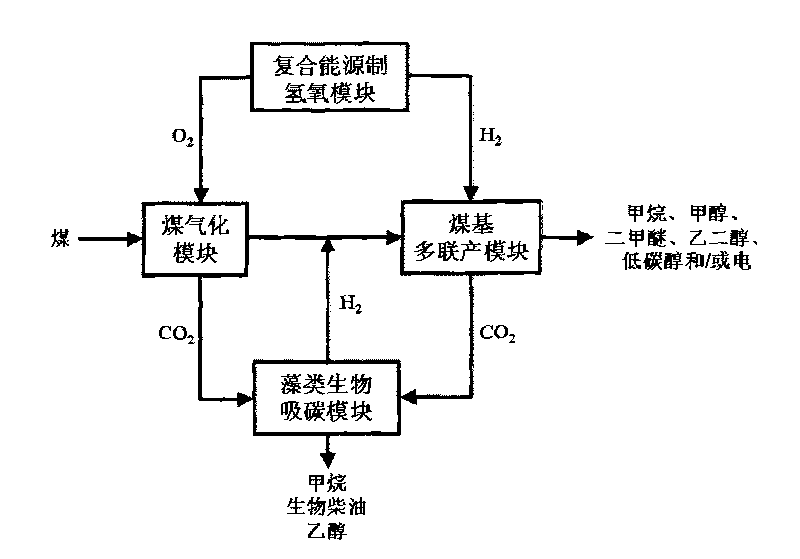

Coal-based energy chemical product poly-generation system and method

A chemical product, polygeneration technology, applied in the fuel system, petroleum industry, energy input and other directions, can solve problems such as unsolved, in the experimental stage, no systematic consideration of emission reduction and resource utilization, etc., to save equipment, simplify The effect of the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

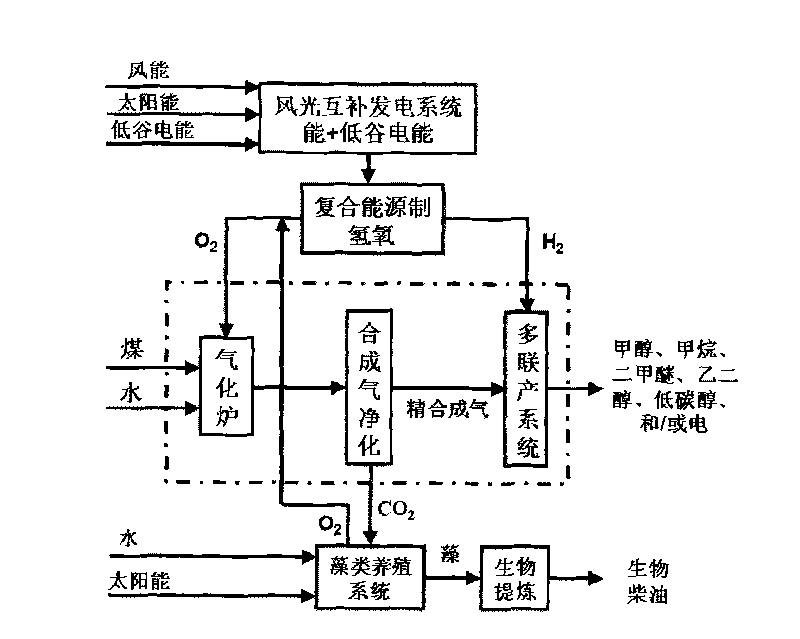

[0056] refer to figure 2 According to the process route, the electric energy required for the production of hydrogen and oxygen by composite energy is mainly from the wind-solar hybrid power station, and at the same time matching the low-peak electric energy, the SPE electrolyzer water electrolysis system is used for water electrolysis. The oxygen produced by water electrolysis is directly transported to the above-ground gasifier as raw material for coal gasification, and the coal is gasified in the gasifier to produce H 2 , CO and CO 2 (sometimes containing CH 4 )-based crude synthesis gas, the crude synthesis gas is purified to obtain H 2 and CO-based refined synthesis gas, while the hydrogen produced by electrolysis is transported to different sections of the coal-based polygeneration module for hydrogen distribution, such as Figure 9process route. Part of the refined synthesis gas is synthesized into methanol by hydrogenation to achieve the hydrogen-to-carbon ratio r...

