Vacuum sewage collecting and treating system

A technology of vacuum collection and treatment system, applied in water/sewage treatment, biological water/sewage treatment, water/sewage multi-stage treatment, etc. issues such as increased costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

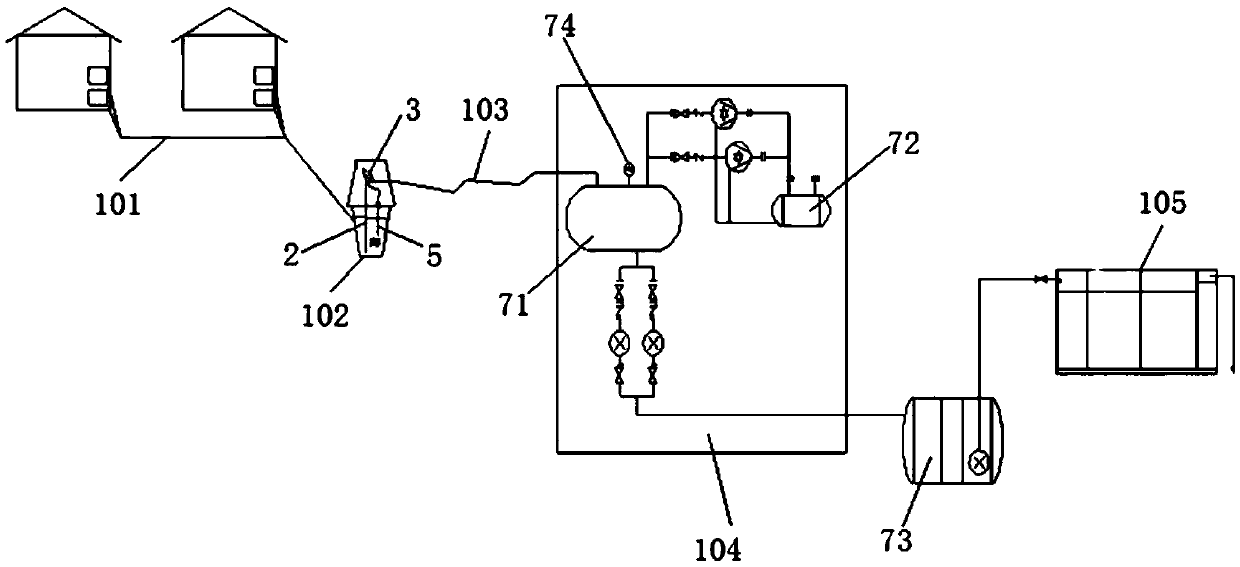

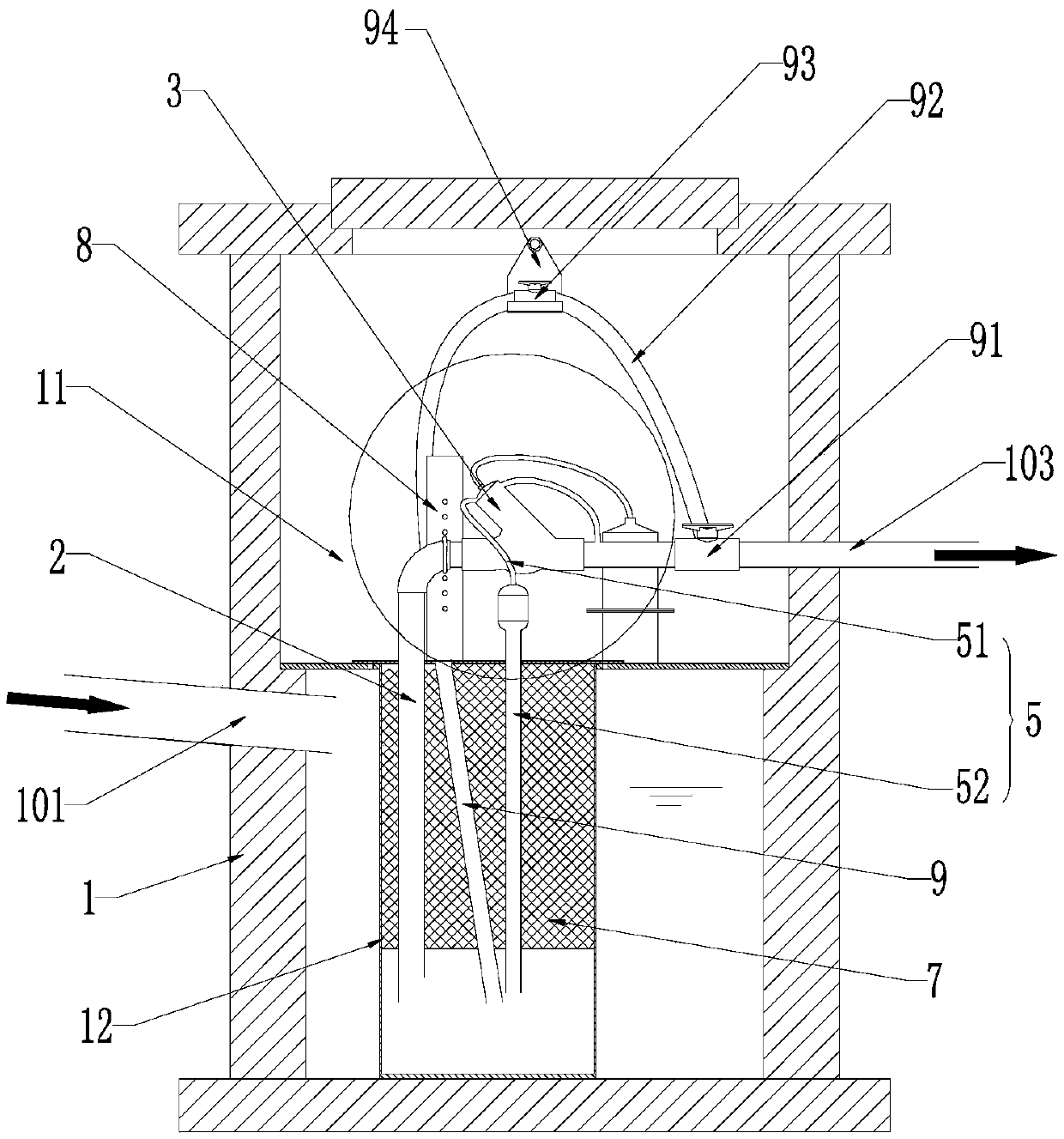

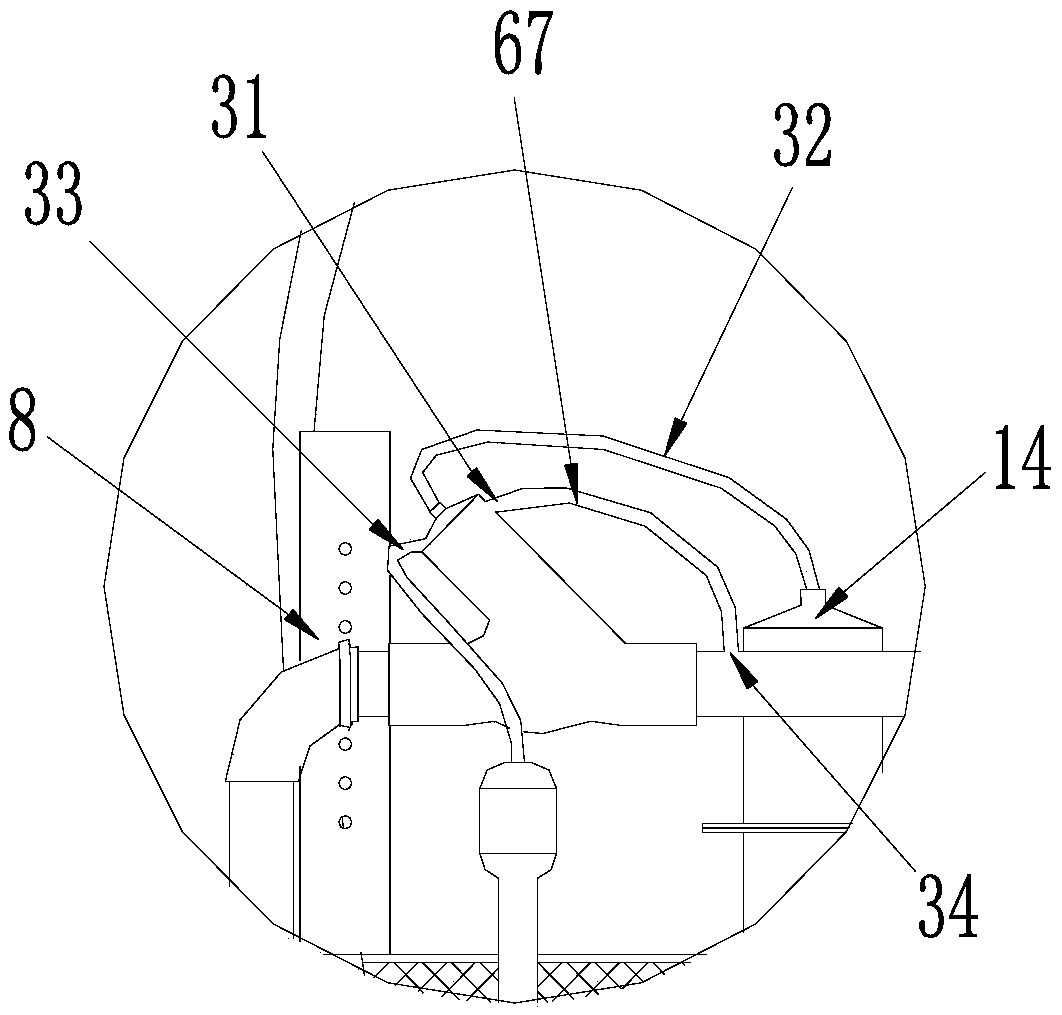

[0056] see figure 1 , a sewage vacuum collection and treatment system, including a sewage confluence pipeline 101, a vacuum collection well 102, a vacuum delivery pipeline 103, a vacuum pump station 104 and a sewage processor 105.

[0057] Wherein, the sewage confluence pipeline 101 guides the sewage discharged from the user end to the vacuum collection well 102 . One vacuum collection well 102 can