Method for closed-circuit microorganism desulfurization and elemental sulfur recovery

A closed-circuit circulation and microbial technology, applied in the field of green environmental protection technology, can solve the problems of by-product generation of sulfate waste liquid, poor desulfurization efficiency stability, waste gas unorganized emission, etc., achieve the recovery of sulfur resources, reduce environmental secondary pollution, Effects of resource recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

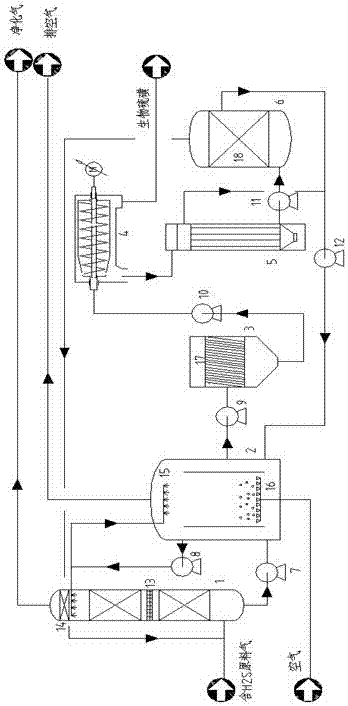

Method used

Image

Examples

Embodiment 1

[0035] Embodiment 1 biogas desulfurization process

[0036] The crude biogas (v / v) to be treated is produced by straw bio-fermentation, its main component is: 40% CO 2 , 0.6%H 2 S, 59.4% CH 4 , the biogas pressure is normal pressure.

[0037] 100 Nm 3 / h biogas enters the chemical absorption tower, the pH value of the lye is 8.6, and the circulation volume is 57.7 L / h. The chemical absorption of hydrogen sulfide is realized through gas-liquid countercurrent contact. Rich H 2 The lye of S enters the biological regeneration tower, and the HS - In air aeration rate 0.08m 3 / h, the ORP value is maintained in the range of -340mV~-360mV, the conductivity is stable at about 32mS / cm, and the HS - Biological oxidation to elemental sulfur. The top exhaust gas is directly discharged into the atmosphere after defoaming spray. The elemental sulfur is separated by centrifugation, and the filtrate enters the membrane separation filter. The operating pressure is 1.0 MPa, the operatin...

Embodiment 2

[0043] Example 2 Sulfur-containing industrial waste gas biological desulfurization process

[0044] To be treated is the mixed waste gas (v / v) of pesticide production enterprises, and its main components are: 30% CO 2 , 2%H 2 S, 68%N 2 ;Exhaust gas pressure: 0.1MPa.

[0045] 100 Nm 3 / h Sulfur-containing industrial waste gas enters the chemical absorption tower, the pH value of the lye is 9.0, and the circulation volume is 0.19 m 3 / h Through gas-liquid countercurrent contact, the chemical absorption of hydrogen sulfide is realized. Rich H 2 The lye of S enters the biological regeneration tower, and the HS - In air aeration rate 0.27m 3 / h, the ORP value is maintained in the range of -340mV~-360mV, the conductivity is stable at about 41 mS / cm, and the HS -Biological oxidation to elemental sulfur. The top exhaust gas is directly discharged into the atmosphere after defoaming spray. The elemental sulfur is separated by centrifugation, and the filtrate enters the membra...

Embodiment 3

[0046] Example 3 High-carbon and high-sulfur natural gas biological desulfurization process

[0047] The high-carbon and high-sulfur natural gas (v / v) to be processed is extracted from natural gas wells, and its main components are: 40% CO 2 , 8%H 2 S, CS 2 / CH 3 SH / COS 2000ppm, 52% N 2 . Natural gas pressure: 4.0 MPa.

[0048] 100 Nm 3 / h High-carbon and high-sulfur natural gas enters the chemical absorption tower, the pH value of the alkali solution is 9.0, and the circulation volume is 30.75 m 3 / h Through gas-liquid countercurrent contact, the chemical absorption of hydrogen sulfide is realized. Rich H 2 The lye of S enters the bioaerobic reactor, HS - In air aeration volume 43.4 m 3 / h, the ORP value is maintained in the range of -330mV~-350mV, the conductivity is stable at about 56 mS / cm, and the HS - Biological oxidation to elemental sulfur. The top exhaust gas is directly discharged into the atmosphere after defoaming spray. The elemental sulfur is separat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com