Embodiment 2

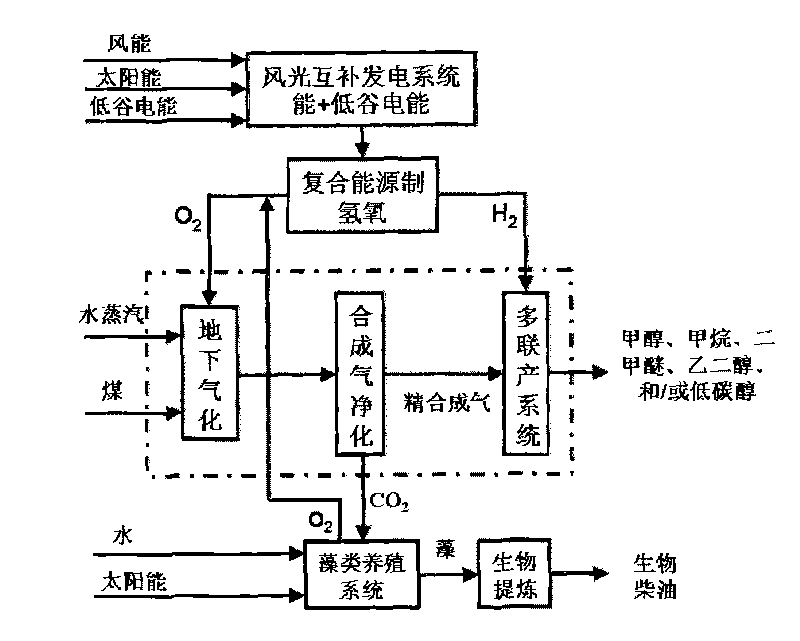

[0058] refer to image 3 According to the process route, the electric energy required for the production of hydrogen and oxygen by composite energy comes from the wind-solar hybrid power station, and at the same time matches the low-peak electric energy, and uses the solid oxide electrolyte electrolyzer water electrolysis system for water electrolysis. Part of the oxygen produced by water electrolysis is used alone or mixed with other gasification agent components and then blown into the underground gasification channel as a gasification agent for underground coal gasification. Coal is produced in the form of H after underground gasification 2 , CO, CH 4 and CO 2 Mainly crude synthesis gas, the crude synthesis gas is purified to obtain H 2 , CO and CH 4 Refined synthesis gas mainly; while the hydrogen produced by electrolysis is transported to different sections of the coal-based polygeneration module for hydrogen distribution, such as Figure 9 process route. Part of th...

Embodiment 3

[0060] refer to Figure 4 According to the process route, the small amount of electricity required for bioelectrochemical hydrogen production comes from wind-solar hybrid power stations, and at the same time matches the low-peak electricity. Coal is gasified in a catalytic gasifier to produce CH 4 、H 2 , CO 2 and CO-based crude synthesis gas, the crude synthesis gas is purified to obtain H 2 , CO and CH 4 Mainly refined synthetic gas. The hydrogen produced by bioelectrochemical hydrogen production is sent to different sections of the coal-based polygeneration module for hydrogen distribution, such as Figure 9 process route. Part of the refined synthesis gas is synthesized into methanol by hydrogenation to achieve the hydrogen-to-carbon ratio required for methanol, and the other part of the refined synthesis gas is mixed with the purge gas generated by methanol synthesis to synthesize methane by hydrogenation to achieve the required hydrogen-to-carbon ratio for methane s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com