Multi-port separation apparatus and method

An outlet device, separation chamber technology, used in separation methods, solid separation, measurement devices, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

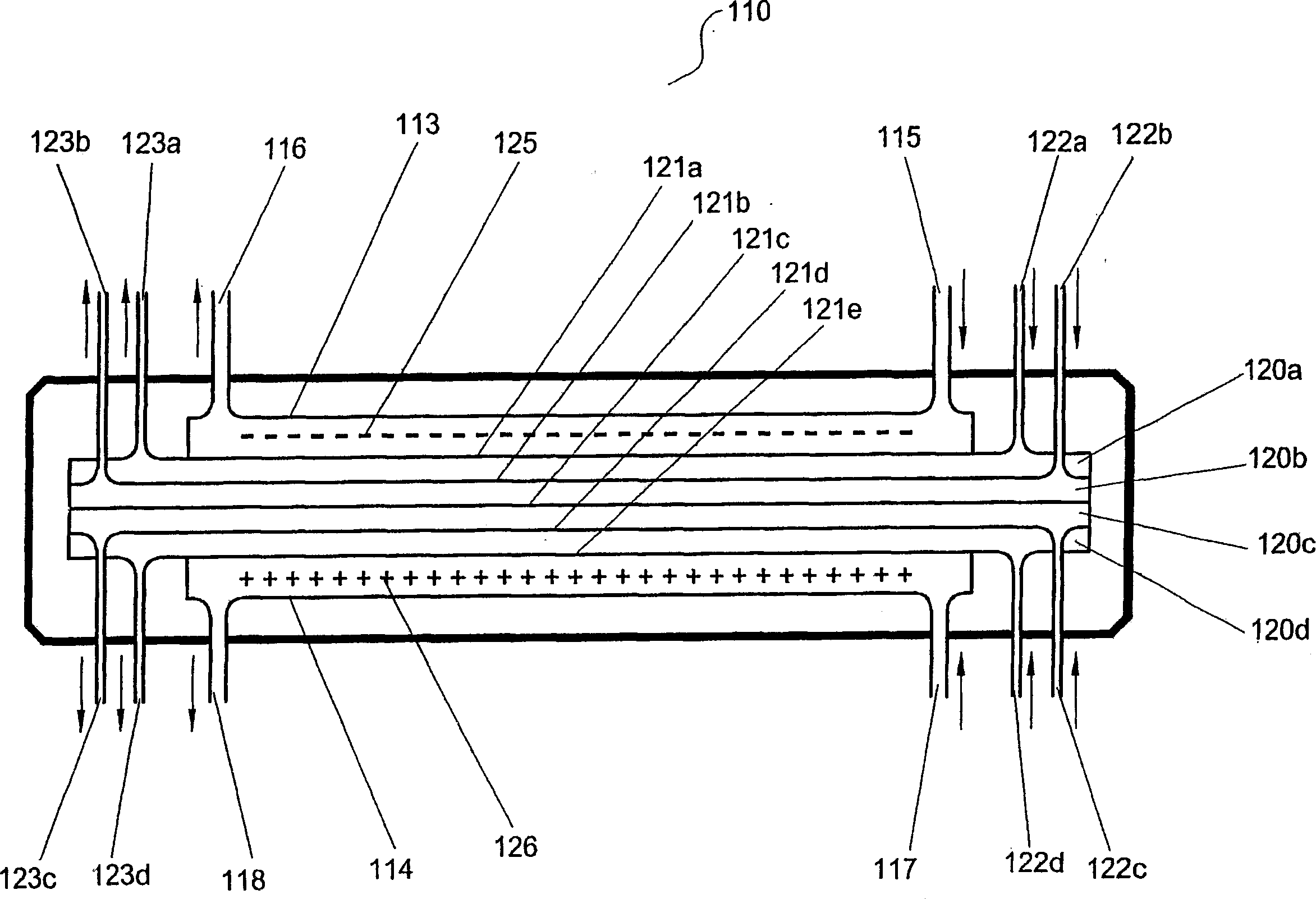

[0190] A device according to the invention comprising twelve separation chambers was used to separate immunoglobulin G (IgG) from human plasma. This example illustrates how the device can be used to process the same supplied sample from the same sample container through four sets of identical, multiple, parallel separation chambers.

