Chemical agglomeration promoter

A technology of chemical agglomeration and accelerator, applied in the fields of energy and environment, can solve the problems of limited agglomeration efficiency of the agglomeration accelerator, unsuitable for large-scale industrial production, complex composition of the agglomeration agent formula, etc. Inexpensive effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

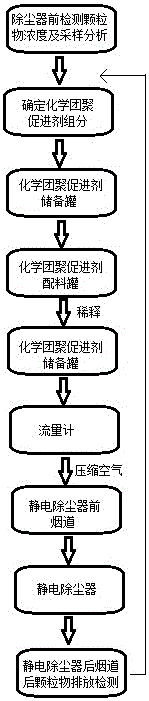

Image

Examples

Embodiment 1

[0023] This example provides a chemical agglomeration accelerator, the formula ratio of which is polyethyleneimine: 0.001%, Tween 80: 0.001%, and the remaining amount is water; a coal-fired fly ash of a power plant is used as the experimental object, and the fly ash particles diameter of 20 μm, the chemical agglomeration promoter of this example is atomized into droplets with an average particle diameter of about 30 μm under the action of external air and sprayed into the agglomeration chamber. The two interact in the simulated flue environment in the agglomeration chamber. For about 10 seconds, the agglomeration accelerator promotes the agglomeration and growth of fly ash fine particles, which are then captured by the subsequent bag filter. The cloth bag adopts conventional chemical fiber filter material, and an isokinetic sampler is used to sample at the rear outlet of the bag dust removal device to measure the emission concentration of fly ash particles. The results show th...

Embodiment 2

[0027] This embodiment provides a chemical agglomeration accelerator, the formula ratio of which is polyethyleneimine: 0.01%, Tween 80: 0.1%, and the remaining amount is water; a coal-fired fly ash of a power plant is used as the experimental object, and the fly ash particles diameter of 20 μm, the chemical agglomeration accelerator of this example was subjected to an agglomeration experiment in the manner of Example 1, and the emission concentration of fly ash particles was measured. The results show that after spraying the agglomeration accelerator described in the formula of this embodiment, the fly ash particles produced obvious agglomeration, and the concentration of fly ash particles after the dust removal device was 280.6 mg m when the agglomeration accelerator was not sprayed. -3 down to 107.8mg·m -3 , the agglomeration efficiency was 61.6%.

Embodiment 3

[0029] In this example, the electric field fly ash of a power plant electrostatic precipitator is mixed with preheated air as simulated flue gas to enter the agglomeration chamber. The mass percentage of the formula is polyethyleneimine: 0.001%, Tween 80: 0.001%, and potassium chloride: 0.1%. The agglomeration accelerator is atomized into droplets with an average particle size of about 30 μm and sprayed into the agglomeration chamber under the action of external air. The two interact in the simulated flue environment in the agglomeration chamber. The particles agglomerate and grow, and then are captured by the subsequent bag filter. The cloth bag adopts conventional chemical fiber filter material, and isokinetic sampling is carried out at the outlet of the rear part of the bag dust removal device by an isokinetic sampler to measure the particle emission concentration. The results show that after spraying the chemical agglomeration accelerator described in the formula of this e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com