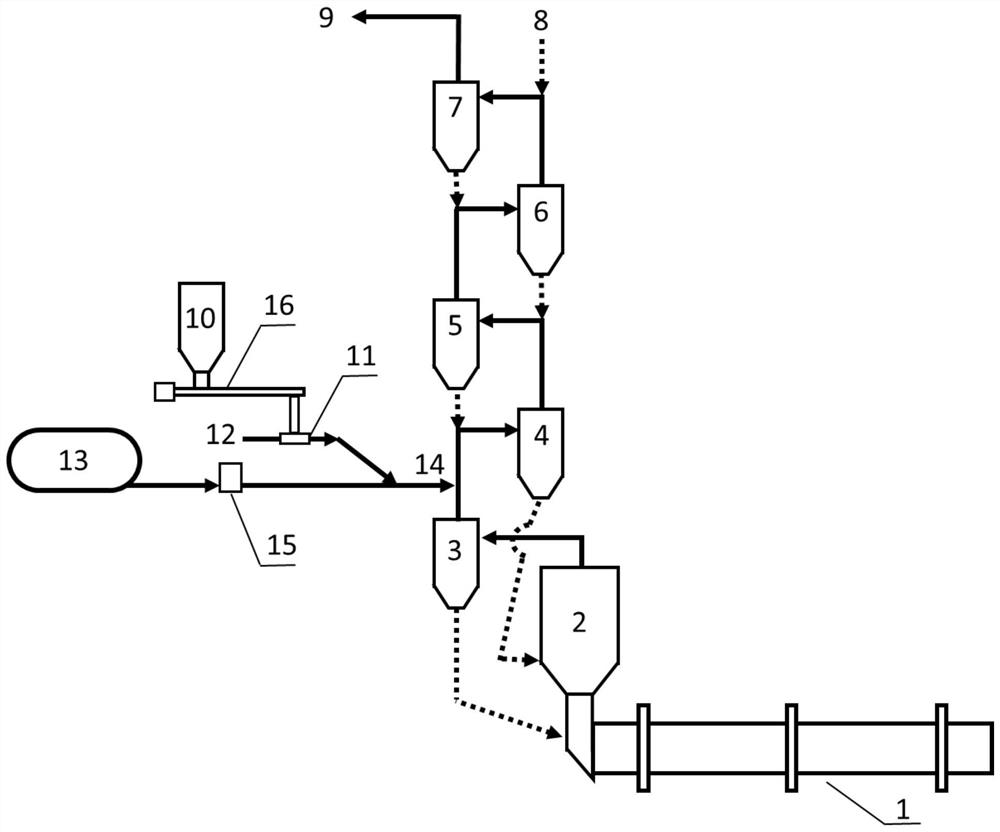

A kind of cement kiln device and sncr denitrification method

A cement kiln and denitration technology, applied in the field of cement kiln denitrification, can solve the problems that the denitration efficiency cannot meet expectations, the composition is complex, and the dust concentration is high, and the effects of avoiding adverse effects, optimizing the injection position and simple maintenance are achieved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0062] Below in conjunction with specific embodiment, further illustrate the present invention. It should be understood that these examples are only used to illustrate the present invention and are not intended to limit the scope of the present invention. In addition, it should be understood that after reading the contents of the present invention, those skilled in the art may make various changes or modifications to the present invention, and these equivalent forms also fall within the scope of the present invention.

[0063] Unless otherwise specified, the percentages in the following examples are all mass percentages.

preparation example 1

[0065] The metal component precursors iron nitrate nonahydrate and nickel nitrate hexahydrate were added to sufficient amount of deionized water respectively, fully stirred at room temperature until completely dissolved, and mixed to obtain a precursor solution. Select HZSM-5 molecular sieve as the carrier, add a sufficient amount of deionized water, and mix with an appropriate amount of precursor solution to obtain a mixed solution. Stir magnetically at 80° C. for 5 hours until the ion exchange is fully completed. The solid-liquid separation of the mixed liquid is achieved by suction filtration with a diaphragm vacuum pump, and an appropriate amount of deionized water is added to the solid matter, and then the mixed solution is filtered and dehydrated to obtain a solid matter. Repeat this step 3 times, and then place the obtained solid in a drying oven at 110°C Dry it for 12 hours, put it in a muffle furnace after crushing, and activate it by calcining at 850°C for 4 hours in...

preparation example 2

[0067] According to the operation in Preparation Example 1, ferric nitrate nonahydrate and ammonium metatungstate were used as precursors to prepare synergist 0.5Fe-W / ZSM-5.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com