[0191] Assembly of the separation unit is described below. All ion permeable barriers are polyacrylamide films with different nominal molecular mass (NMM) cutoffs. The first set of parallel separation chambers starts at 1 between the anode chamber and the first separation chamber st Ion-transmissive barrier with NMM of 5,000 Daltons passing through 1 st and 2 nd Another barrier between the separation chambers with NMM of 100,000 Daltons, then 2 nd and 3 nd Another barrier between the separation chambers having an NMM greater than 1,000,000 Daltons. The second set of parallel separation chambers starts at 3 rd and 4 th A barrier between th...

example 3

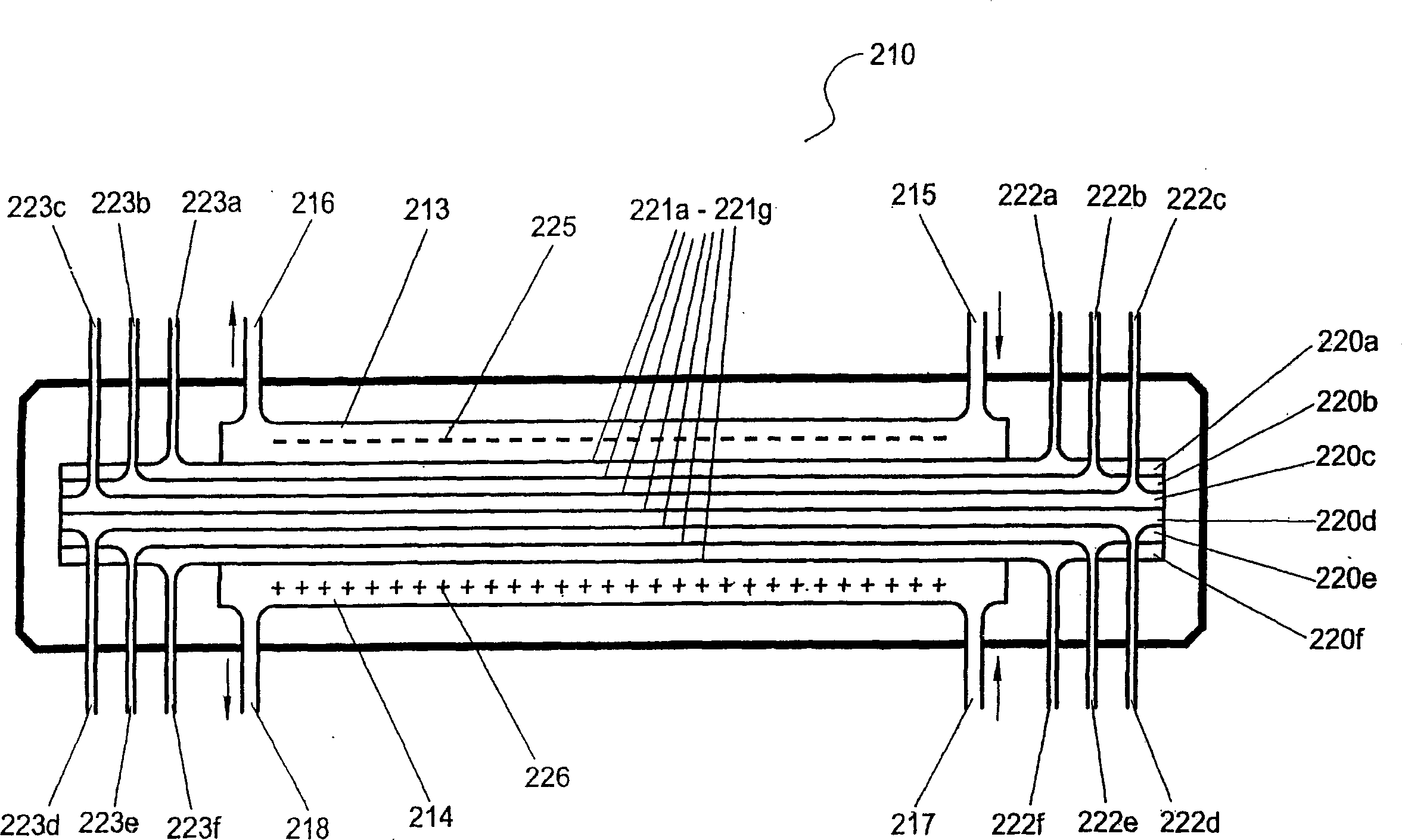

[0200] A device comprising twelve separation chambers according to the invention is used to separate egg white components according to size. This example illustrates how the device can be used to obtain size-based separations by employing a series of ion-permeable barriers with different nominal molecular mass cut-offs.

[0201] Assembly of the separation unit is described below. All ion permeable barriers are polyacrylamide (NMM) films with different nominal molecular mass cut-offs. Anode chamber with 1 stThe ion-permeable barrier between the separation chambers is a polyacrylamide membrane with an NMM of 3,000 Daltons. 1 st and 2 nd The barrier between the separation chambers has a 5,000 Dalton NMM, 2 nd and 3 rd Barrier between separation chambers with 5,000 Dalton NMM, 3 rd and 4 th The barrier between the separation chambers has a 100,000 Dalton NMM, 4 th and 5 th Another barrier between the separation chambers, which has a NMM of 150,000 Daltons, 5 th and 6 t...

