Drilling fluid mud screening and drying treatment method and drilling fluid mud screening device

A processing method and drilling fluid technology, which is applied in the direction of wellbore/well components, earthwork drilling, flushing wellbore, etc., can solve the problems of increasing the total amount of centralized processing, large storage and transportation volume, landing, etc., so as to reduce drilling Increase the liquid content of crumbs, improve the drying effect, and facilitate the collection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

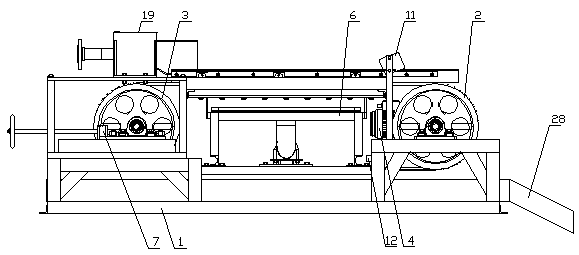

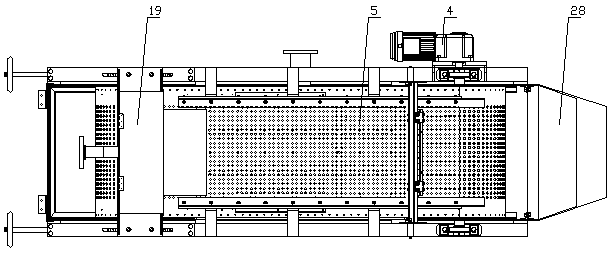

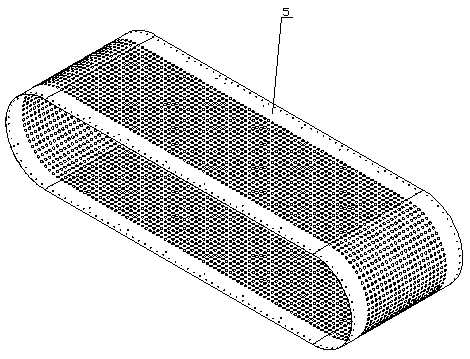

[0043] The drilling fluid mud screening device includes a frame 1, a driving drum 2, a driven drum 3, a driving motor 4, a screen 5 and a vacuum box 6; A collecting box 28 is arranged on the rack 1 . The frame 1 on the other side of the driving drum 2 is equipped with a driving motor 4, and the driving motor 4 is connected to the driving drum 2 through a reducer; the other end of the frame 1 is equipped with a driven drum 3 through a tensioner 7, and the tensioner 7 Consists of a slide rail 25, a mounting plate 26 and an adjustment screw 27, a mounting plate 26 is slidably installed on the slide rail, an adjustment screw 27 is arranged on the mounting plate 26, and the adjustment screw 27 is connected with the frame 1 through a screw nut. The driving drum 2 and the driven drum 3 are provided with screens 5 .

[0044]The driving drum 2 and the driven drum 3 are respectively composed of a drum shaft 8, a supporting drum 9 and a transmission pulley 10. The drum shaft 8 is fixed ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com