Reverse osmosis concentrated water oxidizing and desalting method and system of organic wastewater

A technology of reverse osmosis concentrated water and organic wastewater, applied in chemical instruments and methods, water softening, water/sewage treatment, etc., can solve the problem of less than 75% water production rate of reverse osmosis membrane technology, reduced membrane service life, and easy clogging And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

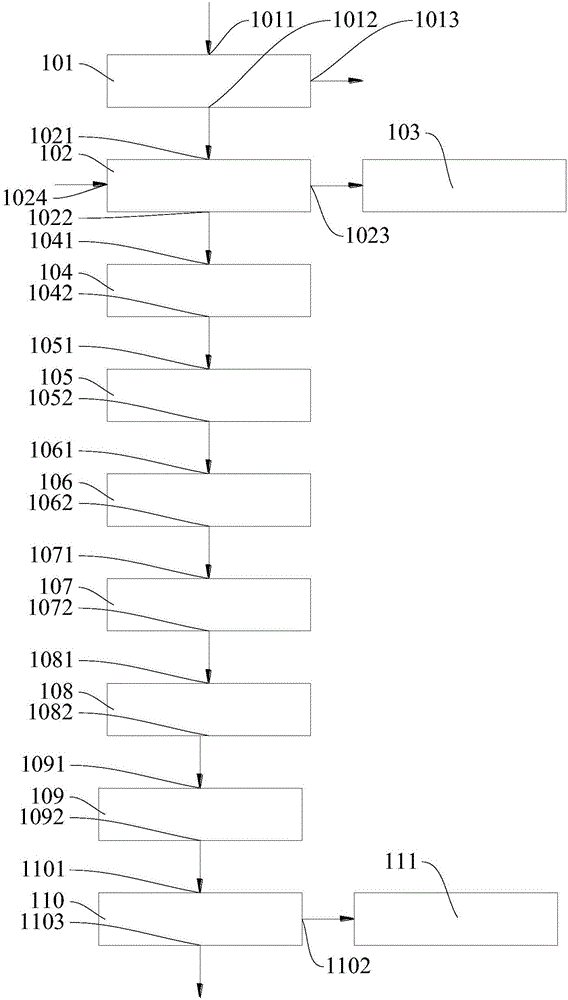

Image

Examples

Embodiment

[0075] The system of the present invention is used for oxidation and desalination of the first-stage reverse osmosis concentrated water of a certain coking wastewater. The conductivity of the primary reverse osmosis concentrated water of coking wastewater is 11ms / cm, the COD is 150mg / L, the total hardness is 360mg / L, and the total iron is 2mg / L. The coking wastewater primary reverse osmosis concentrated water is treated by oxidation reactor The final COD removal rate is 90%, and the ratio of COD to ozone dosage is 1:3; the total hardness of the oxidation wastewater is removed after being treated by softening reactor, coagulation reactor, high-efficiency precipitator and neutralization reactor The rate is 95%, and the softening agent added to the softening reactor is Na(OH), Na 2 CO 3 , the softening reaction controls the reaction pH to be 11, the coagulant and coagulant added to the coagulation reactor are PAC and anion PAM respectively, the acid added to the neutralization r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com