example 4

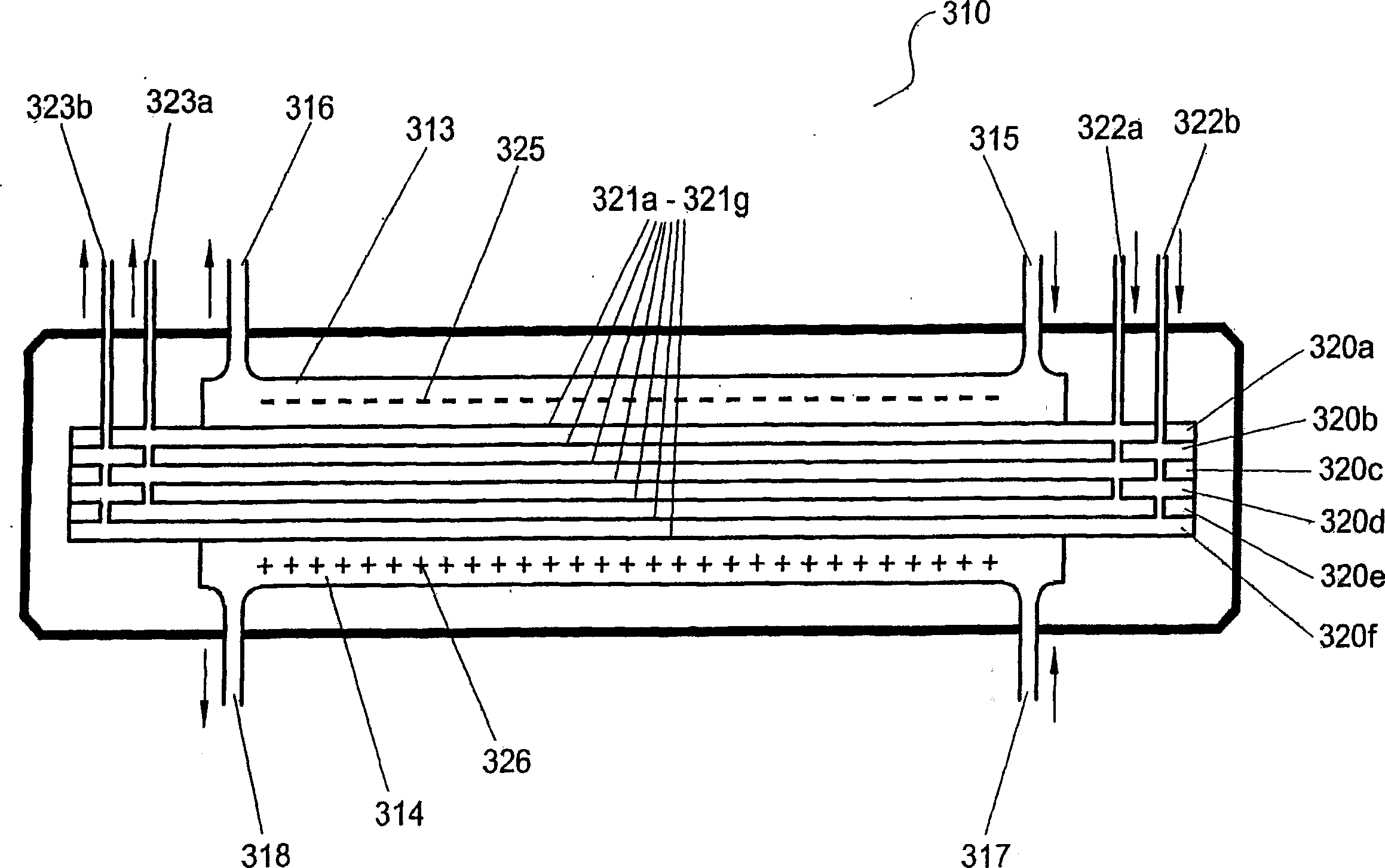

[0204] A device comprising twelve separation chambers according to the invention was used to separate alpha-1-antitrypsin (ATT, 51 kDa, pi=4.8) from human serum albumin (HSA, 66.5 kDa, pi=4.9). This example demonstrates how the device and Bier buffer can be used to perform quasi-isoelectric focusing separation of components with similar pI values in shallow pH gradients resulting from binary mixing of weak electrolytes.

[0205] Assembly of the separation unit is described below. All ion permeable barriers are polyacrylamide (NMM) films with two different nominal molecular mass cut-offs. anode chamber and 1 st between separation chambers, and 12 th The ion permeable barrier between the separation chamber and the cathode chamber has an NMM of 5,000 Daltons. 1 st and 2 nd ,2 nd and 3 rd , 3 rd and 4 th , 4 th and 5 th , 5 th and 6 th ,6 th and 7 th , 7 th and 8 th ,8 th and 9 th ,9 th and 10 th , 10 th and 11 th , last 11 th and 12 th All other barrier...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com