Sealing part, foamed forming mould and manufacturing method of foamed forming body

A technology of foam molding and seals, which is applied to engine seals, household components, household appliances, etc., can solve the problems of time-consuming and labor-intensive removal, and achieve the effect of reducing workload, reducing burrs, and easy removal

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

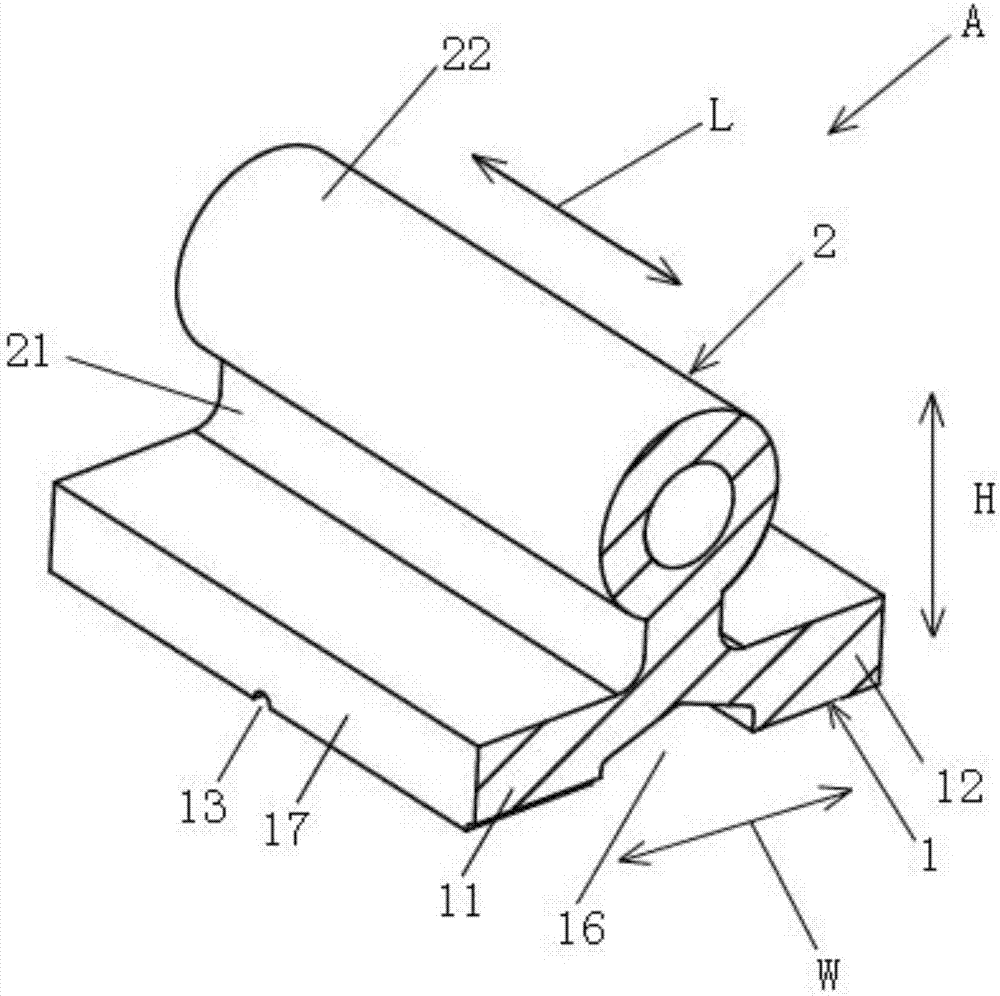

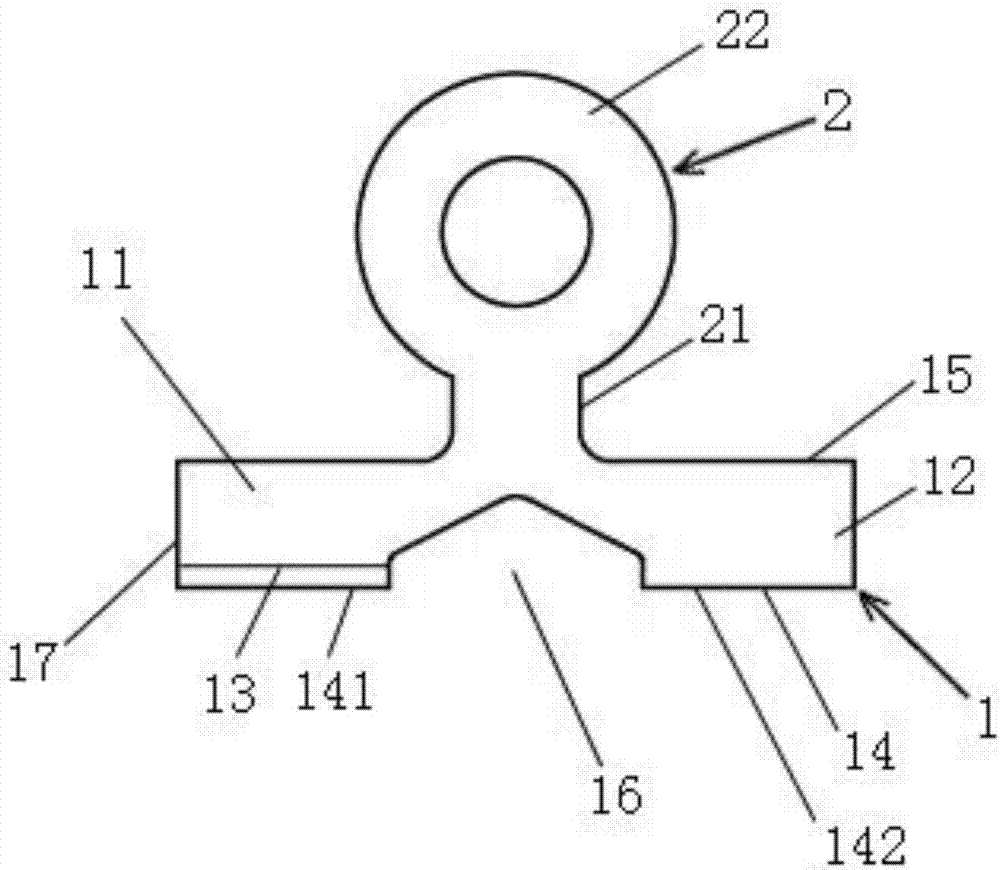

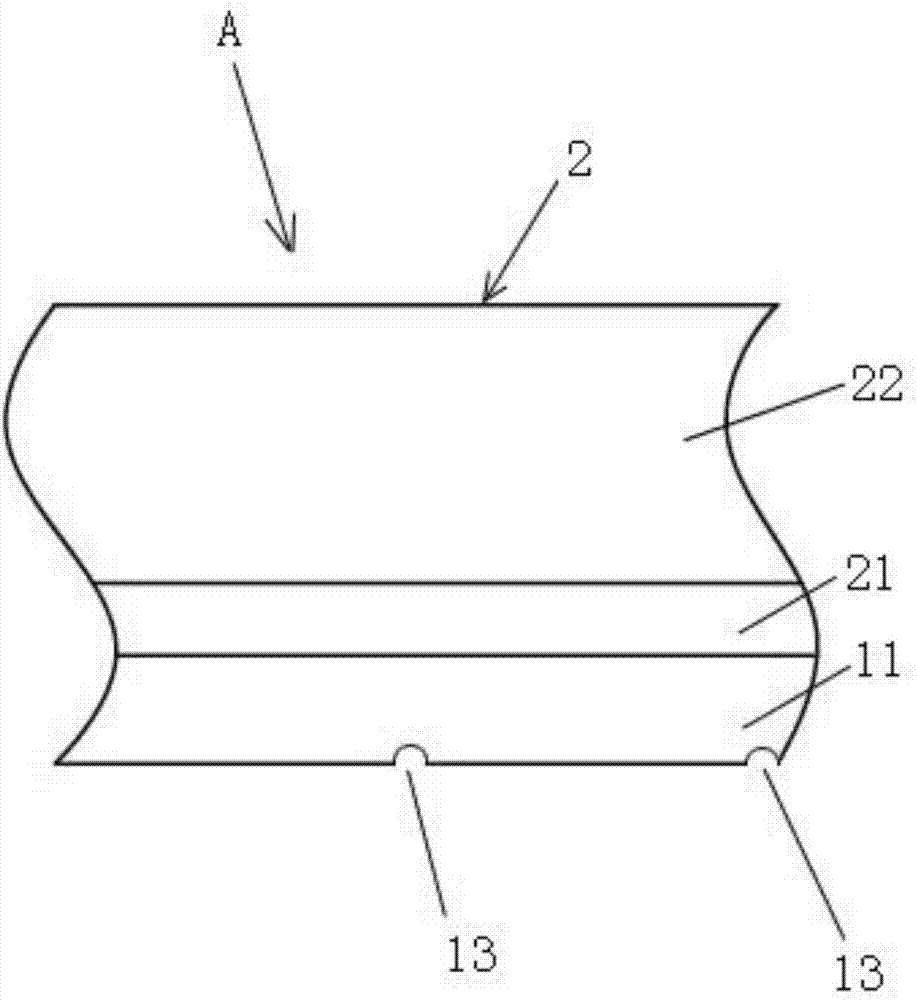

[0044] exist figure 1 The arrows mark the extension direction L, width direction W and thickness direction H of the seal A of the present application. In this application, the extension direction L of the seal A refers to the longitudinal direction of the seal, which is the same as its width The direction W and the thickness direction H are perpendicular to each other.

[0045] The sealing member of the present invention can be applied to a foam molding mold for forming foam moldings such as car seat sponges, and is used to be installed on the parting surface of one of the upper and lower molds, and the molds are aligned after the molds are closed. cavity is sealed. In this embodiment, a foam molding die applied to foam moldings such as car seat sponges is exemplified, but the sealing material of the present invention can also be applied to sealing between opposing surfaces of two members of other types.

[0046] First, the sealing material A of this embodiment will be desc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com