Specific resistance conditioning agent used for lowering fly ash resistivity and application of specific resistance conditioning agent

A technology of specific resistance and regulator, applied in the specific resistance regulator, the application of the specific resistance regulator, the specific resistance regulator field of reducing the specific resistance of fly ash, can solve the problems of reducing the specific resistance of dust, the influence of dust removal efficiency, etc., Achieve the effect of reducing corrosion, achieving integrated removal, and enhancing electrical conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0019] The preparation method of the specific resistance regulator of the present invention: add tap water in a mixing container, then add sodium acetate and dipotassium hydrogen phosphate under constant stirring, after the two are completely dissolved, add lignin sodium carbonate, and then stir until completely dissolved That's it.

[0020] The specific resistance adjuster is stored independently according to different components before mixing, and can also be stored as a high-concentration solution in proportion, and diluted with tap water in proportion when used. But the time should not be too long, preferably a week.

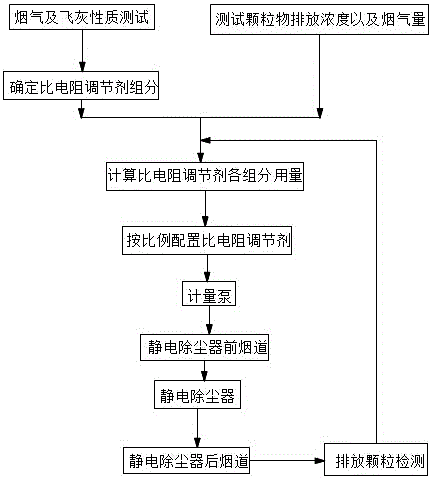

[0021] According to different power plants, different flue gas conditions and coal-fired fly ash characteristics, adjust the proportion of different components of the specific resistance regulator, determine the dosage of the specific resistance regulator, arrange a double-flow atomizing nozzle in the flue before the dust collector, and mix the specific resi...

Embodiment 1

[0024] Sodium acetate 0.001%

[0025] Dipotassium hydrogen phosphate 0.001%

[0026] Sodium Lignin Carbonate 0.001%

[0027] The rest is water.

[0028] Test the properties of flue gas and fly ash, the emission concentration of particulate matter and the amount of flue gas, and determine the specific resistance according to the test results to adjust the dosage of each component, such as the above-mentioned ratio. The specific resistance regulator is sprayed into the flue between the air preheater and the electrostatic precipitator. Under the action of external air, the specific resistance regulator is atomized into droplets with an average particle size of about 30 μm and sprayed into the flue. Interaction occurs in the flue, and the residence time is about 10s. The specific resistance regulator contacts and fuses with the fly ash to adjust the specific resistance, and then is captured by the subsequent electrostatic precipitator. At the outlet of the rear of the electrost...

Embodiment 2

[0030] Sodium acetate 0.005%

[0031] Dipotassium hydrogen phosphate 0.005%

[0032] Sodium lignin carbonate 0.002%

[0033] The rest is water.

[0034] Test the properties of flue gas and fly ash, the emission concentration of particulate matter and the amount of flue gas, and determine the specific resistance according to the test results to adjust the dosage of each component, such as the above-mentioned ratio. In front of the electrostatic precipitator, the specific resistance regulator is charged at 0.05Kg / Nm through the liquid distribution pump, compressed air, and double-flow atomizing nozzles. 3 The flow of flue gas is sprayed into the vertical flue with a particle size of about 25 μm, and the concentration of smoke and dust is changed from the original 38.8mg / Nm 3 Reduced to 25.7mg / Nm 3 , reduced by about 33.8%, meeting the latest national particulate matter emission standards for coal-fired power plants.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical resistance | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com