Water-cooled powder preparation device for reducing noise pollution

A technology of noise pollution and pulverizing equipment, which is applied in the field of water-cooled pulverizing equipment, can solve problems such as temperature rise and loud noise, and achieve the effect of reducing sound wave energy, reducing noise pollution, and realizing recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

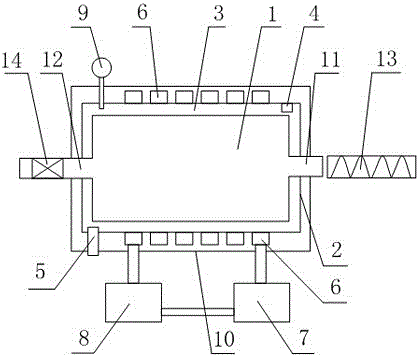

[0021] Such as figure 1The shown water-cooled milling device for reducing noise pollution includes a drum 1 provided with a feed inlet 11 and a powder outlet 12, and is characterized in that: the drum 1 is arranged in a first housing 2, and the first housing There is a gap 3 between the drum 2 and the drum 1, the gap 3 is filled with heat-conducting silicone grease, the upper part of the first shell 2 is provided with a grease injection hole 4, and the lower part of the first shell 2 is provided with a grease discharge hole 5; the first The surface of the housing 2 is wound with a cooling water pipe 6, one end of the cooling water pipe 6 is connected to the water chiller 7, and the other end is connected to the water pump 8, and the water outlet end of the water chiller 7 is connected to the upper water end of the water pump 8 through a pipeline; It also includes a second casing 3 surrounding the outside of the first casing 2, and glass wool is filled between the second casing...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com