correspond to several sewage confluence pipelines 101 leading from the user end. One end of the vacuum delivery pipeline 103 is drawn from the vacuum collection well 102 , and the other end extends to the vacuum sewage storage tank 71 of the vacuum pumping station 104 .

[0058] The vacuum pump station 104 includes a vacuum sewage storage tank 71, a vacuum pump 72, a sewage delivery pump 73, an electrical control system and a generator. The vacuum sewage storage tank 71 is used to collect sewage from the vacuum collection well, and a vacuum pump 72 and a sewage delivery pump 73 ar...

Embodiment 2

[0078] see Figure 12 , the vacuum collection well 12 includes a composting well 10 connected to the sewage confluence line 101, and the valve well 1 described in Embodiment 1. This valve well 1 communicates with the retting fertilizer well 10. The bottoms of the retting well 10 and the valve well 1 are provided with a sewage communication port 20 and a filter grid 21 arranged on the sewage communication port 20 near the retting well side, and a grid tie rod 22 is also fixed on the filter grid 21 . The above-mentioned retting well 10 and the valve well 1 are all formed by pouring reinforced concrete. All the other are with embodiment 1.

[0079]Aiming at the problem that the existing vacuum well does not have a retting function, a retting well connected to the valve well is set between the valve well and the user end, and the user sewage first flows into the retting well through a short-distance gravity pipeline for decomposition and fermentation. The larger floating matter...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com