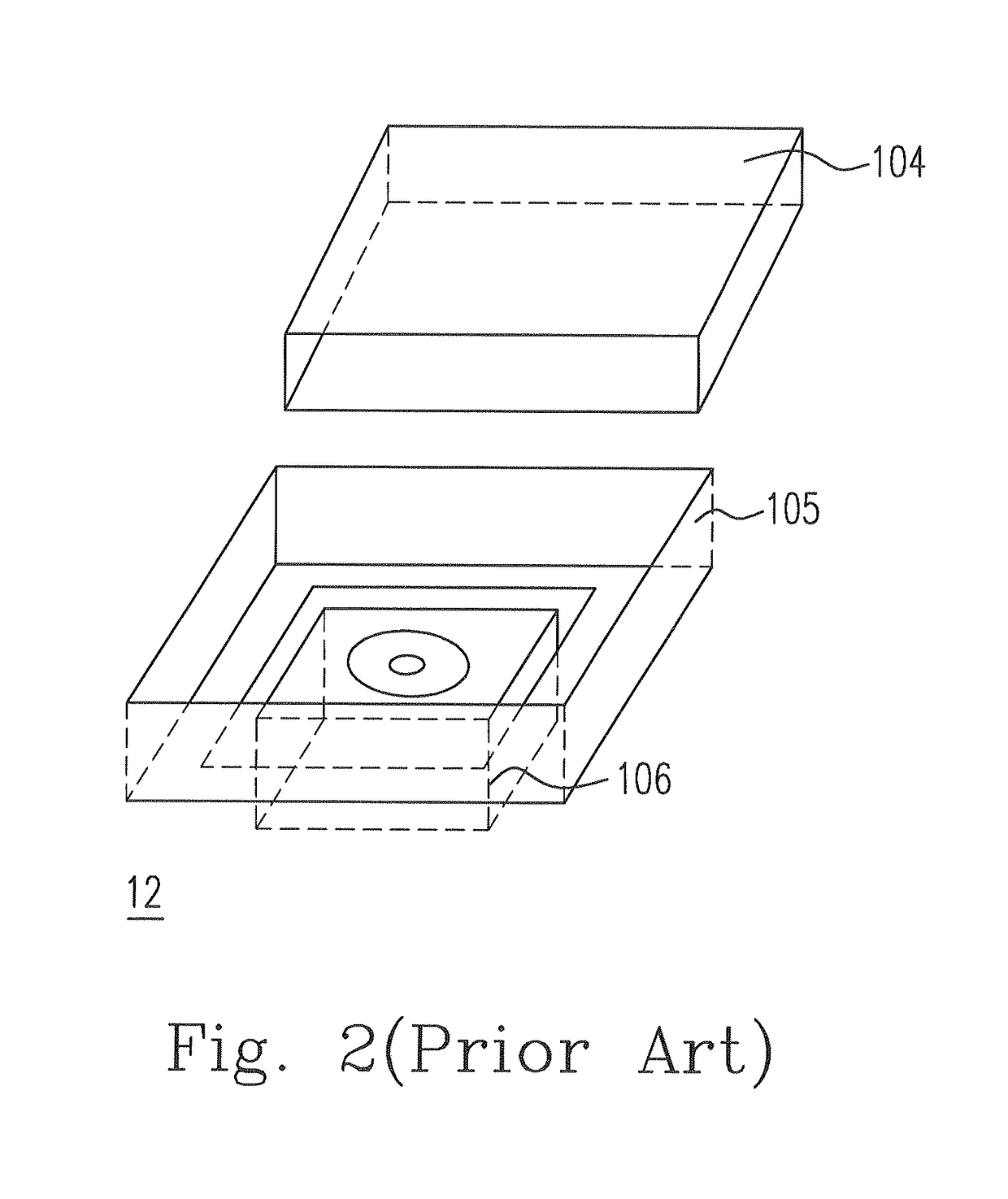

InactiveUS9599787B2Excellent mechanical propertiesEliminate reductionTelevision system detailsColor television detailsCamera lensComputer module

An image capturing device is provided. The image capturing device includes a lens device including a first housing; and a sapphire lens directly connected to the first housing for protecting the lens device, wherein the sapphire lens includes a crystal structure and has a crystal axis, the crystal structure is a single-crystal structure, and the crystal axis includes one selected from a group consisting of c-axis (0001), a-axis (1210), a-axis (1120), a-axis (2110), a-axis (1120), a-axis (2110), a-axis (1210), m-axis (1010), m-axis (1100), m-axis (0110), m-axis (1010), m-axis (1100), m-axis (0110), r-axis (1011), r-axis (1011), r-axis (0111), r-axis (0111), r-axis (1101) and r-axis (1101).

Owner:TERA XTAL TECH CORP

A kind of eutectic aluminum-silicon alloy production process

ActiveCN105331855BSlow down the speed of solidificationIncrease the phase line temperature differenceSilicon alloySlag

The invention discloses a eutectic aluminum-silicon alloy production process. The process includes the following steps that materials are prepared, wherein the required materials are divided into two groups, the first group comprises silicon and pure aluminum, the second group comprises iron and an aluminum-manganese alloy, and the content of the silicon accounts for 11.7% to 11.9% of the total materials; the materials in the first group are added and heated to the temperature ranging from 730 DEG C to 750 DEG C; the materials in the second group are added and stirred so as to be mixed with the materials in the first group, and a mixture is heated to the temperature ranging from 800 DEG C to 830 DEG C; heating is stopped and nitrogen is injected for 8 to 12 minutes, and a refining agent with the content accounting for 0.2% to 0.3% of the total materials is added; stirring is performed after slag-off operation is performed, wherein melting liquid is heated, so that the temperature of the melting liquid is increased to 680 DEG C to 700 DEG C; and casting is performed and the temperature of the melting liquid is kept between 680 DEG C and 720 DEG C in the casting process. The technical problem that shrinkage cavities are generated easily in an existing eutectic aluminum-silicon alloy with the European Union die-casting aluminum mark number 47100 is solved and the eutectic aluminum-silicon alloy production process is capable of reducing or eliminating the shrinkage cavities.

Owner:GUANGZHOU ZHIYUAN ALLOY PROD CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com